electronic tool setter, tool touch off process

- swalts

- Offline

- Senior Member

-

Less

More

- Posts: 65

- Thank you received: 4

18 Jan 2021 14:15 #195796

by swalts

Replied by swalts on topic electronic tool setter, tool touch off process

AH! nice!

I am typing out a step by step now. Will copy/paste shortly.

Thank you Lcvette, I appreciate your time.

I am typing out a step by step now. Will copy/paste shortly.

Thank you Lcvette, I appreciate your time.

Please Log in or Create an account to join the conversation.

- swalts

- Offline

- Senior Member

-

Less

More

- Posts: 65

- Thank you received: 4

18 Jan 2021 14:23 #195798

by swalts

Replied by swalts on topic electronic tool setter, tool touch off process

This is my current understanding of the process. Please correct me if i am wrong.

TOOL LENGTH OFFSET PROCESS

POST WORK PIECE PROBING

probe work piece

SETTING REFERENCE TOOL

1. Load tool 00 for spindle nose.

2. use z probe routine to find z offset value

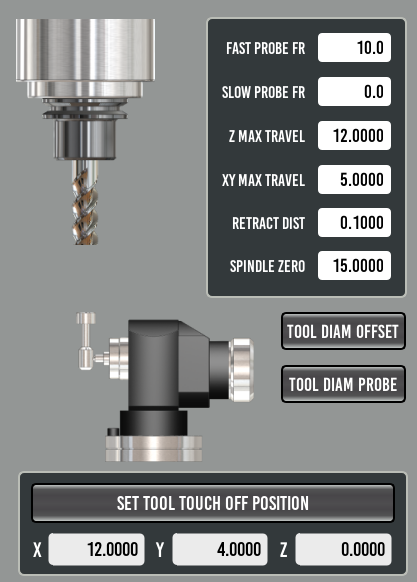

3. manually enter probed length (as positive value) in the "SPINDLE ZERO" box

4. Load tool# to be used on material.

5. Probe Z routine

6. Cycle start

Thanks again.

TOOL LENGTH OFFSET PROCESS

POST WORK PIECE PROBING

probe work piece

SETTING REFERENCE TOOL

1. Load tool 00 for spindle nose.

2. use z probe routine to find z offset value

3. manually enter probed length (as positive value) in the "SPINDLE ZERO" box

4. Load tool# to be used on material.

5. Probe Z routine

6. Cycle start

Thanks again.

Please Log in or Create an account to join the conversation.

- Lcvette

-

- Offline

- Moderator

-

Less

More

- Posts: 1523

- Thank you received: 722

18 Jan 2021 14:24 #195799

by Lcvette

Awesome, thank you!! it is needed for sure as setting it up is a bit clunky at the moment. I like that idea of setting up the spindle zero height from the tool touch off setup page, may need to implement that in the touch off subroutine when i have some free time.

I have a tool touch off probe I need to get installed on my machine and do a proper write up and tweak everything but i have been covered up with life events recently that have not permitted the time to do so. hopefully in the coming weeks I will be able to get to that!

please let me know once you get everything working!

Chris

Replied by Lcvette on topic electronic tool setter, tool touch off process

AH! nice!

I am typing out a step by step now. Will copy/paste shortly.

Thank you Lcvette, I appreciate your time.

Awesome, thank you!! it is needed for sure as setting it up is a bit clunky at the moment. I like that idea of setting up the spindle zero height from the tool touch off setup page, may need to implement that in the touch off subroutine when i have some free time.

I have a tool touch off probe I need to get installed on my machine and do a proper write up and tweak everything but i have been covered up with life events recently that have not permitted the time to do so. hopefully in the coming weeks I will be able to get to that!

please let me know once you get everything working!

Chris

Please Log in or Create an account to join the conversation.

- Lcvette

-

- Offline

- Moderator

-

Less

More

- Posts: 1523

- Thank you received: 722

18 Jan 2021 14:32 #195800

by Lcvette

Ah, i see you are not using the touch off in a repeatable position on your table but moving it to the work piece, this routine is not designed for that type of touch off, this is designed for a static location tool setter on the table. in that scenario you would not need to place the touch plate on the work piece. the way you are doing it is likely going to be very cumbersome as you will also have to reset the touch off position each time as it is going to want to travel there each time the touch off tool button is pressed. you said you have an R8 spindle but i'm guessing you are not using repeatable tool holders ie TTS or solid RB tool holders?

Replied by Lcvette on topic electronic tool setter, tool touch off process

This is my current understanding of the process. Please correct me if i am wrong.

TOOL LENGTH OFFSET PROCESS

POST WORK PIECE PROBING

probe work piece

SETTING REFERENCE TOOL

1. Load tool 00 for spindle nose.

2. use z probe routine to find z offset value

3. manually enter probed length (as positive value) in the "SPINDLE ZERO" box

4. Load tool# to be used on material.

5. Probe Z routine

6. Cycle start

Thanks again.

Ah, i see you are not using the touch off in a repeatable position on your table but moving it to the work piece, this routine is not designed for that type of touch off, this is designed for a static location tool setter on the table. in that scenario you would not need to place the touch plate on the work piece. the way you are doing it is likely going to be very cumbersome as you will also have to reset the touch off position each time as it is going to want to travel there each time the touch off tool button is pressed. you said you have an R8 spindle but i'm guessing you are not using repeatable tool holders ie TTS or solid RB tool holders?

Please Log in or Create an account to join the conversation.

- swalts

- Offline

- Senior Member

-

Less

More

- Posts: 65

- Thank you received: 4

18 Jan 2021 14:36 #195801

by swalts

Replied by swalts on topic electronic tool setter, tool touch off process

This is my current understanding of the process. Please correct me if i am wrong.

TOOL LENGTH OFFSET PROCESS

POST WORK PIECE PROBING

probe work piece

SETTING REFERENCE TOOL

1. Load tool 00 for spindle nose. (tool # may not be accurate)

2. use z probe routine to find z offset value

3. manually enter probed length (as positive value) in the "SPINDLE ZERO" box

4. Load tool# to be used on material.

5. Probe Z routine

6. Cycle start

Thanks again. I can relate with life events.

When you say writing a routine for probing spindle nose. Do you mean turn that into a button? That would make short work of this whole thing.

Button click.

Drive Z down until sensor trip.

Write the value as absolute.

That would be a nice upgrade.

Steve

TOOL LENGTH OFFSET PROCESS

POST WORK PIECE PROBING

probe work piece

SETTING REFERENCE TOOL

1. Load tool 00 for spindle nose. (tool # may not be accurate)

2. use z probe routine to find z offset value

3. manually enter probed length (as positive value) in the "SPINDLE ZERO" box

4. Load tool# to be used on material.

5. Probe Z routine

6. Cycle start

Thanks again. I can relate with life events.

When you say writing a routine for probing spindle nose. Do you mean turn that into a button? That would make short work of this whole thing.

Button click.

Drive Z down until sensor trip.

Write the value as absolute.

That would be a nice upgrade.

Steve

Please Log in or Create an account to join the conversation.

- swalts

- Offline

- Senior Member

-

Less

More

- Posts: 65

- Thank you received: 4

18 Jan 2021 14:42 - 18 Jan 2021 14:45 #195803

by swalts

Replied by swalts on topic electronic tool setter, tool touch off process

I do have some TTS, but not enough for all the tools. At this point i claim nothing is repeatable.

I can lock the tool setter to the table. I just figured i would place it on the table before touch off. I have already had it locked to table before. then i started questioning if it was really coolant resistant...(amazon special).

I use drewtronics probe for workpiece probing and an electronic tool setter for z touch off.

I can lock the tool setter to the table. I just figured i would place it on the table before touch off. I have already had it locked to table before. then i started questioning if it was really coolant resistant...(amazon special).

I use drewtronics probe for workpiece probing and an electronic tool setter for z touch off.

Last edit: 18 Jan 2021 14:45 by swalts. Reason: additional information.

Please Log in or Create an account to join the conversation.

- Lcvette

-

- Offline

- Moderator

-

Less

More

- Posts: 1523

- Thank you received: 722

18 Jan 2021 14:43 #195804

by Lcvette

did you see my post above? the way you are wanting to use the tool touch off isn't going to work most likely at least not very efficiently. you would be better off mounting the touch plate to your table since you also have a spindle mounted touch probe. probe basic is designed around that type of usage as opposed to touching off on the work piece with the tool and tool setting touch plate.

Replied by Lcvette on topic electronic tool setter, tool touch off process

This is my current understanding of the process. Please correct me if i am wrong.

TOOL LENGTH OFFSET PROCESS

POST WORK PIECE PROBING

probe work piece

SETTING REFERENCE TOOL

1. Load tool 00 for spindle nose. (tool # may not be accurate)

2. use z probe routine to find z offset value

3. manually enter probed length (as positive value) in the "SPINDLE ZERO" box

4. Load tool# to be used on material.

5. Probe Z routine

6. Cycle start

Thanks again. I can relate with life events.

When you say writing a routine for probing spindle nose. Do you mean turn that into a button? That would make short work of this whole thing.

Button click.

Drive Z down until sensor trip.

Write the value as absolute.

That would be a nice upgrade.

Steve

did you see my post above? the way you are wanting to use the tool touch off isn't going to work most likely at least not very efficiently. you would be better off mounting the touch plate to your table since you also have a spindle mounted touch probe. probe basic is designed around that type of usage as opposed to touching off on the work piece with the tool and tool setting touch plate.

Please Log in or Create an account to join the conversation.

- swalts

- Offline

- Senior Member

-

Less

More

- Posts: 65

- Thank you received: 4

18 Jan 2021 14:49 #195805

by swalts

Replied by swalts on topic electronic tool setter, tool touch off process

Locking the tool setter down to table is not a problem for me. what would change in the process? As mentioned before I do not have repeatability with tool holders.

Thank you Chris.

-Steve

Thank you Chris.

-Steve

Please Log in or Create an account to join the conversation.

- Lcvette

-

- Offline

- Moderator

-

Less

More

- Posts: 1523

- Thank you received: 722

18 Jan 2021 15:11 #195806

by Lcvette

Replied by Lcvette on topic electronic tool setter, tool touch off process

i'm headed out the door and won't be back on dev until later tonight, but a short and dirty version is that you don't use the z probe for tool touch off, only for the initial spindle height setup, and you need to define the tool touch off location on the offsets page, when doing this be sure that you are at G53 Z0.000 as this is the point at which downward probing will begin, this is a very safe height to start with. for measuring the actual tool lengths you use the "Touch off current tool" button on the tooling page which is what calls for the tool touch off routine. also be sure all of your touch of subroutine settings , they will be personalized to your probing preferences, also setting the slow probe to zero eliminates a second probe and setting a probe speed in "slow probe FR" will initiate the secondary slower probe. that should be enough to get you started!

Attachments:

Please Log in or Create an account to join the conversation.

- swalts

- Offline

- Senior Member

-

Less

More

- Posts: 65

- Thank you received: 4

18 Jan 2021 20:53 #195830

by swalts

Replied by swalts on topic electronic tool setter, tool touch off process

ok This is what seems to have worked so far.

from startup:

0. home machine

1. unload spindle... Tool zero

2. touch off tool

3. input the value into spindle zero length box (red circle from your previous post).

4. load tool 99 (drewtronics probe for me)

5. touch off tool 99

6. load test file

7. run probe routine

8. load tool (it was tool 6 for me)

9. touch off tool 6

10. cycle start

for restarting the file after exit

use 6-10 steps, 4-10 if probe is not repeatable.

i will be taking some test cuts this week to prove this out fully.

Will follow up.

from startup:

0. home machine

1. unload spindle... Tool zero

2. touch off tool

3. input the value into spindle zero length box (red circle from your previous post).

4. load tool 99 (drewtronics probe for me)

5. touch off tool 99

6. load test file

7. run probe routine

8. load tool (it was tool 6 for me)

9. touch off tool 6

10. cycle start

for restarting the file after exit

use 6-10 steps, 4-10 if probe is not repeatable.

i will be taking some test cuts this week to prove this out fully.

Will follow up.

Please Log in or Create an account to join the conversation.

Moderators: KCJ, Lcvette

Time to create page: 0.202 seconds