4th Axis Build

- Lcvette

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1547

- Thank you received: 726

14 Oct 2016 16:18 #81646

by Lcvette

Replied by Lcvette on topic 4th Axis Build

Andy,

For my application the rotary is going to be used for a 6" X 6" X 24" tombstone for production work. So I won't have to get down toward the center for this setup. But those are excellent points. My mill spindle is a BT30. My lathe is a bolt on stud and nut (benchtop machine). I do like the idea of a camlock setup, just have no experience with them. Will have to take a look at it and do some research. I will also play around with mounting a 5C chuck on the table face send see how the spindle clearance looks, that may give some extension to get a tool down near the center without interference from the spindle nose. Worst case scenario i soul grab some BT30 extended ER11 tool holders for small diameter 4th axis work.

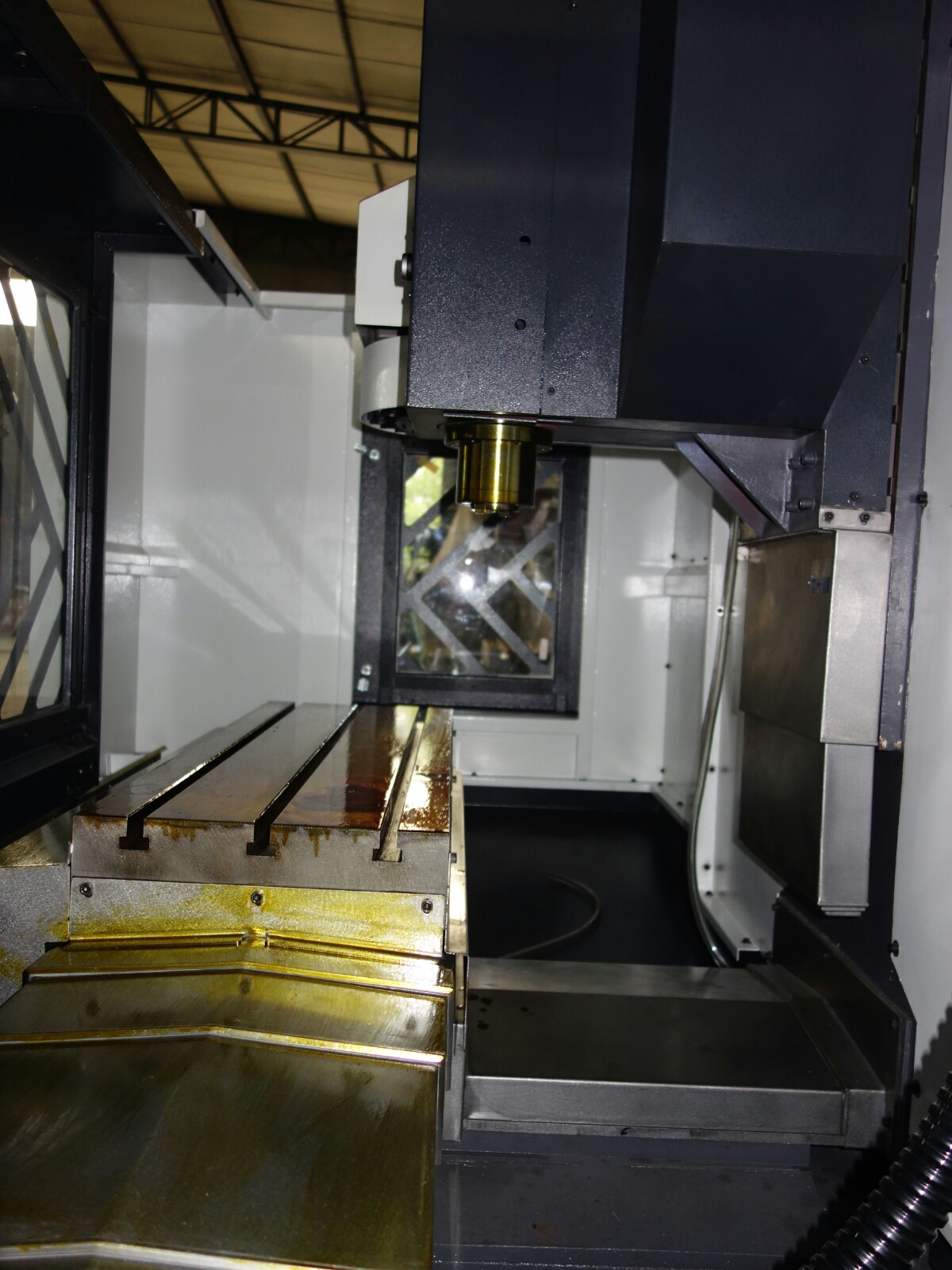

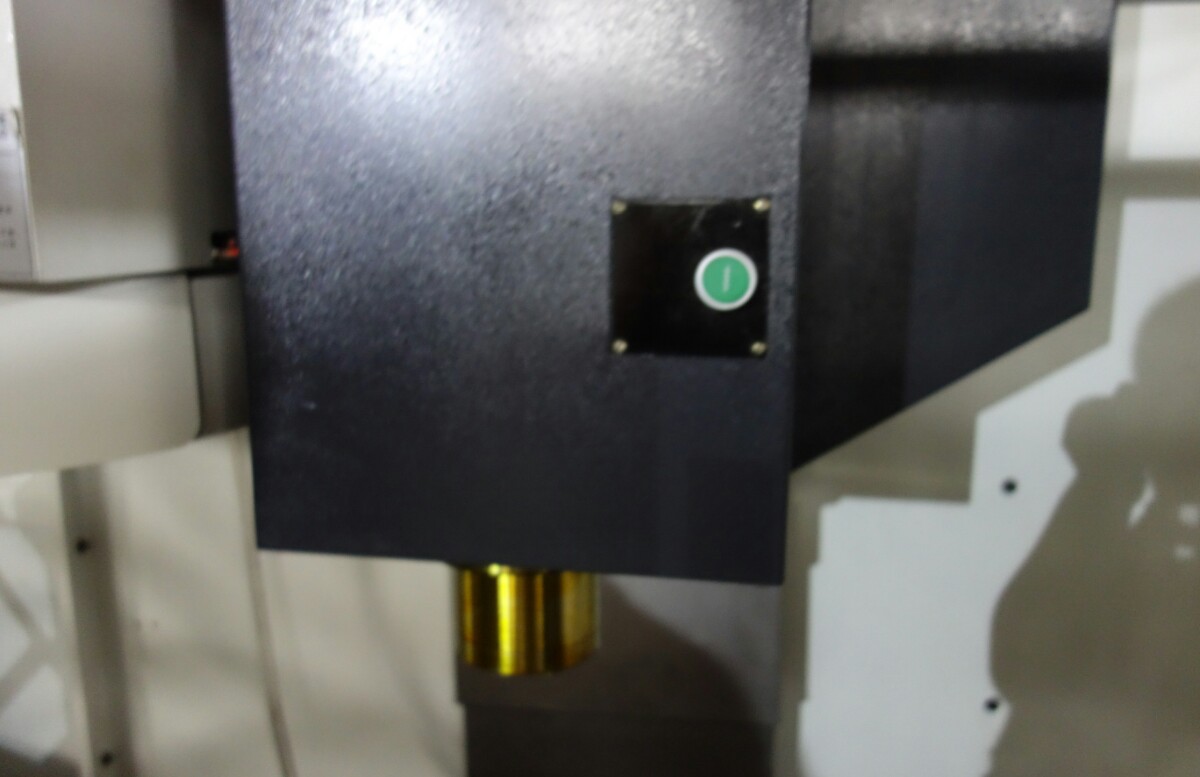

Here are some pictures of the mill spindle and the tool holders I was thinking about to solve being able to f do both fine small work and larger tombstone production work:

For my application the rotary is going to be used for a 6" X 6" X 24" tombstone for production work. So I won't have to get down toward the center for this setup. But those are excellent points. My mill spindle is a BT30. My lathe is a bolt on stud and nut (benchtop machine). I do like the idea of a camlock setup, just have no experience with them. Will have to take a look at it and do some research. I will also play around with mounting a 5C chuck on the table face send see how the spindle clearance looks, that may give some extension to get a tool down near the center without interference from the spindle nose. Worst case scenario i soul grab some BT30 extended ER11 tool holders for small diameter 4th axis work.

Here are some pictures of the mill spindle and the tool holders I was thinking about to solve being able to f do both fine small work and larger tombstone production work:

Please Log in or Create an account to join the conversation.

- gmouer

- Offline

- Elite Member

-

Less

More

- Posts: 212

- Thank you received: 9

24 Oct 2016 20:37 #82008

by gmouer

Replied by gmouer on topic 4th Axis Build

Dale, I have a couple questions.

Did you check the runout obtained using the tapered bearings? Any chance you have the number of those bearings?

I will be building one nearly identical to what you did. I have the harmonic drive and am gathering the remaining parts.

Thanks,

George

Did you check the runout obtained using the tapered bearings? Any chance you have the number of those bearings?

I will be building one nearly identical to what you did. I have the harmonic drive and am gathering the remaining parts.

Thanks,

George

Please Log in or Create an account to join the conversation.

- Dale Lusby

- Offline

- Senior Member

-

Less

More

- Posts: 50

- Thank you received: 2

24 Oct 2016 23:10 - 24 Oct 2016 23:13 #82018

by Dale Lusby

Replied by Dale Lusby on topic 4th Axis Build

I used the same bearings out of the front axle of my truck so they would be easy to source and fairly inexpensive (mine are from Autozone). They are Timken brand but I know the duralast ones have the same part number. The bearing is number 387a and the race is 382a. The seal is 415960. These are from my 1986 Ford F-350 4x4 w/6.9 diesel in case you are at a parts house and want them to look it up. The front axle is a Dana 60 and this is the larger inner bearing of the two. It has a 2.25" bore. The two sets set me back about $50.

The runout I don't have the numbers but I know it is quite low. I believe the main reason tapered rollers are not used for spindles is due to the power loss from friction as it is higher than angular contact bearings. I will try to get some numbers and a video of it in use soon.

The runout I don't have the numbers but I know it is quite low. I believe the main reason tapered rollers are not used for spindles is due to the power loss from friction as it is higher than angular contact bearings. I will try to get some numbers and a video of it in use soon.

Last edit: 24 Oct 2016 23:13 by Dale Lusby.

Please Log in or Create an account to join the conversation.

- gmouer

- Offline

- Elite Member

-

Less

More

- Posts: 212

- Thank you received: 9

24 Oct 2016 23:19 - 24 Oct 2016 23:20 #82021

by gmouer

Replied by gmouer on topic 4th Axis Build

They do use tapered rollers routinely in the import lathes, and they work very well. I looked up specs at timken and it seems their standard grade bearings from zero to 10 inch bore are spec'd at 2 thou max runout. That sounds like a lot to me, thats why I asked. They do have precision grades but of course the price gets prohibitive. Of course, 2 thou runout on a car wheel wouldn't be a problem.

It would be very interesting to see what your runout measures.

It would be very interesting to see what your runout measures.

Last edit: 24 Oct 2016 23:20 by gmouer.

Please Log in or Create an account to join the conversation.

- dkmc

- Offline

- New Member

-

Less

More

- Posts: 7

- Thank you received: 1

15 Jan 2017 09:18 #85809

by dkmc

Replied by dkmc on topic 4th Axis Build

Hello Dale.

Nice build!

I bet those tapered roller bearings will suit your application just fine. And I'll even bet they don't run out more than .001

which is just fine for most applications that "we" deal with isn't it?

Great job.

Nice build!

I bet those tapered roller bearings will suit your application just fine. And I'll even bet they don't run out more than .001

which is just fine for most applications that "we" deal with isn't it?

Great job.

Please Log in or Create an account to join the conversation.

- Boogie

- Offline

- Premium Member

-

Less

More

- Posts: 96

- Thank you received: 9

21 May 2017 22:50 #93456

by Boogie

Replied by Boogie on topic 4th Axis Build

Dale Lusby - have you got some video of your 4th axis running? Nice job man!

Please Log in or Create an account to join the conversation.

Time to create page: 0.250 seconds