Hardinge HC Lathe - CNC Conversion

- johnmc1

- Offline

- Senior Member

-

Less

More

- Posts: 78

- Thank you received: 21

10 Nov 2020 11:30 #188861

by johnmc1

Replied by johnmc1 on topic Hardinge HC Lathe - CNC Conversion

Most Impressive well done.

cheers john

cheers john

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19782

- Thank you received: 4603

10 Nov 2020 11:32 #188862

by andypugh

LinuxCNC just needs to measure the spindle position to know where to place the Z axis for threading.

See this video to see that the spindle does not even need to be powered and in gear for this to work: (He is turning the chuck by hand during a threading operation, then adjusting the workpiece position to pick up a pre-existing thread, then he engages the clutch to finish the operation)

Replied by andypugh on topic Hardinge HC Lathe - CNC Conversion

You mention vfd in an earlier post but I dont see how you can thread repeatable without syncronizing the spindle and feed.

LinuxCNC just needs to measure the spindle position to know where to place the Z axis for threading.

See this video to see that the spindle does not even need to be powered and in gear for this to work: (He is turning the chuck by hand during a threading operation, then adjusting the workpiece position to pick up a pre-existing thread, then he engages the clutch to finish the operation)

Please Log in or Create an account to join the conversation.

- gearheaded

-

- Offline

- Junior Member

-

Less

More

- Posts: 29

- Thank you received: 1

04 Dec 2020 09:26 #191015

by gearheaded

Replied by gearheaded on topic Hardinge HC Lathe - CNC Conversion

Hello:

I too, am a bit late to this thread. Excellent work, a very clean upgrade.

I've had basically the same lathe with an Omniturn attachment for about 15 years. The Hardinge drive belts on the variable pulley system finally gave out and I just tore it apart to convert to direct drive. I had also decided on the GT3 belt system and have been searching the net for pictures or info on other conversions so I don't have to reinvent the wheel. Unfortunately, all I can find is people saying they've done the conversion and are really happy with the performance improvement, but give no part numbers, supplier names, or even descriptive pictures of the completed work.

Any chance you might help a fellow do it yourselfer out? Perhaps give me a few details such as pulley diameters(part #'s), the supplier if you were happy with them, belt width and maybe pitch choice. Also, any issues you might have run into, and maybe how you mounted the new pulley to the (I assume) modified factory spindle pulley.

I already have a good idea what to do, but it would be nice to hear from someone who has successfully accomplished the task.

I swapped the controller for this lathe onto my other Omniturn which had a bad control so I could keep producing parts, but I want to get the spindle back together in preparation for converting it to Linuxcnc.

Thanks ahead of time,

Karl

AKA Gearheaded

I too, am a bit late to this thread. Excellent work, a very clean upgrade.

I've had basically the same lathe with an Omniturn attachment for about 15 years. The Hardinge drive belts on the variable pulley system finally gave out and I just tore it apart to convert to direct drive. I had also decided on the GT3 belt system and have been searching the net for pictures or info on other conversions so I don't have to reinvent the wheel. Unfortunately, all I can find is people saying they've done the conversion and are really happy with the performance improvement, but give no part numbers, supplier names, or even descriptive pictures of the completed work.

Any chance you might help a fellow do it yourselfer out? Perhaps give me a few details such as pulley diameters(part #'s), the supplier if you were happy with them, belt width and maybe pitch choice. Also, any issues you might have run into, and maybe how you mounted the new pulley to the (I assume) modified factory spindle pulley.

I already have a good idea what to do, but it would be nice to hear from someone who has successfully accomplished the task.

I swapped the controller for this lathe onto my other Omniturn which had a bad control so I could keep producing parts, but I want to get the spindle back together in preparation for converting it to Linuxcnc.

Thanks ahead of time,

Karl

AKA Gearheaded

Please Log in or Create an account to join the conversation.

- OT-CNC

- Offline

- Platinum Member

-

Less

More

- Posts: 615

- Thank you received: 75

04 Dec 2020 14:24 #191031

by OT-CNC

Replied by OT-CNC on topic Hardinge HC Lathe - CNC Conversion

gearheaded,

I assume your question went out to the OP, but I figure I would chime in as may have some useful info for you.

I used Eagle PD on my AHC retro. It's the herringbone style timing belt. I would assume the GT3 type will require similar adaptation.

I post machined the hardinge headstock pulley and mating herringbone pulley as I could not find a matching system that would fit inside the head. It's direct drive 5hp motor and 1:1 ratio. The motor pulley was an off the shelf item with taper lock hub. The only negative I found is that I get some vibrations at higher rpm possibly from the long belt. Maybe less of an issue with the GT belt. Not sure. The herringbone has tendency to rise up on the pulley on the trailing side before it drops into the grooves and I found that it has a quieter direction of rotation if the chevrons lead in the direction of your main rotation. I of course got that wrong on my build.

I can dig up photos if that helps...

I assume your question went out to the OP, but I figure I would chime in as may have some useful info for you.

I used Eagle PD on my AHC retro. It's the herringbone style timing belt. I would assume the GT3 type will require similar adaptation.

I post machined the hardinge headstock pulley and mating herringbone pulley as I could not find a matching system that would fit inside the head. It's direct drive 5hp motor and 1:1 ratio. The motor pulley was an off the shelf item with taper lock hub. The only negative I found is that I get some vibrations at higher rpm possibly from the long belt. Maybe less of an issue with the GT belt. Not sure. The herringbone has tendency to rise up on the pulley on the trailing side before it drops into the grooves and I found that it has a quieter direction of rotation if the chevrons lead in the direction of your main rotation. I of course got that wrong on my build.

I can dig up photos if that helps...

Please Log in or Create an account to join the conversation.

- Skippy1

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 44

- Thank you received: 2

23 Jan 2021 07:48 - 23 Jan 2021 21:51 #196316

by Skippy1

Replied by Skippy1 on topic Hardinge HC Lathe - CNC Conversion

Hi Karl, Sorry for the late reply, I haven't been to the site for a while and didn't see your query.

I started with the Gates GT3 Design Manual to get an idea about an appropriate sized belt and pulleys. Like OT-CNC, I wanted to use the largest pulley I could get inside the casting of the lathe headstock. The width of the belt was also limiting factor, as there was only so much room to squeeze it in. Once I had the general idea, I used the Gates Design Flex Pro software to finalise the design. Below is the report.

I purchased two taper-lock Sprockets and the belt off eBay, and bored out one sprocket to fit on the modified Hardinge spindle drive pulley, (which was machined down to suit the bore of the sprocket). The bored out sprocket was a 4 thou interference fit on the modified drive pulley, and was heat-shrunk onto it. I used a standard taper-lock bush to secure the second pulley onto the motor shaft. In the end, I had to jiggle the center distance of the motor/spindle to fit a 5HP motor into the base of the lathe, and used a Gates Powergrip GT3 2400-8MGT-20 belt. It did tend to flog a bit at certain speeds, but increasing the tension fixed most of the problems.

Cheers, Steve.

PS. I had also considered the Goodyear Eagle PD herringbone drive system, as it was highly recommended in a manufacturing forum I frequent. However, the parts, which were only available from the official distributers, were way too expensive for me, and I went for the far more common Gates GT3 ones, which were dirt-cheap on eBay in comparison.

PPS. Something else to consider is, (if you don't need the fixed 1:1 drive ratio, and you already have an encoder mounted on the spindle), is that a Poly V Belt Drive may also be suitable. Before I got target fixation on a 1:1 drive with an encoder on the motor, I was going down this path. It would have been smoother and quieter than the toothed belt drive.

I started with the Gates GT3 Design Manual to get an idea about an appropriate sized belt and pulleys. Like OT-CNC, I wanted to use the largest pulley I could get inside the casting of the lathe headstock. The width of the belt was also limiting factor, as there was only so much room to squeeze it in. Once I had the general idea, I used the Gates Design Flex Pro software to finalise the design. Below is the report.

I purchased two taper-lock Sprockets and the belt off eBay, and bored out one sprocket to fit on the modified Hardinge spindle drive pulley, (which was machined down to suit the bore of the sprocket). The bored out sprocket was a 4 thou interference fit on the modified drive pulley, and was heat-shrunk onto it. I used a standard taper-lock bush to secure the second pulley onto the motor shaft. In the end, I had to jiggle the center distance of the motor/spindle to fit a 5HP motor into the base of the lathe, and used a Gates Powergrip GT3 2400-8MGT-20 belt. It did tend to flog a bit at certain speeds, but increasing the tension fixed most of the problems.

Cheers, Steve.

PS. I had also considered the Goodyear Eagle PD herringbone drive system, as it was highly recommended in a manufacturing forum I frequent. However, the parts, which were only available from the official distributers, were way too expensive for me, and I went for the far more common Gates GT3 ones, which were dirt-cheap on eBay in comparison.

PPS. Something else to consider is, (if you don't need the fixed 1:1 drive ratio, and you already have an encoder mounted on the spindle), is that a Poly V Belt Drive may also be suitable. Before I got target fixation on a 1:1 drive with an encoder on the motor, I was going down this path. It would have been smoother and quieter than the toothed belt drive.

Last edit: 23 Jan 2021 21:51 by Skippy1.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19782

- Thank you received: 4603

25 Jan 2021 00:01 #196491

by andypugh

I think this is worth considering. It should give a better surface finish, and the encoder should be on the spindle in an ideal setup.

There is a huge poly-V belt on my Holbrook lathe, original fitment.

Here it is in conjunction with the spindle encoder:

photos.app.goo.gl/27djhNE8N39eTb3Q8

(Holbrook so over-engineered the changewheel system that I was able to fit an encoder _and_ an eccentric bush to tension the belt, inside the socket for one of the changewheel shafts.)

Replied by andypugh on topic Hardinge HC Lathe - CNC Conversion

PPS. Something else to consider is, (if you don't need the fixed 1:1 drive ratio, and you already have an encoder mounted on the spindle).

I think this is worth considering. It should give a better surface finish, and the encoder should be on the spindle in an ideal setup.

There is a huge poly-V belt on my Holbrook lathe, original fitment.

Here it is in conjunction with the spindle encoder:

photos.app.goo.gl/27djhNE8N39eTb3Q8

(Holbrook so over-engineered the changewheel system that I was able to fit an encoder _and_ an eccentric bush to tension the belt, inside the socket for one of the changewheel shafts.)

Please Log in or Create an account to join the conversation.

- gearheaded

-

- Offline

- Junior Member

-

Less

More

- Posts: 29

- Thank you received: 1

15 Feb 2021 07:09 #198906

by gearheaded

Replied by gearheaded on topic Hardinge HC Lathe - CNC Conversion

Hi Guys:

Thanks for the replies and information provided. If you hadn't caught my other threads, I had removed the controller off my Hardinge and was able to move it to my Proline Hardinge DV-59 clone, and replace its early and unlikable Omni control. I hadn't really moved forward on the belt conversion because of my fathers passing and dealing with fixing up his home, estate sale, covid19, etc. Also, because I had no controller to operate it yet. My plan was to convert the lathe to Linuxcnc with the hope of adding a C-axis in the future, hence the timing belt questions. However, plans have changed somewhat do to a craigslist find.

Last week, I found a DV-59 with Omniturn attachment that had been left out in the rain all winter. It was up in the Oregon coast range mountains, but I decided to check it out with the hope that the enclosures kept the electronics safe. Sure enough, the electronics were dry as a bone, and the Yaskawa VFD was dry as well. Spindle still turned freely and the bearings felt good in the Dunham collet closer. The control was upgraded with an LCD and SSD hard drive, and the motion control card confirmed it was compatible with my likable control. The slide has seen better days but the ball screws seem fine. The linear rails need replacing and the tool table will need a surface grind, but the servo motors seem OK. Unfortunatly, most of the water and rust damage was to the original Hardinge iron and not salvageable at a reasonable price. Anyway, got it for $600, stripped the machine and scrapped the iron($77 for 1000#). Kept the 3HP drive motor and coolant pump. The control is now operating the slide on my Machine destined for the belt drive conversion, and I have lots of spare or resalable parts.

So I need to get this lathe back in operation, and have decided on Poly-V for simplicity and cost effectiveness. When I convert to Linuxcnc and C-axis, I might change it then or convert the other machine to timing belt. Truth is, I machine primarily brass and don't need the C-axis for heavy work, just off center face drilling of hole patterns and the occasional cross drilling or milling of flats, the Poly-V might very well suffice for my needs.

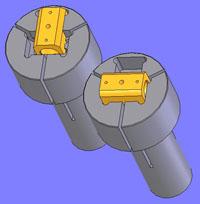

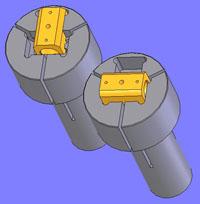

I'm ordering the pulleys tomorrow from B & B Manufacturing, 10 ribbed J section 4.5" diameter. I'm sticking with 1:1 ratio because that is what Omniturn does when they convert them. Also, my machines are both 5hp and seem to have plenty of power for my needs. Here is a picture of their Herringbone conversion and it looks to me like a 4-5" pulley.

Thanks again for the replies, I don't want to hijack Skippy1's thread anymore than I have already. This thread still comes up in many of my searches for information on this conversion, so once I receive the pulleys and begin work, I will start a new thread detailing the upgrade and add a link to it here to help any future people thinking about this conversion.

Karl

AKA Gearheaded

Thanks for the replies and information provided. If you hadn't caught my other threads, I had removed the controller off my Hardinge and was able to move it to my Proline Hardinge DV-59 clone, and replace its early and unlikable Omni control. I hadn't really moved forward on the belt conversion because of my fathers passing and dealing with fixing up his home, estate sale, covid19, etc. Also, because I had no controller to operate it yet. My plan was to convert the lathe to Linuxcnc with the hope of adding a C-axis in the future, hence the timing belt questions. However, plans have changed somewhat do to a craigslist find.

Last week, I found a DV-59 with Omniturn attachment that had been left out in the rain all winter. It was up in the Oregon coast range mountains, but I decided to check it out with the hope that the enclosures kept the electronics safe. Sure enough, the electronics were dry as a bone, and the Yaskawa VFD was dry as well. Spindle still turned freely and the bearings felt good in the Dunham collet closer. The control was upgraded with an LCD and SSD hard drive, and the motion control card confirmed it was compatible with my likable control. The slide has seen better days but the ball screws seem fine. The linear rails need replacing and the tool table will need a surface grind, but the servo motors seem OK. Unfortunatly, most of the water and rust damage was to the original Hardinge iron and not salvageable at a reasonable price. Anyway, got it for $600, stripped the machine and scrapped the iron($77 for 1000#). Kept the 3HP drive motor and coolant pump. The control is now operating the slide on my Machine destined for the belt drive conversion, and I have lots of spare or resalable parts.

So I need to get this lathe back in operation, and have decided on Poly-V for simplicity and cost effectiveness. When I convert to Linuxcnc and C-axis, I might change it then or convert the other machine to timing belt. Truth is, I machine primarily brass and don't need the C-axis for heavy work, just off center face drilling of hole patterns and the occasional cross drilling or milling of flats, the Poly-V might very well suffice for my needs.

I'm ordering the pulleys tomorrow from B & B Manufacturing, 10 ribbed J section 4.5" diameter. I'm sticking with 1:1 ratio because that is what Omniturn does when they convert them. Also, my machines are both 5hp and seem to have plenty of power for my needs. Here is a picture of their Herringbone conversion and it looks to me like a 4-5" pulley.

Thanks again for the replies, I don't want to hijack Skippy1's thread anymore than I have already. This thread still comes up in many of my searches for information on this conversion, so once I receive the pulleys and begin work, I will start a new thread detailing the upgrade and add a link to it here to help any future people thinking about this conversion.

Karl

AKA Gearheaded

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19782

- Thank you received: 4603

16 Feb 2021 10:49 #199041

by andypugh

If the encoder is on the spindle then it doesn't matter what the drive to the spindle is.

Replied by andypugh on topic Hardinge HC Lathe - CNC Conversion

So I need to get this lathe back in operation, and have decided on Poly-V for simplicity and cost effectiveness. When I convert to Linuxcnc and C-axis, I might change it then or convert the other machine to timing belt.

If the encoder is on the spindle then it doesn't matter what the drive to the spindle is.

Please Log in or Create an account to join the conversation.

- mgallelli

- Offline

- New Member

-

Less

More

- Posts: 3

- Thank you received: 1

09 May 2024 21:15 #300243

by mgallelli

Replied by mgallelli on topic Hardinge HC Lathe - CNC Conversion

Hi Steve,

Its been ages and many moves since my last post. I finally have a Hardinge HC lathe in hand. Is there any way to contact you regarding the details of the ballscrews and interfaces? I plan to solve the indexer and automate that.

Its been ages and many moves since my last post. I finally have a Hardinge HC lathe in hand. Is there any way to contact you regarding the details of the ballscrews and interfaces? I plan to solve the indexer and automate that.

Please Log in or Create an account to join the conversation.

- Skippy1

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 44

- Thank you received: 2

09 May 2024 23:22 #300253

by Skippy1

Replied by Skippy1 on topic Hardinge HC Lathe - CNC Conversion

Send us a private message, and we can go from there. Cheers, Steve.

Please Log in or Create an account to join the conversation.

Time to create page: 0.119 seconds