Ohmic sensing with IPTM-60

- Hakan

- Away

- Platinum Member

-

Less

More

- Posts: 1252

- Thank you received: 438

02 Jun 2025 12:24 #329548

by Hakan

Ohmic sensing with IPTM-60 was created by Hakan

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- Hakan

- Away

- Platinum Member

-

Less

More

- Posts: 1252

- Thank you received: 438

03 Jun 2025 08:20 #329591

by Hakan

Replied by Hakan on topic Ohmic sensing with IPTM-60

Not really interested to produce and sell.

Would take so much time, time I want to spend to make new things.

And it's not so unique, it's a remix of existing ideas.

Quite convenient though.

I don't mind at all if you sell units, will only help people.

Would take so much time, time I want to spend to make new things.

And it's not so unique, it's a remix of existing ideas.

Quite convenient though.

I don't mind at all if you sell units, will only help people.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- Hakan

- Away

- Platinum Member

-

Less

More

- Posts: 1252

- Thank you received: 438

03 Jun 2025 15:20 - 03 Jun 2025 20:16 #329611

by Hakan

Replied by Hakan on topic Ohmic sensing with IPTM-60

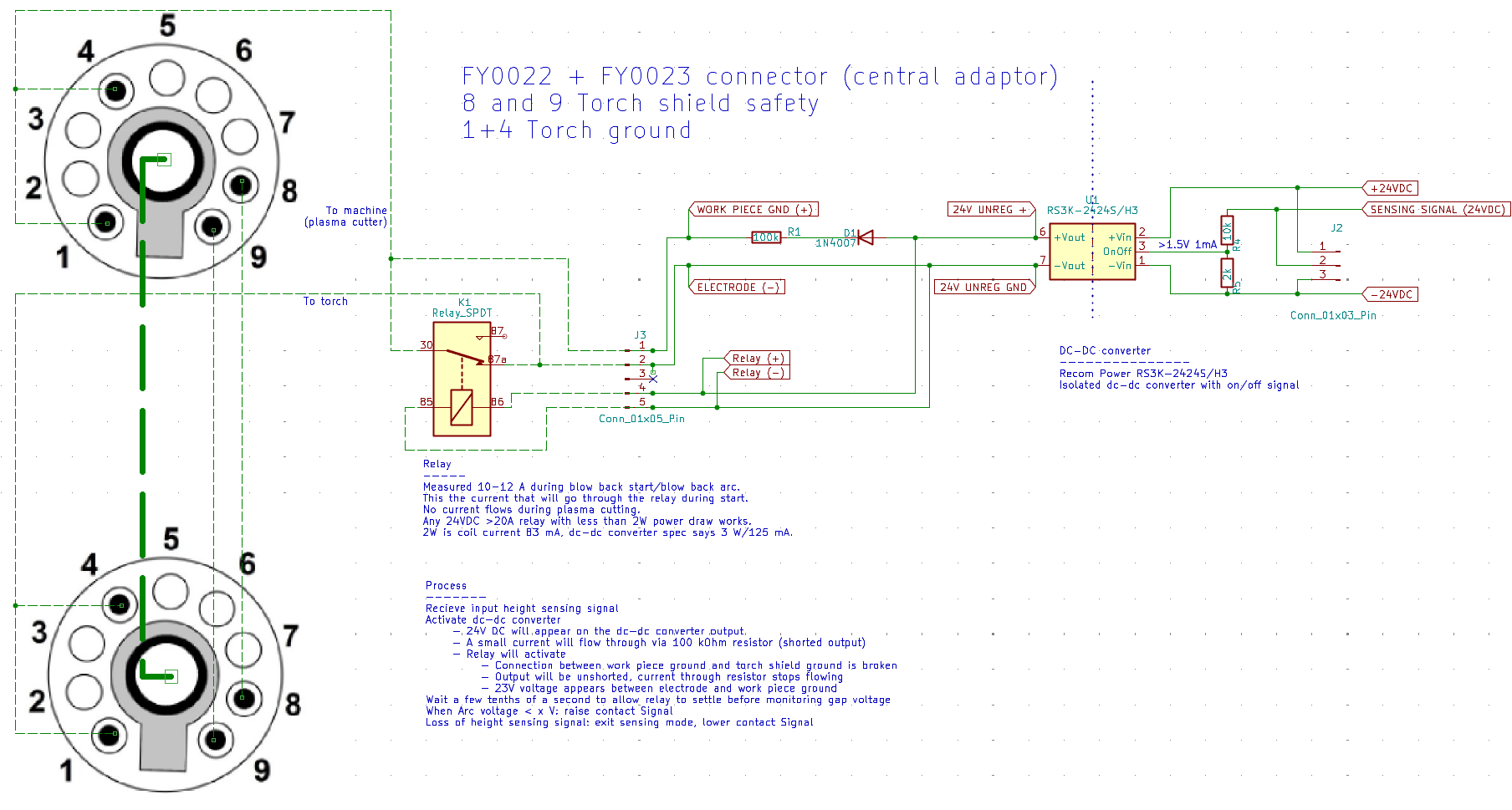

Attachments:

Last edit: 03 Jun 2025 20:16 by Hakan. Reason: Spelling in schema

Please Log in or Create an account to join the conversation.

- Hakan

- Away

- Platinum Member

-

Less

More

- Posts: 1252

- Thank you received: 438

05 Jun 2025 18:15 #329764

by Hakan

Replied by Hakan on topic Ohmic sensing with IPTM-60

Unfortunately this goes back to work-in-progress state.

The normal arc voltage reader didn't give a reliable output during ohmic sensing.

I'll put in another voltage sensor, right over the 24V-ish supply to the torch and ground.

The normal arc voltage reader didn't give a reliable output during ohmic sensing.

I'll put in another voltage sensor, right over the 24V-ish supply to the torch and ground.

Please Log in or Create an account to join the conversation.

- Hakan

- Away

- Platinum Member

-

Less

More

- Posts: 1252

- Thank you received: 438

08 Jun 2025 21:28 #329973

by Hakan

Replied by Hakan on topic Ohmic sensing with IPTM-60

Now it works. Again

The arc voltage connector is not connected directly to the arc and the work piece. There is some electronics in-between I don't even want to know about. The arc voltage is fine when cutting, but not reliable at all when not cutting. And ohmic probing is not cutting.

Instead I had to resort to a second voltage reader and read the voltage where the probing voltage is applied.

And now it works reliably. At least on the tests I have done so far.

Test patterns. I might have used wrong material setting on some but that doesn't matter for the probing test.

A new voltage reader was put in the box, next to the relay that applies probing voltage.

Cover on and pushed in next to the plasma cutter.

Schematics and code is available at github.com/MetalMusings/MyOwnEtherCATDev...th-the-iptm-60-torch

It uses my own Ethercat device. But nothing hinders this principle to be used with other arc voltage measurement devices such as those from Mesa.

The arc voltage connector is not connected directly to the arc and the work piece. There is some electronics in-between I don't even want to know about. The arc voltage is fine when cutting, but not reliable at all when not cutting. And ohmic probing is not cutting.

Instead I had to resort to a second voltage reader and read the voltage where the probing voltage is applied.

And now it works reliably. At least on the tests I have done so far.

Test patterns. I might have used wrong material setting on some but that doesn't matter for the probing test.

A new voltage reader was put in the box, next to the relay that applies probing voltage.

Cover on and pushed in next to the plasma cutter.

Schematics and code is available at github.com/MetalMusings/MyOwnEtherCATDev...th-the-iptm-60-torch

It uses my own Ethercat device. But nothing hinders this principle to be used with other arc voltage measurement devices such as those from Mesa.

Attachments:

Please Log in or Create an account to join the conversation.

- Hakan

- Away

- Platinum Member

-

Less

More

- Posts: 1252

- Thank you received: 438

08 Jun 2025 21:41 - 08 Jun 2025 21:43 #329974

by Hakan

Replied by Hakan on topic Ohmic sensing with IPTM-60

Here is the code used to detect contact

plasmac.ohmic-enable is connected to the "enable" signal in the code below, as well as to the output that activates the relay.

"limitVoltage" = 12V, halfway to 24V

"inVoltage" is the read voltage from the voltage reader.

"ohmicState", internal variable, is used to make sure the voltage first go above the limit and then start watching for contact. The relay has some reaction time, some 10 msecs, enough to need to be handled.

"voltageState", internal, indicates successful voltage reading.

"sensed" is the outsignal for contact yes/no.

plasmac.ohmic-enable is connected to the "enable" signal in the code below, as well as to the output that activates the relay.

"limitVoltage" = 12V, halfway to 24V

"inVoltage" is the read voltage from the voltage reader.

"ohmicState", internal variable, is used to make sure the voltage first go above the limit and then start watching for contact. The relay has some reaction time, some 10 msecs, enough to need to be handled.

"voltageState", internal, indicates successful voltage reading.

"sensed" is the outsignal for contact yes/no.

sensed = 0;

if (enabled && voltageState == 0)

{

if (ohmicState == OHMIC_IDLE && inVoltage > limitVoltage)

{

ohmicState = OHMIC_PROBE;

}

if (ohmicState == OHMIC_PROBE && inVoltage <= limitVoltage)

{

sensed = 1;

}

}

else

{

ohmicState = OHMIC_IDLE;

}

Last edit: 08 Jun 2025 21:43 by Hakan.

Please Log in or Create an account to join the conversation.

- Hakan

- Away

- Platinum Member

-

Less

More

- Posts: 1252

- Thank you received: 438

14 Oct 2025 08:02 #336411

by Hakan

Replied by Hakan on topic Ohmic sensing with IPTM-60

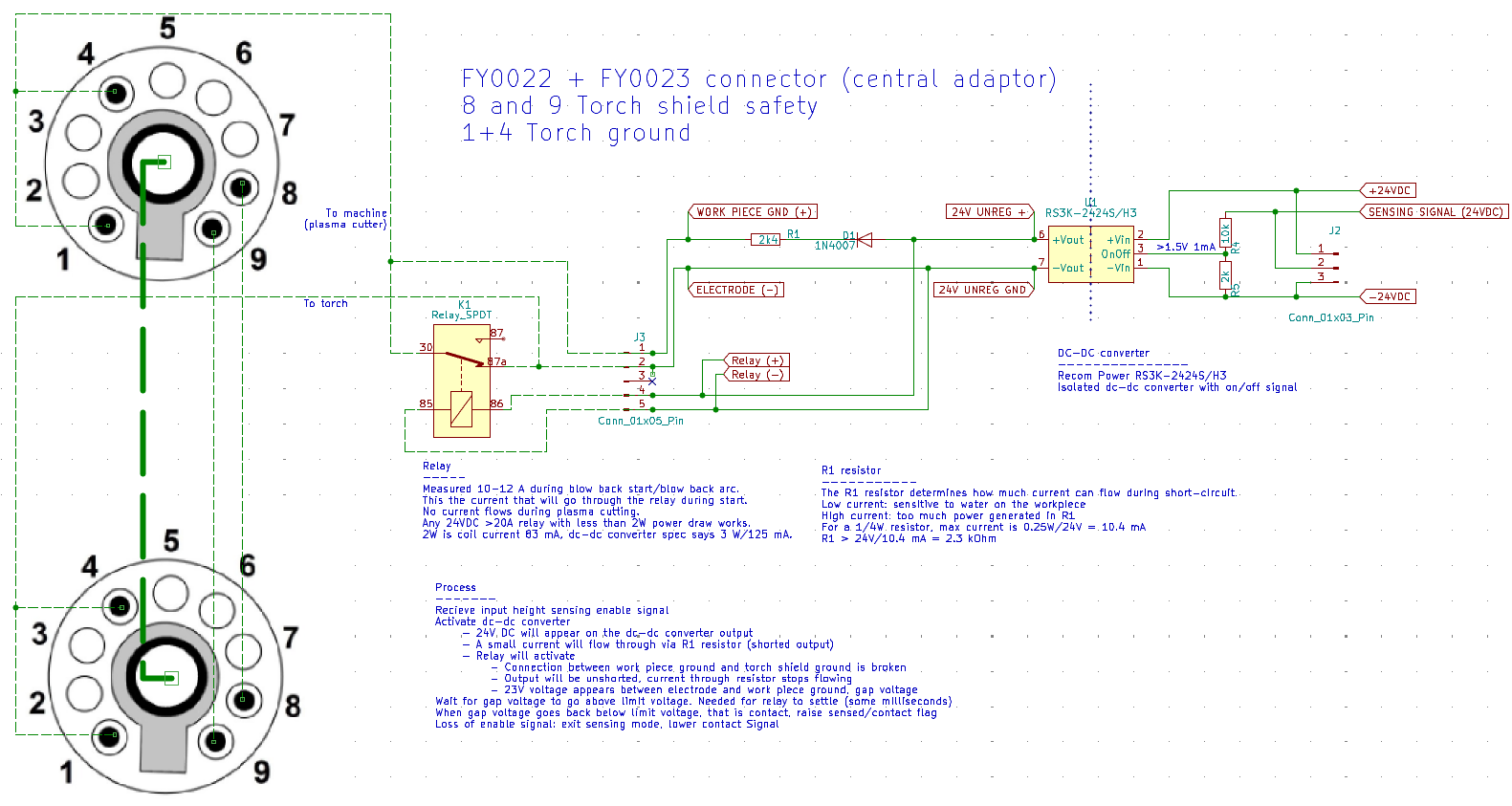

Update of this project.

Regarding water on the table and difficulty to properly detect contact.

Yes, been there, done that.

It seems to be caused by too low R1 resistance. Which means too low current at short-circuit.

Stray currents through water are in the same order of magnitude as the short-circuit current

and influences the voltage measurements.

Too high R1 (low short-circuit current) and water on the table causes two things:

1. The measured voltage will only go to single-digit voltages, like 8V instead of 24V

2. The measured short-circuit voltage drop is only a few Volts. The voltage stays at some 8-3 = 5 V, where it should be 0V.

When looking at the voltage, well working means sharply up to some 23V, then sharp drop to 0V.

Not well working: Damped rise to some 10-ish V, damped drop of a few Volts at short-circuit.

Using R1 = 100 kOhm, short-circuit current = 0.24 mA. This is too low.

Using R1 = 2k7 kOhm, I = 8.9 mA works much better.

Regarding water on the table and difficulty to properly detect contact.

Yes, been there, done that.

It seems to be caused by too low R1 resistance. Which means too low current at short-circuit.

Stray currents through water are in the same order of magnitude as the short-circuit current

and influences the voltage measurements.

Too high R1 (low short-circuit current) and water on the table causes two things:

1. The measured voltage will only go to single-digit voltages, like 8V instead of 24V

2. The measured short-circuit voltage drop is only a few Volts. The voltage stays at some 8-3 = 5 V, where it should be 0V.

When looking at the voltage, well working means sharply up to some 23V, then sharp drop to 0V.

Not well working: Damped rise to some 10-ish V, damped drop of a few Volts at short-circuit.

Using R1 = 100 kOhm, short-circuit current = 0.24 mA. This is too low.

Using R1 = 2k7 kOhm, I = 8.9 mA works much better.

Please Log in or Create an account to join the conversation.

- Hakan

- Away

- Platinum Member

-

Less

More

- Posts: 1252

- Thank you received: 438

14 Oct 2025 08:04 - 14 Oct 2025 08:06 #336412

by Hakan

Replied by Hakan on topic Ohmic sensing with IPTM-60

Attachments:

Last edit: 14 Oct 2025 08:06 by Hakan. Reason: spelling

Please Log in or Create an account to join the conversation.

- Hakan

- Away

- Platinum Member

-

Less

More

- Posts: 1252

- Thank you received: 438

14 Oct 2025 08:50 #336415

by Hakan

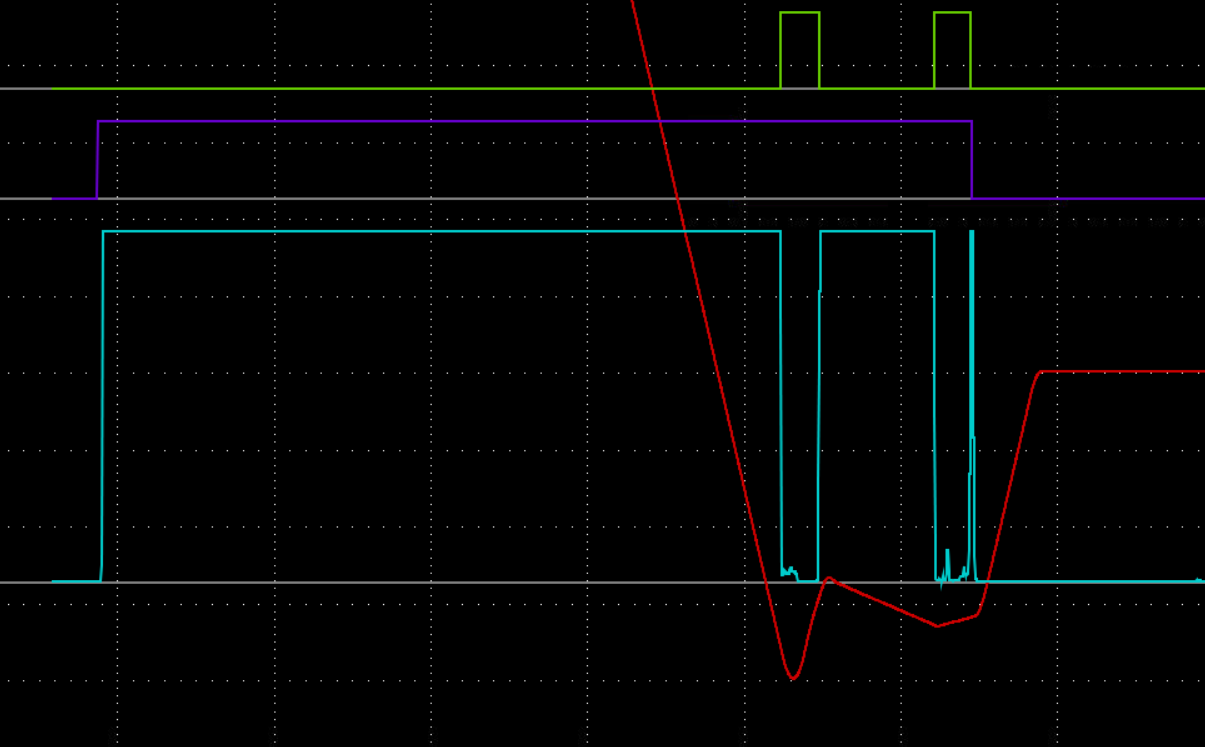

Here is what a sensing cycle looks like under good conditions.

Green: Sensing output signal: 1 if contact, 0 of no contact

Cyan: Voltage between plasma tip and work piece

Purple: Enable ohmic sensing signal

Red: Z-axle position.

First there is a 15 ms reaction time for the relay to switch on, I call it setup time.

After the setup time has expired, the contact evaluation starts.

There are several conditions.

1. Voltage drop below a set voltage limit like 12 V

2. Voltage drop from voltage at end of setup, like 5V drop

3. Overall voltage drop over one cycle, like 5V

4. Overall voltage drop over three cycles, again like 5V.

For good conditions like then one in the picture all conditions triggers at the same time in principle.

Replied by Hakan on topic Ohmic sensing with IPTM-60

Here is what a sensing cycle looks like under good conditions.

Green: Sensing output signal: 1 if contact, 0 of no contact

Cyan: Voltage between plasma tip and work piece

Purple: Enable ohmic sensing signal

Red: Z-axle position.

First there is a 15 ms reaction time for the relay to switch on, I call it setup time.

After the setup time has expired, the contact evaluation starts.

There are several conditions.

1. Voltage drop below a set voltage limit like 12 V

2. Voltage drop from voltage at end of setup, like 5V drop

3. Overall voltage drop over one cycle, like 5V

4. Overall voltage drop over three cycles, again like 5V.

For good conditions like then one in the picture all conditions triggers at the same time in principle.

Attachments:

Please Log in or Create an account to join the conversation.

- Hakan

- Away

- Platinum Member

-

Less

More

- Posts: 1252

- Thank you received: 438

14 Oct 2025 08:57 - 14 Oct 2025 08:57 #336417

by Hakan

Replied by Hakan on topic Ohmic sensing with IPTM-60

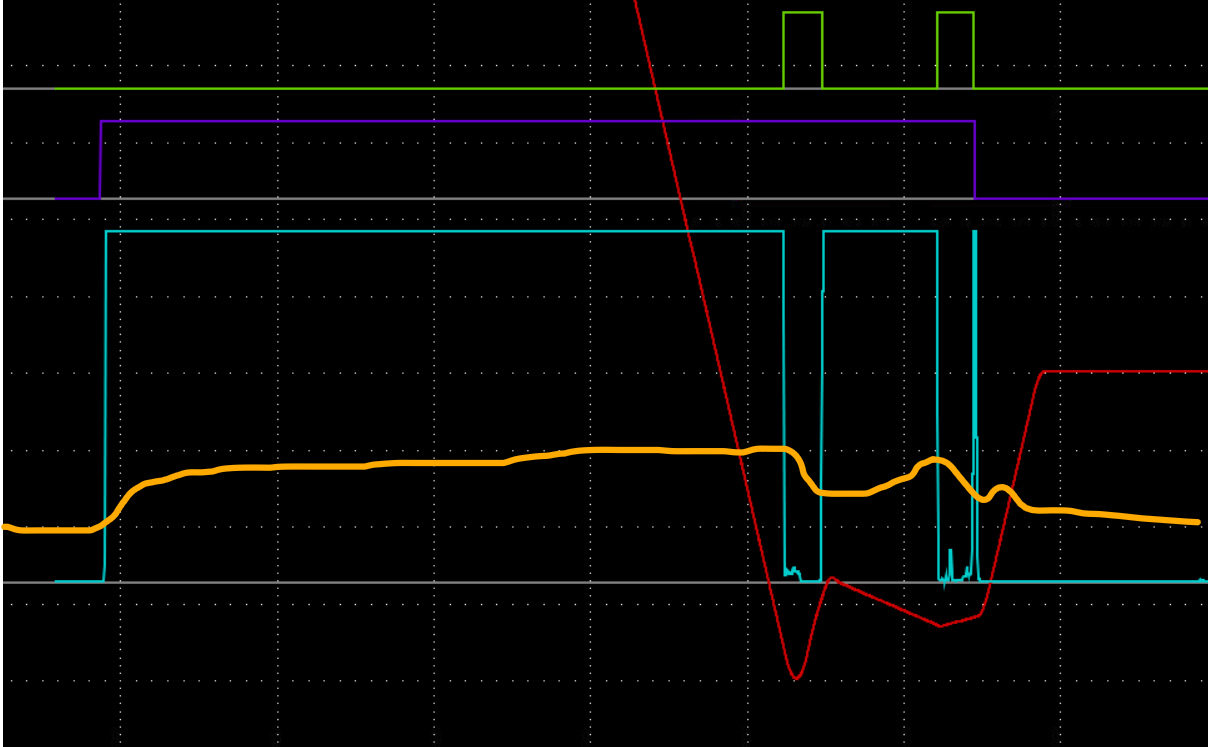

With water on the table and too low short circuit current configured,

we get something like the orange curve. A damped curve with reduced "swing".

No sharp transitions between open and short circuit.

Of course I tried to fix this in software, therefor the four conditions to trigger a sensing contact

The right thing to do was to lower the R1 value and increase the short-circuit current.

we get something like the orange curve. A damped curve with reduced "swing".

No sharp transitions between open and short circuit.

Of course I tried to fix this in software, therefor the four conditions to trigger a sensing contact

The right thing to do was to lower the R1 value and increase the short-circuit current.

Attachments:

Last edit: 14 Oct 2025 08:57 by Hakan.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

Time to create page: 0.310 seconds