Ohmic sensing with IPTM-60

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11738

- Thank you received: 3973

21 Oct 2025 10:32 #336809

by rodw

Replied by rodw on topic Ohmic sensing with IPTM-60

I had a bit of time to study your notes. optimizing probing speeds (time is money for production right?) requires careful attention and trial and error to set probe heights and probe speeds. This video shows the best I got it down to (2.0mm mild steel)

The reason why it sets the material height on up travel when the contact is broken, is that on a larger sheet, you can get a lot of warping (up to 100m) and the sheet is no longer supported by the slats. Even 16mm steel warps.... In this case, the material can bend down on probing which means that you could register a height that is well below the material height when cutting. Setting the height on uptravel eliminates errors from the springiness.

If you observe the torch while probing on a wet sheet, the water can form a meniscus around the torch tip that is dragged up and it can break away from the torch well above the material surface which will explain height variations. Experiment with a MPG on the Z axis to see this.

Note that the purpose of pulsing the torch is to activate preflow air before the cut so water is blown away from the torch as this video demonstrates.

As you can see, there are a lot of things to consider.

On an ethercat drive, it would be interesting to experiment with torque mode homing so the bottom home or limit switch set the material height.

The reason why it sets the material height on up travel when the contact is broken, is that on a larger sheet, you can get a lot of warping (up to 100m) and the sheet is no longer supported by the slats. Even 16mm steel warps.... In this case, the material can bend down on probing which means that you could register a height that is well below the material height when cutting. Setting the height on uptravel eliminates errors from the springiness.

If you observe the torch while probing on a wet sheet, the water can form a meniscus around the torch tip that is dragged up and it can break away from the torch well above the material surface which will explain height variations. Experiment with a MPG on the Z axis to see this.

Note that the purpose of pulsing the torch is to activate preflow air before the cut so water is blown away from the torch as this video demonstrates.

As you can see, there are a lot of things to consider.

On an ethercat drive, it would be interesting to experiment with torque mode homing so the bottom home or limit switch set the material height.

Please Log in or Create an account to join the conversation.

- Hakan

- Away

- Platinum Member

-

Less

More

- Posts: 1252

- Thank you received: 438

21 Oct 2025 13:03 #336827

by Hakan

Replied by Hakan on topic Ohmic sensing with IPTM-60

In the first video it looks like it just bounces on the material.

In the second video there is some hesitation, a few tenths of a second maybe.

This is with standard plasmac settings? Meaning material height set on probe up.

If I had this kind of performance I wouldn't worry about improving it.

I can see that a stiff spring, or large hysteresis, in the float switch can have that effect

with weak materials and that probe up can help. I have actually left the float switch

as is, with probe up. It is more with ohmic sensing where I don't see the need.

Water. A possible problem only the first cut, then there is post-flow of air that blows it away.

Lasts for 15 seconds or so. I can't (or don't know how to) only start air.

Maybe torch on for 1/10 of second. Not a big problem when I have got things to work.

There is an ECT60 for Z. I can try that. What should I be looking at?

In the second video there is some hesitation, a few tenths of a second maybe.

This is with standard plasmac settings? Meaning material height set on probe up.

If I had this kind of performance I wouldn't worry about improving it.

I can see that a stiff spring, or large hysteresis, in the float switch can have that effect

with weak materials and that probe up can help. I have actually left the float switch

as is, with probe up. It is more with ohmic sensing where I don't see the need.

Water. A possible problem only the first cut, then there is post-flow of air that blows it away.

Lasts for 15 seconds or so. I can't (or don't know how to) only start air.

Maybe torch on for 1/10 of second. Not a big problem when I have got things to work.

There is an ECT60 for Z. I can try that. What should I be looking at?

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11738

- Thank you received: 3973

21 Oct 2025 19:37 #336848

by rodw

Replied by rodw on topic Ohmic sensing with IPTM-60

Yes, standard = height set on probing up.

Yes, I saw that hesitation which I think is reducing velocity at probe height which is normal.

Early in the piece, I added a set screw to reduce float switch hysteresis to the barest of minimum.

the second video depends on the float switch to absorb over travel/inertia due to travel speeds.

Yes I don't think a float switch us necessary if you have reliable ohmic probing. In fact my float switch proximity sensor was broken for months and I didn't even know.

I'm not sure about the probing with ethercat, I know some commercial machines sense the material by torque. But if you have torque homing set up and working, perhaps you can use it for material sensing. Maybe you would use the probing function instead. It will be a good experimental project for someone like you

Yes, I saw that hesitation which I think is reducing velocity at probe height which is normal.

Early in the piece, I added a set screw to reduce float switch hysteresis to the barest of minimum.

the second video depends on the float switch to absorb over travel/inertia due to travel speeds.

Yes I don't think a float switch us necessary if you have reliable ohmic probing. In fact my float switch proximity sensor was broken for months and I didn't even know.

I'm not sure about the probing with ethercat, I know some commercial machines sense the material by torque. But if you have torque homing set up and working, perhaps you can use it for material sensing. Maybe you would use the probing function instead. It will be a good experimental project for someone like you

Please Log in or Create an account to join the conversation.

- Hakan

- Away

- Platinum Member

-

Less

More

- Posts: 1252

- Thank you received: 438

22 Oct 2025 07:02 - 22 Oct 2025 08:53 #336859

by Hakan

Replied by Hakan on topic Ohmic sensing with IPTM-60

Found a way to use the standard plasma component.

After contact (probe-down) I let the contact pulse width be say 5 ms, just long enough for it to register contact.

Always 5 ms and I can compensate for the short distance traveled with the Ohmic Offset setting.

Only downside is the pulse is too short for the Ohmic led to blink.

Checked the ECT60 but I don't see an opening. It has the 0x6077 actual torque pdo but that is always zero.

Homing could be possible. But to switch to homing and lose coordinates and fix that.

I don't think it's currently working badly enough for me to want to put in the time needed.

After contact (probe-down) I let the contact pulse width be say 5 ms, just long enough for it to register contact.

Always 5 ms and I can compensate for the short distance traveled with the Ohmic Offset setting.

Only downside is the pulse is too short for the Ohmic led to blink.

Checked the ECT60 but I don't see an opening. It has the 0x6077 actual torque pdo but that is always zero.

Homing could be possible. But to switch to homing and lose coordinates and fix that.

I don't think it's currently working badly enough for me to want to put in the time needed.

Last edit: 22 Oct 2025 08:53 by Hakan.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- Hakan

- Away

- Platinum Member

-

Less

More

- Posts: 1252

- Thank you received: 438

22 Oct 2025 12:02 - 22 Oct 2025 12:16 #336866

by Hakan

Replied by Hakan on topic Ohmic sensing with IPTM-60

Led was easily solved with oneshot to qtplasmac.ohmic_led_in.

It works pretty well now. Time to wrap up this project.

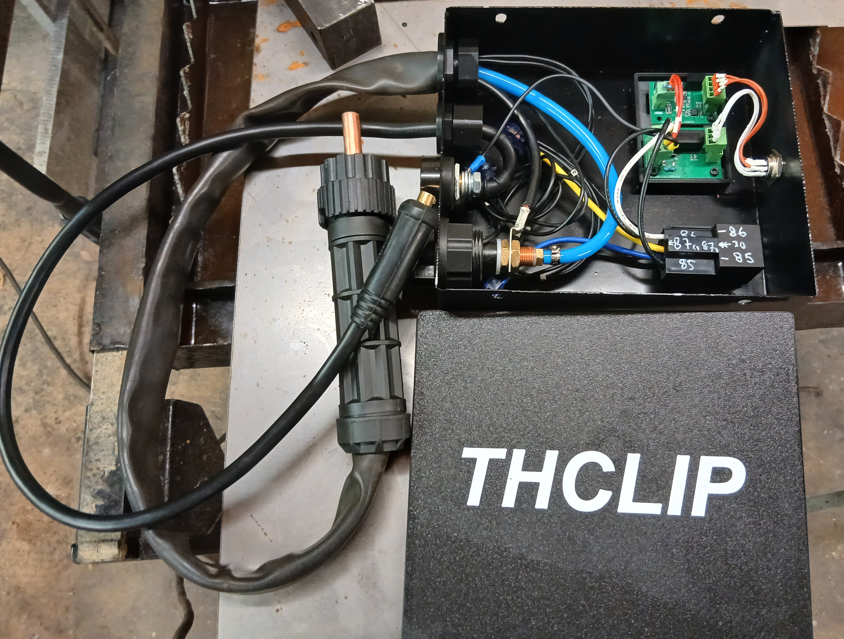

The goal was ohmic sensing with the IPTM-60 (and IPTM-80) torch

without modification to the plasma cutter. I think it came out really nice.

A new box was made, needed to measure on what we call the ground lead.

The box tucked away

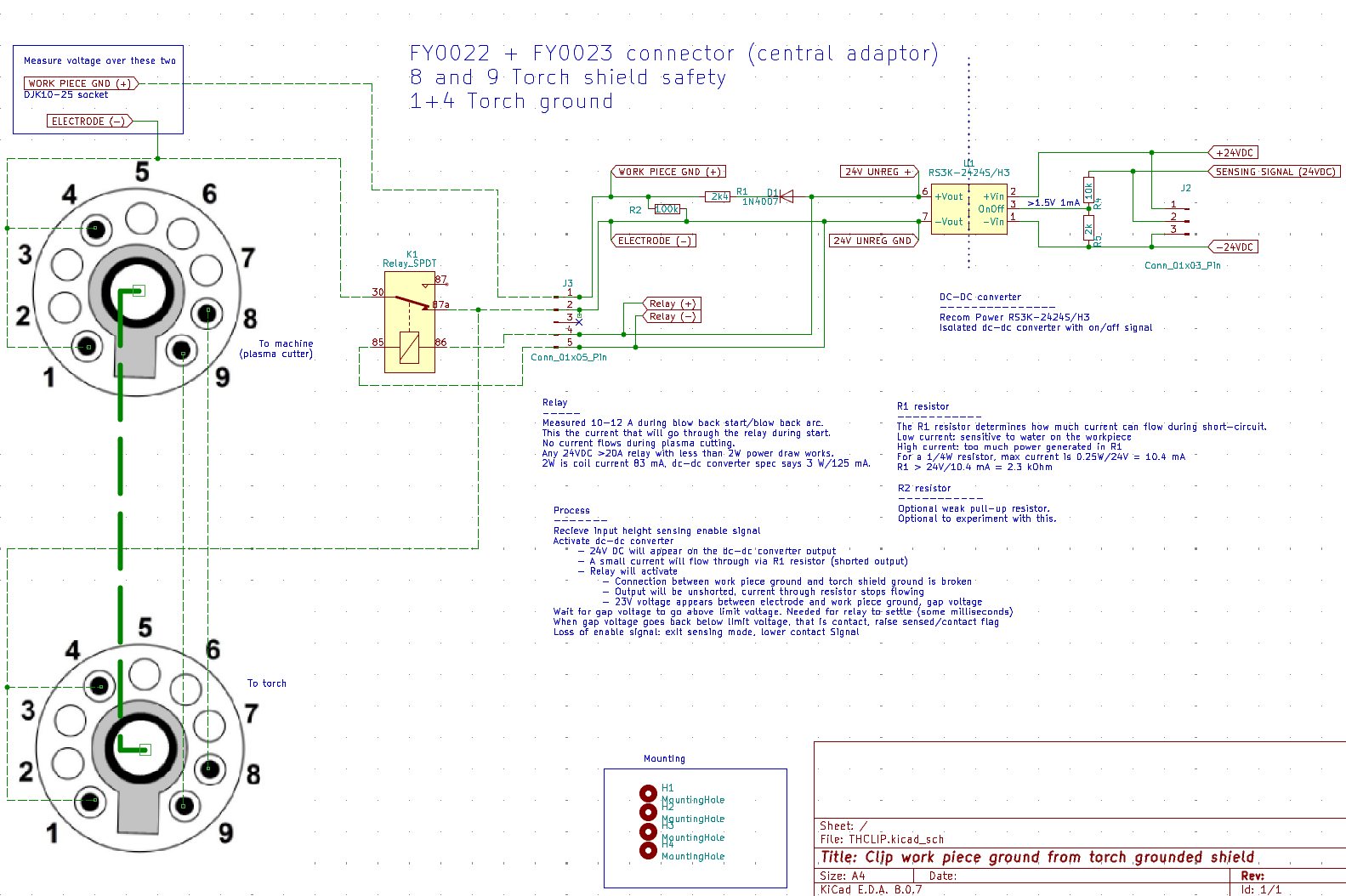

Schematics.

All schematics, code etc are available on github

github.com/MetalMusings/MyOwnEtherCATDevice

specifically the Kicad files for the THCLIP board are here

github.com/MetalMusings/MyOwnEtherCATDev...n/Cards/THCLIP/Kicad

It works pretty well now. Time to wrap up this project.

The goal was ohmic sensing with the IPTM-60 (and IPTM-80) torch

without modification to the plasma cutter. I think it came out really nice.

A new box was made, needed to measure on what we call the ground lead.

The box tucked away

Schematics.

All schematics, code etc are available on github

github.com/MetalMusings/MyOwnEtherCATDevice

specifically the Kicad files for the THCLIP board are here

github.com/MetalMusings/MyOwnEtherCATDev...n/Cards/THCLIP/Kicad

Attachments:

Last edit: 22 Oct 2025 12:16 by Hakan.

The following user(s) said Thank You: tommylight, rodw

Please Log in or Create an account to join the conversation.

Time to create page: 0.278 seconds