Retrofitting a 1986 Maho MH400E

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1540

- Thank you received: 572

23 Dec 2019 12:00 #153094

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

A message to your all from the MAHO...

Merry Christmas,

Mark

Merry Christmas,

Mark

The following user(s) said Thank You: tommylight, Glemigobles

Please Log in or Create an account to join the conversation.

- hanmon

- Offline

- Senior Member

-

Less

More

- Posts: 73

- Thank you received: 23

23 Dec 2019 14:28 #153106

by hanmon

Replied by hanmon on topic Retrofitting a 1986 Maho MH400E

Merry Christmas !!

Nice Idea

I'm currently working on my A-Axis an need 6mm more travel in Y.

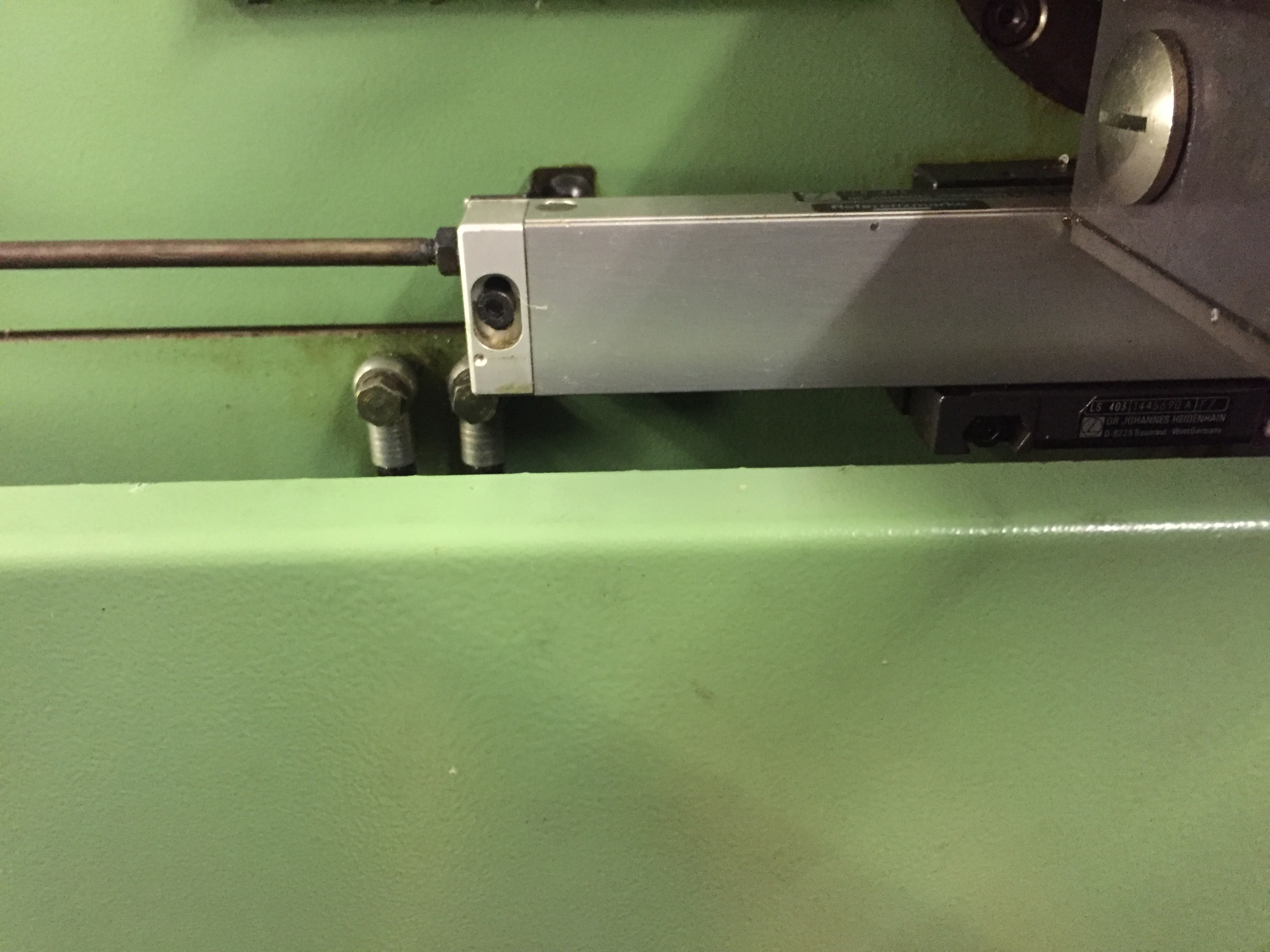

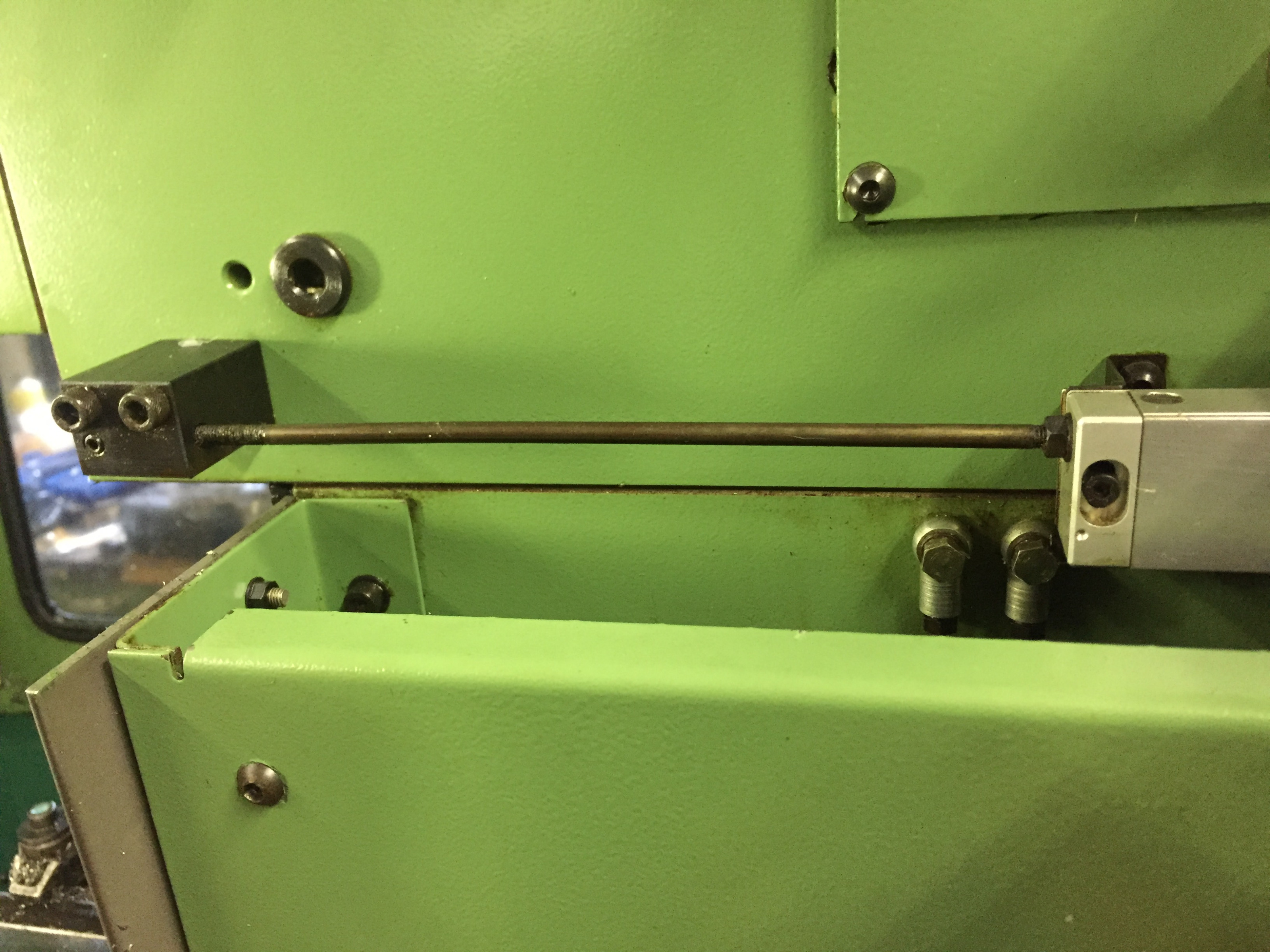

There seems to be a lot of space on the glass-scales (LS403) on both ends and on the ball-screw as well.

Is there any reason to not move the the stoppers for the limit switch?

This rod is meant for what ?

Cheers

Hanno

Nice Idea

I'm currently working on my A-Axis an need 6mm more travel in Y.

There seems to be a lot of space on the glass-scales (LS403) on both ends and on the ball-screw as well.

Is there any reason to not move the the stoppers for the limit switch?

This rod is meant for what ?

Cheers

Hanno

Attachments:

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1540

- Thank you received: 572

23 Dec 2019 15:11 #153108

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Servus Hanno,

Frohe Weihnachten!

That is also a very clean machine.

The rod is made from Invar. This is an alloy which has almost no coefficient of thermal expansion, so it, along with the leaf spring mounting of the encoder, compensate for the thermal expansion of the gearbox.

I would guess that MAHO provided a little over travel on the assumption of a run away hitting the end stop at full rapid speed, to allow for the deceleration before a ball screw goes on block and suffers an RUD.

Mark

Frohe Weihnachten!

That is also a very clean machine.

The rod is made from Invar. This is an alloy which has almost no coefficient of thermal expansion, so it, along with the leaf spring mounting of the encoder, compensate for the thermal expansion of the gearbox.

I would guess that MAHO provided a little over travel on the assumption of a run away hitting the end stop at full rapid speed, to allow for the deceleration before a ball screw goes on block and suffers an RUD.

Mark

Please Log in or Create an account to join the conversation.

- hanmon

- Offline

- Senior Member

-

Less

More

- Posts: 73

- Thank you received: 23

23 Dec 2019 16:10 #153114

by hanmon

Replied by hanmon on topic Retrofitting a 1986 Maho MH400E

Servus Mark,

"Probieren geht über Studieren"

The glass-scale says 370mm on its number plate so

I gained travel from -1/251 to -11/257 (ini-file) by simply sliding the adjustable stops to their end position. There is still 2mm play to the switch. I think one could bring this up to 100mm or more if pushed to the real mechanical limits by moving the stoppers.

Hanno

"Probieren geht über Studieren"

The glass-scale says 370mm on its number plate so

I gained travel from -1/251 to -11/257 (ini-file) by simply sliding the adjustable stops to their end position. There is still 2mm play to the switch. I think one could bring this up to 100mm or more if pushed to the real mechanical limits by moving the stoppers.

Hanno

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1540

- Thank you received: 572

23 Dec 2019 16:13 #153115

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

That is good to know.

You have to post some pictures of your A axis.

Mark

You have to post some pictures of your A axis.

Mark

Please Log in or Create an account to join the conversation.

- J Green

- Offline

- Elite Member

-

Less

More

- Posts: 164

- Thank you received: 24

23 Dec 2019 17:36 #153124

by J Green

Replied by J Green on topic Retrofitting a 1986 Maho MH400E

Wishing all of you Linux CNC ers the seasons best and a even better New Year

Hanno - You are aware the LS 403 scales have a ( RM on the scale label ) reference mark near each end of the glass scale, for near end of travel use? Don't know if you have used them for homing and or soft travel limit .

How do you guys find such clean Mahos? Yes -- More pictures ! Please

Mark -- Looks as if the tool setter is working now. Good to hear. Wondering what the next addition is going to be . Agree with you about faster servo speeds. To me it's the difference of a Umog vers a Ferrari in that do you want to get there an back or look stylish while broken down on the road. I hate walking home!

Did you ever manage to squeeze the Maho into your warm shop ? Hope we don't have another winter white-out of MAHO progress.

Bob

Hanno - You are aware the LS 403 scales have a ( RM on the scale label ) reference mark near each end of the glass scale, for near end of travel use? Don't know if you have used them for homing and or soft travel limit .

How do you guys find such clean Mahos? Yes -- More pictures ! Please

Mark -- Looks as if the tool setter is working now. Good to hear. Wondering what the next addition is going to be . Agree with you about faster servo speeds. To me it's the difference of a Umog vers a Ferrari in that do you want to get there an back or look stylish while broken down on the road. I hate walking home!

Did you ever manage to squeeze the Maho into your warm shop ? Hope we don't have another winter white-out of MAHO progress.

Bob

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

24 Dec 2019 08:48 #153152

by drimaropoylos

Soft limits are going to save you from crank that axis out of limit switches. Limit switches ere going to cut the power from the servo motors in case of runaway and hard limits going to absorb the energy from 600 kgr head going full rapid.

John

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

If you really need that little extra travel for a specific job you can wire a button that shorts the limit switch and use it only when the program needs to.Servus Mark,

"Probieren geht über Studieren"

The glass-scale says 370mm on its number plate so

I gained travel from -1/251 to -11/257 (ini-file) by simply sliding the adjustable stops to their end position. There is still 2mm play to the switch. I think one could bring this up to 100mm or more if pushed to the real mechanical limits by moving the stoppers.

Hanno

Soft limits are going to save you from crank that axis out of limit switches. Limit switches ere going to cut the power from the servo motors in case of runaway and hard limits going to absorb the energy from 600 kgr head going full rapid.

John

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1540

- Thank you received: 572

25 Dec 2019 15:55 #153197

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

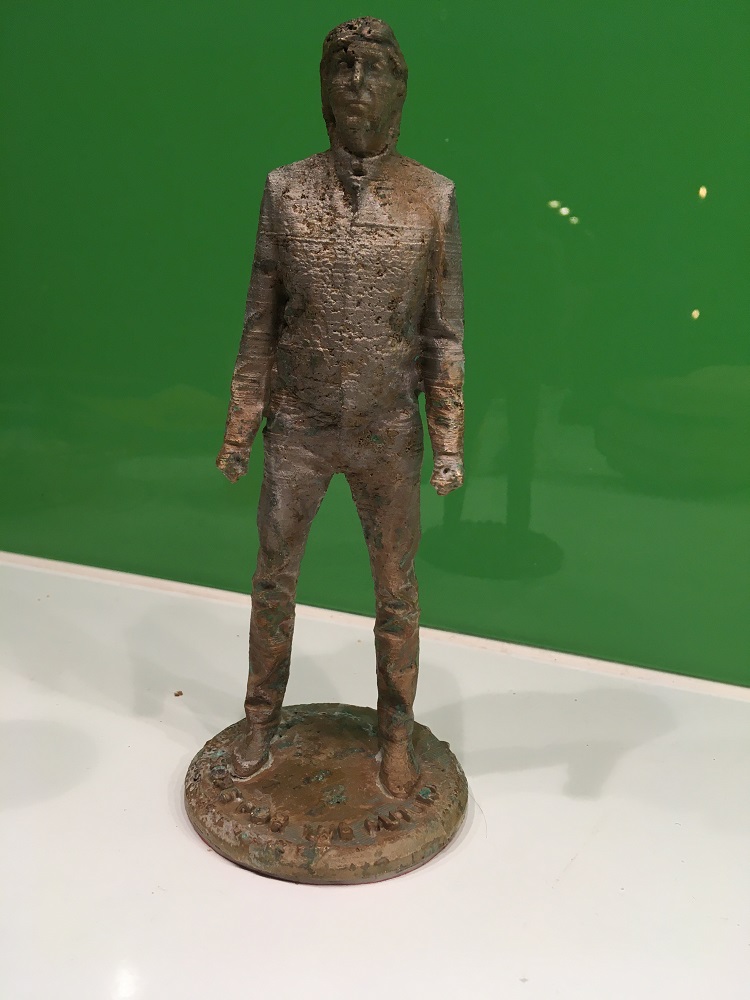

OT, but I did a couple of casting sessions before Xmas. SWMBO is a Beatles fan, so I cast a Paul Mac statue as a pressie for her. The STL model is in the Thingiverse. It was scaled up 50%, and a close fitting flask also 3D printed, to use as little investment as possible. Unfortunately I have no way to pull a vacuum and degas the investment.

The next session was a bit of aluminium, doing parts for Julian HG's , modular flask design. These arent very good. I had the sand a little dry, and had a lot of break out pulling the pattern.

Once the furnace was hot enough, I switched to the oil burner, and did my first successful iron pour. This is a face plate for the Boley 4LV lathe. There are three minor voids visible, and the surface finish is very rough. I didn't use any facing sand with carbon dust in it. The core was made with sugar water bonded sand and baked. The carbon in the core made for a pretty good surface finish in there.

There is an extra boss cast into the front to grip it in the four jaw for boring out and threading the bore for the spindle nose thread.

Mark

The next session was a bit of aluminium, doing parts for Julian HG's , modular flask design. These arent very good. I had the sand a little dry, and had a lot of break out pulling the pattern.

Once the furnace was hot enough, I switched to the oil burner, and did my first successful iron pour. This is a face plate for the Boley 4LV lathe. There are three minor voids visible, and the surface finish is very rough. I didn't use any facing sand with carbon dust in it. The core was made with sugar water bonded sand and baked. The carbon in the core made for a pretty good surface finish in there.

There is an extra boss cast into the front to grip it in the four jaw for boring out and threading the bore for the spindle nose thread.

Mark

Attachments:

Please Log in or Create an account to join the conversation.

- J Green

- Offline

- Elite Member

-

Less

More

- Posts: 164

- Thank you received: 24

26 Dec 2019 11:58 #153226

by J Green

Replied by J Green on topic Retrofitting a 1986 Maho MH400E

Mark

Impressive foundry work you are doing there. Looks as if those who cast dispersions about a broken MAHO purchase can now go pound sand ,or be redirected into mulling sand.

This side of the Atlantic pond, pouring cast iron is fairly rare at the hobby level . Cast iron requires a lot of heat and the stuff added to the melt are hard to get in small amounts. For a vacuum , would a water aspirator be of any use? Andy P. might be of some metallurgy help if you start cooking up various flavours of metal.

When are you going to show a photo of the sand muller? If you are so hung up on form over function then slap lipstick on it.

Wishing the best in the New Year

Bob

Impressive foundry work you are doing there. Looks as if those who cast dispersions about a broken MAHO purchase can now go pound sand ,or be redirected into mulling sand.

This side of the Atlantic pond, pouring cast iron is fairly rare at the hobby level . Cast iron requires a lot of heat and the stuff added to the melt are hard to get in small amounts. For a vacuum , would a water aspirator be of any use? Andy P. might be of some metallurgy help if you start cooking up various flavours of metal.

When are you going to show a photo of the sand muller? If you are so hung up on form over function then slap lipstick on it.

Wishing the best in the New Year

Bob

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19782

- Thank you received: 4604

27 Dec 2019 10:07 #153258

by andypugh

A recent idea on Hackaday for degassing epoxy was one of these.

www.amazon.com/dp/B07Z5W5JD1/

I modified a 12V tyre inflator (by adding a tube to the inlet) when I wanted a vacuum a little while ago.

Replied by andypugh on topic Retrofitting a 1986 Maho MH400E

For a vacuum , would a water aspirator be of any use?

A recent idea on Hackaday for degassing epoxy was one of these.

www.amazon.com/dp/B07Z5W5JD1/

I modified a 12V tyre inflator (by adding a tube to the inlet) when I wanted a vacuum a little while ago.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.360 seconds