Deckel FP4 ATC Retrofit

- Walkahz

- Offline

- Junior Member

-

Less

More

- Posts: 38

- Thank you received: 7

31 Oct 2023 11:21 #284172

by Walkahz

Replied by Walkahz on topic Deckel FP4 ATC Retrofit

Still moving along with my refit. Having issues getting Linux CNC started and connected to my mesa cards but haven't tried in a while so will need to have another go with fresh eyes. Does Linux CNC start without a card connected? I have done a basic configuration to get me started but it won't run.

Control box is coming along, have got most wires I no longer need stripped and I am starting to put it together again. Have fitted up my 3 vfd's and 24v 12v power supplies.

240v power cable fitted and running through breakers and into my various distribution blocks. Having so much cable and componentry I have already removed is useful as there is plenty there for the rebuild.

Control box is coming along, have got most wires I no longer need stripped and I am starting to put it together again. Have fitted up my 3 vfd's and 24v 12v power supplies.

240v power cable fitted and running through breakers and into my various distribution blocks. Having so much cable and componentry I have already removed is useful as there is plenty there for the rebuild.

Attachments:

The following user(s) said Thank You: besriworld

Please Log in or Create an account to join the conversation.

- Walkahz

- Offline

- Junior Member

-

Less

More

- Posts: 38

- Thank you received: 7

22 Jan 2024 10:57 #291333

by Walkahz

Replied by Walkahz on topic Deckel FP4 ATC Retrofit

Long time no post. Still been chipping away at the deckel but time has not been my friend.

have finally got Linux CNC up and running and connecting to my mesa card took lots of google for a newbie like me to find the ins and outs of Linux.

Have got temporary power hooked up to power supplies and vfd's for testing purposes.

Working through reverse engineering the button IO on the original deckel control panel so I can use these as hard buttons.

Gear position sensors wired in as inputs. Still need to wire in the gear change motors and do the HAL not looking forwards to this.

I have purchased X and Y axis servos and done a test to make them spin controlled by LCNC. Z servo to wait until these 2 are fitted and working (as well to save up some more funds)

I am having a problem controlling my fwd and reverse switching on my VFD however.

The output switching on the 7i96 seems to be working when checked with multimeter however VFD will run if output is active or inactive until DCOM wire is removed. Bridging the wires across the terminals on the VFD makes the functions work as expected. Any ideas? Or will this need to run through an external relay?

have finally got Linux CNC up and running and connecting to my mesa card took lots of google for a newbie like me to find the ins and outs of Linux.

Have got temporary power hooked up to power supplies and vfd's for testing purposes.

Working through reverse engineering the button IO on the original deckel control panel so I can use these as hard buttons.

Gear position sensors wired in as inputs. Still need to wire in the gear change motors and do the HAL not looking forwards to this.

I have purchased X and Y axis servos and done a test to make them spin controlled by LCNC. Z servo to wait until these 2 are fitted and working (as well to save up some more funds)

I am having a problem controlling my fwd and reverse switching on my VFD however.

The output switching on the 7i96 seems to be working when checked with multimeter however VFD will run if output is active or inactive until DCOM wire is removed. Bridging the wires across the terminals on the VFD makes the functions work as expected. Any ideas? Or will this need to run through an external relay?

Please Log in or Create an account to join the conversation.

- Walkahz

- Offline

- Junior Member

-

Less

More

- Posts: 38

- Thank you received: 7

20 Mar 2024 10:06 #296383

by Walkahz

Replied by Walkahz on topic Deckel FP4 ATC Retrofit

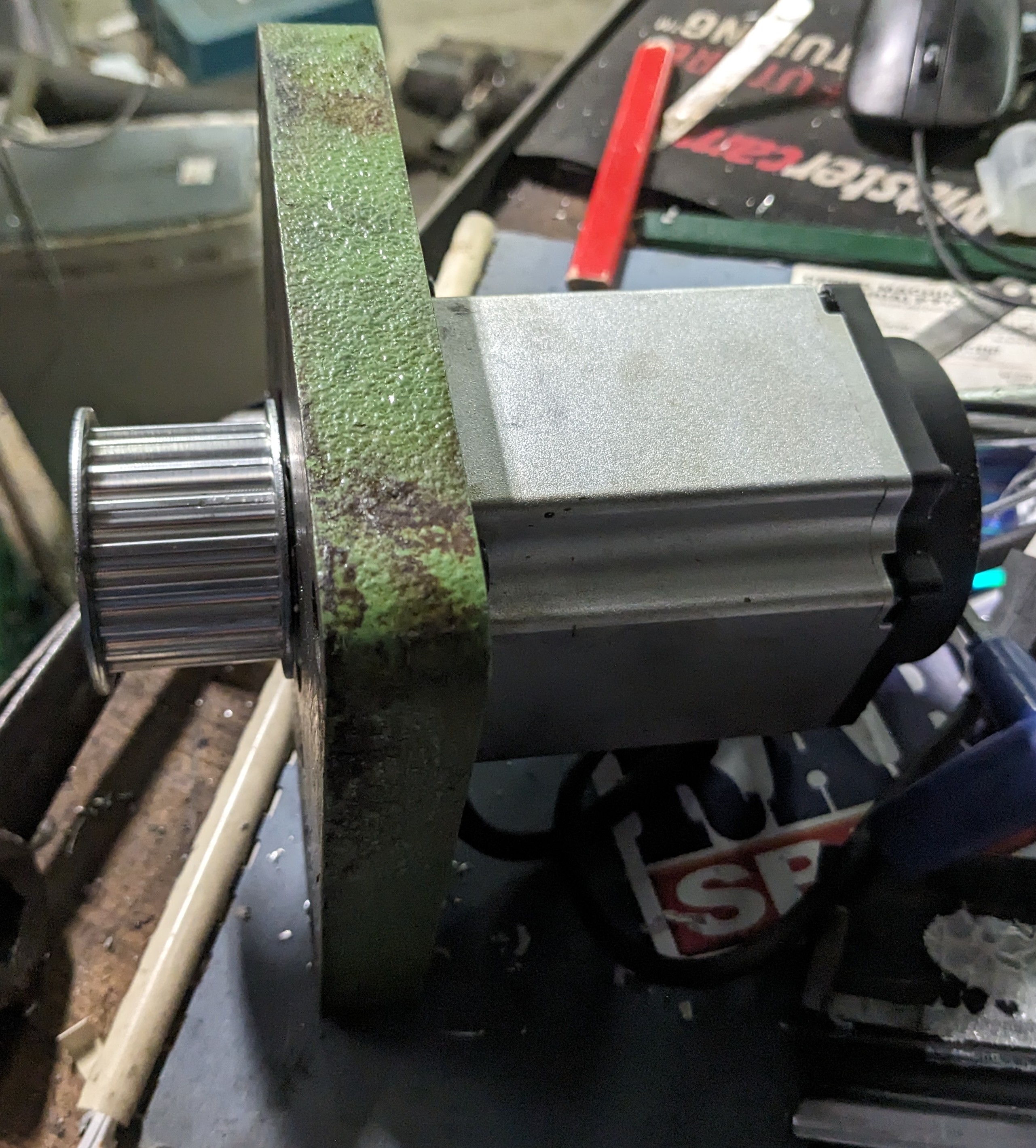

Got the fwd reverse switching working for the VFD. Ended up running through an external relay triggered by the 7i96.Need to read up more on how outputs are used on the 7i84 with only 1 wire unlike the 7i96 with a common side.In the meantime my 8m pulleys arrived from china for my X and y axis. Got my X axis finally moving. Probably the first movement this machine has made under its own power in 10 years!!! Photo of the servo on its mount before fitting.

Attachments:

Please Log in or Create an account to join the conversation.

- Walkahz

- Offline

- Junior Member

-

Less

More

- Posts: 38

- Thank you received: 7

29 Sep 2024 12:21 #311022

by Walkahz

Replied by Walkahz on topic Deckel FP4 ATC Retrofit

Didn't realise how long it has been since posting here.

A lot of things have happened to the mill and on Friday I finally made its first very slow chips in a long long time.

Z axis motor took me some figuring out as the servo drive was not as basic as the X and Y motors.

Have wired up the hydraulic pump and got the tool clamp functional, have kept this running analogue style with just switches and relays for now. Can change to PC control down the track.

Have a tool setter and probe fitted although the probe was DOA from AliExpress so had to arrange another.

Still working on linking my physical buttons on my control panel as well as the biggest task of getting the gearbox running which I have had a few goes at now. I am finally getting some progress on a classic ladder solution for this so hopefully not too far off now.

A lot of things have happened to the mill and on Friday I finally made its first very slow chips in a long long time.

Z axis motor took me some figuring out as the servo drive was not as basic as the X and Y motors.

Have wired up the hydraulic pump and got the tool clamp functional, have kept this running analogue style with just switches and relays for now. Can change to PC control down the track.

Have a tool setter and probe fitted although the probe was DOA from AliExpress so had to arrange another.

Still working on linking my physical buttons on my control panel as well as the biggest task of getting the gearbox running which I have had a few goes at now. I am finally getting some progress on a classic ladder solution for this so hopefully not too far off now.

The following user(s) said Thank You: tommylight, besriworld

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.260 seconds