Standard-modern 1700 series retrofit

- Trav328

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 75

- Thank you received: 31

21 Aug 2023 20:26 - 21 Aug 2023 20:29 #278642

by Trav328

Standard-modern 1700 series retrofit was created by Trav328

Figured this would be the easiest way to keep all my info/questions in one place and keep track.

I have spent the last 4 years in aerospace machining and 7 years in a job shop before that , my old boss who owned the job shop let me know he was moving and if I wanted this lathe I could have it , just had to move it .

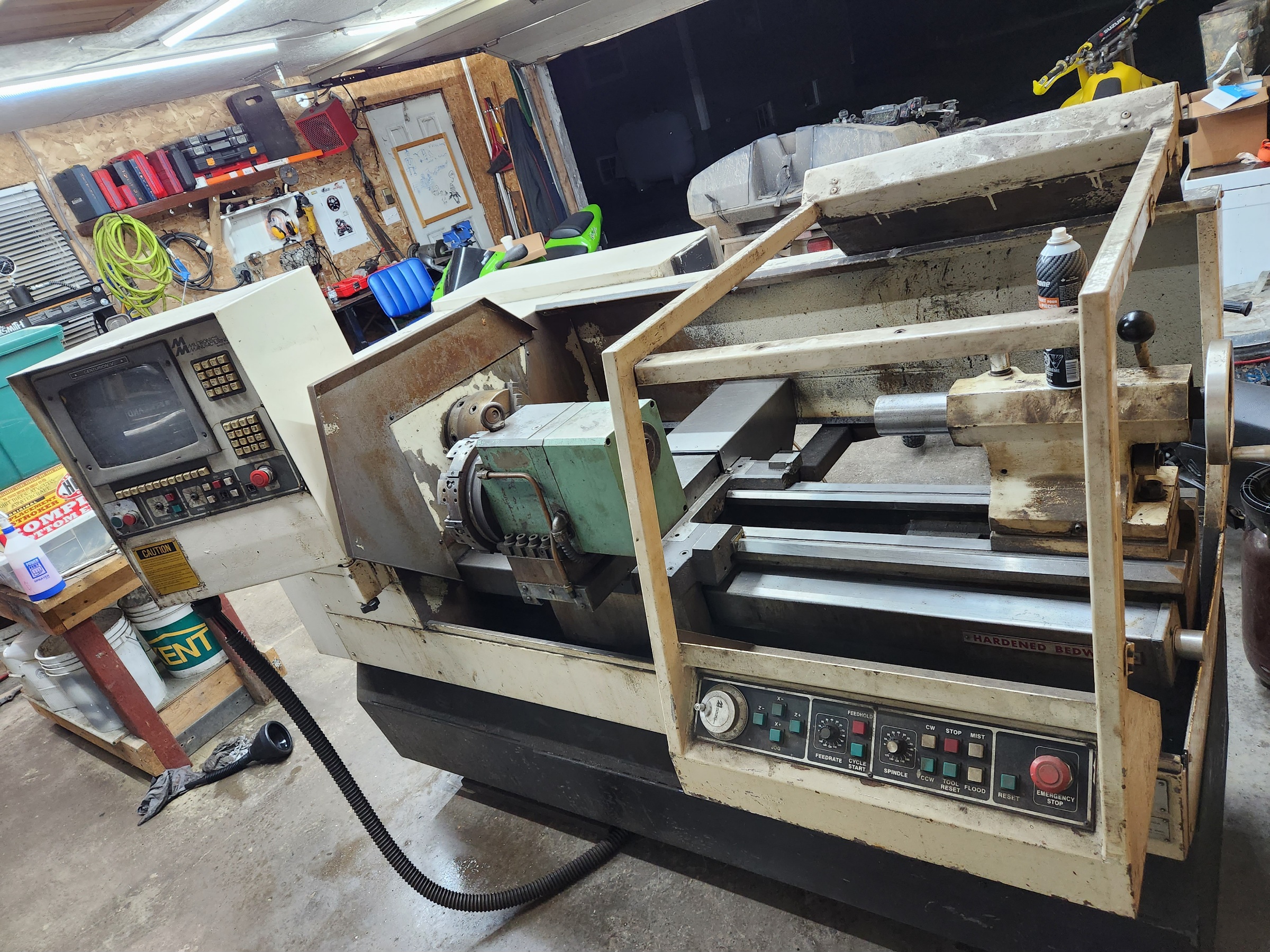

It's a 1996 standard-modern (kestrel) 1700 series 10hp lathe that was made in canada, it had a milltronics centurion V controller that was riddled with problems and never worked quite right so it was just crammed in storage. Linux cnc is the best candidate to save this from the scrap yard.

The drives are MTS (parker hannifin) mpa-06 for the axis and mpa-50 for the spindle with 3 ranges a group of contactors that switch between star/delta & series/parrallel windings , luckily the spindle drive is capable of single phase operation. All drives are analog +/- 10v

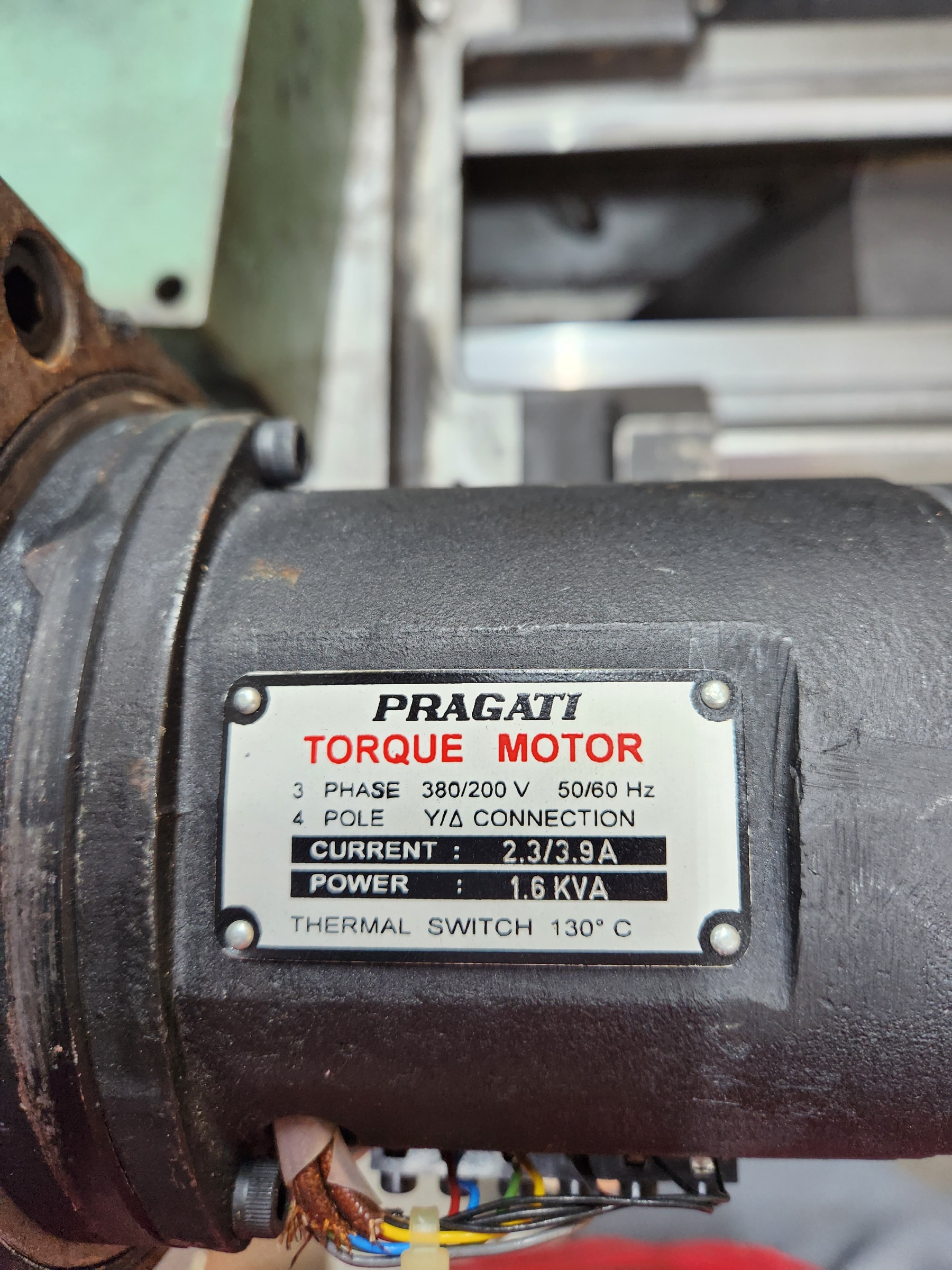

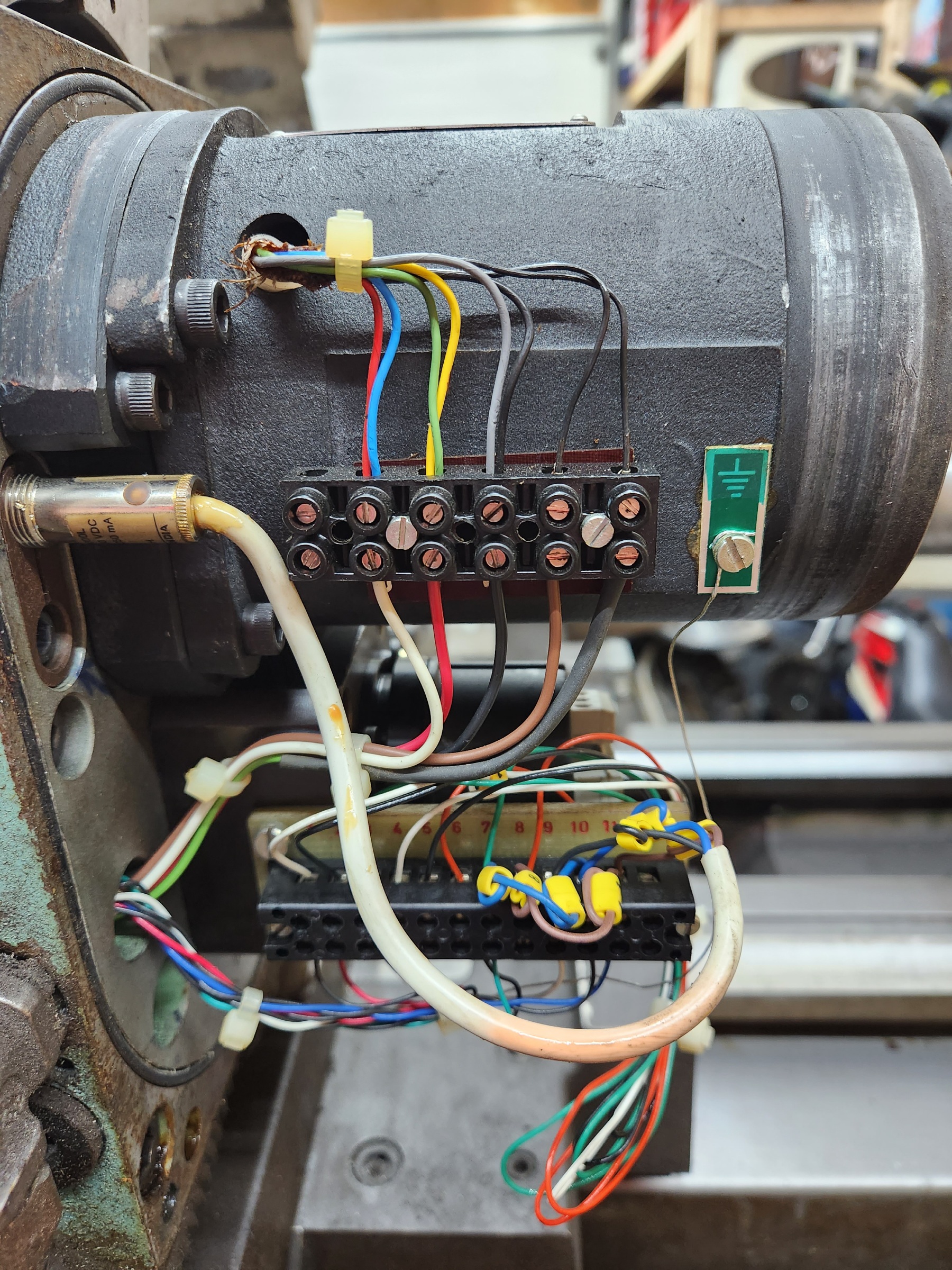

the tool changer is pragati , powered by a 3 phase pragati "torque" motor , it uses a absolute encoder for positioning and a proximity switch for clamp verification.this will be ran by a vfd.

From PCW'S suggestion I will be using a 7i97t when they become avilable in a few weeks , gives lots of time to clean up everything else.

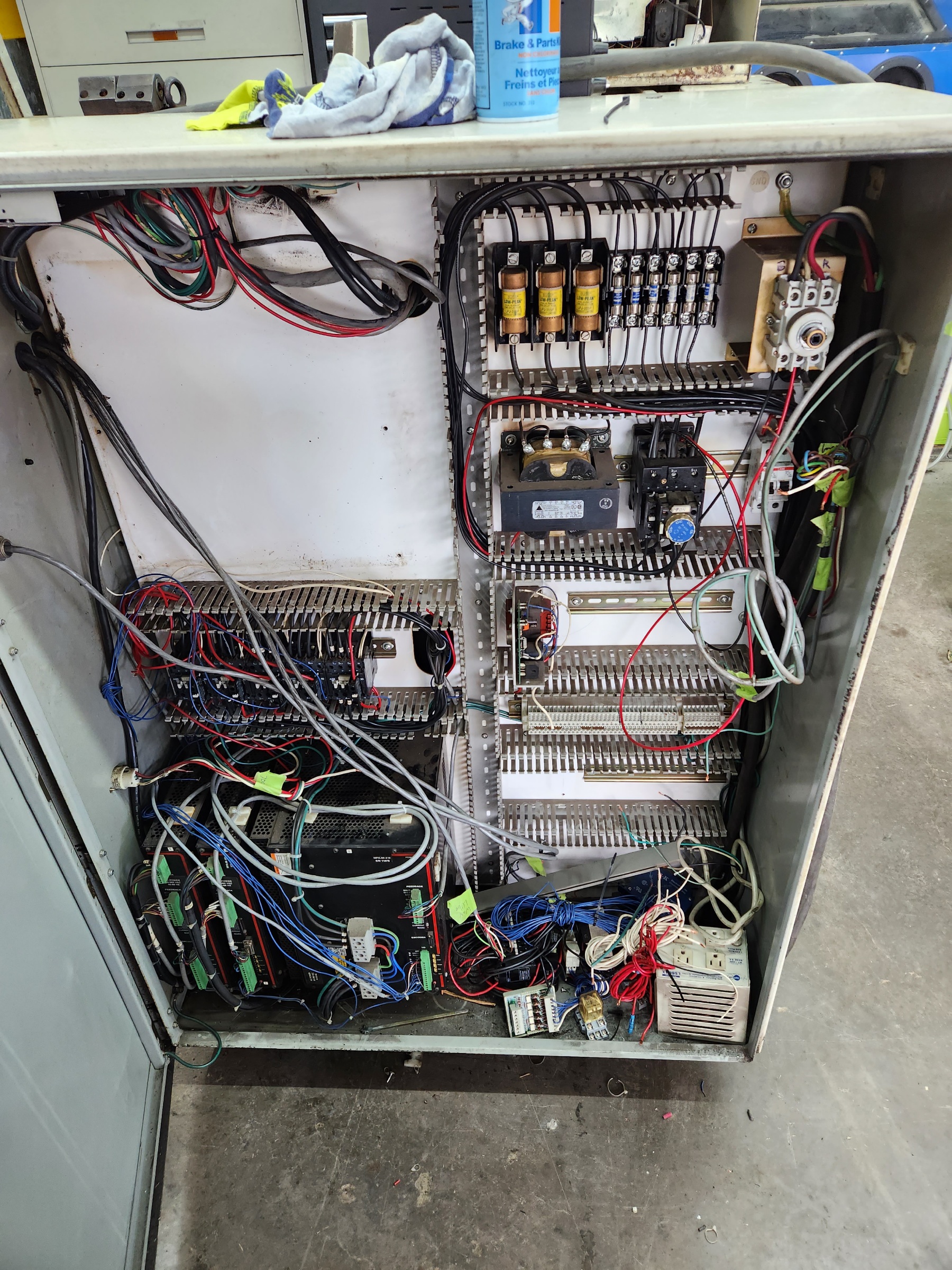

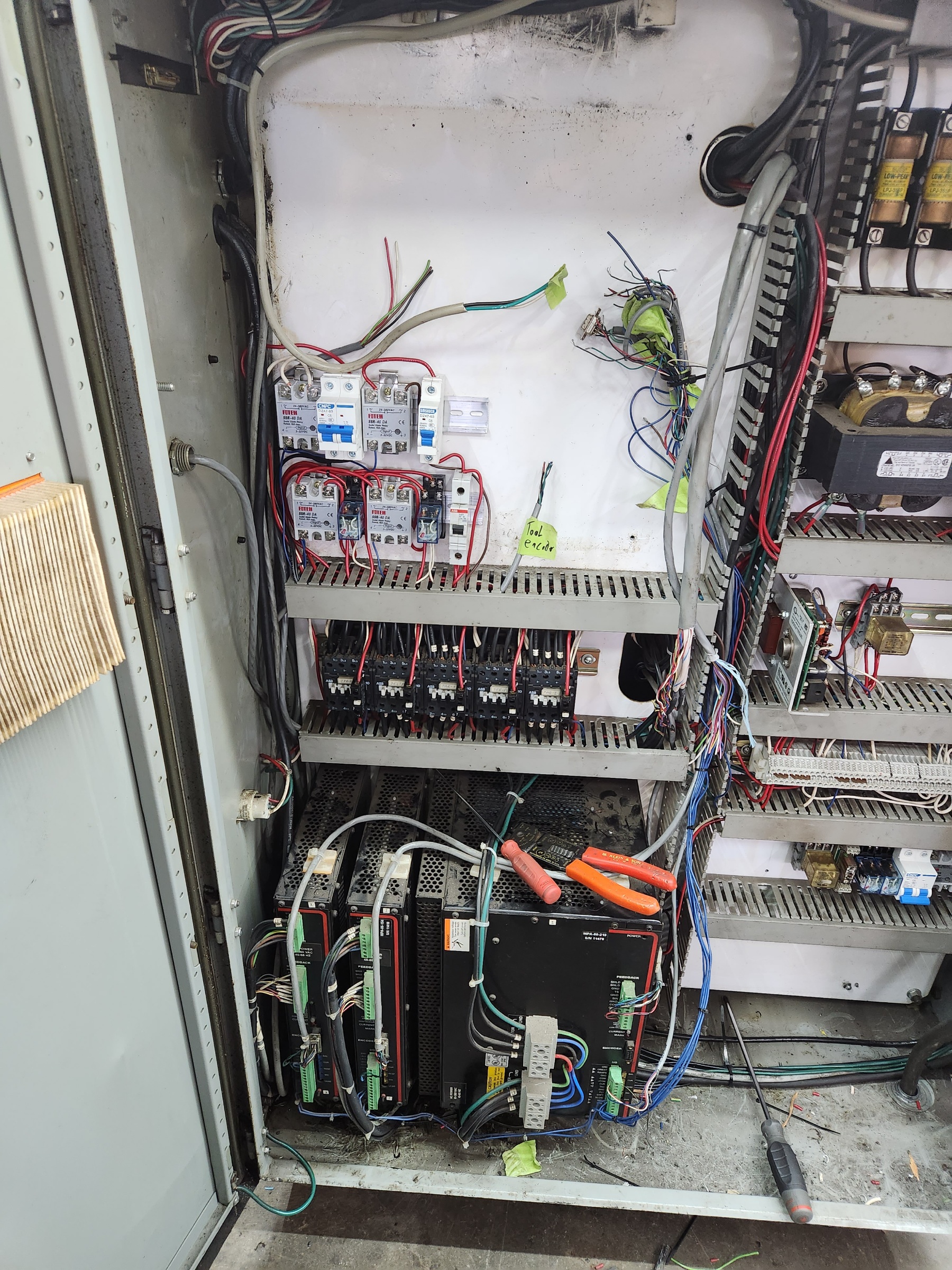

I started tearing into the cabinet a bit before I got any pics but you get the idea. All critisim welcome.

I have spent the last 4 years in aerospace machining and 7 years in a job shop before that , my old boss who owned the job shop let me know he was moving and if I wanted this lathe I could have it , just had to move it .

It's a 1996 standard-modern (kestrel) 1700 series 10hp lathe that was made in canada, it had a milltronics centurion V controller that was riddled with problems and never worked quite right so it was just crammed in storage. Linux cnc is the best candidate to save this from the scrap yard.

The drives are MTS (parker hannifin) mpa-06 for the axis and mpa-50 for the spindle with 3 ranges a group of contactors that switch between star/delta & series/parrallel windings , luckily the spindle drive is capable of single phase operation. All drives are analog +/- 10v

the tool changer is pragati , powered by a 3 phase pragati "torque" motor , it uses a absolute encoder for positioning and a proximity switch for clamp verification.this will be ran by a vfd.

From PCW'S suggestion I will be using a 7i97t when they become avilable in a few weeks , gives lots of time to clean up everything else.

I started tearing into the cabinet a bit before I got any pics but you get the idea. All critisim welcome.

Attachments:

Last edit: 21 Aug 2023 20:29 by Trav328. Reason: Added info

The following user(s) said Thank You: RotarySMP, tommylight, besriworld

Please Log in or Create an account to join the conversation.

- Trav328

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 75

- Thank you received: 31

21 Aug 2023 21:56 #278654

by Trav328

Replied by Trav328 on topic Standard-modern 1700 series retrofit

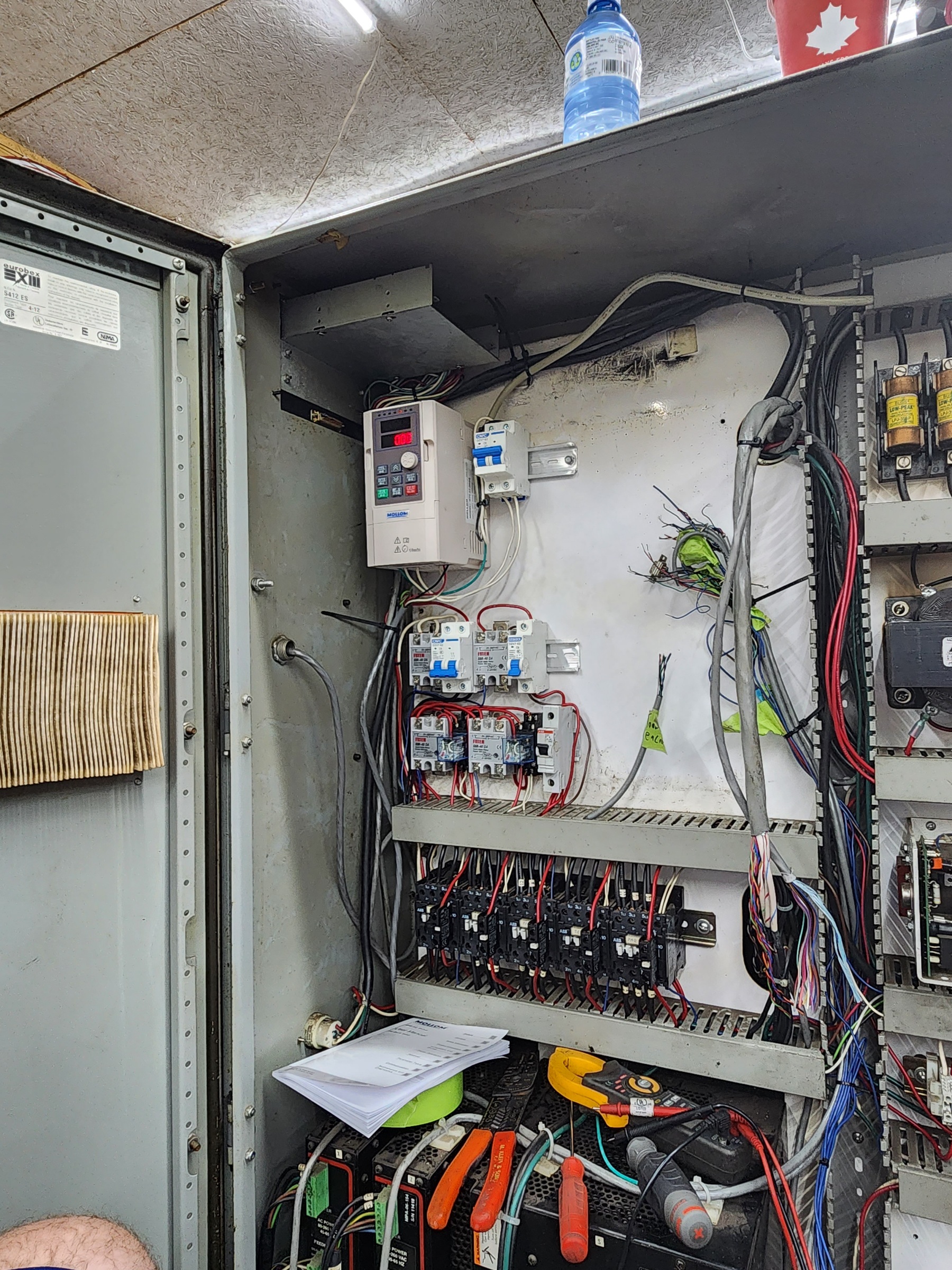

Some of the cabinet that I finished rewiring , 2 double acting relays and 2 ssr's control the 3 spindle ranges , I will have to figure out how to control this from Linux cnc , the spindle has its own encoder but the different ranges change what speed the spindle is in relation to amplifier input voltage.The other 2 ssr are for coolant and spindle lube pump. as well as appropiate breakers for everything.

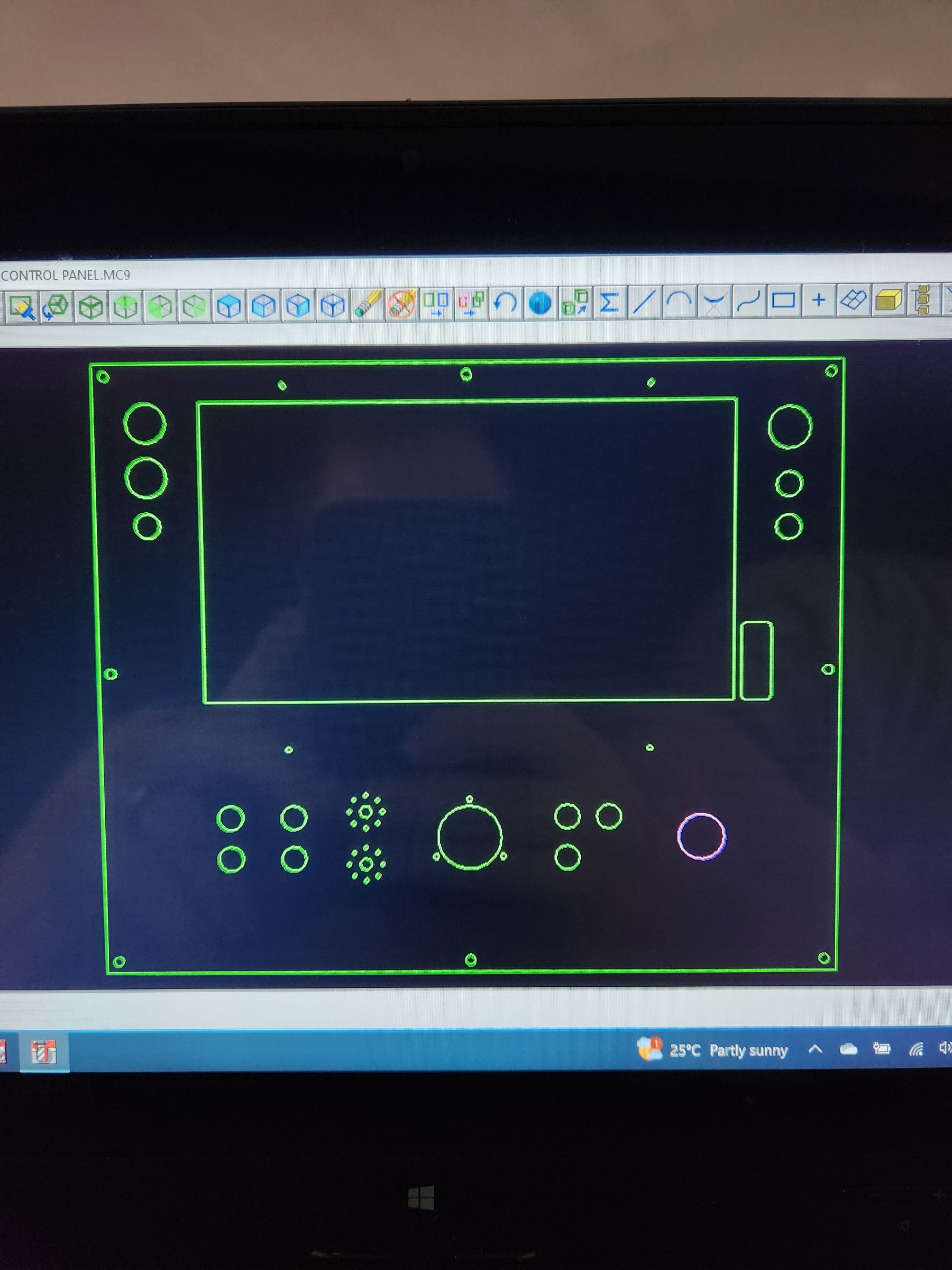

The old front panel gutted and removed so the back can be cut off since there is no more crt.

The new front panel , getting laser cut from 1/8 aluminum , lower portion gets bent up to form a keyboard tray

Some of the new hardware , 15.6 touch screen , mpg wheel and 6 position knobs to select feed override axis jog etc... some easy to identify physical buttons for cycle start and feed hold etc..

The old front panel gutted and removed so the back can be cut off since there is no more crt.

The new front panel , getting laser cut from 1/8 aluminum , lower portion gets bent up to form a keyboard tray

Some of the new hardware , 15.6 touch screen , mpg wheel and 6 position knobs to select feed override axis jog etc... some easy to identify physical buttons for cycle start and feed hold etc..

Attachments:

The following user(s) said Thank You: besriworld

Please Log in or Create an account to join the conversation.

- --Matt--

- Offline

- New Member

-

Less

More

- Posts: 19

- Thank you received: 2

22 Aug 2023 01:51 - 22 Aug 2023 01:51 #278670

by --Matt--

Replied by --Matt-- on topic Standard-modern 1700 series retrofit

I have the same wireless keyboard and trackpad combo. It is great, but unfortunately I think there is a bug with manual jogging via keyboard bindings when using a wireless keyboard. It causes juddery motion when holding the button down continuously. (At least that is my experience. Motion is smooth when mouse clicking the gui jogging buttons).

Good luck with your retrofit.

Good luck with your retrofit.

Last edit: 22 Aug 2023 01:51 by --Matt--.

The following user(s) said Thank You: Trav328

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19802

- Thank you received: 4609

22 Aug 2023 12:39 #278695

by andypugh

Replied by andypugh on topic Standard-modern 1700 series retrofit

I wouldn't bother with a keyboard, except to have one in a drawer for any time that you need to play with the config or OS.

I would suggest setting up the "apron" (which seems to be a sliding cover in this case) with two separate MPGs for X and Z jogging. (Like a manual lathe, and it will allow some limited manual-like operations, but with no feel at all...)

On my lathe apron I also have a small 16-position MPG with built-in pushbutton that I use to select the jog speed, with the button press being used to switch the controller to manual mode. (You can't jog without being in manual mode)

I would suggest setting up the "apron" (which seems to be a sliding cover in this case) with two separate MPGs for X and Z jogging. (Like a manual lathe, and it will allow some limited manual-like operations, but with no feel at all...)

On my lathe apron I also have a small 16-position MPG with built-in pushbutton that I use to select the jog speed, with the button press being used to switch the controller to manual mode. (You can't jog without being in manual mode)

The following user(s) said Thank You: besriworld

Please Log in or Create an account to join the conversation.

- Trav328

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 75

- Thank you received: 31

22 Aug 2023 13:09 #278697

by Trav328

Replied by Trav328 on topic Standard-modern 1700 series retrofit

kind of figured that the keyboard might become irrelevant after everything is setup and dialed in, i guess if this is the case i can always use the keyboard tray for something else or just remove it.

I do plan on setting up the apron in the future and have left all the wiring going to it , i have seen a few of the dual mpg setups like you mentioned , maybe another mpg on the apron as well as an additional estop (like the factory setup)

Once its up and running im sure there will be some changes.

the 16 position with push button sounds pretty slick.

I do plan on setting up the apron in the future and have left all the wiring going to it , i have seen a few of the dual mpg setups like you mentioned , maybe another mpg on the apron as well as an additional estop (like the factory setup)

Once its up and running im sure there will be some changes.

the 16 position with push button sounds pretty slick.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19802

- Thank you received: 4609

22 Aug 2023 13:18 #278699

by andypugh

www.ebay.com/itm/223540328731

A 7i73 in the sliding "apron" will make connecting up a bunch of IO there very easy.

Picture 21 here shows the one that lives in my (much more conventional) lathe apron: bodgesoc.blogspot.com/2016/08/holbrook08.html

Replied by andypugh on topic Standard-modern 1700 series retrofit

They are very cheap.the 16 position with push button sounds pretty slick.

www.ebay.com/itm/223540328731

A 7i73 in the sliding "apron" will make connecting up a bunch of IO there very easy.

Picture 21 here shows the one that lives in my (much more conventional) lathe apron: bodgesoc.blogspot.com/2016/08/holbrook08.html

The following user(s) said Thank You: Trav328

Please Log in or Create an account to join the conversation.

- Trav328

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 75

- Thank you received: 31

23 Aug 2023 01:52 #278740

by Trav328

Replied by Trav328 on topic Standard-modern 1700 series retrofit

Vfd is in for the tool changer and tool changer is rotating forward and reverse. I think having speed control over the TC will help with ensuring its clamped , this TC runs something similiar to a Geneva mechanism.

the first rotation of the shaft inside unlocks it then rotates the turrett then relocks the clamp all in a couple seconds It starts and stops quick pulling very little amperage.

the first rotation of the shaft inside unlocks it then rotates the turrett then relocks the clamp all in a couple seconds It starts and stops quick pulling very little amperage.

Attachments:

Please Log in or Create an account to join the conversation.

- Trav328

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 75

- Thank you received: 31

23 Aug 2023 01:53 #278741

by Trav328

Replied by Trav328 on topic Standard-modern 1700 series retrofit

Vfd is in for the tool changer and tool changer is rotating forward and reverse. I think having speed control over the TC will help with ensuring its clamped , this TC runs something similiar to a Geneva mechanism.

the first rotation of the shaft inside unlocks it then rotates the turret then relocks the clamp all in a couple seconds It starts and stops quick pulling very little amperage.

the first rotation of the shaft inside unlocks it then rotates the turret then relocks the clamp all in a couple seconds It starts and stops quick pulling very little amperage.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Online

- Moderator

-

Less

More

- Posts: 21345

- Thank you received: 7284

23 Aug 2023 11:24 #278778

by tommylight

Replied by tommylight on topic Standard-modern 1700 series retrofit

Please cover those drives with something.

The following user(s) said Thank You: Trav328

Please Log in or Create an account to join the conversation.

- Trav328

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 75

- Thank you received: 31

23 Aug 2023 12:12 #278784

by Trav328

Replied by Trav328 on topic Standard-modern 1700 series retrofit

I have a plastic sheet that gets taped on the back panel and runs to the floor during any drilling or installing but you right I probably should have them covered with something other than whatever junk I'm using at the time

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.419 seconds