RPi4 & 7i96 XY2-100 Following Error at High Velocities

- Limedodge

- Offline

- Senior Member

-

Less

More

- Posts: 40

- Thank you received: 1

05 May 2021 17:38 #208004

by Limedodge

RPi4 & 7i96 XY2-100 Following Error at High Velocities was created by Limedodge

I've been working to get my laser galvo setup running. I have solved my "error finishing read" issue by switching to a different Rpi OS. now I can run a 500,000ns servo thread indefinitely without getting the read error. Success!

I've also hooked it up the hardware and can burn lines. Success!... sorta

I can only get it to function if I manually limit max velocity below 600mm/min. If I go above that, I get following errors.

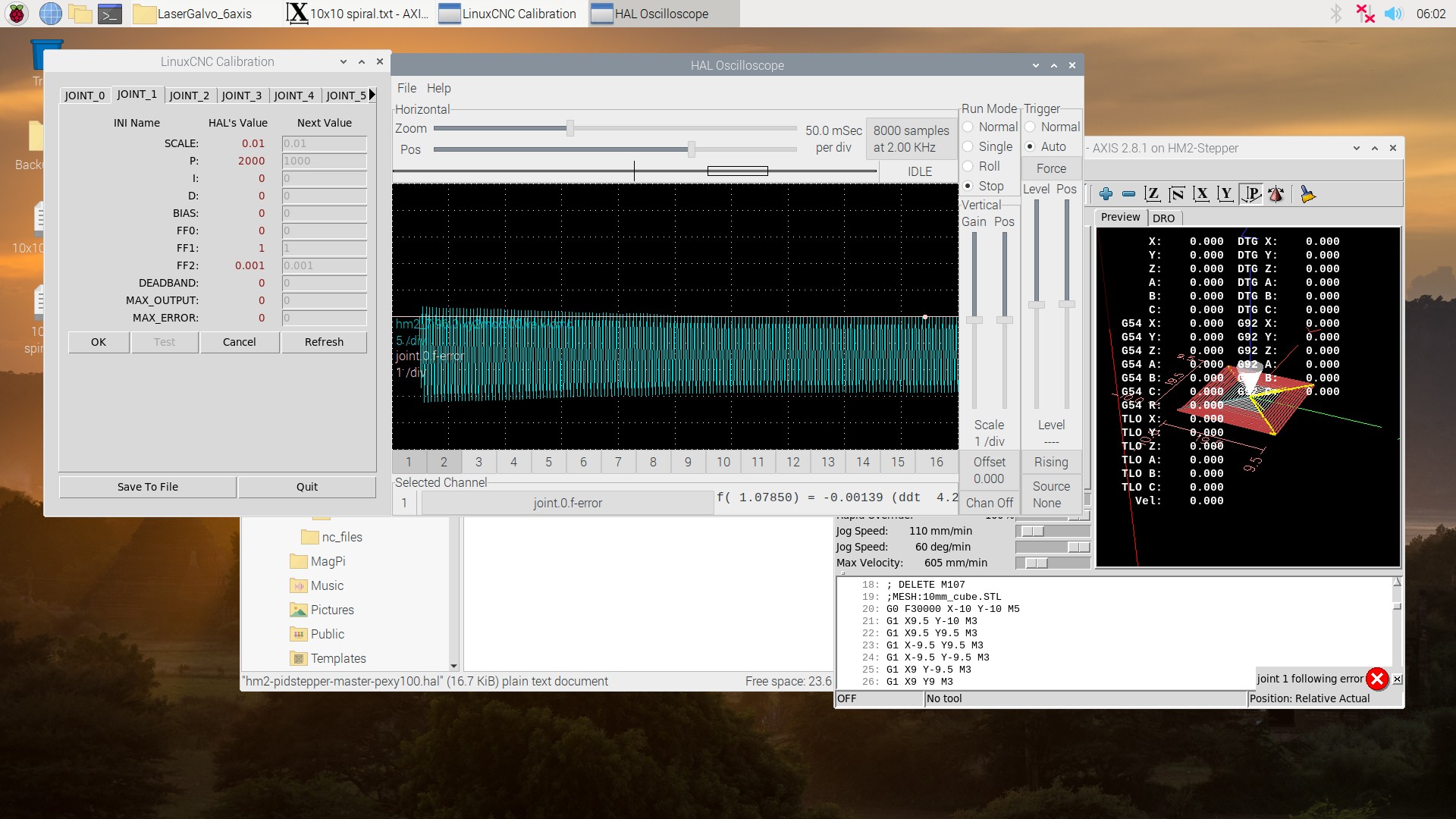

I set the ini inputs per guidance of P=1/servo interval=2000

I get oscillations at P=2000

I get overshoot and ringing at P=1000

Slightly milder overshoot at P=500

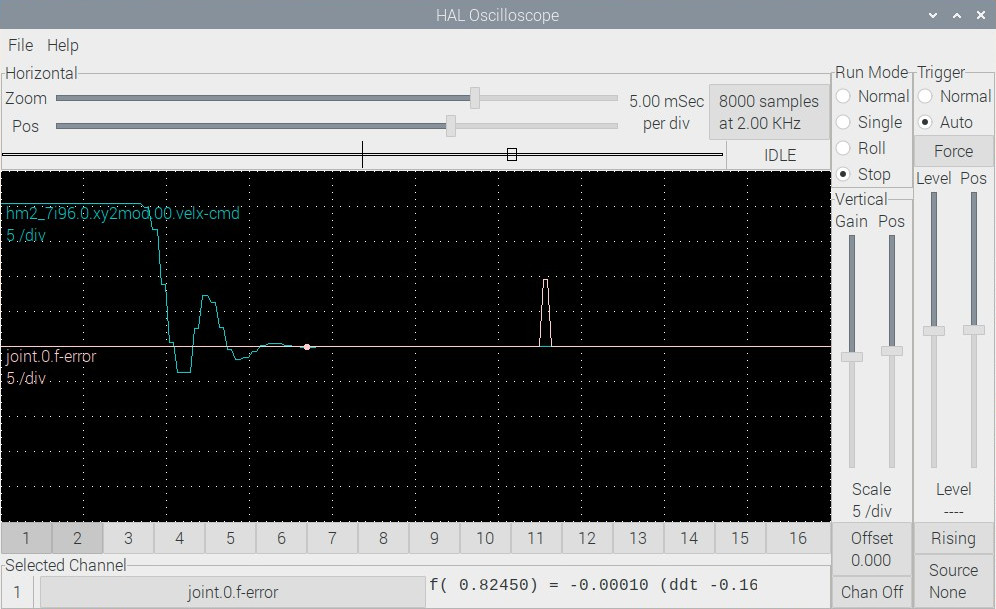

Here's a scope screenshot of the following error.

A few notes:

Both X and Y axis (joints 0 and 1) are identical setups

Max velocity and accelerations are guesses. The velocity less so as I can back out a linear velocity from the galvometer spec.

I intended on figuring out the real max velocity/accelerations based on physical limitations after I get the controller hardware up and running. By running paths at different velocities and accelerations and seeing what the machine can handle

Any thoughts on the following errors?

I noticed there's no STEPGEN_MAX_VELOCITY input for XY2-100.

I've also hooked it up the hardware and can burn lines. Success!... sorta

I can only get it to function if I manually limit max velocity below 600mm/min. If I go above that, I get following errors.

I set the ini inputs per guidance of P=1/servo interval=2000

[AXIS_X]

MIN_LIMIT = -150.0

MAX_LIMIT = 150.0

MAX_VELOCITY = 2000

MAX_ACCELERATION = 20000

[JOINT_0]

TYPE = LINEAR

MAX_VELOCITY = 2400

MAX_ACCELERATION = 240000

# Set Stepgen max 20% higher than the axis

#BACKLASH = 0.000

# scale is XXX step/mm

SCALE = 0.01

MIN_LIMIT = -150.0

MAX_LIMIT = 150.0

FERROR = .020

MIN_FERROR = .01

#HOME = 0.000

#HOME_OFFSET = 0.10

#HOME_SEARCH_VEL = 0.10

#HOME_LATCH_VEL = -0.01

#HOME_USE_INDEX = YES

#HOME_IGNORE_LIMITS = YES

# PID tuning params

DEADBAND = 0

P = 2000

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0.001

BIAS = 0

MAX_OUTPUT = 0

MAX_ERROR = 0

#MAX_ERROR = 0.001I get oscillations at P=2000

I get overshoot and ringing at P=1000

Slightly milder overshoot at P=500

Here's a scope screenshot of the following error.

A few notes:

Both X and Y axis (joints 0 and 1) are identical setups

Max velocity and accelerations are guesses. The velocity less so as I can back out a linear velocity from the galvometer spec.

I intended on figuring out the real max velocity/accelerations based on physical limitations after I get the controller hardware up and running. By running paths at different velocities and accelerations and seeing what the machine can handle

Any thoughts on the following errors?

I noticed there's no STEPGEN_MAX_VELOCITY input for XY2-100.

Attachments:

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17465

- Thank you received: 5101

05 May 2021 19:15 - 05 May 2021 21:15 #208013

by PCW

Replied by PCW on topic RPi4 & 7i96 XY2-100 Following Error at High Velocities

That's really odd to get a following error at 0 velocity

Can you post your hal/ini files?

Note: you can improve the control bandwidth by not setting

the DPLL write timer (comment out any line setting this value)

If you do this, FF2 can be set smaller (say 0.00025) since

this will be the approximate time between reads and writes.

Your oscillation at the suggested P values is likely due to using

the same timer for read and write, this adds a full servo thread

period delay to the feedback loop.

Can you post your hal/ini files?

Note: you can improve the control bandwidth by not setting

the DPLL write timer (comment out any line setting this value)

If you do this, FF2 can be set smaller (say 0.00025) since

this will be the approximate time between reads and writes.

Your oscillation at the suggested P values is likely due to using

the same timer for read and write, this adds a full servo thread

period delay to the feedback loop.

Last edit: 05 May 2021 21:15 by PCW.

Please Log in or Create an account to join the conversation.

- Limedodge

- Offline

- Senior Member

-

Less

More

- Posts: 40

- Thank you received: 1

05 May 2021 21:16 #208024

by Limedodge

Replied by Limedodge on topic RPi4 & 7i96 XY2-100 Following Error at High Velocities

I've attached my .ini and .hal file. Please excuse the mess, I need to go back through and clean them up (including removing the unused spindle portions)

# This config file was created 2021-05-04

[EMC]

# The version string for this INI file.

VERSION = 1.1

# Name of machine, for use with display, etc.

MACHINE = HM2-Stepper

# Debug level, 0 means no messages. See src/emc/nml_int/emcglb.h for others

#DEBUG = 0x00000003

#DEBUG = 0x00000007

DEBUG = 0

[DISPLAY]

# Name of display program, e.g., tkemc

#DISPLAY = tkemc

DISPLAY = axis

# Cycle time, in seconds, that display will sleep between polls

CYCLE_TIME = 0.100

# Path to help file

HELP_FILE = tkemc.txt

# Initial display setting for position, RELATIVE or MACHINE

POSITION_OFFSET = RELATIVE

# Initial display setting for position, COMMANDED or ACTUAL

POSITION_FEEDBACK = ACTUAL

# Highest value that will be allowed for feed override, 1.0 = 100%

MAX_FEED_OVERRIDE = 30

MAX_LINEAR_VELOCITY = 350

# Prefix to be used

PROGRAM_PREFIX = /home/pi/linuxcnc/nc_files/

# Introductory graphic

INTRO_GRAPHIC = emc2.gif

INTRO_TIME = 5

[FILTER]

PROGRAM_EXTENSION = .png,.gif,.jpg Grayscale Depth Image

PROGRAM_EXTENSION = .py Python Script

png = image-to-gcode

gif = image-to-gcode

jpg = image-to-gcode

py = python

[RS274NGC]

# File containing interpreter variables

PARAMETER_FILE = hm2-stepper.var

SUBROUTINE_PATH=/home/pi/linuxcnc-dev/nc_files/remap_lib/common_nc_subs

# this is important - read common_nc_subs/reset_state.ngc

# ON_ABORT_COMMAND= O <RESET_STATE> call

[EMCMOT]

EMCMOT = motmod

# Timeout for comm to emcmot, in seconds

COMM_TIMEOUT = 1.0

# Interval between tries to emcmot, in seconds

COMM_WAIT = 0.010

# Servo task period, in nanoseconds

SERVO_PERIOD = 500000

[TASK]

# Name of task controller program, e.g., milltask

TASK = milltask

# Cycle time, in seconds, that task controller will sleep between polls

CYCLE_TIME = 0.010

[HAL]

# The run script first uses halcmd to execute any HALFILE

# files, and then to execute any individual HALCMD commands.

# list of hal config files to run through halcmd

# files are executed in the order in which they appear

HALFILE = hm2-pidstepper-master-pexy100.hal

# list of halcmd commands to execute

# commands are executed in the order in which they appear

#HALCMD = save neta

[HALUI]

#No Content

[TRAJ]

AXES = 6

COORDINATES = X Y Z A B C

#HOME = 0 0 0

#JOINTS=7

LINEAR_UNITS = mm

ANGULAR_UNITS = degree

#CYCLE_TIME = 0.1

NO_FORCE_HOMING = 1

MAX_VELOCITY = 2000

MAX_ACCELERATION = 200000

[EMCIO]

# Name of IO controller program, e.g., io

EMCIO = io

# cycle time, in seconds

CYCLE_TIME = 0.100

# tool table file

TOOL_TABLE = tool.tbl

[KINS]

KINEMATICS = trivkins

#This is a best-guess at the number of joints, it should be checked

JOINTS = 7

[AXIS_X]

MIN_LIMIT = -150.0

MAX_LIMIT = 150.0

MAX_VELOCITY = 2000

MAX_ACCELERATION = 20000

[JOINT_0]

TYPE = LINEAR

MAX_VELOCITY = 2400

MAX_ACCELERATION = 240000

# Set Stepgen max 20% higher than the axis

#BACKLASH = 0.000

# scale is XXX step/mm

SCALE = 0.01

MIN_LIMIT = -150.0

MAX_LIMIT = 150.0

FERROR = .020

MIN_FERROR = .01

#HOME = 0.000

#HOME_OFFSET = 0.10

#HOME_SEARCH_VEL = 0.10

#HOME_LATCH_VEL = -0.01

#HOME_USE_INDEX = YES

#HOME_IGNORE_LIMITS = YES

# PID tuning params

DEADBAND = 0

P = 1900

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0.001

BIAS = 0

MAX_OUTPUT = 0

MAX_ERROR = 0

#MAX_ERROR = 0.001

[AXIS_Y]

MIN_LIMIT = -150.0

MAX_LIMIT = 150.0

MAX_VELOCITY = 2000

MAX_ACCELERATION = 200000

[JOINT_1]

TYPE = LINEAR

MAX_VELOCITY = 2400

MAX_ACCELERATION = 240000

#MAX_JERK = 2000

#BACKLASH = 0.000

SCALE = 0.01

MIN_LIMIT = -150.0

MAX_LIMIT = 150.0

FERROR = .020

MIN_FERROR = .01

#

# PID tuning params

DEADBAND = 0

P = 1900

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0.001

BIAS = 0

MAX_OUTPUT = 0

MAX_ERROR = 0

[AXIS_Z]

MIN_LIMIT = -3000.0

MAX_LIMIT = 3000.0

MAX_VELOCITY = 200

MAX_ACCELERATION = 2000

[JOINT_2]

TYPE = LINEAR

MAX_VELOCITY = 200

MAX_ACCELERATION = 2000

MAX_JERK = 2000

# Set Stepgen max 20% higher than the axis

STEPGEN_MAX_VEL = 240

STEPGEN_MAX_ACC = 2400

BACKLASH = 0.000

SCALE = 334

MIN_LIMIT = -3000.0

MAX_LIMIT = 3000.0

FERROR = .020

MIN_FERROR = .0005

#HOME = 0.000

#HOME_OFFSET = 0.10

#HOME_SEARCH_VEL = 0.10

#HOME_LATCH_VEL = -0.01

#HOME_USE_INDEX = YES

#HOME_IGNORE_LIMITS = YES

# these are in nanoseconds

DIRSETUP = 3000

DIRHOLD = 3000

STEPLEN = 3000

STEPSPACE = 3000

# PID tuning params

DEADBAND = 0

P = 1000

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0.00025

BIAS = 0

MAX_OUTPUT = 0

MAX_ERROR = 0

[AXIS_A]

MIN_LIMIT = -300.0

MAX_LIMIT = 300.0

MAX_VELOCITY = 200

MAX_ACCELERATION = 2000

[JOINT_3]

TYPE = LINEAR

MAX_VELOCITY = 200

MAX_ACCELERATION = 2000

MAX_JERK = 2000

# Set Stepgen max 20% higher than the axis

STEPGEN_MAX_VEL = 240

STEPGEN_MAX_ACC = 2400

BACKLASH = 0.000

SCALE = 334

MIN_LIMIT = -3000.0

MAX_LIMIT = 3000.0

FERROR = .020

MIN_FERROR = .0005

#HOME = 0.000

#HOME_OFFSET = 0.10

#HOME_SEARCH_VEL = 0.10

#HOME_LATCH_VEL = -0.01

#HOME_USE_INDEX = YES

#HOME_IGNORE_LIMITS = YES

# these are in nanoseconds

DIRSETUP = 3000

DIRHOLD = 3000

STEPLEN = 3000

STEPSPACE = 3000

# PID tuning params

DEADBAND = 0

P = 1000

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0.00025

BIAS = 0

MAX_OUTPUT = 0

MAX_ERROR = 0

[AXIS_B]

MIN_LIMIT = -3000.0

MAX_LIMIT = 3000.0

MAX_VELOCITY = 200

MAX_ACCELERATION = 2000

[JOINT_4]

TYPE = LINEAR

MAX_VELOCITY = 200

MAX_ACCELERATION = 2000

MAX_JERK = 2000

# Set Stepgen max 20% higher than the axis

STEPGEN_MAX_VEL = 240

STEPGEN_MAX_ACC = 2400

BACKLASH = 0.000

SCALE = 40

MIN_LIMIT = -3000.0

MAX_LIMIT = 3000.0

FERROR = .020

MIN_FERROR = .0005

#HOME = 0.000

#HOME_OFFSET = 0.10

#HOME_SEARCH_VEL = 0.10

#HOME_LATCH_VEL = -0.01

#HOME_USE_INDEX = YES

#HOME_IGNORE_LIMITS = YES

# these are in nanoseconds

DIRSETUP = 2000

DIRHOLD = 2000

STEPLEN = 4000

STEPSPACE = 4000

# PID tuning params

DEADBAND = 0

P = 1000

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0.00025

BIAS = 0

MAX_OUTPUT = 0

MAX_ERROR = 0

[AXIS_C]

MIN_LIMIT = -300.0

MAX_LIMIT = 300.0

MAX_VELOCITY = 200

MAX_ACCELERATION = 2000

[JOINT_5]

TYPE = LINEAR

MAX_VELOCITY = 200

MAX_ACCELERATION = 2000

MAX_JERK = 2000

# Set Stepgen max 20% higher than the axis

STEPGEN_MAX_VEL = 240

STEPGEN_MAX_ACC = 2400

BACKLASH = 0.000

SCALE = 40

MIN_LIMIT = -300.0

MAX_LIMIT = 300.0

FERROR = .020

MIN_FERROR = .0005

#HOME = 0.000

#HOME_OFFSET = 0.10

#HOME_SEARCH_VEL = 0.10

#HOME_LATCH_VEL = -0.01

#HOME_USE_INDEX = YES

#HOME_IGNORE_LIMITS = YES

# these are in nanoseconds

DIRSETUP = 2000

DIRHOLD = 2000

STEPLEN = 4000

STEPSPACE = 4000

# PID tuning params

DEADBAND = 0

P = 1000

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0.00025

BIAS = 0

MAX_OUTPUT = 0

MAX_ERROR = 0

[HOSTMOT2]

DRIVER=hm2_eth board_ip="10.10.10.10"

# DRIVER=hm2_eth board_ip="10.10.10.10" debug=-1

BOARD=7i96

CONFIG="num_encoders=1 num_stepgens=5 num_pwmgens=0 sserial_port_0=0000xxxx enable_raw"

[SPINDLE_9]

# PID tuning params

DEADBAND = 0

P = 50

I = 200

D = 0.2

FF0 = 0

FF1 = 0

FF2 = 0

BIAS = 0

MAX_OUTPUT = 0

MAX_ERROR = 50

SCALE = 6000

MINLIM = 0

MAXLIM = 6000# #######################################

#

# HAL file for HostMot2 with 3 steppers

#

# Derived from Ted Hyde's original hm2-servo config

#

# Based up work and discussion with Seb & Peter & Jeff

# GNU license references - insert here. www.linuxcnc.org

#

#

# ########################################

# Firmware files are in /lib/firmware/hm2/7i43/

# Must symlink the hostmot2 firmware directory of sanbox to

# /lib/firmware before running EMC2...

# sudo ln -s $HOME/emc2-sandbox/src/hal/drivers/mesa-hostmot2/firmware /lib/firmware/hm2

#

# See also:

# <http://www.linuxcnc.org/docs/devel/html/man/man9/hostmot2.9.html#config%20modparam>

# and http://wiki.linuxcnc.org/cgi-bin/emcinfo.pl?HostMot2

#

# #####################################################################

# ###################################

# Core EMC/HAL Loads

# ###################################

# kinematics

loadrt [KINS]KINEMATICS

#autoconverted trivkins

# motion controller

loadrt [EMCMOT]EMCMOT servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[KINS]JOINTS num_spindles=1

# standard components

loadrt pid num_chan=7

loadrt mux2 count=7

loadrt oneshot count=1

loadrt and2 count=1

loadrt comp count=1

# hostmot2 driver

loadrt hostmot2

# load low-level driver

loadrt [HOSTMOT2](DRIVER) config=[HOSTMOT2](CONFIG)

setp hm2_[HOSTMOT2](BOARD).0.watchdog.timeout_ns 25000000

# ################################################

# THREADS

# ################################################

addf hm2_[HOSTMOT2](BOARD).0.read servo-thread

addf mux2.0 servo-thread

addf mux2.1 servo-thread

addf mux2.2 servo-thread

addf mux2.3 servo-thread

addf mux2.4 servo-thread

addf mux2.5 servo-thread

addf mux2.6 servo-thread

addf and2.0 servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf pid.0.do-pid-calcs servo-thread

addf pid.1.do-pid-calcs servo-thread

addf pid.2.do-pid-calcs servo-thread

addf pid.3.do-pid-calcs servo-thread

addf pid.4.do-pid-calcs servo-thread

addf pid.5.do-pid-calcs servo-thread

addf pid.6.do-pid-calcs servo-thread

addf hm2_[HOSTMOT2](BOARD).0.write servo-thread

#addf hm2_[HOSTMOT2](BOARD).0.pet_watchdog servo-thread

addf oneshot.0 servo-thread

addf comp.0 servo-thread

# latch 50 usec before nominal read time:

setp hm2_[HOSTMOT2](BOARD).0.dpll.01.timer-us -100

setp hm2_[HOSTMOT2](BOARD).0.stepgen.timer-number -1

## orig setp hm2_[HOSTMOT2](BOARD).0.xy2mod.timer-number 1

setp hm2_[HOSTMOT2](BOARD).0.xy2mod.read-timer-number 1

setp hm2_[HOSTMOT2](BOARD).0.xy2mod.write-timer-number 1

setp hm2_[HOSTMOT2](BOARD).0.packet-read-timeout 80

setp hm2_[HOSTMOT2](BOARD).0.packet-error-limit 50

# ######################################################

# Axis-of-motion Specific Configs (not the GUI)

# ######################################################

# switch fb data to command on packet error:

net perror hm2_[HOSTMOT2](BOARD).0.packet-error => mux2.0.sel mux2.1.sel mux2.2.sel mux2.3.sel

# ################

# X [0] Axis

# ################

# axis enable chain

newsig emcmot.00.enable bit

sets emcmot.00.enable FALSE

net emcmot.00.enable <= joint.0.amp-enable-out

net emcmot.00.enable => hm2_[HOSTMOT2](BOARD).0.xy2mod.00.enable pid.0.enable pid.1.enable

# position command and feedback

net emcmot.00.pos-cmd joint.0.motor-pos-cmd => pid.0.command mux2.0.in1

net fb0 mux2.0.in0 <= hm2_[HOSTMOT2](BOARD).0.xy2mod.00.posx-fb

# feedback position to motion is forced to be commanded position if theres a packet error

net motor.00.pos-fb <= mux2.0.out joint.0.motor-pos-fb pid.0.feedback

net motor.00.command pid.0.output hm2_[HOSTMOT2](BOARD).0.xy2mod.00.velx-cmd

setp pid.0.error-previous-target true

# timing parameters

setp hm2_[HOSTMOT2](BOARD).0.xy2mod.00.posx-scale [JOINT_0]SCALE

# set PID loop gains from inifile

setp pid.0.Pgain [JOINT_0]P

setp pid.0.Igain [JOINT_0]I

setp pid.0.Dgain [JOINT_0]D

setp pid.0.bias [JOINT_0]BIAS

setp pid.0.FF0 [JOINT_0]FF0

setp pid.0.FF1 [JOINT_0]FF1

setp pid.0.FF2 [JOINT_0]FF2

setp pid.0.deadband [JOINT_0]DEADBAND

setp pid.0.maxoutput [JOINT_0]MAX_OUTPUT

setp pid.0.maxerror [JOINT_0]MAX_ERROR

# ################

# Y [1] Axis

# ################

# position command and feedback

net emcmot.01.pos-cmd joint.1.motor-pos-cmd => pid.1.command mux2.1.in1

net fb1 mux2.1.in0 <= hm2_[HOSTMOT2](BOARD).0.xy2mod.00.posy-fb

# feedback position to motion is forced to be commanded position if theres a packet error

net motor.01.pos-fb <= mux2.1.out joint.1.motor-pos-fb pid.1.feedback

net motor.01.command pid.1.output hm2_[HOSTMOT2](BOARD).0.xy2mod.00.vely-cmd

setp pid.1.error-previous-target true

# timing parameters

setp hm2_[HOSTMOT2](BOARD).0.xy2mod.00.posy-scale [JOINT_1]SCALE

# set PID loop gains from inifile

setp pid.1.Pgain [JOINT_1]P

setp pid.1.Igain [JOINT_1]I

setp pid.1.Dgain [JOINT_1]D

setp pid.1.bias [JOINT_1]BIAS

setp pid.1.FF0 [JOINT_1]FF0

setp pid.1.FF1 [JOINT_1]FF1

setp pid.1.FF2 [JOINT_1]FF2

setp pid.1.deadband [JOINT_1]DEADBAND

setp pid.1.maxoutput [JOINT_1]MAX_OUTPUT

setp pid.1.maxerror [JOINT_1]MAX_ERROR

# ################

# Z [2] Axis -Build Platform

# ################

# axis enable chain

newsig emcmot.02.enable bit

sets emcmot.02.enable FALSE

net emcmot.02.enable <= joint.2.amp-enable-out

net emcmot.02.enable => hm2_[HOSTMOT2](BOARD).0.stepgen.00.enable pid.2.enable

# position command and feedback

net emcmot.02.pos-cmd joint.2.motor-pos-cmd => pid.2.command mux2.2.in1

#net emcmot.02.vel-cmd joint.2.vel-cmd => pid.2.command-deriv

net fb2 mux2.2.in0 <= hm2_[HOSTMOT2](BOARD).0.stepgen.00.position-fb

# feedback position to motion is forced to be commanded position if theres a packet error

net motor.02.pos-fb <= mux2.2.out joint.2.motor-pos-fb pid.2.feedback

net motor.02.command pid.2.output hm2_[HOSTMOT2](BOARD).0.stepgen.00.velocity-cmd

setp pid.2.error-previous-target true

# timing parameters

setp hm2_[HOSTMOT2](BOARD).0.stepgen.00.dirsetup [JOINT_2]DIRSETUP

setp hm2_[HOSTMOT2](BOARD).0.stepgen.00.dirhold [JOINT_2]DIRHOLD

setp hm2_[HOSTMOT2](BOARD).0.stepgen.00.steplen [JOINT_2]STEPLEN

setp hm2_[HOSTMOT2](BOARD).0.stepgen.00.stepspace [JOINT_2]STEPSPACE

setp hm2_[HOSTMOT2](BOARD).0.stepgen.00.position-scale [JOINT_2]SCALE

setp hm2_[HOSTMOT2](BOARD).0.stepgen.00.maxvel [JOINT_2]STEPGEN_MAX_VEL

setp hm2_[HOSTMOT2](BOARD).0.stepgen.00.maxaccel [JOINT_2]STEPGEN_MAX_ACC

setp hm2_[HOSTMOT2](BOARD).0.stepgen.00.step_type 0

setp hm2_[HOSTMOT2](BOARD).0.stepgen.00.control-type 1

# set PID loop gains from inifile

setp pid.2.Pgain [JOINT_2]P

setp pid.2.Igain [JOINT_2]I

setp pid.2.Dgain [JOINT_2]D

setp pid.2.bias [JOINT_2]BIAS

setp pid.2.FF0 [JOINT_2]FF0

setp pid.2.FF1 [JOINT_2]FF1

setp pid.2.FF2 [JOINT_2]FF2

setp pid.2.deadband [JOINT_2]DEADBAND

setp pid.2.maxoutput [JOINT_2]MAX_OUTPUT

setp pid.2.maxerror [JOINT_2]MAX_ERROR

# ################

# A [3] Axis - Supply Platform

# ################

# axis enable chain

newsig emcmot.03.enable bit

sets emcmot.03.enable FALSE

net emcmot.03.enable <= joint.3.amp-enable-out

net emcmot.03.enable => hm2_[HOSTMOT2](BOARD).0.stepgen.01.enable pid.3.enable

# position command and feedback

net emcmot.03.pos-cmd joint.3.motor-pos-cmd => pid.3.command mux2.3.in1

#net emcmot.03.vel-cmd joint.3.vel-cmd => pid.3.command-deriv

net fb3 mux2.3.in0 <= hm2_[HOSTMOT2](BOARD).0.stepgen.01.position-fb

# feedback position to motion is forced to be commanded position if theres a packet error

net motor.03.pos-fb <= mux2.3.out joint.3.motor-pos-fb pid.3.feedback

net motor.03.command pid.3.output hm2_[HOSTMOT2](BOARD).0.stepgen.01.velocity-cmd

setp pid.3.error-previous-target true

# timing parameters

setp hm2_[HOSTMOT2](BOARD).0.stepgen.01.dirsetup [JOINT_3]DIRSETUP

setp hm2_[HOSTMOT2](BOARD).0.stepgen.01.dirhold [JOINT_3]DIRHOLD

setp hm2_[HOSTMOT2](BOARD).0.stepgen.01.steplen [JOINT_3]STEPLEN

setp hm2_[HOSTMOT2](BOARD).0.stepgen.01.stepspace [JOINT_3]STEPSPACE

setp hm2_[HOSTMOT2](BOARD).0.stepgen.01.position-scale [JOINT_3]SCALE

setp hm2_[HOSTMOT2](BOARD).0.stepgen.01.maxvel [JOINT_3]STEPGEN_MAX_VEL

setp hm2_[HOSTMOT2](BOARD).0.stepgen.01.maxaccel [JOINT_3]STEPGEN_MAX_ACC

setp hm2_[HOSTMOT2](BOARD).0.stepgen.01.step_type 0

setp hm2_[HOSTMOT2](BOARD).0.stepgen.01.control-type 1

# set PID loop gains from inifile

setp pid.3.Pgain [JOINT_3]P

setp pid.3.Igain [JOINT_3]I

setp pid.3.Dgain [JOINT_3]D

setp pid.3.bias [JOINT_3]BIAS

setp pid.3.FF0 [JOINT_3]FF0

setp pid.3.FF1 [JOINT_3]FF1

setp pid.3.FF2 [JOINT_3]FF2

setp pid.3.deadband [JOINT_3]DEADBAND

setp pid.3.maxoutput [JOINT_3]MAX_OUTPUT

setp pid.3.maxerror [JOINT_3]MAX_ERROR

# ################

# B [4] Axis - Roller

# ################

# axis enable chain

newsig emcmot.04.enable bit

sets emcmot.04.enable FALSE

net emcmot.04.enable <= joint.4.amp-enable-out

net emcmot.04.enable => hm2_[HOSTMOT2](BOARD).0.stepgen.02.enable pid.4.enable

# position command and feedback

net emcmot.04.pos-cmd joint.4.motor-pos-cmd => pid.4.command mux2.4.in1

#net emcmot.04.vel-cmd joint.4.vel-cmd => pid.4.command-deriv

net fb4 mux2.4.in0 <= hm2_[HOSTMOT2](BOARD).0.stepgen.02.position-fb

# feedback position to motion is forced to be commanded position if theres a packet error

net motor.04.pos-fb <= mux2.4.out joint.4.motor-pos-fb pid.4.feedback

net motor.04.command pid.4.output hm2_[HOSTMOT2](BOARD).0.stepgen.02.velocity-cmd

setp pid.4.error-previous-target true

# timing parameters

setp hm2_[HOSTMOT2](BOARD).0.stepgen.02.dirsetup [JOINT_4]DIRSETUP

setp hm2_[HOSTMOT2](BOARD).0.stepgen.02.dirhold [JOINT_4]DIRHOLD

setp hm2_[HOSTMOT2](BOARD).0.stepgen.02.steplen [JOINT_4]STEPLEN

setp hm2_[HOSTMOT2](BOARD).0.stepgen.02.stepspace [JOINT_4]STEPSPACE

setp hm2_[HOSTMOT2](BOARD).0.stepgen.02.position-scale [JOINT_4]SCALE

setp hm2_[HOSTMOT2](BOARD).0.stepgen.02.maxvel [JOINT_4]STEPGEN_MAX_VEL

setp hm2_[HOSTMOT2](BOARD).0.stepgen.02.maxaccel [JOINT_4]STEPGEN_MAX_ACC

setp hm2_[HOSTMOT2](BOARD).0.stepgen.02.step_type 0

setp hm2_[HOSTMOT2](BOARD).0.stepgen.02.control-type 1

# set PID loop gains from inifile

setp pid.4.Pgain [JOINT_4]P

setp pid.4.Igain [JOINT_4]I

setp pid.4.Dgain [JOINT_4]D

setp pid.4.bias [JOINT_4]BIAS

setp pid.4.FF0 [JOINT_4]FF0

setp pid.4.FF1 [JOINT_4]FF1

setp pid.4.FF2 [JOINT_4]FF2

setp pid.4.deadband [JOINT_4]DEADBAND

setp pid.4.maxoutput [JOINT_4]MAX_OUTPUT

setp pid.4.maxerror [JOINT_4]MAX_ERROR

# ################

# C [5] Axis - Scraper

# ################

# axis enable chain

newsig emcmot.05.enable bit

sets emcmot.05.enable FALSE

net emcmot.05.enable <= joint.5.amp-enable-out

net emcmot.05.enable => hm2_[HOSTMOT2](BOARD).0.stepgen.03.enable pid.5.enable

# position command and feedback

net emcmot.05.pos-cmd joint.5.motor-pos-cmd => pid.5.command mux2.5.in1

#net emcmot.05.vel-cmd joint.5.vel-cmd => pid.5.command-deriv

net fb5 mux2.5.in0 <= hm2_[HOSTMOT2](BOARD).0.stepgen.03.position-fb

# feedback position to motion is forced to be commanded position if theres a packet error

net motor.05.pos-fb <= mux2.5.out joint.5.motor-pos-fb pid.5.feedback

net motor.05.command pid.5.output hm2_[HOSTMOT2](BOARD).0.stepgen.03.velocity-cmd

setp pid.5.error-previous-target true

# timing parameters

setp hm2_[HOSTMOT2](BOARD).0.stepgen.03.dirsetup [JOINT_5]DIRSETUP

setp hm2_[HOSTMOT2](BOARD).0.stepgen.03.dirhold [JOINT_5]DIRHOLD

setp hm2_[HOSTMOT2](BOARD).0.stepgen.03.steplen [JOINT_5]STEPLEN

setp hm2_[HOSTMOT2](BOARD).0.stepgen.03.stepspace [JOINT_5]STEPSPACE

setp hm2_[HOSTMOT2](BOARD).0.stepgen.03.position-scale [JOINT_5]SCALE

setp hm2_[HOSTMOT2](BOARD).0.stepgen.03.maxvel [JOINT_5]STEPGEN_MAX_VEL

setp hm2_[HOSTMOT2](BOARD).0.stepgen.03.maxaccel [JOINT_5]STEPGEN_MAX_ACC

setp hm2_[HOSTMOT2](BOARD).0.stepgen.03.step_type 0

setp hm2_[HOSTMOT2](BOARD).0.stepgen.03.control-type 1

# set PID loop gains from inifile

setp pid.5.Pgain [JOINT_5]P

setp pid.5.Igain [JOINT_5]I

setp pid.5.Dgain [JOINT_5]D

setp pid.5.bias [JOINT_5]BIAS

setp pid.5.FF0 [JOINT_5]FF0

setp pid.5.FF1 [JOINT_5]FF1

setp pid.5.FF2 [JOINT_5]FF2

setp pid.5.deadband [JOINT_5]DEADBAND

setp pid.5.maxoutput [JOINT_5]MAX_OUTPUT

setp pid.5.maxerror [JOINT_5]MAX_ERROR

# #############

# Laser controls

# #############

# set soft limits on frequency

setp hm2_[HOSTMOT2](BOARD).0.stepgen.04.maxvel 600000

setp hm2_[HOSTMOT2](BOARD).0.stepgen.04.maxaccel 0

# Set stepgen to quadrature (ie. A AB B 0)

setp hm2_[HOSTMOT2](BOARD).0.stepgen.04.step_type 2

# set the spacing/timing small so as not to interfere when frequency gets large

setp hm2_[HOSTMOT2](BOARD).0.stepgen.04.stepspace 10

setp hm2_[HOSTMOT2](BOARD).0.stepgen.04.steplen 10

# set the scale. should be 1:1 in quadrature mode

setp hm2_[HOSTMOT2](BOARD).0.stepgen.04.position-scale 1

# set the control type to velocity. this should allow it to keep going

setp hm2_[HOSTMOT2](BOARD).0.stepgen.04.control-type 1

# ### signals to wire everything up

# turn on PRR when machine is enabled

net PRR_on motion.motion-enabled

net PRR_on hm2_[HOSTMOT2](BOARD).0.stepgen.04.enable

net PRR_freq hm2_[HOSTMOT2](BOARD).0.stepgen.04.velocity-cmd

# set an initial value. to be adjusted by M102

sets PRR_freq 200000

# Set up one shot to latch power

setp oneshot.0.width .00000001

setp hm2_[HOSTMOT2](BOARD).0.gpio.048.is_output TRUE

# one shot sends signal to GPIO pin

net power_latch oneshot.0.out

net power_latch hm2_7i96.0.gpio.048.out

# set up signal to drive oneshot

net latch_trig oneshot.0.in

# setup spindle 0 as main power spindle

# ##################################

# Read laser fault codes

setp hm2_[HOSTMOT2](BOARD).0.gpio.010.is_output False

setp hm2_[HOSTMOT2](BOARD).0.gpio.009.is_output False

# connect AP laser pins

setp hm2_[HOSTMOT2](BOARD).0.gpio.049.is_output True

net Main_laser_on spindle.0.on

net Main_laser_on hm2_[HOSTMOT2](BOARD).0.gpio.049.out

# Emergency Stop safety feature

# Estop pin needs to be high for normal operation. 7i96 IO pins initalize to HIGH. During an error all pins go high and the laser turns on

# To stop this, SSR0+ will be connected to 5V, SSR0- connect to laser Estop pin. Thereby, the pin will be forced high as long as the board is connected

net emcmot.00.enable hm2_7i96.0.ssr.00.out-00

# MO needs to be high before laser emits. basically laser power turned on. If joints are not on, no reason to be powered

setp hm2_[HOSTMOT2](BOARD).0.gpio.039.is_output True

# logic to make sure red laser is off

net emcmot.00.enable and2.0.in0

net mo_in_1 and2.0.in1

sets mo_in_1 True

net mo_out and2.0.out hm2_7i96.0.ssr.00.out-01

# setup GPIO as red laser dot

# ##############################

# red laser will be called via M103 instead of spindle

# Must be turned off with M104 to return to normal

setp hm2_[HOSTMOT2](BOARD).0.gpio.050.is_output TRUE

net red_laser_on hm2_[HOSTMOT2](BOARD).0.gpio.050.out

setp pid.6.Pgain [SPINDLE_9]P

setp pid.6.Igain [SPINDLE_9]I

setp pid.6.Dgain [SPINDLE_9]D

setp pid.6.bias [SPINDLE_9]BIAS

setp pid.6.FF0 [SPINDLE_9]FF0

setp pid.6.FF1 [SPINDLE_9]FF1

setp pid.6.FF2 [SPINDLE_9]FF2

setp pid.6.deadband [SPINDLE_9]DEADBAND

setp pid.6.maxoutput [SPINDLE_9]MAX_OUTPUT

setp pid.6.maxerror [SPINDLE_9]MAX_ERROR

#setp hm2_[HOSTMOT2](BOARD).0.7i76.0.0.spinout-scalemax [SPINDLE_9]SCALE

#setp hm2_[HOSTMOT2](BOARD).0.7i76.0.0.spinout-minlim [SPINDLE_9]MINLIM

#setp hm2_[HOSTMOT2](BOARD).0.7i76.0.0.spinout-maxlim [SPINDLE_9]MAXLIM

net spindle-index-enable <=> hm2_[HOSTMOT2](BOARD).0.encoder.00.index-enable <=> spindle.0.index-enable

# ##################################################

# Standard I/O Block - EStop, Etc

# ##################################################

# create a signal for the estop loopback

net estop-loop iocontrol.0.user-enable-out => iocontrol.0.emc-enable-in

# create signals for tool loading loopback

net tool-prep-loop iocontrol.0.tool-prepare => iocontrol.0.tool-prepared

net tool-change-loop iocontrol.0.tool-change => iocontrol.0.tool-changed

# ##################################################

# 8 bit power signal to laser

# ##################################################

# set up pins for 8 bit logic

# pin 040 is bit 0, pin 047 is bit 7(128)

setp hm2_[HOSTMOT2](BOARD).0.gpio.040.is_output TRUE

setp hm2_[HOSTMOT2](BOARD).0.gpio.041.is_output TRUE

setp hm2_[HOSTMOT2](BOARD).0.gpio.042.is_output TRUE

setp hm2_[HOSTMOT2](BOARD).0.gpio.043.is_output TRUE

setp hm2_[HOSTMOT2](BOARD).0.gpio.044.is_output TRUE

setp hm2_[HOSTMOT2](BOARD).0.gpio.045.is_output TRUE

setp hm2_[HOSTMOT2](BOARD).0.gpio.046.is_output TRUE

setp hm2_[HOSTMOT2](BOARD).0.gpio.047.is_output TRUEPlease Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17465

- Thank you received: 5101

05 May 2021 21:24 #208026

by PCW

Replied by PCW on topic RPi4 & 7i96 XY2-100 Following Error at High Velocities

You would definitely want to remove or comment out this line:

setp hm2_[HOSTMOT2](BOARD).0.xy2mod.write-timer-number 1

and then set the FF2 values to say 0.00025 (this can be tuned with halscope)

You also might want to widen the ferror limits until everything is tuned

(say min_ferror = 0.01 and ferror =0.10)

setp hm2_[HOSTMOT2](BOARD).0.xy2mod.write-timer-number 1

and then set the FF2 values to say 0.00025 (this can be tuned with halscope)

You also might want to widen the ferror limits until everything is tuned

(say min_ferror = 0.01 and ferror =0.10)

Please Log in or Create an account to join the conversation.

- Limedodge

- Offline

- Senior Member

-

Less

More

- Posts: 40

- Thank you received: 1

05 May 2021 21:32 #208027

by Limedodge

Replied by Limedodge on topic RPi4 & 7i96 XY2-100 Following Error at High Velocities

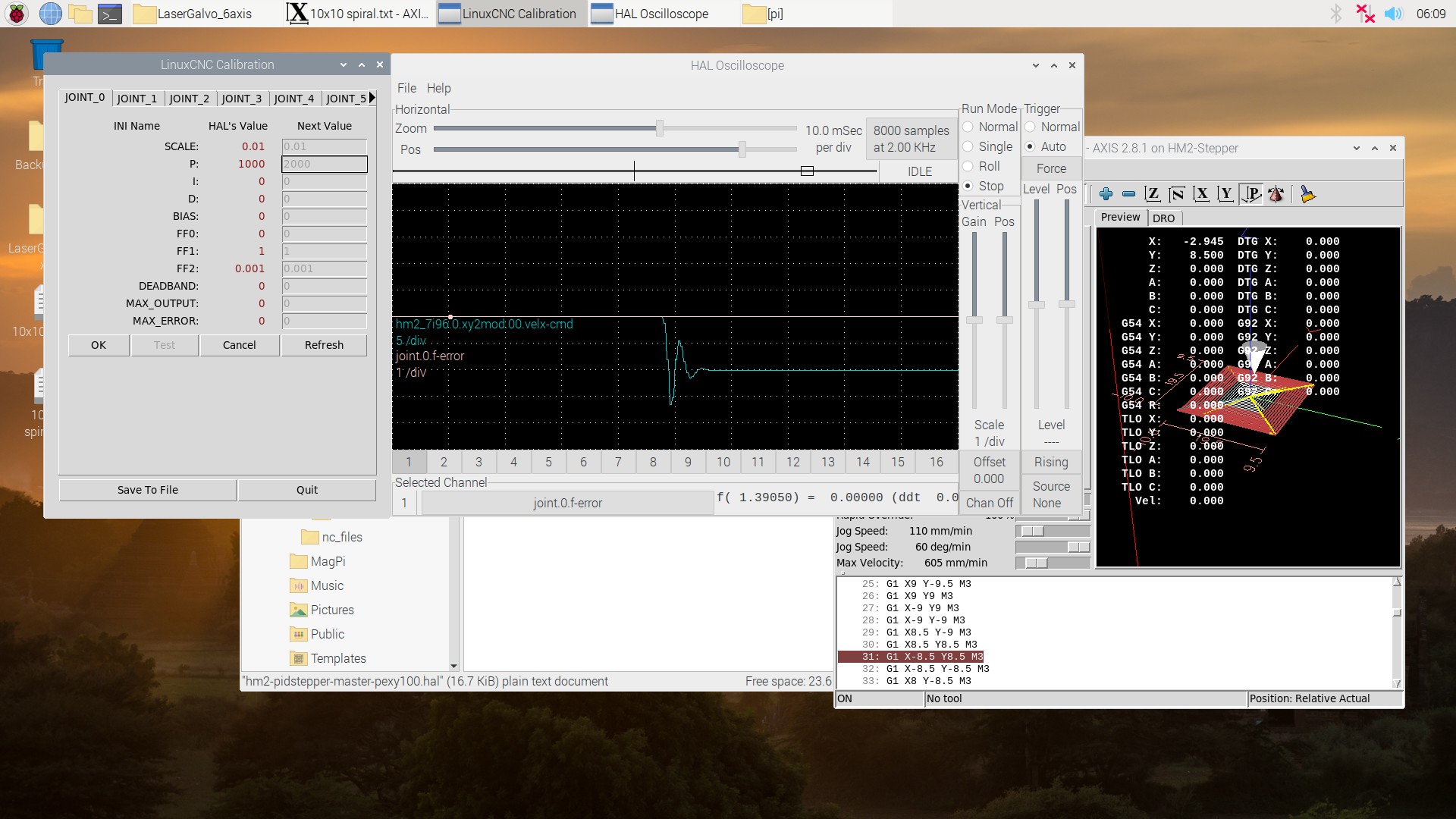

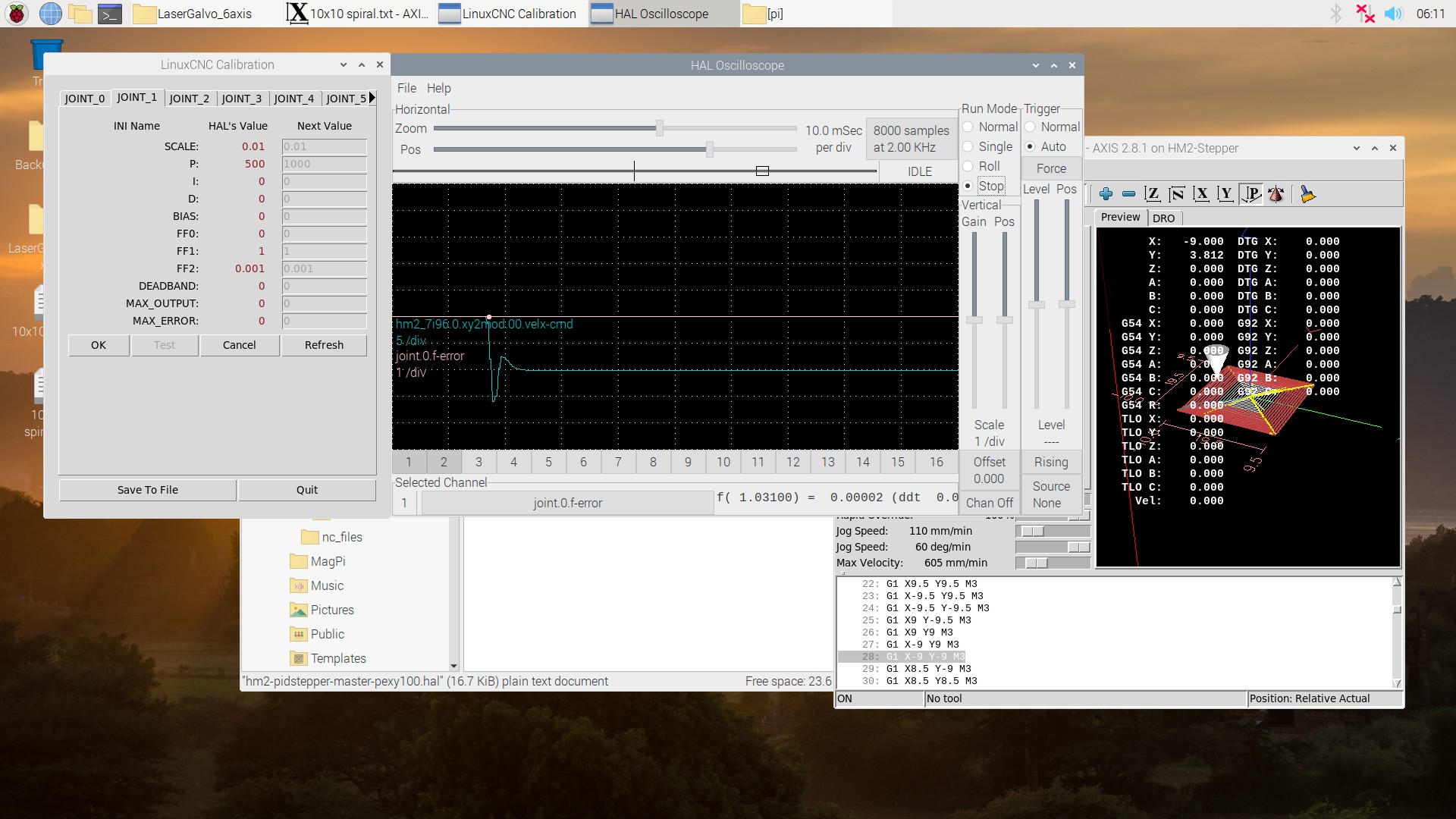

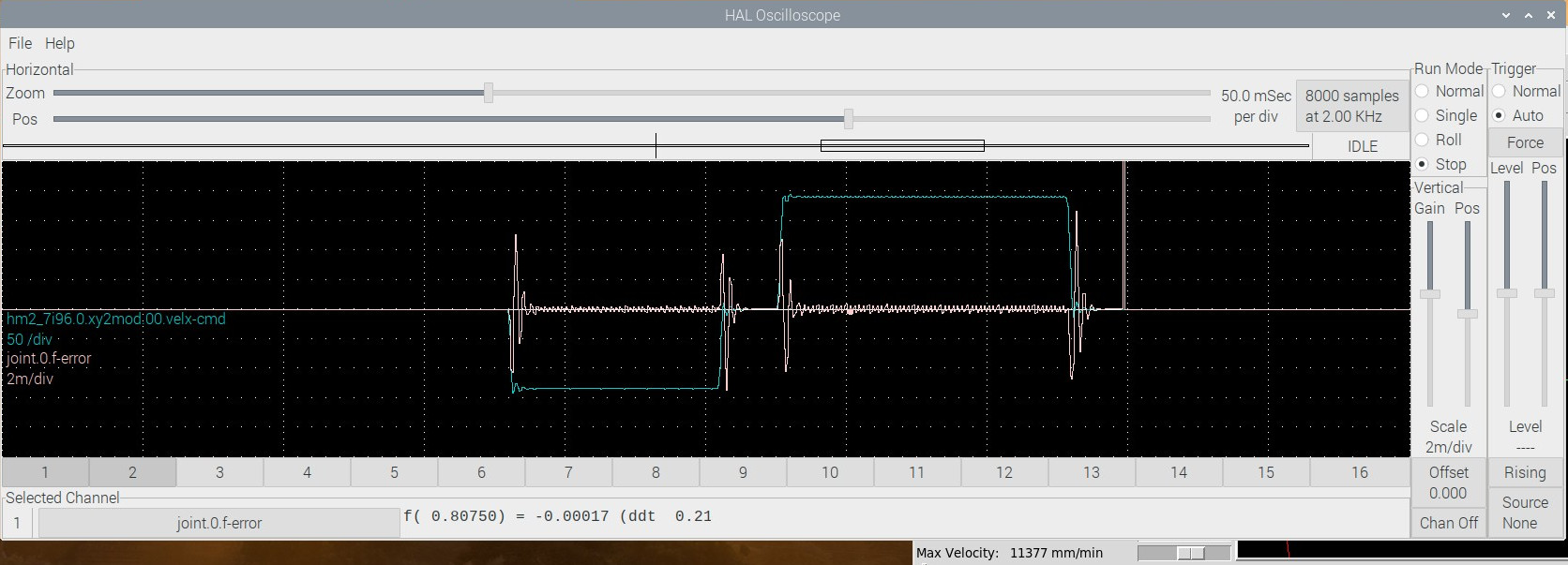

OK, progress!

commented out

#setp hm2_[HOSTMOT2](BOARD).0.xy2mod.write-timer-number 1

P=2000

FF2=.00025

I can get max velocity up to 13117mm/min before it hits a following error

The galvo can mechanically/physically go faster (max rate is ~7000mm/sec), not sure whats going to be the limit of the controller?

I'll switch out the Ferror and see what it does. Will this affect the precision? Will physical errors of 0.1mm be the consequence?

commented out

#setp hm2_[HOSTMOT2](BOARD).0.xy2mod.write-timer-number 1

P=2000

FF2=.00025

I can get max velocity up to 13117mm/min before it hits a following error

The galvo can mechanically/physically go faster (max rate is ~7000mm/sec), not sure whats going to be the limit of the controller?

I'll switch out the Ferror and see what it does. Will this affect the precision? Will physical errors of 0.1mm be the consequence?

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17465

- Thank you received: 5101

05 May 2021 21:53 - 05 May 2021 21:53 #208029

by PCW

Replied by PCW on topic RPi4 & 7i96 XY2-100 Following Error at High Velocities

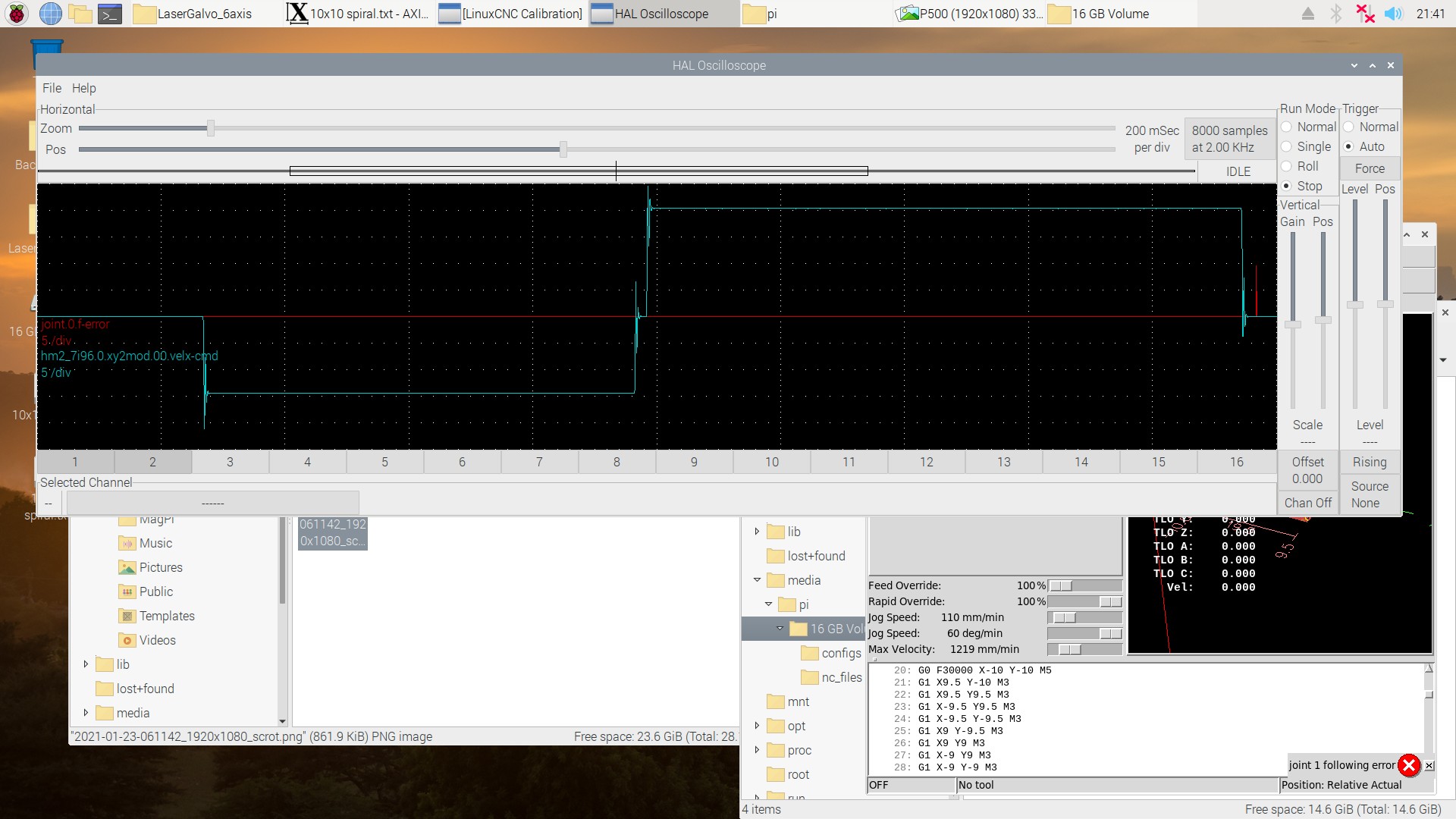

You should be able to halscope the ferror (say at .02 mm/division)

and see more clearly what is going on. The ferror limits do not

affect precision, they just determine when a following error fault is tripped.

Also note that the following error is just an apparent following error

and can be affected by residual DPLL position sample time jitter

and how well the scaling is setup to use the full 16 bit galvanometer

range.

and see more clearly what is going on. The ferror limits do not

affect precision, they just determine when a following error fault is tripped.

Also note that the following error is just an apparent following error

and can be affected by residual DPLL position sample time jitter

and how well the scaling is setup to use the full 16 bit galvanometer

range.

Last edit: 05 May 2021 21:53 by PCW.

Please Log in or Create an account to join the conversation.

- Limedodge

- Offline

- Senior Member

-

Less

More

- Posts: 40

- Thank you received: 1

05 May 2021 22:25 #208033

by Limedodge

Replied by Limedodge on topic RPi4 & 7i96 XY2-100 Following Error at High Velocities

Attachments:

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17465

- Thank you received: 5101

05 May 2021 22:46 #208034

by PCW

Replied by PCW on topic RPi4 & 7i96 XY2-100 Following Error at High Velocities

OK that's a following error at 0 or near velocity

Is that an error in the command or feedback?

Have you possibly run into the galvanometer limits?

that is, are the posx or posy overrange bits set?

Is that an error in the command or feedback?

Have you possibly run into the galvanometer limits?

that is, are the posx or posy overrange bits set?

Please Log in or Create an account to join the conversation.

- Limedodge

- Offline

- Senior Member

-

Less

More

- Posts: 40

- Thank you received: 1

05 May 2021 23:09 #208037

by Limedodge

Replied by Limedodge on topic RPi4 & 7i96 XY2-100 Following Error at High Velocities

How do I tell whether the error is from command or feedback?

I don't have the galvometer connected right now. Those charts are dry running on the bench. I really don't think it hit the limits but I'll double check on the overrun bits

That said, the galvo's total scan footprint is 150mm x 150mm. I've been running a test Gcode with a 20mm square spiral. Crazy enough, a scale of .01 is almost perfect. I etched lines and measured with a caliper and they were only off by hundredths of a mm.

side note, once I get it up and running I'll need to calibrate a compensation file as the galvo is inherently angular being converted to linear. There will be a function of Cosine error, as you get further from center. Haven't gotten that far yet. That might even explain the slight error I measured

I don't have the galvometer connected right now. Those charts are dry running on the bench. I really don't think it hit the limits but I'll double check on the overrun bits

That said, the galvo's total scan footprint is 150mm x 150mm. I've been running a test Gcode with a 20mm square spiral. Crazy enough, a scale of .01 is almost perfect. I etched lines and measured with a caliper and they were only off by hundredths of a mm.

side note, once I get it up and running I'll need to calibrate a compensation file as the galvo is inherently angular being converted to linear. There will be a function of Cosine error, as you get further from center. Haven't gotten that far yet. That might even explain the slight error I measured

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17465

- Thank you received: 5101

05 May 2021 23:17 #208038

by PCW

Replied by PCW on topic RPi4 & 7i96 XY2-100 Following Error at High Velocities

The overrange bits are set when you exceed the galvanometers range

(that is outside the 16 bit or 18 bit range) if the scale is .01,

the range would be +-100

(that is outside the 16 bit or 18 bit range) if the scale is .01,

the range would be +-100

Please Log in or Create an account to join the conversation.

Moderators: PCW, jmelson

Time to create page: 0.211 seconds