RPi4 & 7i96 XY2-100 Following Error at High Velocities

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17384

- Thank you received: 5069

06 May 2021 02:26 #208060

by PCW

Replied by PCW on topic RPi4 & 7i96 XY2-100 Following Error at High Velocities

That looks OK, Not sure what is going on

I'll try and duplicate this on a RPI4

I'll try and duplicate this on a RPI4

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17384

- Thank you received: 5069

06 May 2021 13:26 #208103

by PCW

Replied by PCW on topic RPi4 & 7i96 XY2-100 Following Error at High Velocities

I looked into this a bit more, and I think its related to the PIDs FF2

being 1 sample late. This causes an apparent ferror spike at the beginning

and and of acceleration. Because its acceleration dependent its not really noticeable

until you have very high accelerations. Also since the error is not velocity dependent

the normal large ferror small min_ferror velocity dependent settings don't help

I suspect you can eliminate the issue by setting the ferror _and min_ferror to say 0.1 mm. Also bounding the PID error may help reduce PID overreaction to this delay

being 1 sample late. This causes an apparent ferror spike at the beginning

and and of acceleration. Because its acceleration dependent its not really noticeable

until you have very high accelerations. Also since the error is not velocity dependent

the normal large ferror small min_ferror velocity dependent settings don't help

I suspect you can eliminate the issue by setting the ferror _and min_ferror to say 0.1 mm. Also bounding the PID error may help reduce PID overreaction to this delay

Please Log in or Create an account to join the conversation.

- Limedodge

- Offline

- Senior Member

-

Less

More

- Posts: 40

- Thank you received: 1

06 May 2021 17:35 #208137

by Limedodge

Replied by Limedodge on topic RPi4 & 7i96 XY2-100 Following Error at High Velocities

Well, raising Min_Ferror allows it to complete the test Gcode at max velocity. Success!

I have a few questions to help in my understanding

1. There is still ringing in the vel-cmd. I will work on the FF2 number to see it it can improved, but I'm not sure what the ultimate consequence will be. My understanding of the PID function (and what FF2 does) makes me think the best i can do is get the ringing to decay faster but not necessarily do much for the initial overshoot portion. Is this where the max_error comes in? It's almost like it needs some D term in the error function part.

2. I've mapped out the posx_fb and posy_fb and the lines are pretty crisp and straight. There is a bit of a ring in pos values that is directly related to the velocity ringing, but not too bad (probably close enough for my purposes +/- .01mm). Is that pos_fb value essentially the value the card writes to the galvo? ie, it's the direct 16bit output corrected to machine units? I wish there was a pin to see the raw 16bit values being fed to the galvos

I have a few questions to help in my understanding

1. There is still ringing in the vel-cmd. I will work on the FF2 number to see it it can improved, but I'm not sure what the ultimate consequence will be. My understanding of the PID function (and what FF2 does) makes me think the best i can do is get the ringing to decay faster but not necessarily do much for the initial overshoot portion. Is this where the max_error comes in? It's almost like it needs some D term in the error function part.

2. I've mapped out the posx_fb and posy_fb and the lines are pretty crisp and straight. There is a bit of a ring in pos values that is directly related to the velocity ringing, but not too bad (probably close enough for my purposes +/- .01mm). Is that pos_fb value essentially the value the card writes to the galvo? ie, it's the direct 16bit output corrected to machine units? I wish there was a pin to see the raw 16bit values being fed to the galvos

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17384

- Thank you received: 5069

06 May 2021 18:01 - 06 May 2021 18:08 #208143

by PCW

Replied by PCW on topic RPi4 & 7i96 XY2-100 Following Error at High Velocities

You can calculate the 16 bit value because the full range is +-32767 which would be

the full scale range = +-(1/scale)

There are a couple things you can do to reduce the ringing

1. Lower the P term (this is a compromise, lowering it too much will increase the following error)

2. Tune FF2

3. Bound the PID error (set MAX_ERROR to say 0.01 mm)

The position feedback is a scaled floating point representation of the 16 bit galvanometer number

its also has higher resolution (32 bits) so the PID deals with a high resolution number which is

rounded down to 16/18 bits for the galvanometer data.

the full scale range = +-(1/scale)

There are a couple things you can do to reduce the ringing

1. Lower the P term (this is a compromise, lowering it too much will increase the following error)

2. Tune FF2

3. Bound the PID error (set MAX_ERROR to say 0.01 mm)

The position feedback is a scaled floating point representation of the 16 bit galvanometer number

its also has higher resolution (32 bits) so the PID deals with a high resolution number which is

rounded down to 16/18 bits for the galvanometer data.

Last edit: 06 May 2021 18:08 by PCW.

Please Log in or Create an account to join the conversation.

- Limedodge

- Offline

- Senior Member

-

Less

More

- Posts: 40

- Thank you received: 1

07 May 2021 01:11 #208173

by Limedodge

Replied by Limedodge on topic RPi4 & 7i96 XY2-100 Following Error at High Velocities

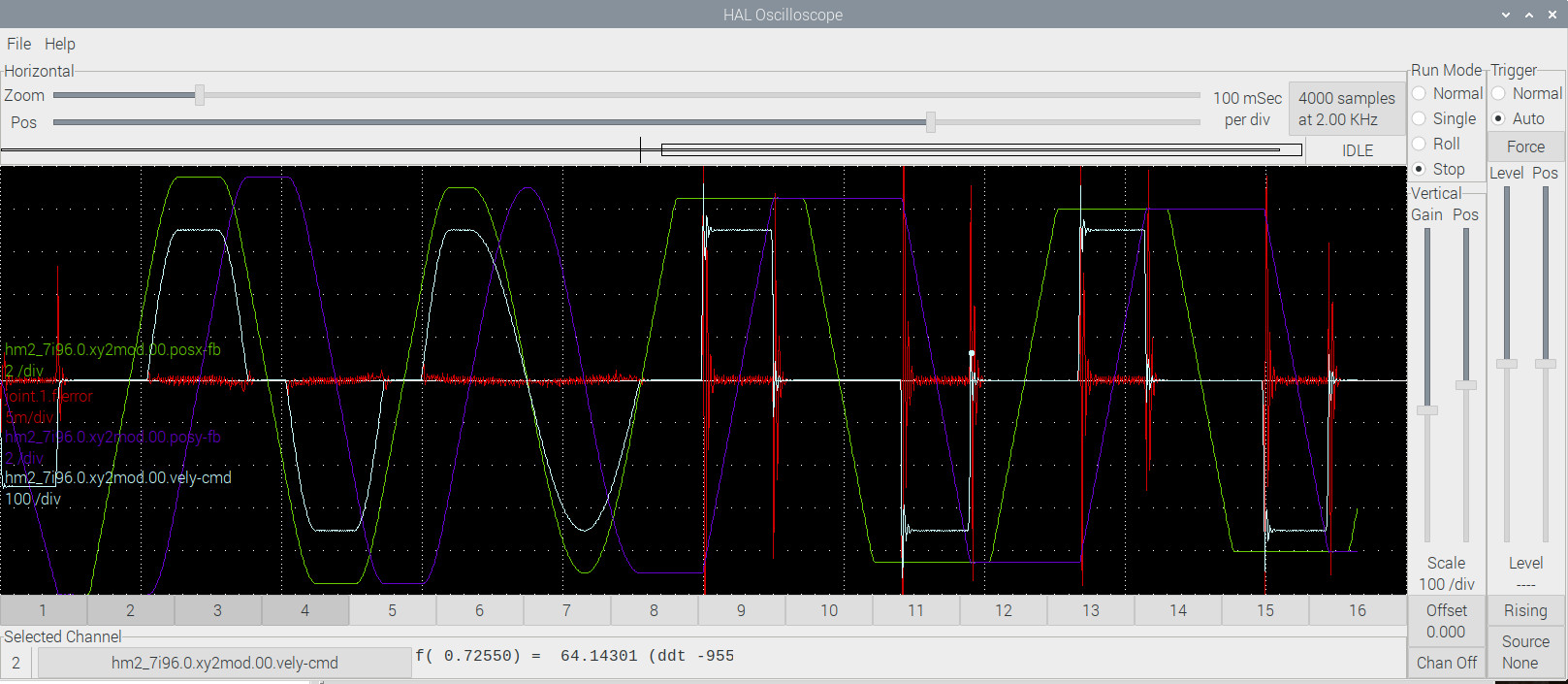

I found something peculiar in my trials and figured it's worth showing for everyone's reference. Let me know if you think I should start a new thread.

I am currently using a spindle command to M3 and M5 to signify which paths should be laser on and which ones should be non lase movements. In that way, I can use G-code to handle the on/off automatically. The spindle-on pin is wired to a GPIO and fed to the laser. pretty simple on/off switch. I couldn't figure out a better way to do this since there's not really a binary joint-on pin when the joint is being commanded. Joint-active doesn't work since it's always active. So I went with the spindle solution which does work. I just add a M3 or M5 on every line regardless of whether the preceding line has the same spindle command or not. I wrote a script that looks for G1 versus G0. Works pretty well

Example

G1 X10 Y10 M3 (laser on and move to 10,10)

G1 X-10 Y-10 M5 (laser off and move to -10,-10)

Looking at the scope of my spiral program, I noticed there is a slight pause/delay between Gcode commanded positions which should ordinary be a smooth transition.

For example:

G1 X5 Y5 M3 (laser on and move to 5,5)

G1 X10 Y10 M3 (laser on and continue the straight move to 10,10)

G1 X-10 Y-10 M5 (laser off and move to -10,-10)

In the above code, there will be a slight pause (~.021 sec) at the 5,5 point

So I experimented with removing some of the M3 commands from the end of the Gcode commands As you can see in the attached image, the profile of ferror, velx-cmd, posx_fb, and posy_fb changed DRASTICALLY and I'm not sure why

This confuses me as the spindle-at-speed pin is always True so there shouldn't be a delay. I don't really understand why the left half is different than the right half just by removing spindle commands.

I am currently using a spindle command to M3 and M5 to signify which paths should be laser on and which ones should be non lase movements. In that way, I can use G-code to handle the on/off automatically. The spindle-on pin is wired to a GPIO and fed to the laser. pretty simple on/off switch. I couldn't figure out a better way to do this since there's not really a binary joint-on pin when the joint is being commanded. Joint-active doesn't work since it's always active. So I went with the spindle solution which does work. I just add a M3 or M5 on every line regardless of whether the preceding line has the same spindle command or not. I wrote a script that looks for G1 versus G0. Works pretty well

Example

G1 X10 Y10 M3 (laser on and move to 10,10)

G1 X-10 Y-10 M5 (laser off and move to -10,-10)

Looking at the scope of my spiral program, I noticed there is a slight pause/delay between Gcode commanded positions which should ordinary be a smooth transition.

For example:

G1 X5 Y5 M3 (laser on and move to 5,5)

G1 X10 Y10 M3 (laser on and continue the straight move to 10,10)

G1 X-10 Y-10 M5 (laser off and move to -10,-10)

In the above code, there will be a slight pause (~.021 sec) at the 5,5 point

So I experimented with removing some of the M3 commands from the end of the Gcode commands As you can see in the attached image, the profile of ferror, velx-cmd, posx_fb, and posy_fb changed DRASTICALLY and I'm not sure why

This confuses me as the spindle-at-speed pin is always True so there shouldn't be a delay. I don't really understand why the left half is different than the right half just by removing spindle commands.

Attachments:

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17384

- Thank you received: 5069

07 May 2021 03:56 #208177

by PCW

Replied by PCW on topic RPi4 & 7i96 XY2-100 Following Error at High Velocities

Wouldn't you normally use M62 and M63 for this kind of operation?

Please Log in or Create an account to join the conversation.

- Limedodge

- Offline

- Senior Member

-

Less

More

- Posts: 40

- Thank you received: 1

07 May 2021 15:39 #208226

by Limedodge

Replied by Limedodge on topic RPi4 & 7i96 XY2-100 Following Error at High Velocities

To be honest, I didn't know those existed until you just pointed them out. Thank you!

I just tried them out and they behave the same as the "no M3/M5" chart shown above. I've got some rework to do with my ini/hal but I think I can make that work and can finally switch over to tuning velocities/accelerations.

I can't thank you enough PCW for all your help.

I just tried them out and they behave the same as the "no M3/M5" chart shown above. I've got some rework to do with my ini/hal but I think I can make that work and can finally switch over to tuning velocities/accelerations.

I can't thank you enough PCW for all your help.

Please Log in or Create an account to join the conversation.

- Sergei

- Offline

- New Member

-

Less

More

- Posts: 1

- Thank you received: 0

04 Oct 2021 08:52 #222176

by Sergei

Replied by Sergei on topic RPi4 & 7i96 XY2-100 Following Error at High Velocities

Dear all, where I can get firmware for 7i96 xy2mod?

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17384

- Thank you received: 5069

04 Oct 2021 15:17 #222202

by PCW

Replied by PCW on topic RPi4 & 7i96 XY2-100 Following Error at High Velocities

freeby.mesanet.com/7i96_xymod.bit

I'll add this to the standard 7I96 distribution when I get a chance

I'll add this to the standard 7I96 distribution when I get a chance

Please Log in or Create an account to join the conversation.

Moderators: PCW, jmelson

Time to create page: 0.150 seconds