G540 + EMC2 = missing steps

- DaBit

- Offline

- Elite Member

-

Less

More

- Posts: 203

- Thank you received: 19

26 Mar 2014 15:56 #45270

by DaBit

Replied by DaBit on topic G540 + EMC2 = missing steps

I have seen two cases of step loss when using simultaneous motion over multiple axes:

- Case 1: the problem was the switch mode power supply. Although it was a hefty 48V/10Amp supply, it was not capable of running 3 motors at the same time. Switch mode power supplies are not good motor supplies unless grossly overdimensioned; they have problems coping with regenerative energy. Solution: I had the guy add a second power supply and power one of the axes from that one.

- Case 2: The problem was some deformation in the machine frame. When the X axis was moving the Y axis was binding and vice versa. Alignment and stiffening solved the problems.

Not sure if this is the problem here, but checking it doesn't hurt.

- Case 1: the problem was the switch mode power supply. Although it was a hefty 48V/10Amp supply, it was not capable of running 3 motors at the same time. Switch mode power supplies are not good motor supplies unless grossly overdimensioned; they have problems coping with regenerative energy. Solution: I had the guy add a second power supply and power one of the axes from that one.

- Case 2: The problem was some deformation in the machine frame. When the X axis was moving the Y axis was binding and vice versa. Alignment and stiffening solved the problems.

Not sure if this is the problem here, but checking it doesn't hurt.

Please Log in or Create an account to join the conversation.

- Fredasiong

- Offline

- New Member

-

Less

More

- Posts: 17

- Thank you received: 0

26 Mar 2014 22:12 - 26 Mar 2014 23:06 #45282

by Fredasiong

Replied by Fredasiong on topic Re:G540 + EMC2 = missing steps

Arceye,

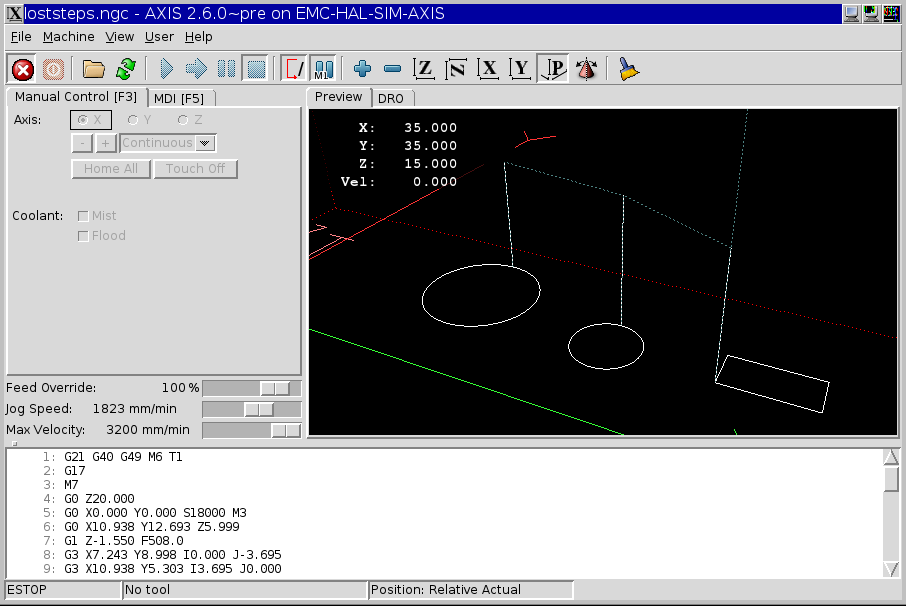

Sorry, I forgot to mention the controller is by Xylotex. See attached emc2 code.

Thanks

Sorry, I forgot to mention the controller is by Xylotex. See attached emc2 code.

Thanks

Last edit: 26 Mar 2014 23:06 by Fredasiong.

Please Log in or Create an account to join the conversation.

- ArcEye

- Offline

- Junior Member

-

Less

More

- Posts: 22

- Thank you received: 240

26 Mar 2014 22:47 - 27 Mar 2014 00:07 #45283

by ArcEye

Replied by ArcEye on topic Re:G540 + EMC2 = missing steps

Hi

The code is typical generated, no spacing, unnecessary repeats etc but no use of cutter compensation, so that is out.

The points by DaBit are good ones, his first point was my next gambit.

The overcuts correspond exactly with the entry plunges at the start of the cut (and the retraction). The entry is preceeded by a 3 axis move to co-ordinates and the exit is a XY moving into Z

I have amended the code as per below.

I have introduced G61 to force exact path mode, broken the 3 axis moves with included spindle startup into a S18000 M3, then XY followed by a Z,

reduced the seemingly suicidal F508 feed for the Z plunge to F100 (this is used thereafter for cutting for now)

and spaced the code so you can read it!

Give it a try and see if it cuts properly.

If so you can add things back until it errors and you will get a good idea what is causing problems.

regards

The code is typical generated, no spacing, unnecessary repeats etc but no use of cutter compensation, so that is out.

The points by DaBit are good ones, his first point was my next gambit.

The overcuts correspond exactly with the entry plunges at the start of the cut (and the retraction). The entry is preceeded by a 3 axis move to co-ordinates and the exit is a XY moving into Z

I have amended the code as per below.

I have introduced G61 to force exact path mode, broken the 3 axis moves with included spindle startup into a S18000 M3, then XY followed by a Z,

reduced the seemingly suicidal F508 feed for the Z plunge to F100 (this is used thereafter for cutting for now)

and spaced the code so you can read it!

Give it a try and see if it cuts properly.

If so you can add things back until it errors and you will get a good idea what is causing problems.

regards

G21 G40 G49

G17 G61

M6 T1

M7

S18000 M3

G0 Z20.000

G0 X0.000 Y0.000

G0 X10.938 Y12.693

G0 Z5.999

G1 Z-1.550 F100

G3 X7.243 Y8.998 I0.000 J-3.695

G3 X10.938 Y5.303 I3.695 J0.000

G3 X14.634 Y8.998 I0.000 J3.695

G3 X10.938 Y12.693 I-3.695 J0.000

G0 Z5.999

;S18000 M03

G0 X19.816 Y10.924 Z5.999

G1 Z-2.700 F100

G3 X17.606 Y8.714 I0.000 J-2.210

G3 X19.816 Y6.504 I2.210 J0.000

G3 X22.026 Y8.714 I0.000 J2.210

G3 X19.816 Y10.924 I-2.210 J0.000

G0 Z5.999

;S18000 M03

G0 X26.758 Y7.333 Z5.999

G1 Z-2.000 F100

G1 X32.191

G1 Y9.892

G1 X26.758

G1 Y7.333

G0 Z5.999

G0 Z20.000

G0 X0.000 Y0.000

M2

Last edit: 27 Mar 2014 00:07 by ArcEye.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4613

27 Mar 2014 07:20 #45296

by andypugh

Tangential arc lead-in moves would be nicer.

Replied by andypugh on topic Re:G540 + EMC2 = missing steps

How does the hole size compare to what is being requested? I could imagine what you see being due to machine flex. (especially if the Z rocks during a plunge)Sorry, I forgot to mention the controller is by Xylotex. See attached emc2 code.

Tangential arc lead-in moves would be nicer.

Please Log in or Create an account to join the conversation.

- Fredasiong

- Offline

- New Member

-

Less

More

- Posts: 17

- Thank you received: 0

27 Mar 2014 21:47 #45313

by Fredasiong

Replied by Fredasiong on topic Re:G540 + EMC2 = missing steps

Sorry, just got in. Thank you very for the excellent support that I am getting.

I will try this new code but I am a rookie on this. Where can I edit this code to add this statements?

Thanks

I will try this new code but I am a rookie on this. Where can I edit this code to add this statements?

Thanks

Please Log in or Create an account to join the conversation.

- ArcEye

- Offline

- Junior Member

-

Less

More

- Posts: 22

- Thank you received: 240

28 Mar 2014 00:54 #45318

by ArcEye

The code has already been changed as I outlined.

Just cut and paste the code in the yellow code box, paste it in gedit and save as say test.ngc

Then run Linuxcnc and load test.ngc and try it.

regards

Replied by ArcEye on topic Re:G540 + EMC2 = missing steps

I will try this new code but I am a rookie on this. Where can I edit this code to add this statements?

The code has already been changed as I outlined.

Just cut and paste the code in the yellow code box, paste it in gedit and save as say test.ngc

Then run Linuxcnc and load test.ngc and try it.

regards

Please Log in or Create an account to join the conversation.

- Fredasiong

- Offline

- New Member

-

Less

More

- Posts: 17

- Thank you received: 0

28 Mar 2014 02:09 #45319

by Fredasiong

Replied by Fredasiong on topic Re:G540 + EMC2 = missing steps

Arceye,

Thank you very much. Perfect outcome on circles and square. Now that you have solved the problem, how do I do this if I have 3000 lines of code ?

Regards

Thank you very much. Perfect outcome on circles and square. Now that you have solved the problem, how do I do this if I have 3000 lines of code ?

Regards

Please Log in or Create an account to join the conversation.

- ArcEye

- Offline

- Junior Member

-

Less

More

- Posts: 22

- Thank you received: 240

28 Mar 2014 03:20 #45323

by ArcEye

Replied by ArcEye on topic Re:G540 + EMC2 = missing steps

Hi

The gcode takes the strain off the PSU by only having a max of two axes at once operating.

The answer is not to change your gcode but to beef up your power supply.

As an experiment I ran my big mill with a 24v 350W PSU covering all 3 axes, the results were diabolical, could hardly move without losing steps.

My normal setup is a 76v 14A PSU for X and Y and 56v toroidal 8A PSU for Z

Difference, next to impossible to lose steps with the latter

regards

The gcode takes the strain off the PSU by only having a max of two axes at once operating.

The answer is not to change your gcode but to beef up your power supply.

As an experiment I ran my big mill with a 24v 350W PSU covering all 3 axes, the results were diabolical, could hardly move without losing steps.

My normal setup is a 76v 14A PSU for X and Y and 56v toroidal 8A PSU for Z

Difference, next to impossible to lose steps with the latter

regards

Please Log in or Create an account to join the conversation.

- Fredasiong

- Offline

- New Member

-

Less

More

- Posts: 17

- Thank you received: 0

28 Mar 2014 04:07 #45324

by Fredasiong

Replied by Fredasiong on topic Re:G540 + EMC2 = missing steps

would it be okay if I change my power supply to 350 watt from 125. ( I am using xylotex (3) 269 oz stepper @ 2.8amp each.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4613

28 Mar 2014 06:05 #45325

by andypugh

If you are running at 24V then 125W is only 1.7A per motor. If you are running at a higher voltage than that, then you have even less current.

350W is enough for your motors if you are running at less than 40V.

Replied by andypugh on topic Re:G540 + EMC2 = missing steps

would it be okay if I change my power supply to 350 watt from 125. ( I am using xylotex (3) 269 oz stepper @ 2.8amp each.

If you are running at 24V then 125W is only 1.7A per motor. If you are running at a higher voltage than that, then you have even less current.

350W is enough for your motors if you are running at less than 40V.

Please Log in or Create an account to join the conversation.

Time to create page: 0.128 seconds