Retrofit Gloria Europa 2/40 machining centre

- backtime

- Offline

- Senior Member

-

Less

More

- Posts: 56

- Thank you received: 0

30 Jun 2016 15:50 #76851

by backtime

Replied by backtime on topic Retrofit Gloria Europa 2/40 machining centre

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

30 Jun 2016 15:57 #76852

by andypugh

You should change that, immediately.

Replied by andypugh on topic Retrofit Gloria Europa 2/40 machining centre

In my hal file i have

setp pid.x.maxerror .0005

You should change that, immediately.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17630

- Thank you received: 5158

30 Jun 2016 16:02 - 30 Jun 2016 16:03 #76854

by PCW

Replied by PCW on topic Retrofit Gloria Europa 2/40 machining centre

You will also likely find that your P term is way too high for an encoder feedback situation

so i would set it lower to start

so i would set it lower to start

Last edit: 30 Jun 2016 16:03 by PCW.

Please Log in or Create an account to join the conversation.

- backtime

- Offline

- Senior Member

-

Less

More

- Posts: 56

- Thank you received: 0

30 Jun 2016 16:23 #76855

by backtime

Yes sir... immediately he he he

Actually i have P=1000, I found this value by reading a few posts on the forum, what value would you use as a starting value?

P=50 might be fine as starting point?

Replied by backtime on topic Retrofit Gloria Europa 2/40 machining centre

You should change that, immediately.

Yes sir... immediately he he he

You will also likely find that your P term is way too high for an encoder feedback situation

so i would set it lower to start

Actually i have P=1000, I found this value by reading a few posts on the forum, what value would you use as a starting value?

P=50 might be fine as starting point?

Please Log in or Create an account to join the conversation.

- backtime

- Offline

- Senior Member

-

Less

More

- Posts: 56

- Thank you received: 0

30 Jun 2016 16:38 #76856

by backtime

Replied by backtime on topic Retrofit Gloria Europa 2/40 machining centre

Meanwhile I was able to retrieve the configuration files.

Are preliminary files in which only the X axis has been configured, I'll setup other axes when the axis X will work properly.

For halscope plot I have to wait to get back to the workshop.

Thanks for your help

Are preliminary files in which only the X axis has been configured, I'll setup other axes when the axis X will work properly.

For halscope plot I have to wait to get back to the workshop.

Thanks for your help

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17630

- Thank you received: 5158

30 Jun 2016 16:43 #76858

by PCW

Replied by PCW on topic Retrofit Gloria Europa 2/40 machining centre

Yes P=1000 makes sense for open loop stepgens but is likely too high for closed loop

because there is much larger delay from VelocityCommand --> Step -->Drive --> Mechanics --> Encoder --> LinuxCNC

vs open loops VelocityCommand --> StepgenPositionFeedback

because there is much larger delay from VelocityCommand --> Step -->Drive --> Mechanics --> Encoder --> LinuxCNC

vs open loops VelocityCommand --> StepgenPositionFeedback

Please Log in or Create an account to join the conversation.

- backtime

- Offline

- Senior Member

-

Less

More

- Posts: 56

- Thank you received: 0

04 Jul 2016 17:00 - 04 Jul 2016 17:03 #76976

by backtime

Replied by backtime on topic Retrofit Gloria Europa 2/40 machining centre

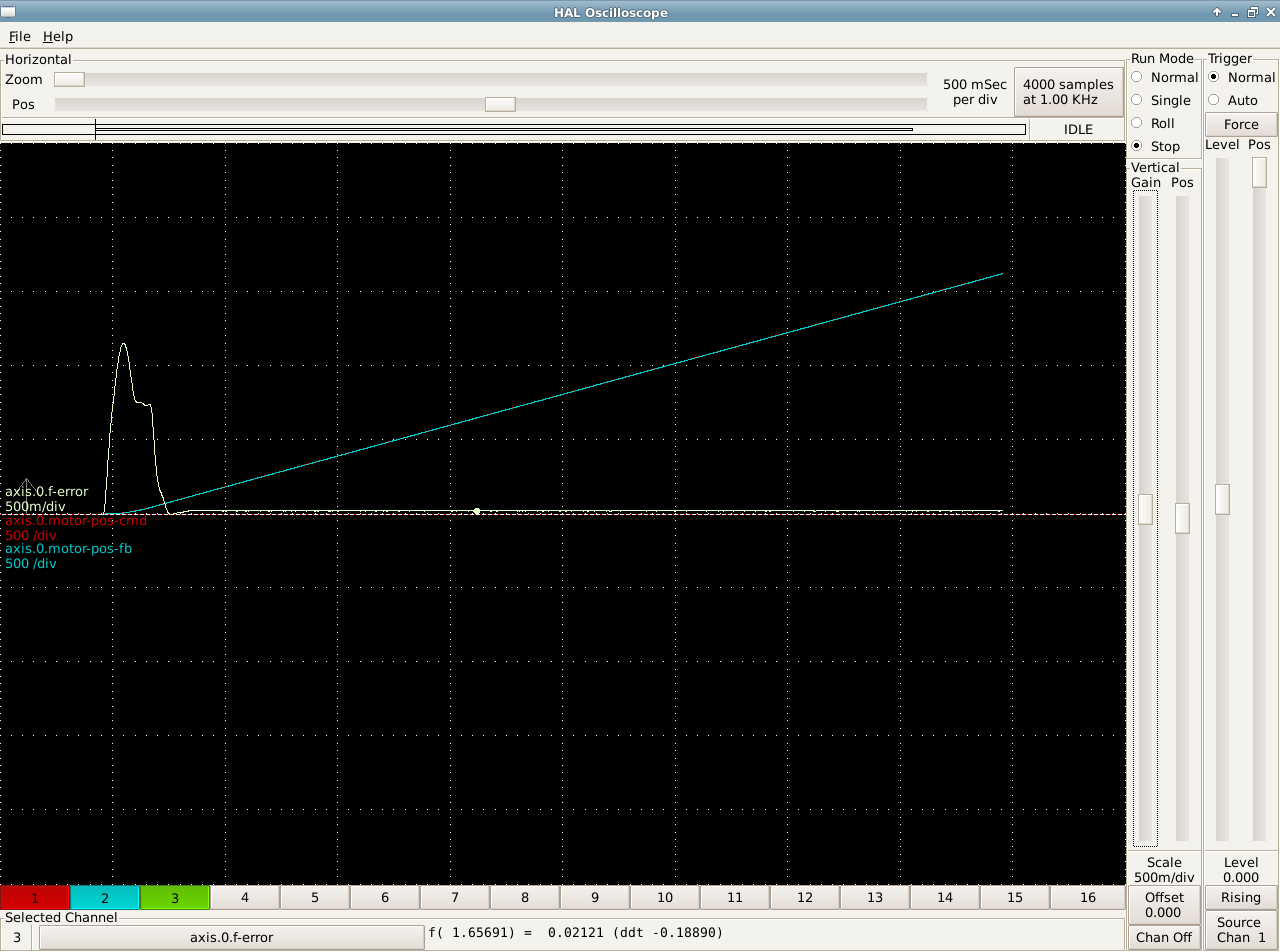

Ok, withthings are much better

Now i have P=50 and error is stable at 0.02 at high speed, I will make a few tries with other PID parameters,

but this is a great value.

The only problem is a peak at the beginning of the acceleration ramp (ferror raise to 1/1.1), i have taken a screenshot of halscope and saved halscope data file. Pins in halshow are: motor-pos-cmd, motor-pos-fb and ferror.

if you have suggestions let me know.

p.s. the command "Open data file" in halscope is greyed out, saved data cannot be loaded?

setp pid.x.maxerror 0Now i have P=50 and error is stable at 0.02 at high speed, I will make a few tries with other PID parameters,

but this is a great value.

The only problem is a peak at the beginning of the acceleration ramp (ferror raise to 1/1.1), i have taken a screenshot of halscope and saved halscope data file. Pins in halshow are: motor-pos-cmd, motor-pos-fb and ferror.

if you have suggestions let me know.

p.s. the command "Open data file" in halscope is greyed out, saved data cannot be loaded?

Last edit: 04 Jul 2016 17:03 by backtime.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17630

- Thank you received: 5158

04 Jul 2016 17:18 - 04 Jul 2016 17:41 #76977

by PCW

Replied by PCW on topic Retrofit Gloria Europa 2/40 machining centre

I suspect your drives cannot accelerate as fast as requested probably because

your INI file velocity and acceleration settings are too high for a mill

(500 mm/sec is possible on a fast router but scary fast for a mill)

your INI file velocity and acceleration settings are too high for a mill

(500 mm/sec is possible on a fast router but scary fast for a mill)

Last edit: 04 Jul 2016 17:41 by PCW.

Please Log in or Create an account to join the conversation.

- backtime

- Offline

- Senior Member

-

Less

More

- Posts: 56

- Thank you received: 0

05 Jul 2016 08:48 #77014

by backtime

Replied by backtime on topic Retrofit Gloria Europa 2/40 machining centre

It can be, but the data of speed and acceleration are provided by the manufacturer and are the result of simulations carried out by the manufacturer considering the masses involved.

This is the simulation for the X axis

Anyway I will try to decrease the values of acceleration and maximum speed up to eliminate the peak.

Thanks for answers.

This is the simulation for the X axis

Anyway I will try to decrease the values of acceleration and maximum speed up to eliminate the peak.

Thanks for answers.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

05 Jul 2016 09:20 #77017

by andypugh

Replied by andypugh on topic Retrofit Gloria Europa 2/40 machining centre

Do you have any FF1 term in the PID? There is a pin to connect the velocity command from HAL to make that work better.

axis.N.joint-vel-cmd => pid.N.command-deriv

You are showing a 1mm out-of-position error at the star of a rapid. This will be top limit for the off-of-path error, which will typically be rather smaller. (ie, the tool will be behind the commanded position, but often fairly close to the path despite this)

You might find that the error reduces rapidly with lower accel limits.

axis.N.joint-vel-cmd => pid.N.command-deriv

You are showing a 1mm out-of-position error at the star of a rapid. This will be top limit for the off-of-path error, which will typically be rather smaller. (ie, the tool will be behind the commanded position, but often fairly close to the path despite this)

You might find that the error reduces rapidly with lower accel limits.

Please Log in or Create an account to join the conversation.

Time to create page: 0.127 seconds