Chiron FZ 18 S retrofit

- radom

- Offline

- Senior Member

-

Less

More

- Posts: 61

- Thank you received: 7

17 Oct 2021 15:19 - 17 Oct 2021 15:22 #223390

by radom

Chiron FZ 18 S retrofit was created by radom

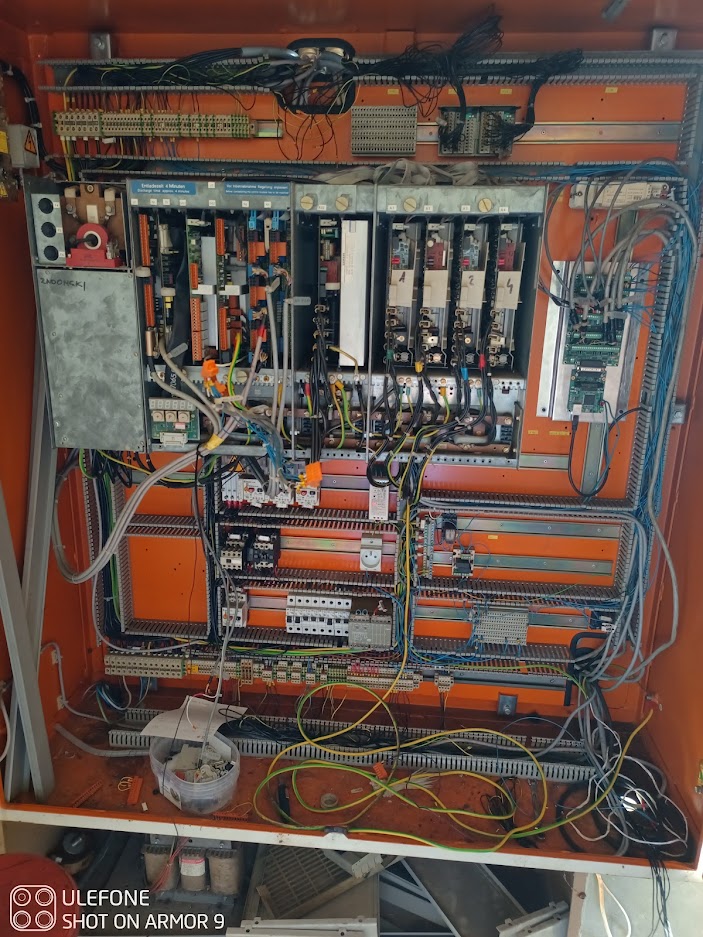

I bought this Chiron VMC earlier this year and I'm almost done with my retrofit but have a couple of questions,

my setup:

7i92 + 7i77

Siemens Simodrive 690 analog +/-10V servo 4 axis + spindle

In theory machine is capable of 20m/min rapids,

4000rpm servo at 10V , 2:1 belt reduction, 10mm pitch ballscrew = 20m/min = 333.333 mm/s

is this correct then?:

OUTPUT_SCALE = 333.333

OUTPUT_MIN_LIMIT = -333.333

OUTPUT_MAX_LIMIT = 333.333

MAX_VELOCITY = 333.333

but what do I do if I don't need 20m/min, lets say I want to limit rapids to 10m/min

do I leave output_scale as it is and change min limit max limit and max velocity to 166.166?

my setup:

7i92 + 7i77

Siemens Simodrive 690 analog +/-10V servo 4 axis + spindle

In theory machine is capable of 20m/min rapids,

4000rpm servo at 10V , 2:1 belt reduction, 10mm pitch ballscrew = 20m/min = 333.333 mm/s

is this correct then?:

OUTPUT_SCALE = 333.333

OUTPUT_MIN_LIMIT = -333.333

OUTPUT_MAX_LIMIT = 333.333

MAX_VELOCITY = 333.333

but what do I do if I don't need 20m/min, lets say I want to limit rapids to 10m/min

do I leave output_scale as it is and change min limit max limit and max velocity to 166.166?

Last edit: 17 Oct 2021 15:22 by radom.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21183

- Thank you received: 7237

17 Oct 2021 20:07 #223412

by tommylight

Replied by tommylight on topic Chiron FZ 18 S retrofit

No need, just set the max velocity in the ini file for each axis and joint, but also in the "display" and "traj" sections of the ini file.

The following user(s) said Thank You: radom

Please Log in or Create an account to join the conversation.

- anfänger

-

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

18 Oct 2021 10:57 #223444

by anfänger

Replied by anfänger on topic Chiron FZ 18 S retrofit

Nice another Chiron on LinuxCNC.

As Tommy said

Scales must be on 333.333 and set the max velocity on the joints/axis, traj and Ini to 166

As Tommy said

Scales must be on 333.333 and set the max velocity on the joints/axis, traj and Ini to 166

The following user(s) said Thank You: radom

Please Log in or Create an account to join the conversation.

- radom

- Offline

- Senior Member

-

Less

More

- Posts: 61

- Thank you received: 7

10 Dec 2021 20:44 - 10 Dec 2021 20:46 #228812

by radom

I have a question for you, as you have similar machine

how do you do tool clamp/unclamp, do you use only one air solenoid?

I have four air connections on the spindle,

bottom left - is air blast,

bottom right I have no idea what the air is doing and where is going,

top left is tool unclamp?

top right - does it force push the tool out?

I think I got ahead of myself

Replied by radom on topic Chiron FZ 18 S retrofit

Nice another Chiron on LinuxCNC.

As Tommy said

Scales must be on 333.333 and set the max velocity on the joints/axis, traj and Ini to 166

I have a question for you, as you have similar machine

how do you do tool clamp/unclamp, do you use only one air solenoid?

I have four air connections on the spindle,

bottom left - is air blast,

bottom right I have no idea what the air is doing and where is going,

top left is tool unclamp?

top right - does it force push the tool out?

I think I got ahead of myself

Last edit: 10 Dec 2021 20:46 by radom.

Please Log in or Create an account to join the conversation.

- anfänger

-

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

11 Dec 2021 11:16 #228866

by anfänger

Replied by anfänger on topic Chiron FZ 18 S retrofit

looks a bit different than mine, bit I never have removed the tool changer. And got a 10.000 rpm spindle.

I only have airblast and tool release, bit tool release has two lines.

Maybe your machine has a second line for airblast?

I can't see it in my schematics. If you like I can share them

Cheers Patrick

I only have airblast and tool release, bit tool release has two lines.

Maybe your machine has a second line for airblast?

I can't see it in my schematics. If you like I can share them

Cheers Patrick

Please Log in or Create an account to join the conversation.

- radom

- Offline

- Senior Member

-

Less

More

- Posts: 61

- Thank you received: 7

11 Dec 2021 12:18 #228872

by radom

this is 7,5kw 10500rpm spindle

maybe its airblast only something is clogged who knows, I'm more interested in tool release, do you use both lines?

I know one line moves air cylinder down to release tool but I'm not sure if I should be providing air to the other line after tool change?

it looks like the other line is for forcing air cylinder up so it doesn't rest on drawbar springs

if you could share tool change schematic it would be greatly appreciated

Replied by radom on topic Chiron FZ 18 S retrofit

I removed the tool changer because I don't have those fancy tool holders and half of the arms were damaged/missinglooks a bit different than mine, bit I never have removed the tool changer. And got a 10.000 rpm spindle.

I only have airblast and tool release, bit tool release has two lines.

Maybe your machine has a second line for airblast?

I can't see it in my schematics. If you like I can share them

Cheers Patrick

this is 7,5kw 10500rpm spindle

maybe its airblast only something is clogged who knows, I'm more interested in tool release, do you use both lines?

I know one line moves air cylinder down to release tool but I'm not sure if I should be providing air to the other line after tool change?

it looks like the other line is for forcing air cylinder up so it doesn't rest on drawbar springs

if you could share tool change schematic it would be greatly appreciated

Please Log in or Create an account to join the conversation.

- anfänger

-

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

11 Dec 2021 13:24 #228874

by anfänger

Replied by anfänger on topic Chiron FZ 18 S retrofit

I thin also pushing the cylinder up, well make the tool change more reliable. For schematics see the dropbox link below.

www.dropbox.com/sh/gytxrb7iajy0585/AABte...BtZ9Yl6xX8CzgWa?dl=0

let me know if you can access my scans.

(They are not well organized but all I got with the machine)

www.dropbox.com/sh/gytxrb7iajy0585/AABte...BtZ9Yl6xX8CzgWa?dl=0

let me know if you can access my scans.

(They are not well organized but all I got with the machine)

The following user(s) said Thank You: radom

Please Log in or Create an account to join the conversation.

- radom

- Offline

- Senior Member

-

Less

More

- Posts: 61

- Thank you received: 7

26 Feb 2022 17:16 #235854

by radom

Replied by radom on topic Chiron FZ 18 S retrofit

thank you for the scans,

I get rid of of all the old air valves and installed one single 5/2 valve for manual toolchange

I need to regrease the spindle bearings because they are incredibly loud, or maybe even change them but I keep putting it off, I don't know if I'd be able to disassembly the spindle

another issue is my pc is not up to par, I'm getting errors:

Unexpected realtime delay on task 0 with period 100000

hm2/hm2_7i92.0: Smart serial port 0: dolt not cleared from previous servo thread

hm2/hm2_7i92.0: error finishing read!

latency is around 110.000 is that too much or could it be ethernet problem?Fujitsu S720 AMD GX-217GA with RTL8111/8168/8411 PCI Express Gigabit Ethernet Controller Linux fuji 4.19.0-17-rt-amd64 #1 SMP PREEMPT RT Debian 4.19.194-2 (2021-06-21) x86_64 GNU/Linuxradom@fuji:~$ halcmd show param *.tmax

Parameters:

Owner Type Dir Value Name

26 s32 RW 0 hm2_7i92.0.read-request.tmax

26 s32 RW 1562510 hm2_7i92.0.read.tmax

26 s32 RW 342526 hm2_7i92.0.write.tmax

42 s32 RW 121449 ilowpass.0.tmax

19 s32 RW 44974 motion-command-handler.tmax

19 s32 RW 261740 motion-controller.tmax

39 s32 RW 67324 mux4.0.tmax

29 s32 RW 85587 pid.a.do-pid-calcs.tmax

29 s32 RW 65697 pid.s.do-pid-calcs.tmax

29 s32 RW 80970 pid.x.do-pid-calcs.tmax

29 s32 RW 63853 pid.y.do-pid-calcs.tmax

29 s32 RW 75640 pid.z.do-pid-calcs.tmax

20 s32 RW 1991729 servo-thread.tmax

32 s32 RW 65582 timedelay.0.tmax

32 s32 RW 67835 timedelay.1.tmax

radom@fuji:~$ ping 10.10.10.11

PING 10.10.10.11 (10.10.10.11) 56(84) bytes of data.

64 bytes from 10.10.10.11: icmp_seq=1 ttl=64 time=0.083 ms

64 bytes from 10.10.10.11: icmp_seq=2 ttl=64 time=0.090 ms

64 bytes from 10.10.10.11: icmp_seq=3 ttl=64 time=0.100 ms

64 bytes from 10.10.10.11: icmp_seq=4 ttl=64 time=0.103 ms

64 bytes from 10.10.10.11: icmp_seq=5 ttl=64 time=0.080 ms

64 bytes from 10.10.10.11: icmp_seq=6 ttl=64 time=0.076 ms

64 bytes from 10.10.10.11: icmp_seq=7 ttl=64 time=0.073 ms

64 bytes from 10.10.10.11: icmp_seq=8 ttl=64 time=0.098 ms

64 bytes from 10.10.10.11: icmp_seq=9 ttl=64 time=0.108 ms

64 bytes from 10.10.10.11: icmp_seq=10 ttl=64 time=0.082 ms

64 bytes from 10.10.10.11: icmp_seq=11 ttl=64 time=0.085 ms

64 bytes from 10.10.10.11: icmp_seq=12 ttl=64 time=0.088 ms

64 bytes from 10.10.10.11: icmp_seq=13 ttl=64 time=0.098 ms

64 bytes from 10.10.10.11: icmp_seq=14 ttl=64 time=0.084 ms

^C

--- 10.10.10.11 ping statistics ---

14 packets transmitted, 14 received, 0% packet loss, time 326ms

rtt min/avg/max/mdev = 0.073/0.089/0.108/0.011 ms

I get rid of of all the old air valves and installed one single 5/2 valve for manual toolchange

I need to regrease the spindle bearings because they are incredibly loud, or maybe even change them but I keep putting it off, I don't know if I'd be able to disassembly the spindle

another issue is my pc is not up to par, I'm getting errors:

Unexpected realtime delay on task 0 with period 100000

hm2/hm2_7i92.0: Smart serial port 0: dolt not cleared from previous servo thread

hm2/hm2_7i92.0: error finishing read!

latency is around 110.000 is that too much or could it be ethernet problem?Fujitsu S720 AMD GX-217GA with RTL8111/8168/8411 PCI Express Gigabit Ethernet Controller Linux fuji 4.19.0-17-rt-amd64 #1 SMP PREEMPT RT Debian 4.19.194-2 (2021-06-21) x86_64 GNU/Linuxradom@fuji:~$ halcmd show param *.tmax

Parameters:

Owner Type Dir Value Name

26 s32 RW 0 hm2_7i92.0.read-request.tmax

26 s32 RW 1562510 hm2_7i92.0.read.tmax

26 s32 RW 342526 hm2_7i92.0.write.tmax

42 s32 RW 121449 ilowpass.0.tmax

19 s32 RW 44974 motion-command-handler.tmax

19 s32 RW 261740 motion-controller.tmax

39 s32 RW 67324 mux4.0.tmax

29 s32 RW 85587 pid.a.do-pid-calcs.tmax

29 s32 RW 65697 pid.s.do-pid-calcs.tmax

29 s32 RW 80970 pid.x.do-pid-calcs.tmax

29 s32 RW 63853 pid.y.do-pid-calcs.tmax

29 s32 RW 75640 pid.z.do-pid-calcs.tmax

20 s32 RW 1991729 servo-thread.tmax

32 s32 RW 65582 timedelay.0.tmax

32 s32 RW 67835 timedelay.1.tmax

radom@fuji:~$ ping 10.10.10.11

PING 10.10.10.11 (10.10.10.11) 56(84) bytes of data.

64 bytes from 10.10.10.11: icmp_seq=1 ttl=64 time=0.083 ms

64 bytes from 10.10.10.11: icmp_seq=2 ttl=64 time=0.090 ms

64 bytes from 10.10.10.11: icmp_seq=3 ttl=64 time=0.100 ms

64 bytes from 10.10.10.11: icmp_seq=4 ttl=64 time=0.103 ms

64 bytes from 10.10.10.11: icmp_seq=5 ttl=64 time=0.080 ms

64 bytes from 10.10.10.11: icmp_seq=6 ttl=64 time=0.076 ms

64 bytes from 10.10.10.11: icmp_seq=7 ttl=64 time=0.073 ms

64 bytes from 10.10.10.11: icmp_seq=8 ttl=64 time=0.098 ms

64 bytes from 10.10.10.11: icmp_seq=9 ttl=64 time=0.108 ms

64 bytes from 10.10.10.11: icmp_seq=10 ttl=64 time=0.082 ms

64 bytes from 10.10.10.11: icmp_seq=11 ttl=64 time=0.085 ms

64 bytes from 10.10.10.11: icmp_seq=12 ttl=64 time=0.088 ms

64 bytes from 10.10.10.11: icmp_seq=13 ttl=64 time=0.098 ms

64 bytes from 10.10.10.11: icmp_seq=14 ttl=64 time=0.084 ms

^C

--- 10.10.10.11 ping statistics ---

14 packets transmitted, 14 received, 0% packet loss, time 326ms

rtt min/avg/max/mdev = 0.073/0.089/0.108/0.011 ms

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21183

- Thank you received: 7237

26 Feb 2022 22:00 #235879

by tommylight

Replied by tommylight on topic Chiron FZ 18 S retrofit

In the .ini file, put back the servo period to 1000000 where it was, it will not work at 100000.

Please Log in or Create an account to join the conversation.

- radom

- Offline

- Senior Member

-

Less

More

- Posts: 61

- Thank you received: 7

27 Feb 2022 06:35 #235894

by radom

Replied by radom on topic Chiron FZ 18 S retrofit

thats my mistake, I was rewriting the errors from memory,

servo thread is of course 1000000 in .ini

servo thread is of course 1000000 in .ini

Please Log in or Create an account to join the conversation.

Time to create page: 0.098 seconds