FLOAT PIN FOR FOLLOWING ERRORS?

- COlger81

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 187

- Thank you received: 6

14 Nov 2018 14:10 #120679

by COlger81

Replied by COlger81 on topic FLOAT PIN FOR FOLLOWING ERRORS?

What following error would you expect to see roughly at 150 IPM from a decent mill? .030" (.762mm) seems pretty extreme and i think i have some tuning to do.

Please Log in or Create an account to join the conversation.

- dgarrett

- Offline

- Platinum Member

-

Less

More

- Posts: 492

- Thank you received: 297

14 Nov 2018 14:24 #120681

by dgarrett

Replied by dgarrett on topic FLOAT PIN FOR FOLLOWING ERRORS?

joint.N.f-error-lim is a hal output pin from the motion module

linuxcnc.org/docs/master/html/man/man9/motion.9.html

Relevant ini settings:Ref: linuxcnc.org/docs/master/html/config/ini-config.html

Note: Above docs are for the master branch (2.8~pre)

$ man motion

...

joint.N.f−error−lim OUT FLOAT

The following error limit

...Relevant ini settings:

2.13. [JOINT_<num>]Section

...

MIN_FERROR = 0.010 - This is the value in machine

units by which the axis is permitted to deviate

from commanded position at very low speeds. If

MIN_FERROR is smaller than FERROR, the two produce

a ramp of error trip points. You could think of

this as a graph where one dimension is speed and

the other is permitted following error. As speed

increases the amount of following error also

increases toward the FERROR value.

FERROR = 1.0 - FERROR is the maximum allowable

following error, in machine units. If the

difference between commanded and sensed position

exceeds this amount, the controller disables servo

calculations, sets all the outputs to 0.0, and

disables the amplifiers. If MIN_FERROR is present

in the .ini file, velocity-proportional following

errors are used. Here, the maximum allowable

following error is proportional to the speed, with

FERROR applying to the rapid rate set by

[TRAJ]MAX_VELOCITY, and proportionally smaller

following errors for slower speeds. The maximum

allowable following error will always be greater

than MIN_FERROR. This prevents small following

errors for stationary axes from inadvertently

aborting motion. Small following errors will

always be present due to vibration, etc.Note: Above docs are for the master branch (2.8~pre)

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19797

- Thank you received: 4606

14 Nov 2018 14:29 #120682

by andypugh

It depends a lot on the machine, and also how the acceleration and velocity limits in the controller compare to the actual physical limits of the machine.

Do you have reason to believe that things were better before switching to 2.8, or had you just not really looked in detail?

(Assuming I have not got my posters mixed up).

What happens if you lower the acceleration limits of the joints, does the f-error reduce?

I-gain might help.

When cruising at high speed and with a large f-error, is the amplifier anywhere near saturated?

Replied by andypugh on topic FLOAT PIN FOR FOLLOWING ERRORS?

What following error would you expect to see roughly at 150 IPM from a decent mill? .030" (.762mm) seems pretty extreme and i think i have some tuning to do.

It depends a lot on the machine, and also how the acceleration and velocity limits in the controller compare to the actual physical limits of the machine.

Do you have reason to believe that things were better before switching to 2.8, or had you just not really looked in detail?

(Assuming I have not got my posters mixed up).

What happens if you lower the acceleration limits of the joints, does the f-error reduce?

I-gain might help.

When cruising at high speed and with a large f-error, is the amplifier anywhere near saturated?

Please Log in or Create an account to join the conversation.

- COlger81

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 187

- Thank you received: 6

14 Nov 2018 16:35 #120688

by COlger81

Replied by COlger81 on topic FLOAT PIN FOR FOLLOWING ERRORS?

Lowering accelerations had no effect on the following errors. I am using the halscope right now. I think it's just a tuning issue.

Please Log in or Create an account to join the conversation.

- COlger81

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 187

- Thank you received: 6

14 Nov 2018 20:34 #120697

by COlger81

Replied by COlger81 on topic FLOAT PIN FOR FOLLOWING ERRORS?

Andy;

I was getting too aggressive on the drives so i changed my plan. I tuned the drives to Fadal manual spec. Now i'm going through PID tuning in software. Halscope looks pretty linear as far as following errors go. I just need to stiffen them up to reduce following errors. Any starting suggestions? I lowered max velocity to 30 and I'm at P of 120 currently.

I was getting too aggressive on the drives so i changed my plan. I tuned the drives to Fadal manual spec. Now i'm going through PID tuning in software. Halscope looks pretty linear as far as following errors go. I just need to stiffen them up to reduce following errors. Any starting suggestions? I lowered max velocity to 30 and I'm at P of 120 currently.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17678

- Thank you received: 5170

14 Nov 2018 20:54 #120698

by PCW

Replied by PCW on topic FLOAT PIN FOR FOLLOWING ERRORS?

Are the drives running in velocity mode?

If so the main tuning is via FF1

If so the main tuning is via FF1

Please Log in or Create an account to join the conversation.

- COlger81

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 187

- Thank you received: 6

14 Nov 2018 21:33 - 14 Nov 2018 21:34 #120703

by COlger81

Replied by COlger81 on topic FLOAT PIN FOR FOLLOWING ERRORS?

Yes, they are in velocity mode. I currently have P=400 and FF1=1.152;

2.88volts at 150 ipm

10volts at 520.833

520.833/60=8.681

10/8.681=1.152

Does this look correct?

(I'm getting .007" following error at 150 IPM)

2.88volts at 150 ipm

10volts at 520.833

520.833/60=8.681

10/8.681=1.152

Does this look correct?

(I'm getting .007" following error at 150 IPM)

Last edit: 14 Nov 2018 21:34 by COlger81.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17678

- Thank you received: 5170

14 Nov 2018 21:59 #120704

by PCW

Replied by PCW on topic FLOAT PIN FOR FOLLOWING ERRORS?

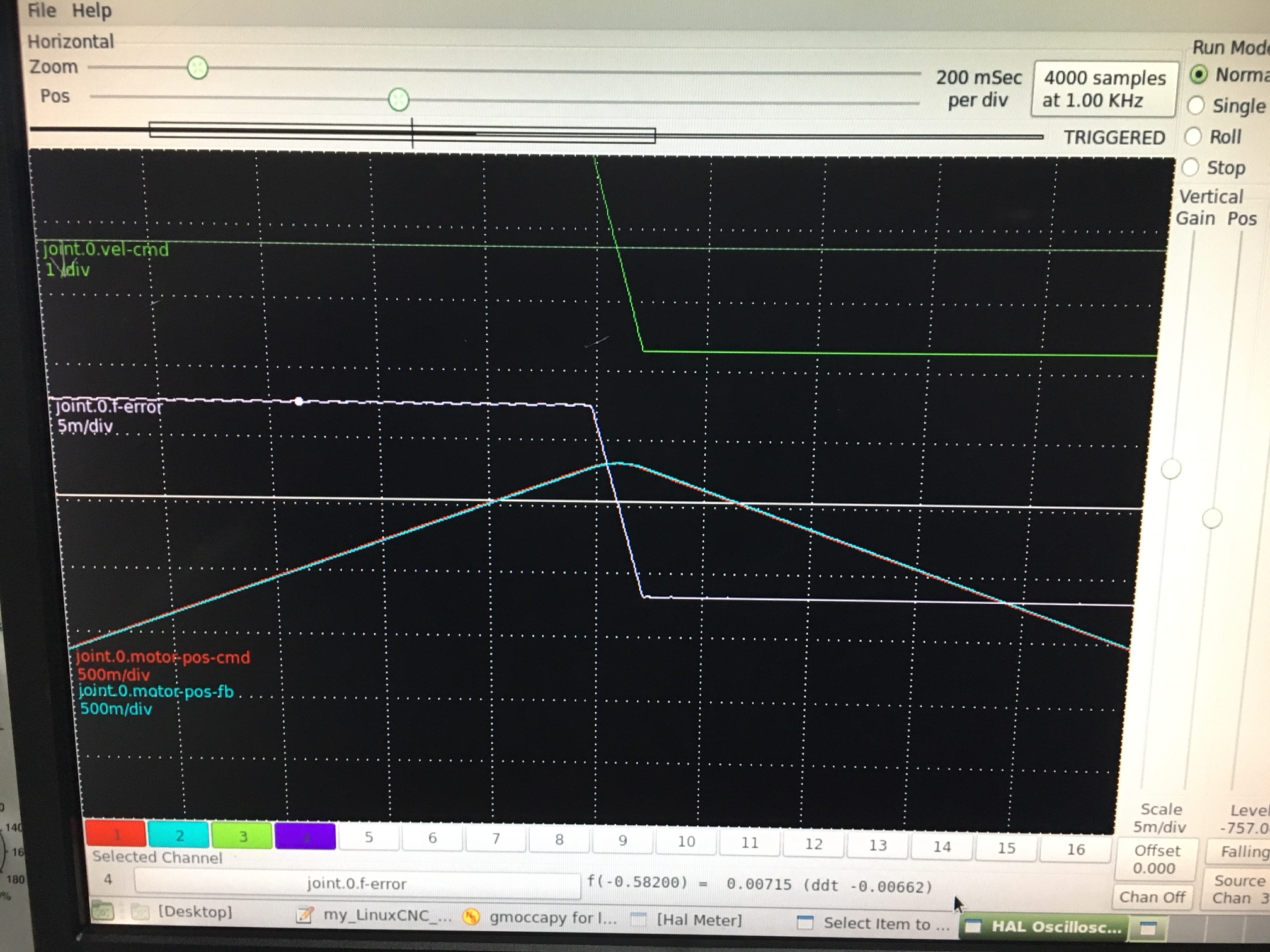

Can you post a halscope plot of following error + commanded velocity?

Note that even if you cannot get the calibrate popup to work,

you can set the PID parameters "live" via halcmd. You can also do this with

halshow, but halcmd is easier since it has the consoles command history and line editing features

Note that even if you cannot get the calibrate popup to work,

you can set the PID parameters "live" via halcmd. You can also do this with

halshow, but halcmd is easier since it has the consoles command history and line editing features

Please Log in or Create an account to join the conversation.

- COlger81

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 187

- Thank you received: 6

14 Nov 2018 22:21 #120705

by COlger81

Replied by COlger81 on topic FLOAT PIN FOR FOLLOWING ERRORS?

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17678

- Thank you received: 5170

14 Nov 2018 22:33 - 14 Nov 2018 22:39 #120706

by PCW

Replied by PCW on topic FLOAT PIN FOR FOLLOWING ERRORS?

That looks like almost exclusively FF1 tweaking needed:

( halcmd setp pid.N.ff1 something, make a 10% change, is it better or worse? )

( halcmd setp pid.N.ff1 something, make a 10% change, is it better or worse? )

Last edit: 14 Nov 2018 22:39 by PCW.

Please Log in or Create an account to join the conversation.

Time to create page: 0.323 seconds