- LinuxCNC

- General LinuxCNC Questions

- Circular path (or any path that require two axis movement at one time)

Circular path (or any path that require two axis movement at one time)

- Python

- Offline

- New Member

-

- Posts: 12

- Thank you received: 0

I've been building a CNC machine for a while. And of course I've been struggling from time to time, because lack of knowledge, but thanks to this forum and many many topics, that saved a lot of time and nerve.

First of all, I would like to tell you about what problems I've been facing in the past.

At first there was some inaccuracies in distance due to poor quality rack and pinion system.

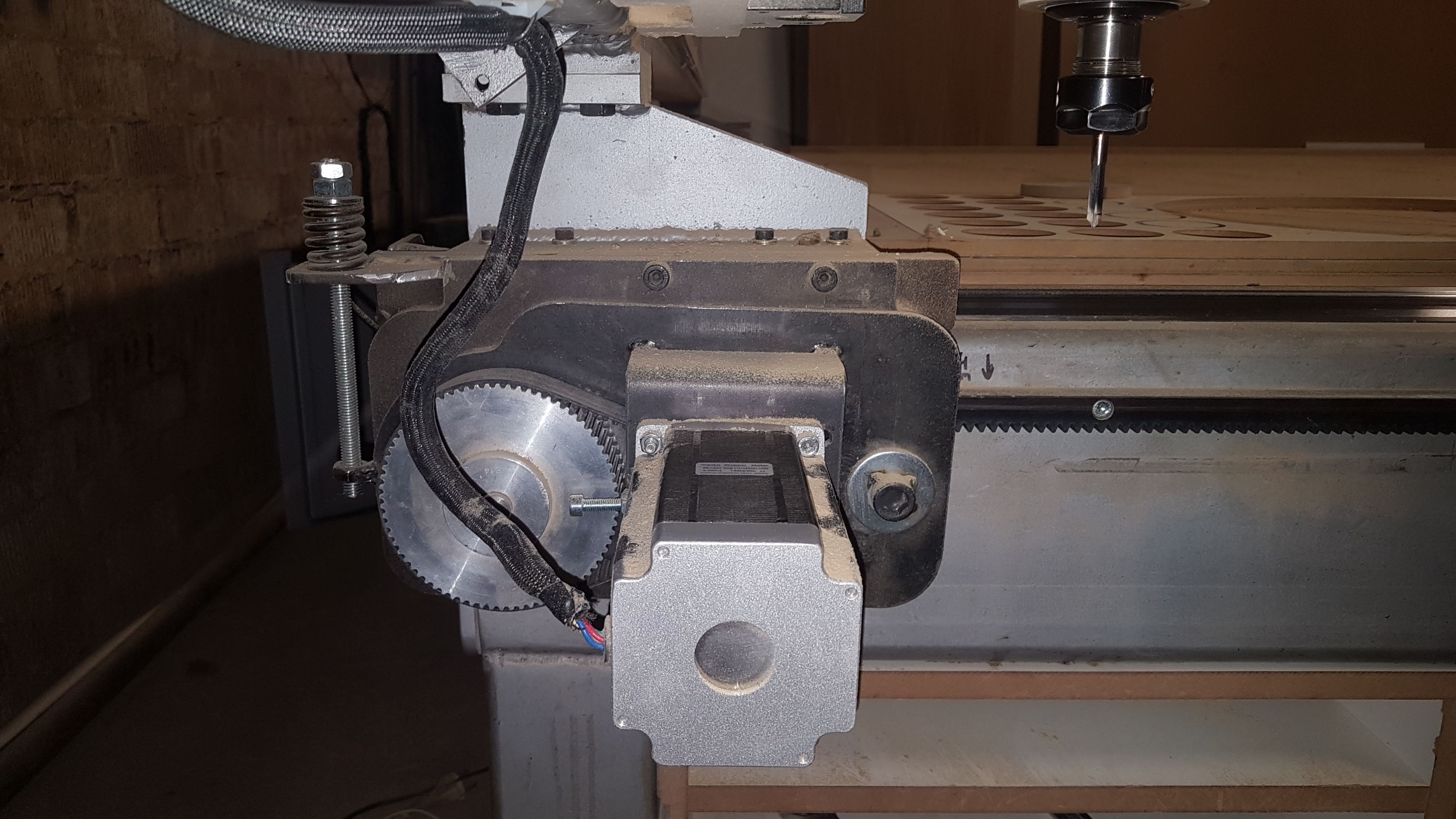

Then there was a lot of noise and movement with vibration due to stepper motor and pinion. Pinion was mounted straight on the motor axle. Today we solved this by instaling custom made gear reduction system (1:4 (pinion turns one time, while motor turns 4 time's at the same time). At this moment machine works really silent and has power that meets our needs. Speed is a little bit to slow, but that is okey, because machine works only at full speed when it is'nt cutting (160mm/s). Also we upgraded rack and pinion from M1.5 to M2.0.

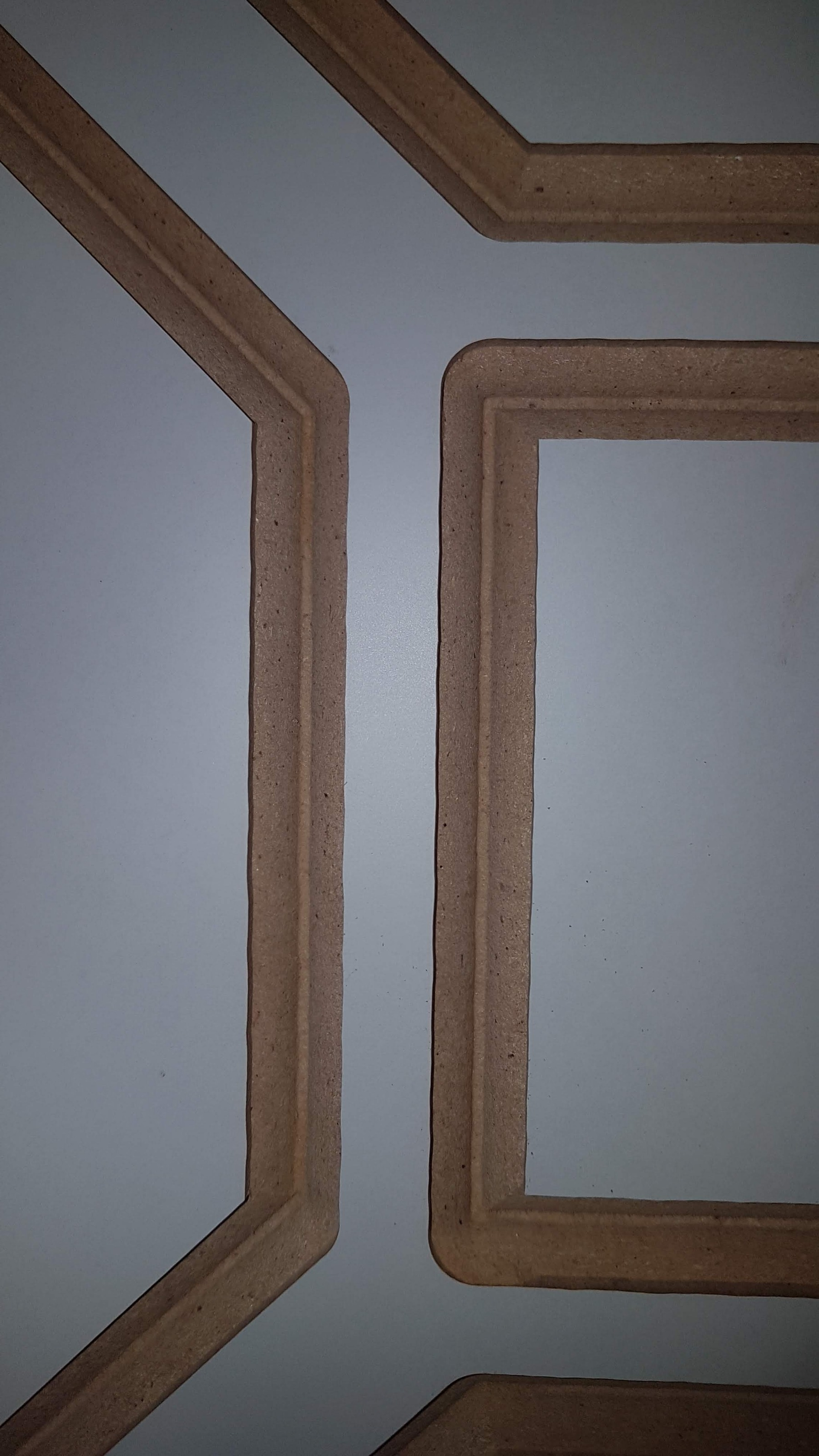

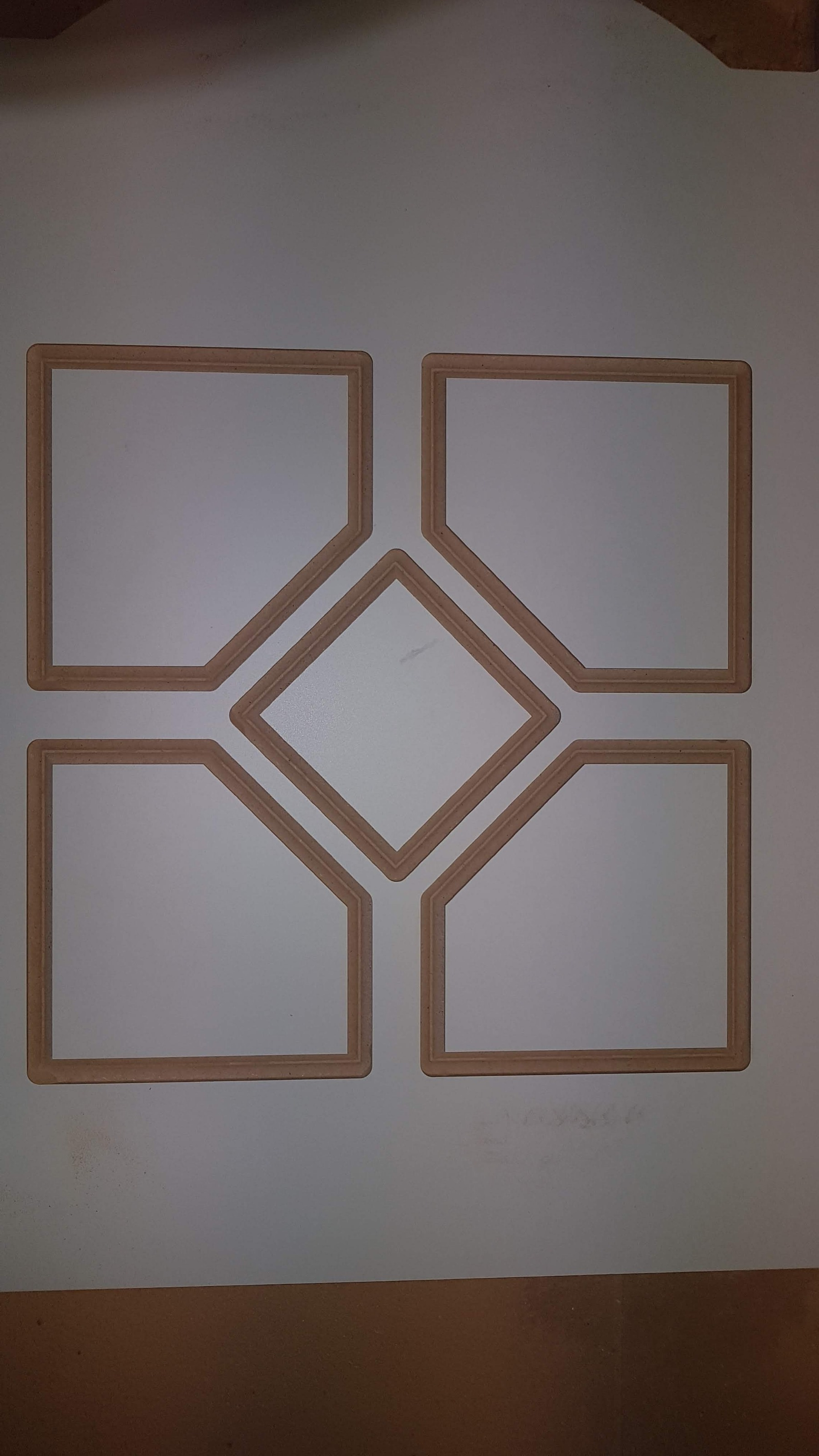

But now we are facing kind of "new" problem. We thought that until we matched parts that were cut before machine upgrade and pieces that we are cutting now. So the problem is that when only one axis is moving there are no problems, the cut is flawless. But when I want to cut part that needs two axis movement, when the cut gets some kind wavy no matter at what speed I'm cutting that purt (5-50mm/s). Old parts wavy cut kind of matches the new parts wavy cut. And now I don't know what to do.

I tried using G-Code from other software (Always used Vectric, there wasn't so such problem on other machine).

Also tried to set up machine settings from very start. Tried chaging microstepping setting also amperage from driver.

Machine is equiped with

NEMA34(85BYGH450C-060),

Drivers DQ860MA,

power supply 60V

BOB from china for a few bucks (that one with the relay),

Linux CNC installed in DELL DV051.

Maybe someone has an idea, what can be possibly wrong?

I'm thinking that the BOB is sending pulses to slow (MAX servo thread was 27k while surfing net, watching youtube, etc.)

OR there some isues with my PC.

Thank YOU in advance.

Please Log in or Create an account to join the conversation.

- Leon82

- Offline

- Platinum Member

-

- Posts: 592

- Thank you received: 79

Please Log in or Create an account to join the conversation.

- Python

- Offline

- New Member

-

- Posts: 12

- Thank you received: 0

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

- Posts: 2203

- Thank you received: 482

Machine is equiped with

NEMA34(85BYGH450C-060),

Drivers DQ860MA,

power supply 60V

BOB from china for a few bucks (that one with the relay),

Linux CNC installed in DELL DV051.

Maybe someone has an idea, what can be possibly wrong?

Personally I think that 60V is to low for nema 24 motors (but the drives may not handle more!!)

Also is the power supply able to supply the current to drive two motors?

Have you checked for back lash?

Please Log in or Create an account to join the conversation.

- Python

- Offline

- New Member

-

- Posts: 12

- Thank you received: 0

There is a seperate pover supply for seperate driver. Each motor have it's own pover supply and the driver.

No, there is no backlash, I checked it with the gauge.

Leon82:

How to check is there any harmonics? It's new to me, never heard of it before.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

- Posts: 17677

- Thank you received: 5170

a non concentric pulley or stretched belt might do this

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

- Posts: 4696

- Thank you received: 1439

Please Log in or Create an account to join the conversation.

- Python

- Offline

- New Member

-

- Posts: 12

- Thank you received: 0

Yesterday I've been "playing" with as many solutions as I can think of, but nothing changed anything. So the friend of mine gave me computer, that have had Mach 3 installed, after some time, I managed to configure my CNC and tried to cut circle to no avail. Waving was exactly as cutting with the Linux CNC, so I think, that there are no software issues.

I think, that I have to recheck hardware of the machine as other members suggested.

Please Log in or Create an account to join the conversation.

- Python

- Offline

- New Member

-

- Posts: 12

- Thank you received: 0

PCW, in my opinion and observation there is no wobble in gearing. The belt isn't tightened to much. IMHO.

But I'll check it one more time, to be sure.

Please Log in or Create an account to join the conversation.

- Leon82

- Offline

- Platinum Member

-

- Posts: 592

- Thank you received: 79

If there is slack the tool can be pulling the slack forward.

Try conventional milling a pass

Please Log in or Create an account to join the conversation.

- LinuxCNC

- General LinuxCNC Questions

- Circular path (or any path that require two axis movement at one time)