- LinuxCNC

- General LinuxCNC Questions

- Circular path (or any path that require two axis movement at one time)

Circular path (or any path that require two axis movement at one time)

- Python

- Offline

- New Member

-

Less

More

- Posts: 12

- Thank you received: 0

14 Mar 2019 11:27 - 14 Mar 2019 11:27 #128573

by Python

Replied by Python on topic Circular path (or any path that require two axis movement at one time)

Tried both yesterday, the results are the same. Spindle works fine, in all range of RPM, no extra noise or vibrations during milling and free spin. (It worked for as much as 100h...)

Last edit: 14 Mar 2019 11:27 by Python.

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

14 Mar 2019 11:35 #128574

by pl7i92

Replied by pl7i92 on topic Circular path (or any path that require two axis movement at one time)

i personly woudt guess you to do a 1mm more offset to 3mm Rest Depth and speed over

with a full Depth and the Final maybe also on CRC use

THE Final in Conventiona move

this wil bring the contour to a stright nice finish shine

with a full Depth and the Final maybe also on CRC use

THE Final in Conventiona move

this wil bring the contour to a stright nice finish shine

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

Less

More

- Posts: 4696

- Thank you received: 1439

14 Mar 2019 14:41 #128586

by Todd Zuercher

Rack and pinions can be tricky to set up right. I have battled with similar problems on some $70k factory built machines. On those machines the problem is usually worn bearings on the pinion shafts, and/or worn bearings on the intermediate shaft of the belt reduction between the servo motor and the pinion. (I am replacing these parts on these 2 machines every 2-3 years)

But any misalignment of the pinion to the rack can lead to not smooth motion. Worn pinion gears can also give these results, but that shouldn't be a problem on a new build.

Replied by Todd Zuercher on topic Circular path (or any path that require two axis movement at one time)

Yes, Todd, both axis are rack and pinion. I'll check meshing as soon as possible.

PCW, in my opinion and observation there is no wobble in gearing. The belt isn't tightened to much. IMHO.

But I'll check it one more time, to be sure.

Rack and pinions can be tricky to set up right. I have battled with similar problems on some $70k factory built machines. On those machines the problem is usually worn bearings on the pinion shafts, and/or worn bearings on the intermediate shaft of the belt reduction between the servo motor and the pinion. (I am replacing these parts on these 2 machines every 2-3 years)

But any misalignment of the pinion to the rack can lead to not smooth motion. Worn pinion gears can also give these results, but that shouldn't be a problem on a new build.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21260

- Thank you received: 7255

14 Mar 2019 16:12 #128591

by tommylight

Replied by tommylight on topic Circular path (or any path that require two axis movement at one time)

Watch the springs while the machine is cutting, they are likely moving while cutting. Getting the right ammount of pressure on those things is very hard as that depends on a lot of mechanical stuff, like how far is the axis that the reduction is mounted on, what angle it is set at etc.

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

14 Mar 2019 16:17 #128592

by pl7i92

Replied by pl7i92 on topic Circular path (or any path that require two axis movement at one time)

as it apears so regular it is more noice to the tool

Please Log in or Create an account to join the conversation.

- Mike_Eitel

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1052

- Thank you received: 183

14 Mar 2019 19:58 #128604

by Mike_Eitel

Replied by Mike_Eitel on topic Circular path (or any path that require two axis movement at one time)

I wonder if the distance is related to the pitch of your screw. And if the distance in both axis is equal.

I understand that you have the big whell directly connected to the screw. If distance is smaller as pith, have a look to the small wheel. If bigger than pitch look if it is the factor of big wheel tooth to length/teeth of belt. If it's equal pitch look big wheel. None of them : take a beer or two ;-(

Mike

I understand that you have the big whell directly connected to the screw. If distance is smaller as pith, have a look to the small wheel. If bigger than pitch look if it is the factor of big wheel tooth to length/teeth of belt. If it's equal pitch look big wheel. None of them : take a beer or two ;-(

Mike

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11701

- Thank you received: 3954

16 Mar 2019 06:44 #128704

by rodw

Replied by rodw on topic Circular path (or any path that require two axis movement at one time)

Also if you have helical cut misalignment shaft joiner, the motor torque can easily exceed the design limits of the joiner and result in backlash within the coupling. I moved to a fairly expensive oldham style coupling to eliminate that

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19797

- Thank you received: 4606

17 Mar 2019 18:36 - 17 Mar 2019 18:39 #128841

by andypugh

Replied by andypugh on topic Circular path (or any path that require two axis movement at one time)

Speed variation in a cut on only one axis will not show up in the work, it is only when you have two axes moving that you see the problem.

So, this is because one or more axes are not moving at a steady speed.

This could be mechanical, it could also be in the motor controllers if these are closed-loop steppers or step-servos.

I did at first think that it could be the PID tuning in LinuxCNC (there is a PID even with steppers) but the Mach3 swap eliminated that possibility.

So, what motors and drivers are you using?

I see now that you said it was steppers and simple step/dir drivers.

I think that analysing the pitch of the waves (orthogonal to each axis) is likely to be a very instructive step. Does it match one turn of a shaft, or one turn of a gear.

So, this is because one or more axes are not moving at a steady speed.

This could be mechanical, it could also be in the motor controllers if these are closed-loop steppers or step-servos.

I did at first think that it could be the PID tuning in LinuxCNC (there is a PID even with steppers) but the Mach3 swap eliminated that possibility.

I see now that you said it was steppers and simple step/dir drivers.

I think that analysing the pitch of the waves (orthogonal to each axis) is likely to be a very instructive step. Does it match one turn of a shaft, or one turn of a gear.

Last edit: 17 Mar 2019 18:39 by andypugh.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21260

- Thank you received: 7255

18 Mar 2019 00:10 #128866

by tommylight

Replied by tommylight on topic Circular path (or any path that require two axis movement at one time)

After some analysing it looks like you have something sloppy there as the distance of the anomaly is not exactly the same always.

Check well everything, there is no easier way to say it.

BTW, did you edit anything in the INI and HAL files ?

Check well everything, there is no easier way to say it.

BTW, did you edit anything in the INI and HAL files ?

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19797

- Thank you received: 4606

19 Mar 2019 14:05 #128971

by andypugh

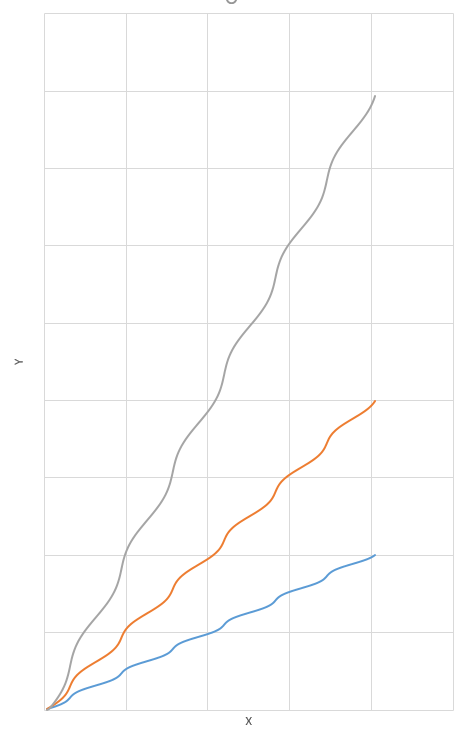

The wiggle pitch will vary depending on the direction of motion. (but, if mechanical) should be constant if projected to an axis.

This picture shows the result of a constant wiggle on X combined with a constant Y at various angles.

You will see nothing in a straight Y move (as X doesn't move) and nothing in a straight X move (As the wiggle is along the cut line)

Replied by andypugh on topic Circular path (or any path that require two axis movement at one time)

After some analysing it looks like you have something sloppy there as the distance of the anomaly is not exactly the same always.

The wiggle pitch will vary depending on the direction of motion. (but, if mechanical) should be constant if projected to an axis.

This picture shows the result of a constant wiggle on X combined with a constant Y at various angles.

You will see nothing in a straight Y move (as X doesn't move) and nothing in a straight X move (As the wiggle is along the cut line)

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- LinuxCNC

- General LinuxCNC Questions

- Circular path (or any path that require two axis movement at one time)

Time to create page: 0.157 seconds