Control panel hardware buttons

- blazini36

- Offline

- Platinum Member

-

- Posts: 972

- Thank you received: 167

Not sure what you mean by "analog" buttons. How many LinuxCNC users use a normal PC keyboard next to their machine? Tormach doesn't supply anything special with a $30k machine.

We all have different views on valuation. Some could say they're near free considering what they can pack and enable (professional grade hmi). Ol'style analog buttons floating over a pcb ain't dust and fluid proof my friend (hazardous). That was accepted back in the 1960's when membrane weren't optional, but not anymore.

I'm gonna put the matrix buttons on an easily removeable panel like spumco's. Personally I don't spray my mill with paint thinner so if they hold up reasonably well to some WD40 or water soluble coolant for a while I'm happy. If not I can whip something else up that will fit in it's spot.

unless the 7i73 firmware can be modified I'm thinking of using ArduinoConnector

Please Log in or Create an account to join the conversation.

- Mecanix

- Offline

- Platinum Member

-

- Posts: 447

- Thank you received: 227

Please Log in or Create an account to join the conversation.

- blazini36

- Offline

- Platinum Member

-

- Posts: 972

- Thank you received: 167

Lol you get a bit dramatic sometimes.I was under the assumption that a few/many was planned, as in a commercial unit. Speed-reading habit, apologies. If your project is a one-off (for personal use) then all/anything goes really... a.k.a no warranty claims, injuries, legal, claims, etc etc.

Please Log in or Create an account to join the conversation.

- Mecanix

- Offline

- Platinum Member

-

- Posts: 447

- Thank you received: 227

Please Log in or Create an account to join the conversation.

- blazini36

- Offline

- Platinum Member

-

- Posts: 972

- Thank you received: 167

I do appreciate the suggestion, just not what I have in mind for this specific purpose.Nah. I was genuinely trying to help you out. Let's hope the given contact and facilitation to professional grade interfacing helps someone else!

Please Log in or Create an account to join the conversation.

- RotarySMP

-

- Offline

- Platinum Member

-

- Posts: 1571

- Thank you received: 580

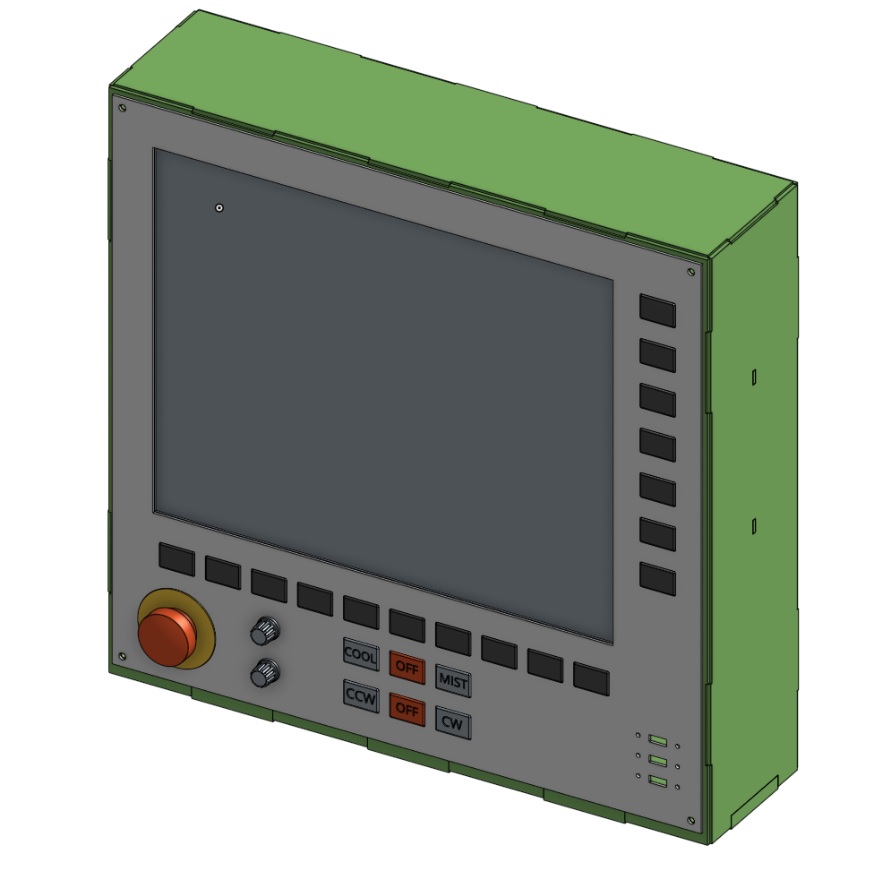

and for a Schaublin Lathe:

Some of my thoughts...

I duplicated the bezel soft keys with hardware. I much prefer using hardware keys rather than the touch screen for all those important functions like cycle start, pause, etc. So important that I am even adding a dedicated set of stop, pause, single line buttons directly below the feed override encoder.

It has taken me too many crashes to learn (and relearn) the safe workflow of using feed override and pause to approach work. So a feed override encoder is something I would consider essential.

As you add more complex functionality to a machine (ATC, spindle gearing, touch probe, collet closer, Pneumatic tailstock, bar feeder), you need more buttons. I broke up my monitor panel from the button sub panel on the Schaublin's panel, as I could possibly replace one, at a later date without affecting the other. I have some extra buttons on this panel, which I am not really sure yet how I will use.

I really like having USB ports on the control panel. I tend to have my machines disconnected from the network, and use the sneaker net to transfer files.

Attachments:

Please Log in or Create an account to join the conversation.

- blazini36

- Offline

- Platinum Member

-

- Posts: 972

- Thank you received: 167

I agree with you about the feed override and pause, I tend to have my finger right next to the UI pause button everytime I think something might go wrong.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

- Offline

- Platinum Member

-

- Posts: 1571

- Thank you received: 580

Look forward to seeing how your panel comes out.

Cheers,

Mark

Please Log in or Create an account to join the conversation.

- blazini36

- Offline

- Platinum Member

-

- Posts: 972

- Thank you received: 167

Please Log in or Create an account to join the conversation.

- my1987toyota

-

- Offline

- Platinum Member

-

- Posts: 975

- Thank you received: 430

Please Log in or Create an account to join the conversation.