plasma control panel

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11603

- Thank you received: 3900

28 Mar 2019 00:50 #129810

by rodw

Replied by rodw on topic plasma control panel

PCW has shared the THCAD rise time delay here and its super quick. Z axis Acceleration is an important tuning parameter for THC I found. and the AMP connectors are available from RS Components in Oz. You are going to smash this Phill!

The following user(s) said Thank You: phillc54

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

23 Apr 2019 06:57 - 23 Apr 2019 06:57 #131607

by phillc54

Replied by phillc54 on topic plasma control panel

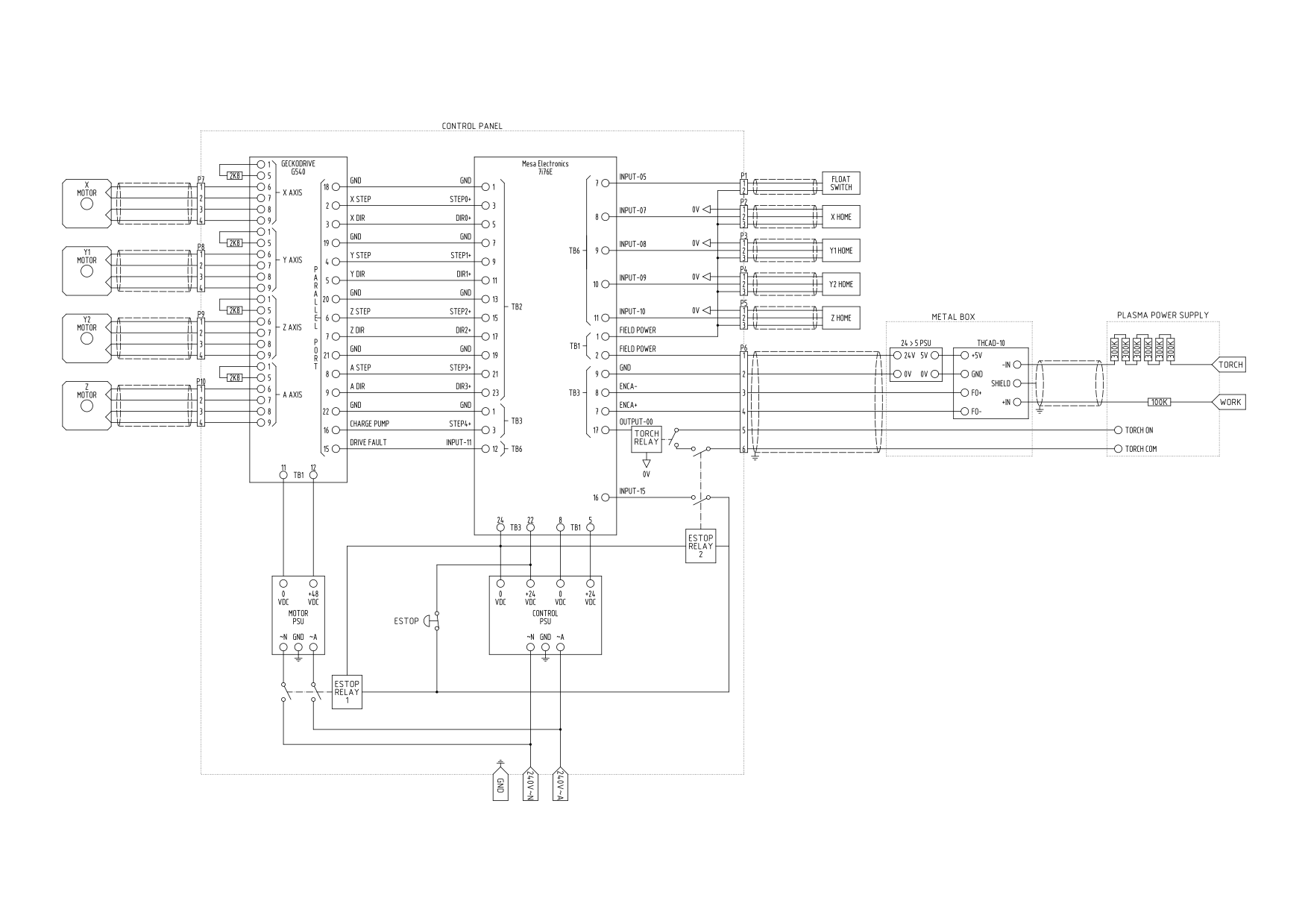

I have come up with this wiring diagram, all comments welcome.

I haven't forgotten limit switches, I don't really want to use them as I haven't on any of my other machines and not had too many dramas..

Actually this is the first time I will use home switches, I usually just eyeball matchmarks which has served well in the past.

Cheers, Phill.

I haven't forgotten limit switches, I don't really want to use them as I haven't on any of my other machines and not had too many dramas..

Actually this is the first time I will use home switches, I usually just eyeball matchmarks which has served well in the past.

Cheers, Phill.

Last edit: 23 Apr 2019 06:57 by phillc54.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21145

- Thank you received: 7221

23 Apr 2019 09:29 #131614

by tommylight

Replied by tommylight on topic plasma control panel

That looks all good.

The following user(s) said Thank You: phillc54

Please Log in or Create an account to join the conversation.

- abcdefg

- Offline

- Platinum Member

-

Less

More

- Posts: 1132

- Thank you received: 533

23 Apr 2019 09:34 #131615

by abcdefg

Replied by abcdefg on topic plasma control panel

Phil,

Just wondering what program you used to draw up that diagram, I am about to convert my machine to open source linux from CommandCNC and I need to draw up something very similar. You wouldnt happen to have the diagram in a DWG format you could share?

Just wondering what program you used to draw up that diagram, I am about to convert my machine to open source linux from CommandCNC and I need to draw up something very similar. You wouldnt happen to have the diagram in a DWG format you could share?

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

23 Apr 2019 09:55 #131618

by phillc54

Replied by phillc54 on topic plasma control panel

Here you go, the forum doesn't like DWG so just take .TXT off the end. If that is no good I can do DXF. I use QCAD-Pro.

Cheers, Phill.

Cheers, Phill.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11603

- Thank you received: 3900

23 Apr 2019 10:06 - 23 Apr 2019 10:07 #131620

by rodw

Replied by rodw on topic plasma control panel

Phil, Aside from adding limit switches it looks good! You got the inputs so put them in where you can. I use PNP prox sensors so all wiring is on the gantry. On the Z axis, I ran a 9 wire cable up with DB9 connectors. 2 wires for 24 volts and that left 7 inputs.

PCW has suggested you can use the onboard spindle relay to turn the torch on but I do it the way you do it.

To be compliant you are not meant to use relays on an estop circuit as it introduces a further point of failure. I used a cheap estop from Jaycar which has two sides to it. One sends a signal to the 7i76e and the other side trjps power to the stepper controller 48 v power supply.

Then I added a pendant and another estop button which are all chained together in hal using estop-latch.

If I did estop again I would use one of these switches becasue you can clip on additional switch mechanisims behind the button.

oceancontrols.com.au/HNR-241.html

Finally a friend suggested to add a led indicator for each power supply in the system (Plus I have one on the gantry). I have found that very useful isolating faults. You wonder why its not working and then you check all the power is up before panicking!. I added another LED on the gantry breakout box power.

PCW has suggested you can use the onboard spindle relay to turn the torch on but I do it the way you do it.

To be compliant you are not meant to use relays on an estop circuit as it introduces a further point of failure. I used a cheap estop from Jaycar which has two sides to it. One sends a signal to the 7i76e and the other side trjps power to the stepper controller 48 v power supply.

Then I added a pendant and another estop button which are all chained together in hal using estop-latch.

If I did estop again I would use one of these switches becasue you can clip on additional switch mechanisims behind the button.

oceancontrols.com.au/HNR-241.html

Finally a friend suggested to add a led indicator for each power supply in the system (Plus I have one on the gantry). I have found that very useful isolating faults. You wonder why its not working and then you check all the power is up before panicking!. I added another LED on the gantry breakout box power.

Last edit: 23 Apr 2019 10:07 by rodw.

The following user(s) said Thank You: phillc54

Please Log in or Create an account to join the conversation.

- abcdefg

- Offline

- Platinum Member

-

Less

More

- Posts: 1132

- Thank you received: 533

20 May 2019 23:51 - 21 May 2019 23:35 #134415

by abcdefg

Replied by abcdefg on topic plasma control panel

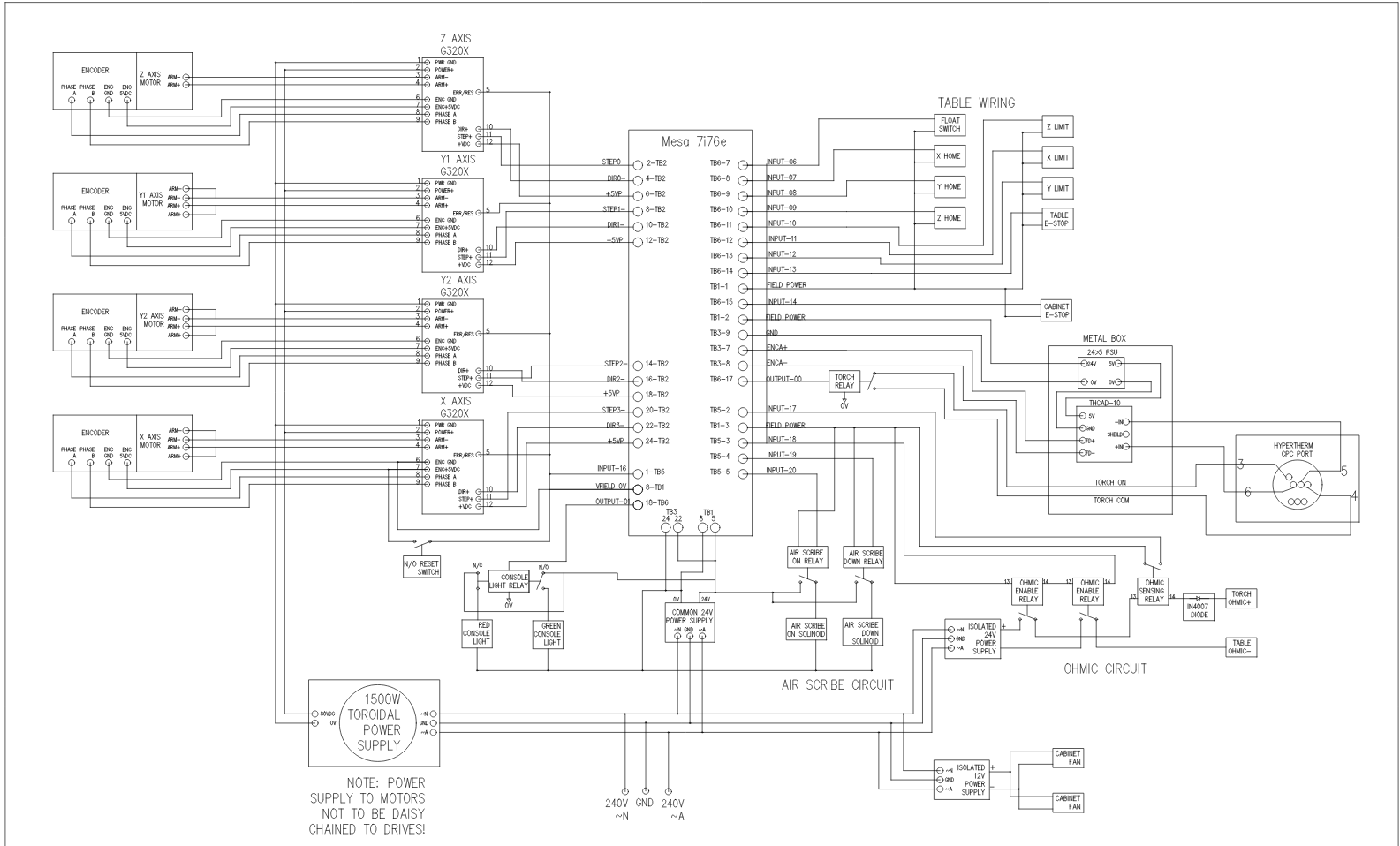

Hi Guys,

Instead of starting a new topic I thought I would add to this one,

Can I get some help proof reading my wiring diagram,

There might be some things that stand out that I should change, Just want to be sure before wiring up the beast!

Instead of starting a new topic I thought I would add to this one,

Can I get some help proof reading my wiring diagram,

There might be some things that stand out that I should change, Just want to be sure before wiring up the beast!

Last edit: 21 May 2019 23:35 by abcdefg.

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2345

21 May 2019 00:23 - 21 May 2019 00:37 #134417

by Grotius

Replied by Grotius on topic plasma control panel

@Stefan,

Your Pdf is rotated 90 degrees. My neck could not last that long.

Your mese thcad10.... You use a divided arc voltage in from cpc 5 and 6...

I thought for your resolution, mesa is designed for a raw arc voltage? If not why don't you use 0 to 10v input with different jumper settings in HP?

The Metal Box text can be also, " thc module "

I miss the future modbuss port and the future mobbuss connection to the mesa. This one is easy. The python code for the modbuss HP protocoll is provided by the pakastani/india friend at this forum about 2 years ago.

The Estop circuit is a problem. Are you in America?

For The fabricator i give a value of 8 out of 10 for this post. Very, very nice to see this development into the linuxcnc forum.

Nice done !! Very good illustrated. It does me to think about manhatten style. And if that is so, Mesa is learning from you.

Your Pdf is rotated 90 degrees. My neck could not last that long.

Your mese thcad10.... You use a divided arc voltage in from cpc 5 and 6...

I thought for your resolution, mesa is designed for a raw arc voltage? If not why don't you use 0 to 10v input with different jumper settings in HP?

The Metal Box text can be also, " thc module "

I miss the future modbuss port and the future mobbuss connection to the mesa. This one is easy. The python code for the modbuss HP protocoll is provided by the pakastani/india friend at this forum about 2 years ago.

The Estop circuit is a problem. Are you in America?

For The fabricator i give a value of 8 out of 10 for this post. Very, very nice to see this development into the linuxcnc forum.

Nice done !! Very good illustrated. It does me to think about manhatten style. And if that is so, Mesa is learning from you.

Attachments:

Last edit: 21 May 2019 00:37 by Grotius.

The following user(s) said Thank You: abcdefg

Please Log in or Create an account to join the conversation.

- abcdefg

- Offline

- Platinum Member

-

Less

More

- Posts: 1132

- Thank you received: 533

21 May 2019 00:45 #134418

by abcdefg

Replied by abcdefg on topic plasma control panel

Thanks for that,

How do you suggest I wire the E-stop circuit? I am in Australia.

I have read that putting a E-stop between the power supply and the servo drives is a bad idea, Gecko clearly say in there manual that this will damage if not destroy the drive ,

I have also read that putting a disconnect on the AC side of the power supply can damage drives and motors

How do you suggest I wire the E-stop circuit? I am in Australia.

I have read that putting a E-stop between the power supply and the servo drives is a bad idea, Gecko clearly say in there manual that this will damage if not destroy the drive ,

I have also read that putting a disconnect on the AC side of the power supply can damage drives and motors

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2345

21 May 2019 01:18 - 21 May 2019 01:30 #134423

by Grotius

Replied by Grotius on topic plasma control panel

@Stefan,

The most safe option is a hard wired (physical wired) E-stop-out function to switch off the main power of the machine.

This above is okey to do in Europe following CE.

If it damages your servo drive, that is not important for court. Court only askes : why is employee damaged? And what are your preqourtions following the spec's in law.

So for Australia, you can contact a local safety institute to take care of the situation.

They will provide you information how to make your machine safe by law. It depend's on machine speed, machine risk class, etc.

For example, a waterjet will provide 4000 bar and is provided with safety line around the machine, because of danger.

Best option is to ask your local safety agent. Most of the advice is for free.

The second way is to use a 2 channel safety channel. This is mostly used by the modern automotive industrie.

forum.linuxcnc.org/24-hal-components/223...?start=710#gallery-3

It's on our forum too. Chimeno, a core member : forum.linuxcnc.org/24-hal-components/223...ver?start=710#133267

For example, if you crash with a tesla, you must wait for tesla experts to make sure for the fire resque peolpe that there is no current around by the car when it's destructed in pieces. If you have a gasoline car, you could be in fire. So how to solve this? It's not solved by one button.

The most safe option is a hard wired (physical wired) E-stop-out function to switch off the main power of the machine.

This above is okey to do in Europe following CE.

If it damages your servo drive, that is not important for court. Court only askes : why is employee damaged? And what are your preqourtions following the spec's in law.

So for Australia, you can contact a local safety institute to take care of the situation.

They will provide you information how to make your machine safe by law. It depend's on machine speed, machine risk class, etc.

For example, a waterjet will provide 4000 bar and is provided with safety line around the machine, because of danger.

Best option is to ask your local safety agent. Most of the advice is for free.

The second way is to use a 2 channel safety channel. This is mostly used by the modern automotive industrie.

forum.linuxcnc.org/24-hal-components/223...?start=710#gallery-3

It's on our forum too. Chimeno, a core member : forum.linuxcnc.org/24-hal-components/223...ver?start=710#133267

For example, if you crash with a tesla, you must wait for tesla experts to make sure for the fire resque peolpe that there is no current around by the car when it's destructed in pieces. If you have a gasoline car, you could be in fire. So how to solve this? It's not solved by one button.

Last edit: 21 May 2019 01:30 by Grotius.

The following user(s) said Thank You: abcdefg

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.360 seconds