Low budget plasma setup, what do I need?

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

27 Apr 2019 16:35 #132098

by pl7i92

Replied by pl7i92 on topic Low budget plasma setup, what do I need?

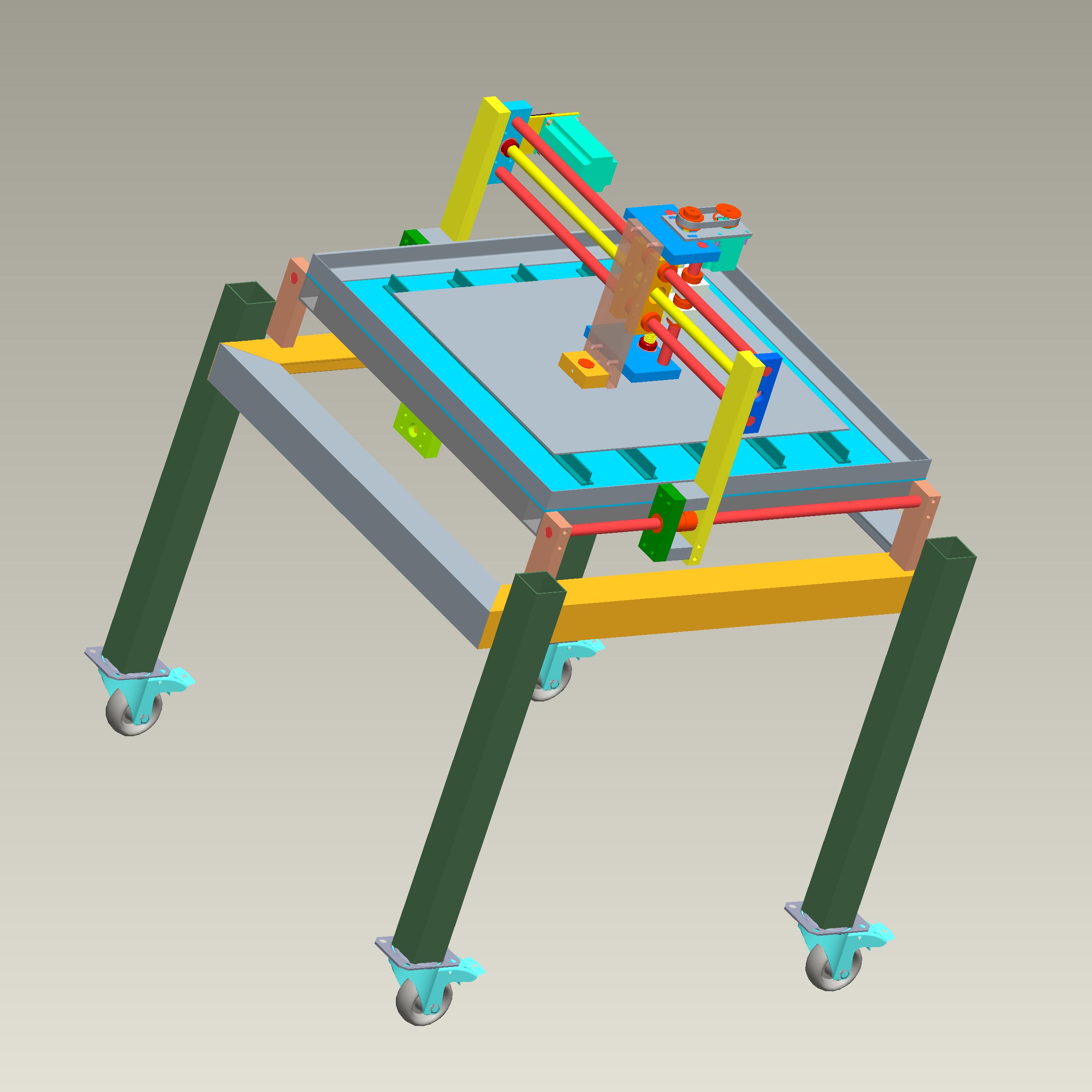

Attachments:

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

27 Apr 2019 16:47 #132105

by tecno

Replied by tecno on topic Low budget plasma setup, what do I need?

I will design mine to take 1000x500 material size.

Plan is to have a stand with water-pan outside and the CNC frame is to be lifted in place to register on the stand.

Budget is very low, I have the material for the CNC frame that will be 80x40 Bosch alu extrusions. Linear rails I already have Bosh R1651. Not decided yet how to drive my X/Y but probably timing-belt as the frame needs to be kind of rugged with minimal manhandling problems during storage.

I have to purchase the material for the stand.

Plan is to have a stand with water-pan outside and the CNC frame is to be lifted in place to register on the stand.

Budget is very low, I have the material for the CNC frame that will be 80x40 Bosch alu extrusions. Linear rails I already have Bosh R1651. Not decided yet how to drive my X/Y but probably timing-belt as the frame needs to be kind of rugged with minimal manhandling problems during storage.

I have to purchase the material for the stand.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11666

- Thank you received: 3930

27 Apr 2019 21:55 #132126

by rodw

Replied by rodw on topic Low budget plasma setup, what do I need?

I think 60mm would be OK. I started with a 150mm ball screw and by the time its was built travel is a maximum of 84mm and a lot of that (10-15mm) is currently below the slats based on where I have clamped off the torch.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21227

- Thank you received: 7249

28 Apr 2019 00:08 #132136

by tommylight

Replied by tommylight on topic Low budget plasma setup, what do I need?

That is usable for sure. If you intend to use floating head ( highly recommended ), make it so it has as little travel to trip the switch as possible.

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

28 Apr 2019 08:31 #132163

by tecno

Replied by tecno on topic Low budget plasma setup, what do I need?

OK I hear what you say Tommy.

So I need to shout out to PCW for some help to add code for 7i37 (P2 or P3) as I will need inputs to get a floating head switch working.

So I need to shout out to PCW for some help to add code for 7i37 (P2 or P3) as I will need inputs to get a floating head switch working.

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

28 Apr 2019 13:33 - 28 Apr 2019 13:43 #132175

by tecno

Replied by tecno on topic Low budget plasma setup, what do I need?

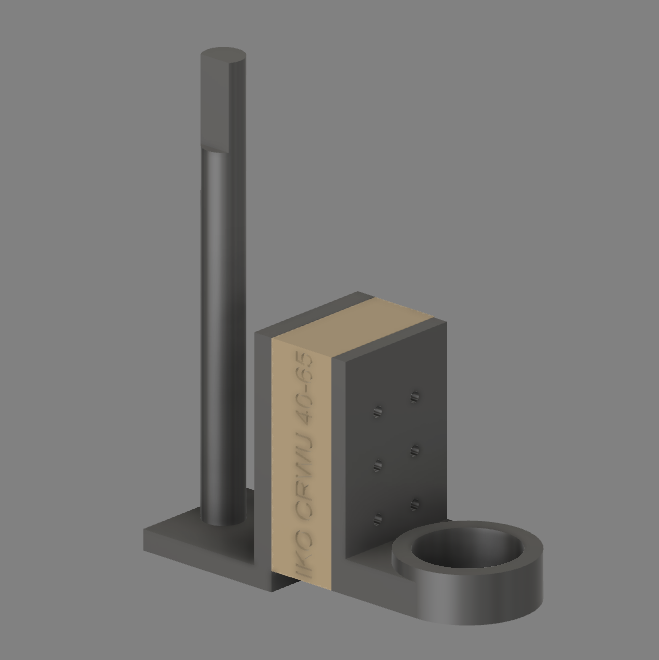

Attachments:

Last edit: 28 Apr 2019 13:43 by tecno. Reason: added picture

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

28 Apr 2019 15:54 #132182

by pl7i92

Replied by pl7i92 on topic Low budget plasma setup, what do I need?

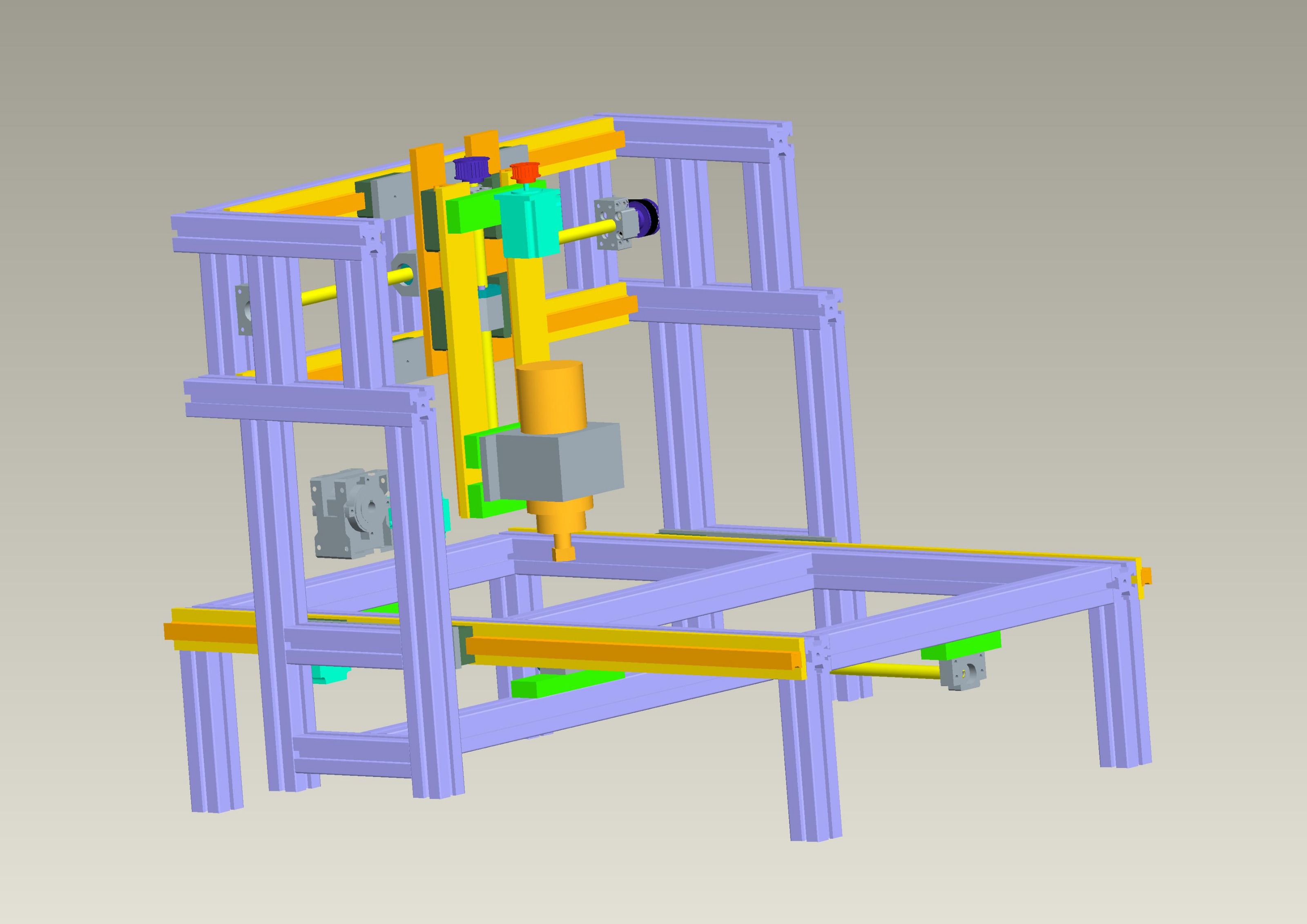

Attachments:

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

28 Apr 2019 16:28 #132186

by tecno

Replied by tecno on topic Low budget plasma setup, what do I need?

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21227

- Thank you received: 7249

29 Apr 2019 01:40 #132227

by tommylight

Replied by tommylight on topic Low budget plasma setup, what do I need?

One rail on each axis, linear rails, mind you. Nice!

That should work nicely for that size.

That should work nicely for that size.

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

29 Apr 2019 06:38 #132246

by pl7i92

Replied by pl7i92 on topic Low budget plasma setup, what do I need?

im not going with toms suggestion one rail at a 800mm Span

you need to go double rail even if you use SBR12 better then leave it with dirt running on aluminium

and on that size it is a posible middle Ballscrew drive

as special as he gots very stiff framing

he also planing to use a water plate you need no more then 2inches of water table hight pool seeling clue is enoff to hold the metal together

at that length and width hight

if you use L-profile it will give you even more stiffness

you need to go double rail even if you use SBR12 better then leave it with dirt running on aluminium

and on that size it is a posible middle Ballscrew drive

as special as he gots very stiff framing

he also planing to use a water plate you need no more then 2inches of water table hight pool seeling clue is enoff to hold the metal together

at that length and width hight

if you use L-profile it will give you even more stiffness

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.238 seconds