Inputs & outputs & relays ohmic

- JTknives

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 243

- Thank you received: 32

21 Apr 2019 04:17 #131368

by JTknives

Inputs & outputs & relays ohmic was created by JTknives

So as the title says rather cleverly I might add I'm wondering how many realys and Inputs/outputs I need. I have everything with the stepper motors encoders wired up as well as the limit switches. These switched include the X, Y, Z and Z floating head switch.

Now was moving onto the actual control of the plasma its self. I'm going to use a hyperthermia 30XP so I don't have an interface on the plasma to connect to. I'm guessing I'm going to need a relay for the torch start. Does that need to be a DPDT NO. That way the 7i76 knows when it's not triggered by feeding back through the closed leg? I will be using a thcad10 which I know will need some resistors to work with the 30XP. I do have a floating Z with a NC switch. It's set up so when the torch touches off the slide lifts off the switch closing it. It's a very accurate switch designed for tool setters for cnc machines.

The next question is incorporating ohmic and what relays I need for that. I'm guessing I can use the 30XP as it's consumables are shielded except the the fine cut.

I'm guessing there is some clever relay circuitry to incorporate this all together and prevent blasting the 7i76ED with 300v when it fires. And speaking of firing how is the arc ok signal generated for LinuxCNC to see. I would think it would involve an amp reading which is sent back to the analog inputs. But I could be way off.

Thanks guys for any tips or help you can provide. I'm so close to cutting I can taste it lol.

JTknives

Now was moving onto the actual control of the plasma its self. I'm going to use a hyperthermia 30XP so I don't have an interface on the plasma to connect to. I'm guessing I'm going to need a relay for the torch start. Does that need to be a DPDT NO. That way the 7i76 knows when it's not triggered by feeding back through the closed leg? I will be using a thcad10 which I know will need some resistors to work with the 30XP. I do have a floating Z with a NC switch. It's set up so when the torch touches off the slide lifts off the switch closing it. It's a very accurate switch designed for tool setters for cnc machines.

The next question is incorporating ohmic and what relays I need for that. I'm guessing I can use the 30XP as it's consumables are shielded except the the fine cut.

I'm guessing there is some clever relay circuitry to incorporate this all together and prevent blasting the 7i76ED with 300v when it fires. And speaking of firing how is the arc ok signal generated for LinuxCNC to see. I would think it would involve an amp reading which is sent back to the analog inputs. But I could be way off.

Thanks guys for any tips or help you can provide. I'm so close to cutting I can taste it lol.

JTknives

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

21 Apr 2019 05:32 - 21 Apr 2019 05:34 #131371

by rodw

Replied by rodw on topic Inputs & outputs & relays ohmic

I think I've ended up with 4 relays on my machine

1. Stepper motor disable on estop (optional but due to having an estop on a wireless pendant)

2. Torch on relay but PCW has suggested using the spindle output on the 7i76 so you might be able to drop it

3. Ohmic enable relay (triggered by an output)

4. Ohmic sensing relay (input)

5. IN4007 1000 volt diode

6. Dedicated 24 volt isolated power supply Meanwell 0.5 amp approx

I think I have it right. For the arc, the torch is negative and the work piece is positive.

So the isolated ohmic power supply (-24v) is earthed to the table

My wire on the torch is 24v positive

The Ohmic sensing relay is triggered when the shield touches the workpiece and sends 24v field power to an input but:

The Enable relay ensures the power to the ohmic sensing relay is only enabled when probing and turned off at other times.

The diode will prevent a reverse current flow if something goes wrong with the arc voltage.

Initially, I had the -24v going through a diode to earth as well but I had some spurious voltage potentials floating around between the torch and the table so took the diode out of the equation.

1. Stepper motor disable on estop (optional but due to having an estop on a wireless pendant)

2. Torch on relay but PCW has suggested using the spindle output on the 7i76 so you might be able to drop it

3. Ohmic enable relay (triggered by an output)

4. Ohmic sensing relay (input)

5. IN4007 1000 volt diode

6. Dedicated 24 volt isolated power supply Meanwell 0.5 amp approx

I think I have it right. For the arc, the torch is negative and the work piece is positive.

So the isolated ohmic power supply (-24v) is earthed to the table

My wire on the torch is 24v positive

The Ohmic sensing relay is triggered when the shield touches the workpiece and sends 24v field power to an input but:

The Enable relay ensures the power to the ohmic sensing relay is only enabled when probing and turned off at other times.

The diode will prevent a reverse current flow if something goes wrong with the arc voltage.

Initially, I had the -24v going through a diode to earth as well but I had some spurious voltage potentials floating around between the torch and the table so took the diode out of the equation.

Last edit: 21 Apr 2019 05:34 by rodw.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21370

- Thank you received: 7288

21 Apr 2019 13:41 #131394

by tommylight

hy·per·ther·mi·a

/ˌhīpərˈTHərmēə/

nounMedicine

noun: hyperthermia

the condition of having a body temperature greatly above normal.

Replied by tommylight on topic Inputs & outputs & relays ohmic

Oh no, not hyperthermia please !!!I'm going to use a hyperthermia 30XP ......

hy·per·ther·mi·a

/ˌhīpərˈTHərmēə/

nounMedicine

noun: hyperthermia

the condition of having a body temperature greatly above normal.

Please Log in or Create an account to join the conversation.

- JTknives

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 243

- Thank you received: 32

21 Apr 2019 15:22 #131400

by JTknives

Replied by JTknives on topic Inputs & outputs & relays ohmic

You can thank my phones auto correct for that one lol.

Please Log in or Create an account to join the conversation.

- JTknives

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 243

- Thank you received: 32

21 Apr 2019 16:18 #131405

by JTknives

Are you saying that pins 5&6 on TB4 can be used to close the torch start switch?

Replied by JTknives on topic Inputs & outputs & relays ohmic

I think I've ended up with 4 relays on my machine

1. Stepper motor disable on estop (optional but due to having an estop on a wireless pendant)

2. Torch on relay but PCW has suggested using the spindle output on the 7i76 so you might be able to drop it

3. Ohmic enable relay (triggered by an output)

4. Ohmic sensing relay (input)

5. IN4007 1000 volt diode

6. Dedicated 24 volt isolated power supply Meanwell 0.5 amp approx

I think I have it right. For the arc, the torch is negative and the work piece is positive.

So the isolated ohmic power supply (-24v) is earthed to the table

My wire on the torch is 24v positive

The Ohmic sensing relay is triggered when the shield touches the workpiece and sends 24v field power to an input but:

The Enable relay ensures the power to the ohmic sensing relay is only enabled when probing and turned off at other times.

The diode will prevent a reverse current flow if something goes wrong with the arc voltage.

Initially, I had the -24v going through a diode to earth as well but I had some spurious voltage potentials floating around between the torch and the table so took the diode out of the equation.

Are you saying that pins 5&6 on TB4 can be used to close the torch start switch?

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

Less

More

- Posts: 757

- Thank you received: 216

21 Apr 2019 18:10 #131414

by islander261

Replied by islander261 on topic Inputs & outputs & relays ohmic

1. The use of an opto isolator is strongly advised because it allows probing at much lower voltages and current.

2. The ohmic enable relay is to physically disconnect the sensing circuit from the work piece and torch shield when not probing. This needs to a single Double Pole (DP) or two Single Pole (SP) (what I have) relays.

3. You must be sure the power supply is truly isolated. This causes the most problem for people. Check that the output minus is not internally connected to the safety ground, third wire or DIN rail clamp or to the neutral wire.

4. Please find attached the circuit I have used for several years with no problems.

John

2. The ohmic enable relay is to physically disconnect the sensing circuit from the work piece and torch shield when not probing. This needs to a single Double Pole (DP) or two Single Pole (SP) (what I have) relays.

3. You must be sure the power supply is truly isolated. This causes the most problem for people. Check that the output minus is not internally connected to the safety ground, third wire or DIN rail clamp or to the neutral wire.

4. Please find attached the circuit I have used for several years with no problems.

John

Attachments:

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

21 Apr 2019 19:00 #131419

by rodw

Yes, I believe so.

Replied by rodw on topic Inputs & outputs & relays ohmic

Are you saying that pins 5&6 on TB4 can be used to close the torch start switch?

Yes, I believe so.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

21 Apr 2019 19:06 #131420

by rodw

Hmm, thanks, I'll change some wiring on the workpiece side. Something was worrying me.

I know you've shared that circuit several times but when I needed it, I couldn't find it.

Replied by rodw on topic Inputs & outputs & relays ohmic

1

2. The ohmic enable relay is to physically disconnect the sensing circuit from the work piece and torch shield when not probing. This needs to a single Double Pole (DP) or two Single Pole (SP) (what I have) relays.

Hmm, thanks, I'll change some wiring on the workpiece side. Something was worrying me.

I know you've shared that circuit several times but when I needed it, I couldn't find it.

Please Log in or Create an account to join the conversation.

- JTknives

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 243

- Thank you received: 32

21 Apr 2019 23:40 #131432

by JTknives

Replied by JTknives on topic Inputs & outputs & relays ohmic

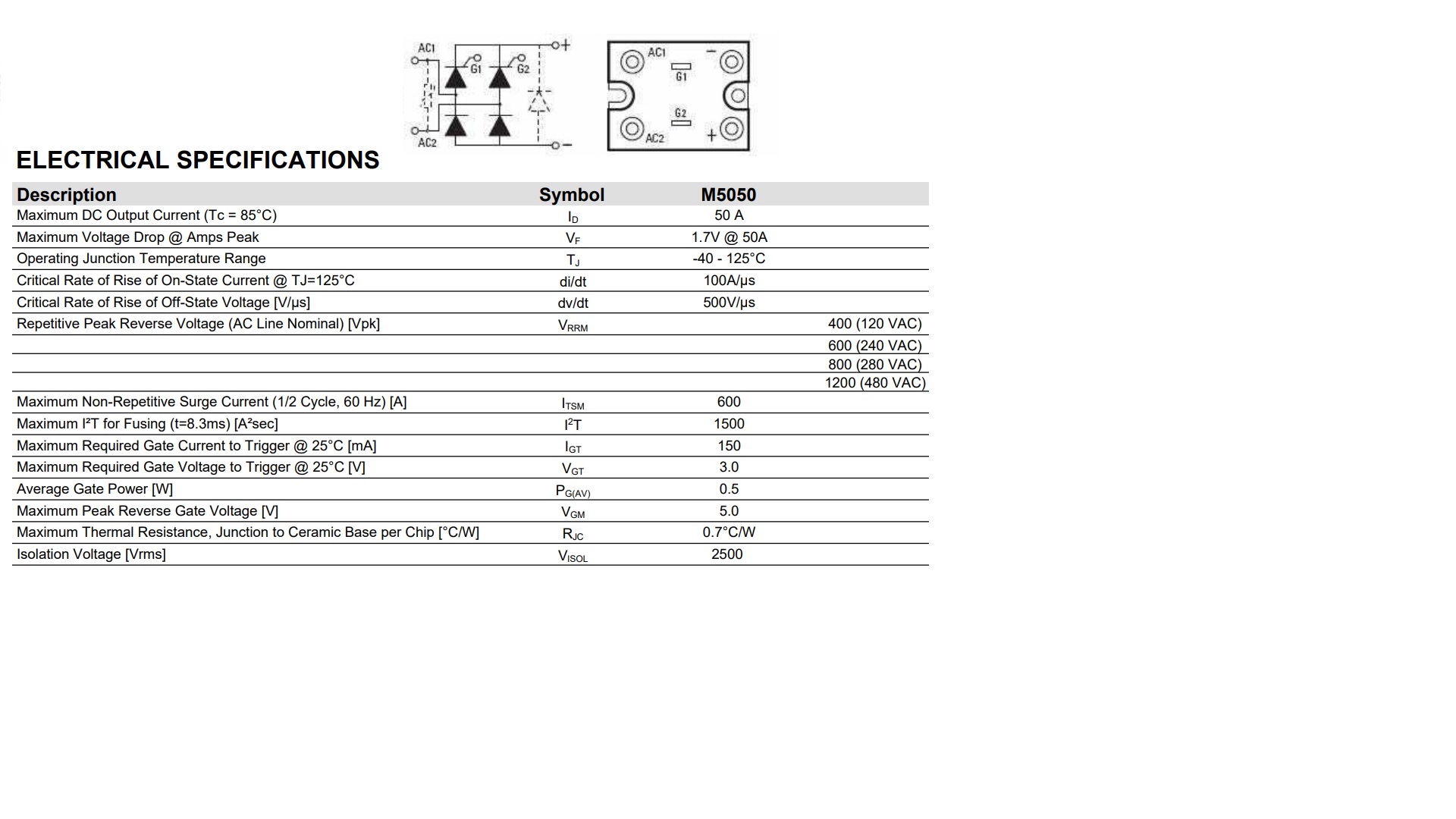

OK, looking across the schismatic i see a few things. First your running the 7i76 off 24v field power and the only other supply you have is a 12v supply for the probing. you run the -12v through the opto and then through a NO relay to the shield. relay one and 2 are both triggered by pin22 on TB6. relay 2 connects the +12v to the work. when shield touches the work the opto goes high and sends field voltage to pin12 on tb6. And your torch "on" is ran through relay 4 which is NO and triggered by pin23 on tb6.

now onto the question(s)

Can I just run my probe sensing through a crydom M505012F. I have 2 just laying around and been looking for a use for them. here is their layout. also my 7i76 is the ED version so its outputs are syncing not sourcing.

now onto the question(s)

Can I just run my probe sensing through a crydom M505012F. I have 2 just laying around and been looking for a use for them. here is their layout. also my 7i76 is the ED version so its outputs are syncing not sourcing.

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21370

- Thank you received: 7288

22 Apr 2019 00:41 #131435

by tommylight

The problem with them is that once opened they will remain opened until there is not more current flowing through them and that is something that in AC happens 50 or 60 times per second while in DC it does not until the power is cut off.

Also that is a non isolated type so in the future if you use them, keep that in mind.

Replied by tommylight on topic Inputs & outputs & relays ohmic

Unfortunately no, those are SCR used for switching AC, not DC.Can I just run my probe sensing through a crydom M505012F.

The problem with them is that once opened they will remain opened until there is not more current flowing through them and that is something that in AC happens 50 or 60 times per second while in DC it does not until the power is cut off.

Also that is a non isolated type so in the future if you use them, keep that in mind.

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.347 seconds