New Plasma build question

- Clive S

- Away

- Platinum Member

-

- Posts: 2203

- Thank you received: 482

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11732

- Thank you received: 3973

Please Log in or Create an account to join the conversation.

- Clive S

- Away

- Platinum Member

-

- Posts: 2203

- Thank you received: 482

Z axis nearly finished with floating head. photos.app.goo.gl/mEhB8WJ8V7MzB3ks5

Needs the sensors fitting yet. I know I need a floating head switch does it also need a breakaway switch as I seem to have read somewhere that the float switch will do both.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

- Posts: 21368

- Thank you received: 7288

Please Log in or Create an account to join the conversation.

- Clive S

- Away

- Platinum Member

-

- Posts: 2203

- Thank you received: 482

I now have the Z axis built and now need to work out the the floating head sensor and breakout sensor.

So; The floating head (with the torch on a separate magnetic mount) rides up & down on a rail about 75mm long.

What are the steps for this ie. Does the total Z axis (on the screw) move down until the torch hits the part then it keeps moving down until the floating head switch trips.

When this switch trips does it then does move the total Z axis up until the floating head trips again.

As the floating head must be in the down position with gravity when cutting.

Have I got this correct.?

I would like to put the breakout torch plate switch on a separate pin. Is this the correct way. I am using a 7i95 mesa

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

- Posts: 21368

- Thank you received: 7288

Please Log in or Create an account to join the conversation.

- Clive S

- Away

- Platinum Member

-

- Posts: 2203

- Thank you received: 482

There are two Z axis together for floating head, one with 10 - 20 mm travel for the switch, the other is the normal Z axis.

Yes I understand that I thought I said that here:

What are the steps for this ie. Does the total Z axis (on the screw) move down until the torch hits the part then it keeps moving down until the floating head switch trips.

When this switch trips does it then does move the total Z axis up until the floating head trips again.

As the floating head must be in the down position with gravity when cutting.

I have a separate switch already for the main Z axis fitted at the top.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

- Posts: 21368

- Thank you received: 7288

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11732

- Thank you received: 3973

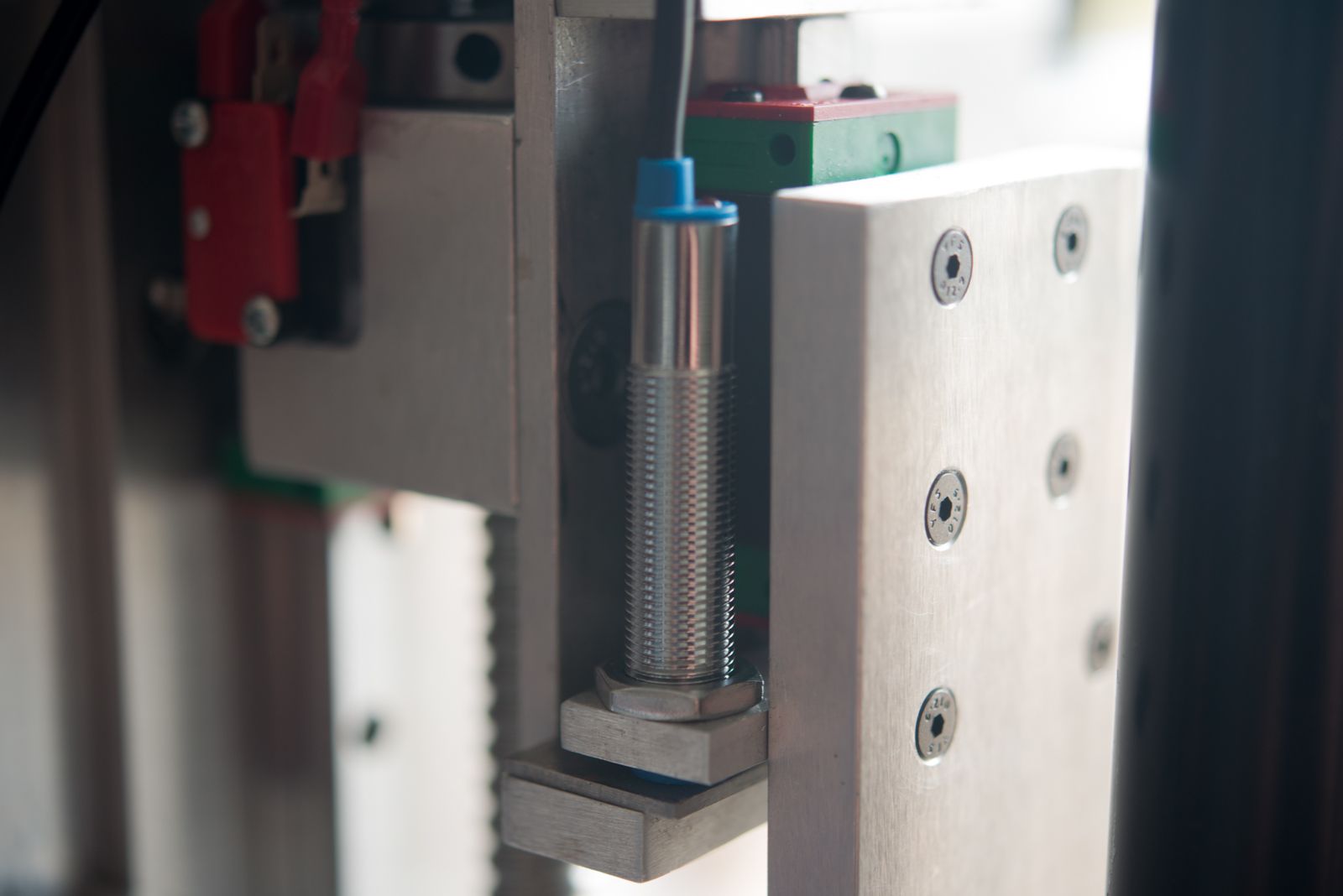

I think if I did this again, i'd probably just notch the side side of the plate and place a microswitch or more compact prox sensor as it hangs out a bit at the back now.

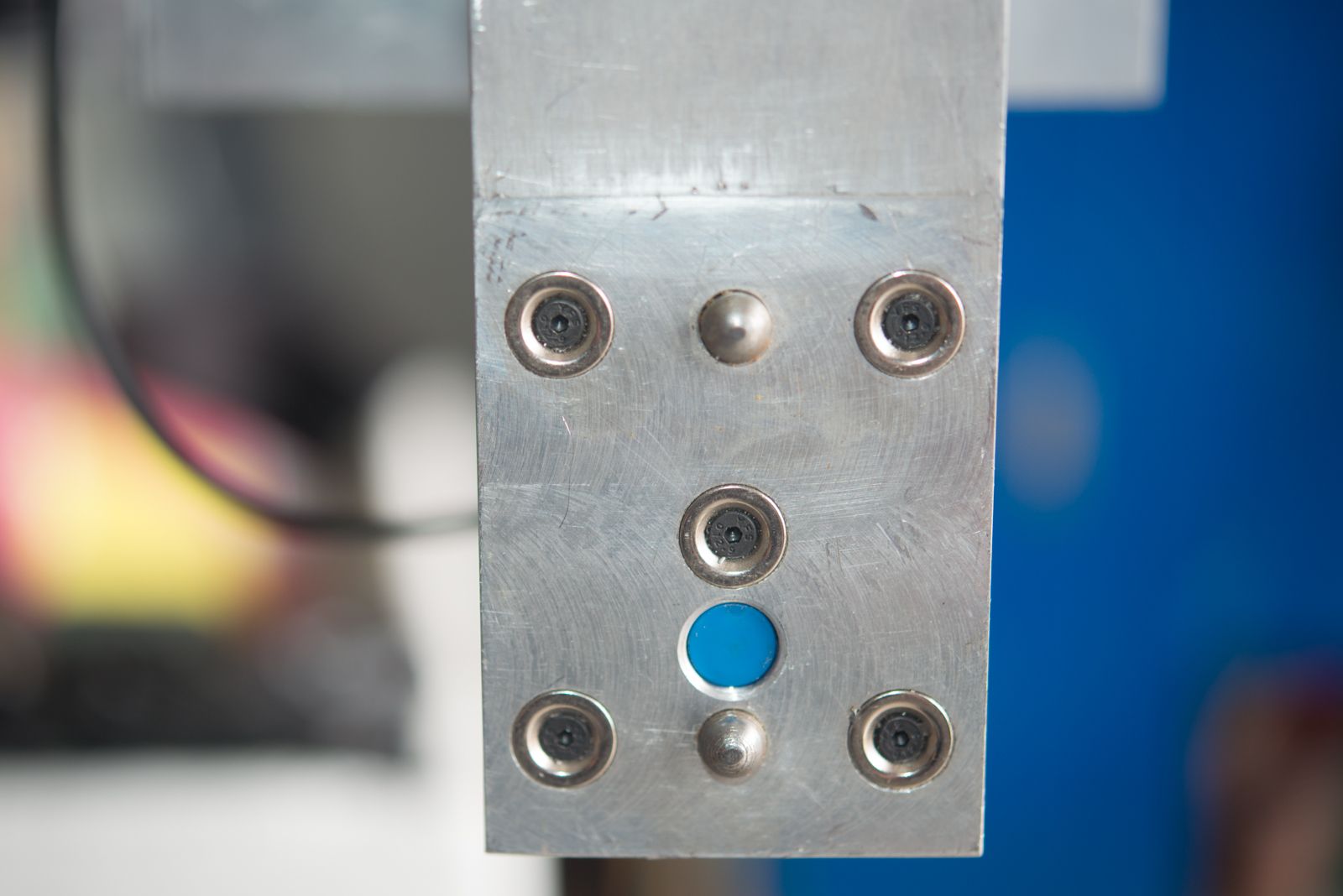

My float switch. I added a steel plate to make sure the prox xensor triggered but it was probably not required.

I subsequently added a set screw on the other side so I could fine tune the amount of sensor hysteresis. All I did was drill and tap a hole thru the same part the sensor is threaded into, insert a flat headed countersunk screw with a lock nut from the underside. That way I could easilly adjust the sensor distance so the hystersis is at a minimum.

And yes, the torch hangs at the lower position while cutting. When I was using Gcode, I probed towards the surface and then probed away at a slower speed until it reset.. Then set the material height after allowing for any offset for switch hysteresis (which is why I made that adjustable). I think plasmac does the same thing.

Please Log in or Create an account to join the conversation.

- Clive S

- Away

- Platinum Member

-

- Posts: 2203

- Thank you received: 482

Sorry I am still not sure I understand the logic. Looking at the last photo with the blue sensor and red micro switch is the plate to the right your floating plate? If that is so when probing that plate will move up towards the sensor OR is the sensor fixed to that plate so that the sensor moves with the plate away from the target.

What is the red micro switch for Is that your home switch.

You can see my home switch on my Z axis with a metal target. photos.google.com/photo/AF1QipNUdw-6hGS_...SRapcTq-N4AMKs6eNIo9

Is this logic correct:-

Does the total Z axis (on the screw) move down until the torch hits the part then it keeps moving down until the floating head switch trips.

When this switch trips does it then does move the total Z axis up until the floating head trips again.

As the floating head must be in the down position with gravity when cutting.

Please Log in or Create an account to join the conversation.