Bought material, the journey continues.

- CNCFred

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 217

- Thank you received: 43

22 Apr 2020 06:25 #165048

by CNCFred

Replied by CNCFred on topic Bought material, the journey continues.

I added my ngc file with manually added settings.

Did I get this right? if it reduces speed to 60% but is already slow for thick material is it not to slow then?

if I have a 90 degree lead in and lead out..can I still use overcut?

Did I get this right? if it reduces speed to 60% but is already slow for thick material is it not to slow then?

if I have a 90 degree lead in and lead out..can I still use overcut?

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

22 Apr 2020 06:34 #165049

by phillc54

Replied by phillc54 on topic Bought material, the journey continues.

You cannot have a leadout for overcut.

You have #<holes>=1 so that will work, that is for slow down only.

You are only cutting two 32.8mm holes so if you think you want to cut at full speed then just cut normally and disable THC in the Run Panel

You have #<holes>=1 so that will work, that is for slow down only.

You are only cutting two 32.8mm holes so if you think you want to cut at full speed then just cut normally and disable THC in the Run Panel

The following user(s) said Thank You: CNCFred

Please Log in or Create an account to join the conversation.

- CNCFred

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 217

- Thank you received: 43

22 Apr 2020 07:40 - 22 Apr 2020 07:42 #165053

by CNCFred

Replied by CNCFred on topic Bought material, the journey continues.

G3 I-16.4 I figured out  Now.

Now.

knowing gcode better the two holes would be possible with plasmac extra tab!! I guess.

Lucky me to get a 35mm hole as needed !!!!!!!.

seems compensation is quite a bit.

I will try with reduced speed that is fine!

the learning curve stays high.

I had to increase cutting height otherwise the torch runs into cutting dross .

If one circle is done but the other failed to start with the second only do I have to edit the Gcode file to start again only with the second one or is there a possibility to skip , or start at a gcode line?

haven't tested if torch enable works during a run??(that would be great)

knowing gcode better the two holes would be possible with plasmac extra tab!! I guess.

Lucky me to get a 35mm hole as needed !!!!!!!.

seems compensation is quite a bit.

I will try with reduced speed that is fine!

the learning curve stays high.

I had to increase cutting height otherwise the torch runs into cutting dross .

If one circle is done but the other failed to start with the second only do I have to edit the Gcode file to start again only with the second one or is there a possibility to skip , or start at a gcode line?

haven't tested if torch enable works during a run??(that would be great)

Last edit: 22 Apr 2020 07:42 by CNCFred.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21357

- Thank you received: 7286

22 Apr 2020 12:07 #165084

by tommylight

Replied by tommylight on topic Bought material, the journey continues.

On the axis screen, down where the gcode is shown, left click on the line you want to continue from, right click on that same line and click on "run from here".

Choose the line above M3 so it does not miss firing the torch.

Choose the line above M3 so it does not miss firing the torch.

The following user(s) said Thank You: CNCFred

Please Log in or Create an account to join the conversation.

- CNCFred

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 217

- Thank you received: 43

22 Apr 2020 14:41 #165110

by CNCFred

Replied by CNCFred on topic Bought material, the journey continues.

OK.next time I will use it. Thank you!

Do you think a waterpan in some sort of plastic is usable as well?

Do you think a waterpan in some sort of plastic is usable as well?

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21357

- Thank you received: 7286

22 Apr 2020 14:55 #165111

by tommylight

Replied by tommylight on topic Bought material, the journey continues.

No plastic !

Metal sheet, 2mm is OK, i make them out of 3mm thick sheet, always.

Metal sheet, 2mm is OK, i make them out of 3mm thick sheet, always.

The following user(s) said Thank You: CNCFred

Please Log in or Create an account to join the conversation.

- CNCFred

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 217

- Thank you received: 43

23 Apr 2020 19:10 - 23 Apr 2020 19:16 #165289

by CNCFred

Replied by CNCFred on topic Bought material, the journey continues.

Dear all,

at the end the torch dived again in the hole, so I had a look and it seems the 10mm lead out enables thc again?

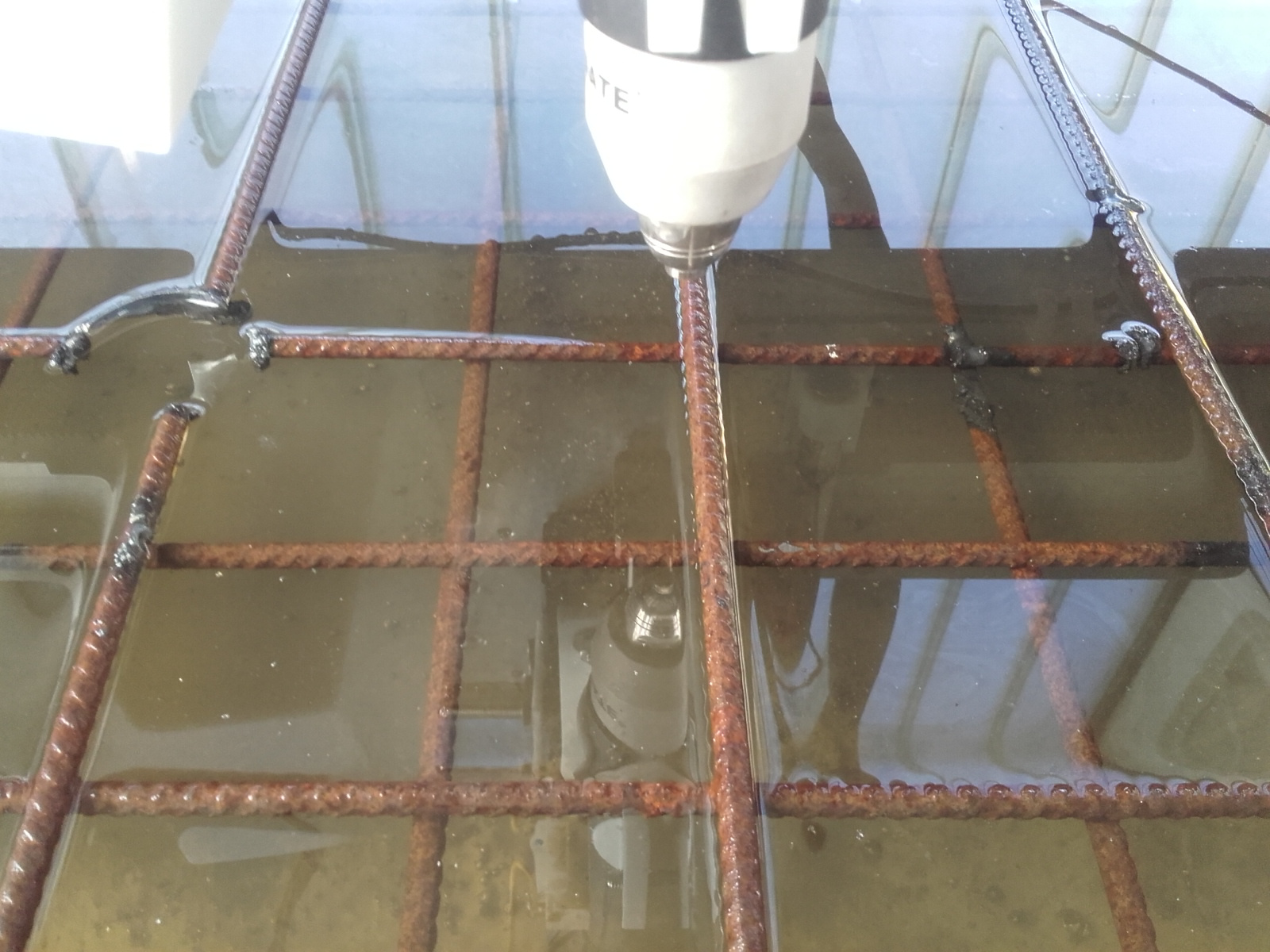

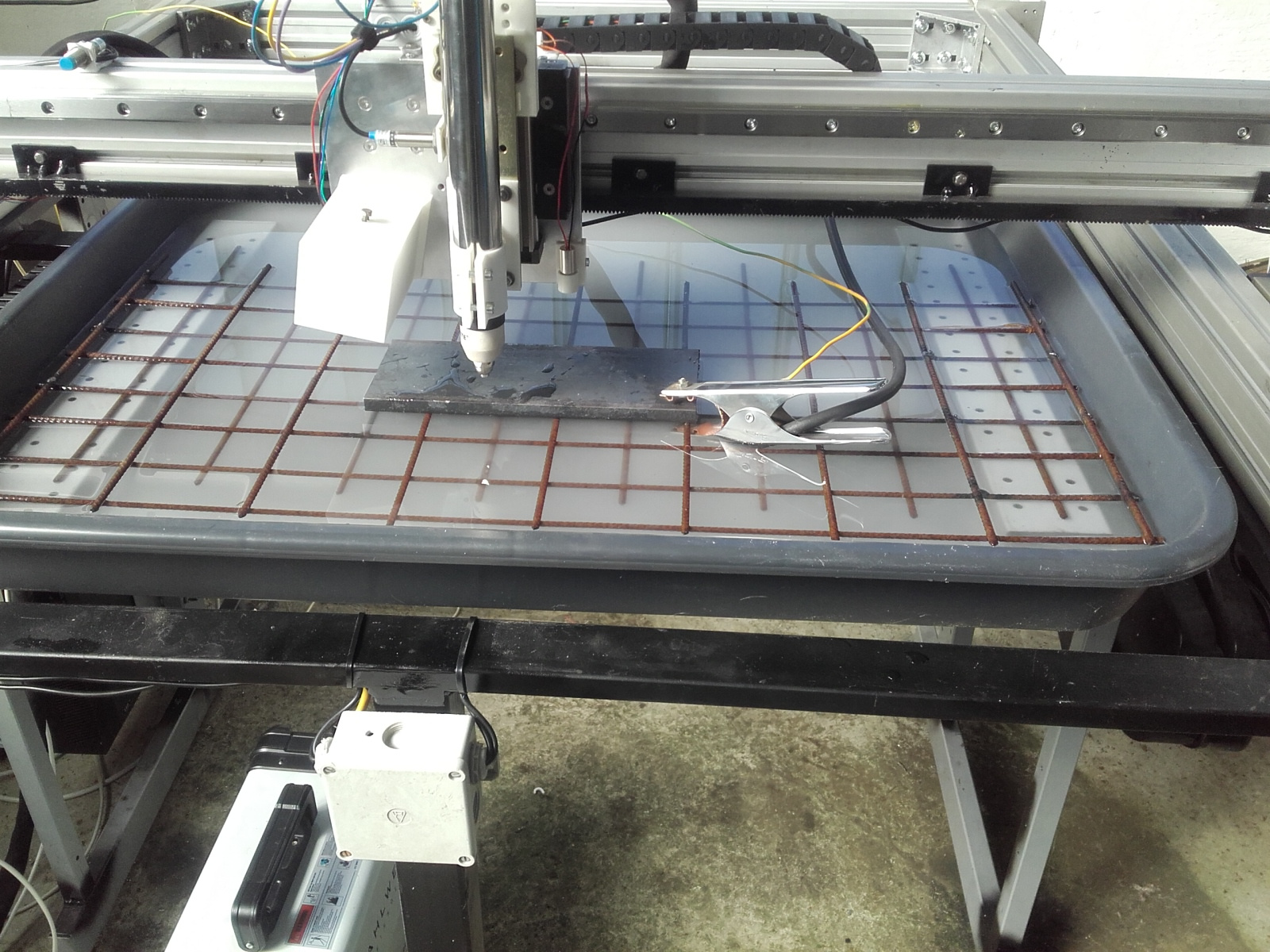

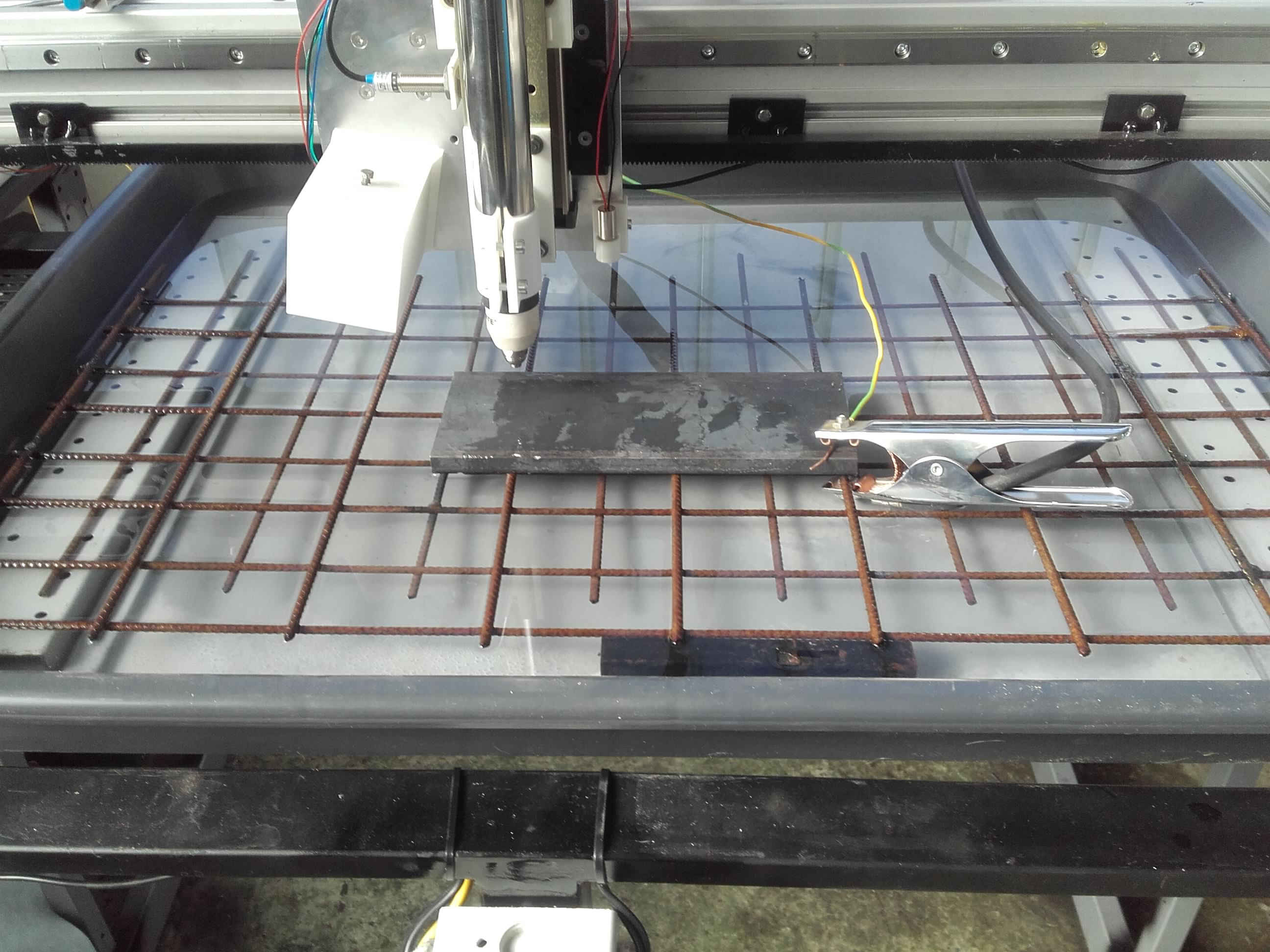

Tommylight sorry didn't get a metal pan but a plastic one for testing...this is great what a difference cutting .

pictures will follow

any hint how to embede youtube videos? video link and url did not work...

at the end the torch dived again in the hole, so I had a look and it seems the 10mm lead out enables thc again?

Tommylight sorry didn't get a metal pan but a plastic one for testing...this is great what a difference cutting .

pictures will follow

any hint how to embede youtube videos? video link and url did not work...

Last edit: 23 Apr 2020 19:16 by CNCFred.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21357

- Thank you received: 7286

23 Apr 2020 19:33 #165295

by tommylight

Replied by tommylight on topic Bought material, the journey continues.

That THCAD is quick ! !!

No lead out's for plasma cutting, just lead in.

On the first cut it went 5mm deep, on the second nearly 30mm !

And now you know why i insisted on covering the motor, water gets everywhere.

Nice work.

As for embedding youtube, open the video in browser, click on the link in the address bar and copy that. Works always.

No lead out's for plasma cutting, just lead in.

On the first cut it went 5mm deep, on the second nearly 30mm !

And now you know why i insisted on covering the motor, water gets everywhere.

Nice work.

As for embedding youtube, open the video in browser, click on the link in the address bar and copy that. Works always.

The following user(s) said Thank You: CNCFred

Please Log in or Create an account to join the conversation.

- CNCFred

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 217

- Thank you received: 43

23 Apr 2020 19:43 - 23 Apr 2020 19:45 #165298

by CNCFred

Replied by CNCFred on topic Bought material, the journey continues.

New nozzle and nice cut... Never the less to small the first hole... Fileing 12mm steel not much fun I can tell... So with a grinder the round one

Stopped the cut... Edited the second hole bit bigger started from gcode line! Great!

Is the kerf with different from material to material? Thickness?

The grid is to weak needs support.. The only material I had at the moment.

Glad I had a kilo baking soda at home....

Stopped the cut... Edited the second hole bit bigger started from gcode line! Great!

Is the kerf with different from material to material? Thickness?

The grid is to weak needs support.. The only material I had at the moment.

Glad I had a kilo baking soda at home....

Last edit: 23 Apr 2020 19:45 by CNCFred.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- CNCFred

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 217

- Thank you received: 43

23 Apr 2020 19:49 - 23 Apr 2020 20:02 #165299

by CNCFred

Replied by CNCFred on topic Bought material, the journey continues.

@Tommylight, thx for mentioning the motor cover!

I am also astonished how good rack and pinion works. Even I bought 10mm AT5 belt and racks.

Not using them at the moment.

Did you see the dive-in on the z axis numbers? Got to check that out. Man you are good!

I am also astonished how good rack and pinion works. Even I bought 10mm AT5 belt and racks.

Not using them at the moment.

Did you see the dive-in on the z axis numbers? Got to check that out. Man you are good!

Last edit: 23 Apr 2020 20:02 by CNCFred.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.861 seconds