Downunder 4x2 build

- OxxAndBert

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 17

15 Jul 2021 13:18 #214869

by OxxAndBert

Replied by OxxAndBert on topic Downunder 4x2 build

Thanks Tommy. I have access to plenty of old laptop power supplies through my day job, so will grab one of those and hook up a prox sensor to test.

We've just been hit with another 5-day covid lockdown here in Victoria, so I suddenly have another priority task at home. Work out a way (that doesn't involve using my back) to move the 10m3 of gravel that was delivered today and is currently blocking my driveway.

It was going to be spread by a contractor tomorrow, but he can't come now until after the lockdown.

I think I see the construction of a makeshift dozer blade for the forklift in my immediate future......

Steve

We've just been hit with another 5-day covid lockdown here in Victoria, so I suddenly have another priority task at home. Work out a way (that doesn't involve using my back) to move the 10m3 of gravel that was delivered today and is currently blocking my driveway.

It was going to be spread by a contractor tomorrow, but he can't come now until after the lockdown.

I think I see the construction of a makeshift dozer blade for the forklift in my immediate future......

Steve

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21162

- Thank you received: 7226

15 Jul 2021 15:57 #214891

by tommylight

Who said you need a crystal ball to see the future ?

Replied by tommylight on topic Downunder 4x2 build

I think I see the construction of a makeshift dozer blade for the forklift in my immediate future......

Who said you need a crystal ball to see the future ?

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11620

- Thank you received: 3911

16 Jul 2021 21:54 #215099

by rodw

Replied by rodw on topic Downunder 4x2 build

Something like a Meanwell MDR-60-24 power supply will set you back about $40 from element 14 will solve your power supply woes.

As far as the gravel, I'd offer to help but you are off limits for us in Queensland!

As far as the gravel, I'd offer to help but you are off limits for us in Queensland!

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 3990

- Thank you received: 994

16 Jul 2021 23:08 #215105

by BigJohnT

Replied by BigJohnT on topic Downunder 4x2 build

I'd be happy to spread your gravel with my `56 Ferguson F40 but I can't hold my breath that long to get there... and she is younger than me!

www.everythingattachments.com/v/vspfiles...ts/images/masf40.jpg

I wish mine looked that good... maybe one day.

JT

www.everythingattachments.com/v/vspfiles...ts/images/masf40.jpg

I wish mine looked that good... maybe one day.

JT

The following user(s) said Thank You: Coachbuilder

Please Log in or Create an account to join the conversation.

- OxxAndBert

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 17

24 Jul 2021 11:51 #215766

by OxxAndBert

Replied by OxxAndBert on topic Downunder 4x2 build

Thanks for the offers of help with the gravel guys

Gravel got sorted, and the makeshift blade worked well - but its a very fine line between getting enough bite with the blade or too much (in which case you've just dug in the drive wheels and beached yourself). Once you've got a solid base to work on its OK. Definitely not the right machine for the job but sometimes you have to make do with what you've got....

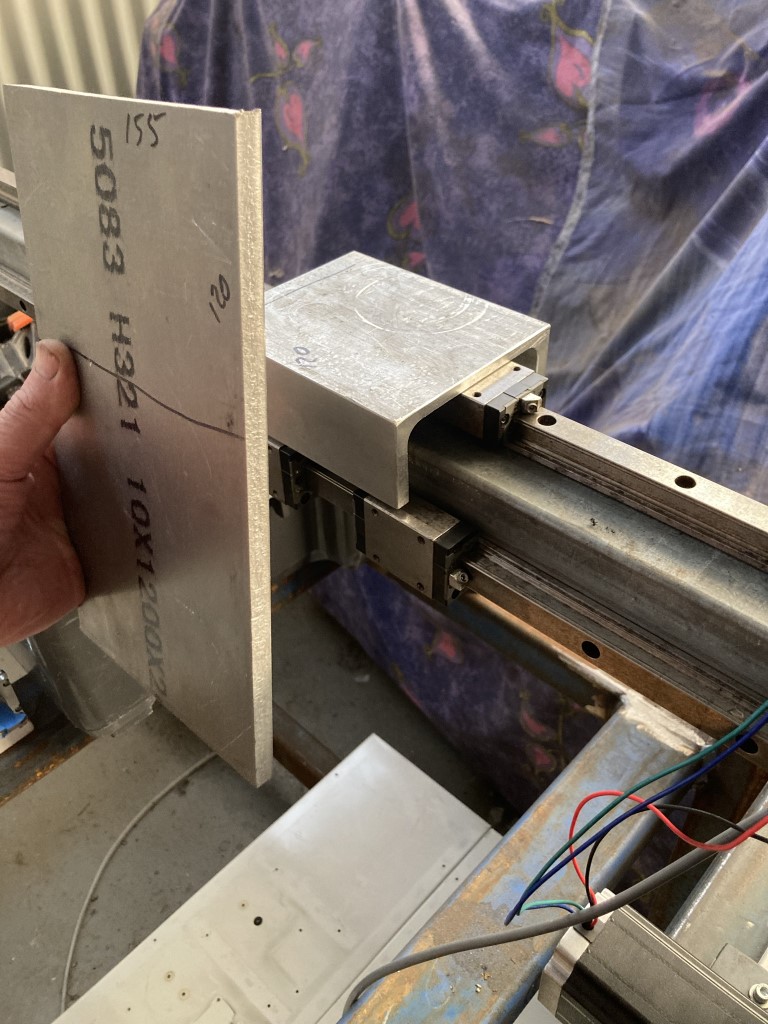

Got a bit more done over the last week. Made up the side plates - rough cut them with the cheap plasma then tacked together with the welder and drilled the holes etc on the mill so both sides were exactly the same.

Have one linear rail secured in place, and the other just has a single bolt at one end so I can get it all parallel.

First mistake of the build - due to uncontrolled change and not referring to design drawings!!

I've attached the RHS side rails with the long side vertical rather than flat as I'd originally drawn it up. That means the holes for the belt idler pulleys are too high up, and the pulleys will interfere with the side rail.

No biggie - I've got plenty of vertical distance down to the drive pulley so will just drill another couple of holes further down for the idlers.

I added horizontal rails across the front and back legs of the table to allow me to use a pallet jack to move it. I'm sure it will end up being a shelf, but for now just need the rails to be able to move it.

Cable chain arrived the other day, but still waiting for the pulleys and belts to turn up. before I can do anything more with the gantry drive.

Next step is probably to get the linear rails onto the gantry, and start looking into the Z axis.

Steve

Gravel got sorted, and the makeshift blade worked well - but its a very fine line between getting enough bite with the blade or too much (in which case you've just dug in the drive wheels and beached yourself). Once you've got a solid base to work on its OK. Definitely not the right machine for the job but sometimes you have to make do with what you've got....

Got a bit more done over the last week. Made up the side plates - rough cut them with the cheap plasma then tacked together with the welder and drilled the holes etc on the mill so both sides were exactly the same.

Have one linear rail secured in place, and the other just has a single bolt at one end so I can get it all parallel.

First mistake of the build - due to uncontrolled change and not referring to design drawings!!

I've attached the RHS side rails with the long side vertical rather than flat as I'd originally drawn it up. That means the holes for the belt idler pulleys are too high up, and the pulleys will interfere with the side rail.

No biggie - I've got plenty of vertical distance down to the drive pulley so will just drill another couple of holes further down for the idlers.

I added horizontal rails across the front and back legs of the table to allow me to use a pallet jack to move it. I'm sure it will end up being a shelf, but for now just need the rails to be able to move it.

Cable chain arrived the other day, but still waiting for the pulleys and belts to turn up. before I can do anything more with the gantry drive.

Next step is probably to get the linear rails onto the gantry, and start looking into the Z axis.

Steve

Please Log in or Create an account to join the conversation.

- OxxAndBert

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 17

24 Jul 2021 12:03 #215768

by OxxAndBert

Replied by OxxAndBert on topic Downunder 4x2 build

Bugger - just realised why the side rails needed to be long side horizontal -

Its to give enough width so the drive motors don't overhang the table.

Thankfully I'm well aware of my ability to take something simple and stuff it up, so the side rails are only tacked on so its an easy fix.

Another bonus is there's only 3 of the M4 holes for the linear rails tapped so far - not about 20...

And I shouldn't have to re-drill the belt idler pulley holes

Steve

Its to give enough width so the drive motors don't overhang the table.

Thankfully I'm well aware of my ability to take something simple and stuff it up, so the side rails are only tacked on so its an easy fix.

Another bonus is there's only 3 of the M4 holes for the linear rails tapped so far - not about 20...

And I shouldn't have to re-drill the belt idler pulley holes

Steve

Attachments:

Please Log in or Create an account to join the conversation.

- OxxAndBert

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 17

28 Nov 2021 08:38 #227801

by OxxAndBert

Replied by OxxAndBert on topic Downunder 4x2 build

Over 3 months since my last update (life gets in the way of projects), and not a huge amount done on the plasma.

New power source - SWS Speedcut 50 - finally arrived. Very happy with it so far. Simple to use, cuts great hand-held, and they now include the CNC interface with the standard model so no need to pay additional for that option.

Only extra I had to buy was the machine torch. Think that was AUD$180 and it takes the same consumables as the hand torch (PT-60 style).

Set at the maximum 50A setting it draws more current than my 240v 16A breaker can handle .

Pretty happy with this manual cut on 16mm material.

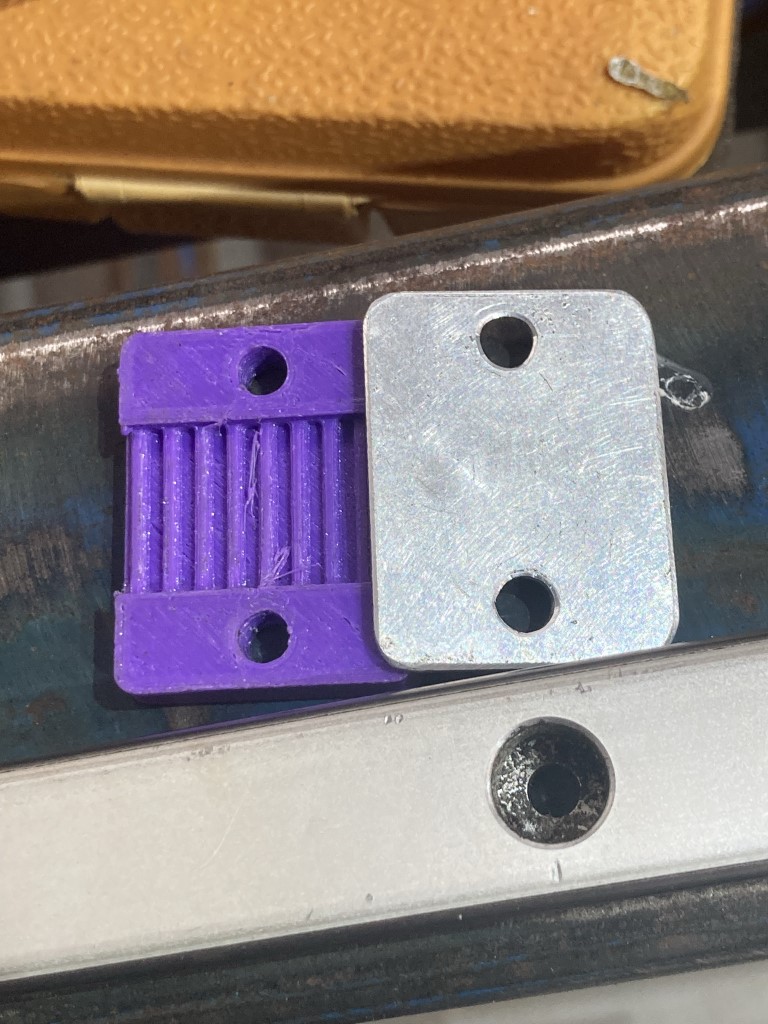

Made some bits to attach and tension the drive belts. Combination of 3D printed toothed plate and aluminium clamp sides. Riveted the adjuster together with some short pieces of 1/8" alloy TIG rod. The adjuster bolt piece was machined from solid on the lathe and mill.

Adjustment end:

Fixed end:

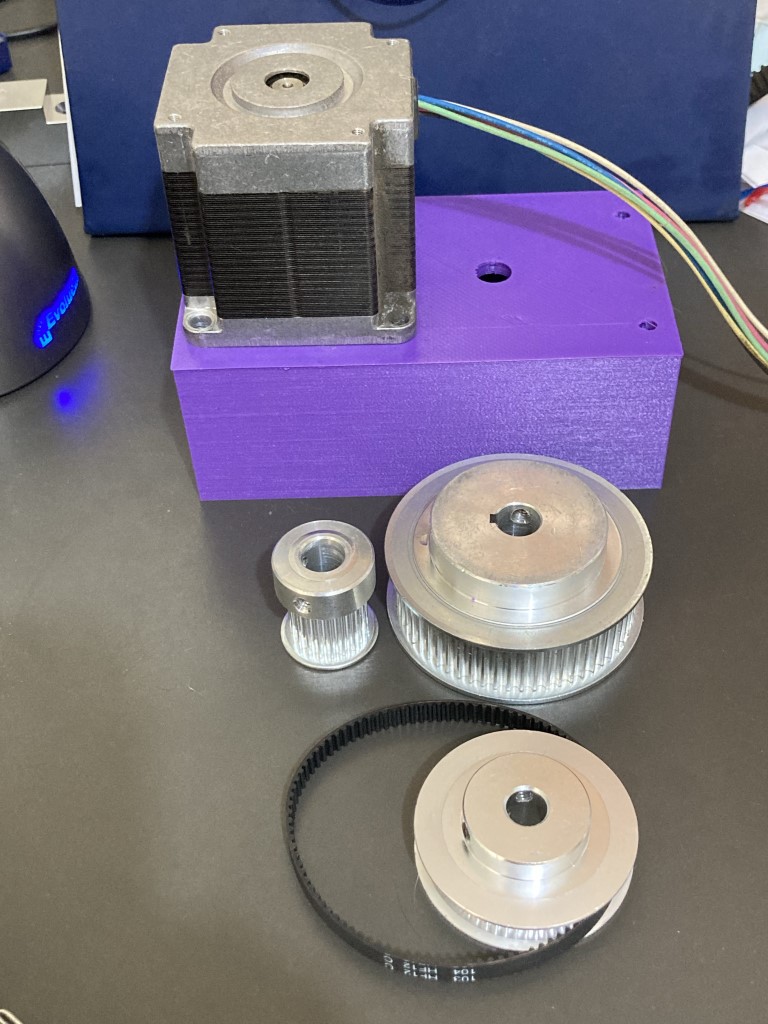

Machined up some idler pulleys and bits and got the reduction drive all sorted.

At that point I just HAD to make it move, so connected it to the Mesa 7i96 and the stepper drivers.

Slight issue in that because the motors are mirrored they were driving each side of the gantry in a different direction.

Looking through a few older posts here I worked out it just needed one of the Y-axis motors step and direction "invert" selected in pncConf.

Ran it again with that change and all good.

Have a couple of salvaged 15mm linear rails mounted on the gantry for the X-axis, and just starting to put some thought into making up the carriage. Found a piece of channel and some plate that could cut to size and bolted together and then mounted to the linear rail carriages.

Steve

New power source - SWS Speedcut 50 - finally arrived. Very happy with it so far. Simple to use, cuts great hand-held, and they now include the CNC interface with the standard model so no need to pay additional for that option.

Only extra I had to buy was the machine torch. Think that was AUD$180 and it takes the same consumables as the hand torch (PT-60 style).

Set at the maximum 50A setting it draws more current than my 240v 16A breaker can handle .

Pretty happy with this manual cut on 16mm material.

Made some bits to attach and tension the drive belts. Combination of 3D printed toothed plate and aluminium clamp sides. Riveted the adjuster together with some short pieces of 1/8" alloy TIG rod. The adjuster bolt piece was machined from solid on the lathe and mill.

Adjustment end:

Fixed end:

Machined up some idler pulleys and bits and got the reduction drive all sorted.

At that point I just HAD to make it move, so connected it to the Mesa 7i96 and the stepper drivers.

Slight issue in that because the motors are mirrored they were driving each side of the gantry in a different direction.

Looking through a few older posts here I worked out it just needed one of the Y-axis motors step and direction "invert" selected in pncConf.

Ran it again with that change and all good.

Have a couple of salvaged 15mm linear rails mounted on the gantry for the X-axis, and just starting to put some thought into making up the carriage. Found a piece of channel and some plate that could cut to size and bolted together and then mounted to the linear rail carriages.

Steve

Attachments:

The following user(s) said Thank You: phillc54, tommylight, RNJFAB

Please Log in or Create an account to join the conversation.

- OxxAndBert

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 17

30 Nov 2021 05:57 #227979

by OxxAndBert

Replied by OxxAndBert on topic Downunder 4x2 build

Decided I needed a smaller footprint reduction drive for the X axis, so designed and 3D printed this to see how it fits.

Not sure if it will need some adjustment capability to take up any belt slack or whether I can just make it so the belt fits tightly.

There will be bearings of some sort top and bottom on the large pulley, and the shaft will connect to a 20T on the HTD3 belt.

Have ordered some short HTD3 belts to try for the reduction, but I've also got the option of going with a 2M reduction.

Likely need to mess around with bore sizes on the pulleys as of course what I've got doesn't match the motors...

Found some smaller Minebea brand Nema 23 steppers that I'd salvaged out of old printers at work, so might just use one of those.

The big ones I've used on the Y axis are probably overkill on the X - particularly with the gearing reduction.

Quick question - I found the specs on the small stepper, and its in the region of max 3A at 24v. Since I'm running 36v supplies for the drives, can I still use the smaller stepper?

My understanding is it will be fine, but I could do with a reality check from someone with experience.

Steve

Not sure if it will need some adjustment capability to take up any belt slack or whether I can just make it so the belt fits tightly.

There will be bearings of some sort top and bottom on the large pulley, and the shaft will connect to a 20T on the HTD3 belt.

Have ordered some short HTD3 belts to try for the reduction, but I've also got the option of going with a 2M reduction.

Likely need to mess around with bore sizes on the pulleys as of course what I've got doesn't match the motors...

Found some smaller Minebea brand Nema 23 steppers that I'd salvaged out of old printers at work, so might just use one of those.

The big ones I've used on the Y axis are probably overkill on the X - particularly with the gearing reduction.

Quick question - I found the specs on the small stepper, and its in the region of max 3A at 24v. Since I'm running 36v supplies for the drives, can I still use the smaller stepper?

My understanding is it will be fine, but I could do with a reality check from someone with experience.

Steve

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21162

- Thank you received: 7226

30 Nov 2021 09:34 #227987

by tommylight

Replied by tommylight on topic Downunder 4x2 build

Yes you can.

The following user(s) said Thank You: OxxAndBert

Please Log in or Create an account to join the conversation.

- OxxAndBert

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 17

18 Feb 2022 12:10 #235231

by OxxAndBert

Replied by OxxAndBert on topic Downunder 4x2 build

Due to other priority projects, I hadn't made much progress since I last posted.

Unfortunately though, last week the plasma table build took a large backwards step when some stray welding sparks set fire to the old bedsheet I had covering it from grinding dust etc.

To make matters worse, I still had the electronics laid out on a temporary board, so they were directly under the sheet.

If the fire didn't kill them directly, then I'm sure the dry powder from the extinguisher will do it over time...

One of the melted stepper drivers - possibly still functional

Worst was the 7i96 also got damaged

I just tried to order a replacement 7i96 from Mesa shop but seems there's no stock

Anyone downunder got a spare they would be prepared to part with?

Steve

Unfortunately though, last week the plasma table build took a large backwards step when some stray welding sparks set fire to the old bedsheet I had covering it from grinding dust etc.

To make matters worse, I still had the electronics laid out on a temporary board, so they were directly under the sheet.

If the fire didn't kill them directly, then I'm sure the dry powder from the extinguisher will do it over time...

One of the melted stepper drivers - possibly still functional

Worst was the 7i96 also got damaged

I just tried to order a replacement 7i96 from Mesa shop but seems there's no stock

Anyone downunder got a spare they would be prepared to part with?

Steve

Attachments:

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 1.065 seconds