Rods "Spaceship" Scratch built Plasma Cutter build

- docwelch

- Offline

- Senior Member

-

- Posts: 58

- Thank you received: 25

Yes, I've already found that connection sheet and referred to it numerous times. I'm getting close to having enough time to actually start collecting parts and building the machine. Right now, I'm just trying to put it all on paper/CAD and wrap my head around how LinuxCNC works. Certainly, Phil's plasmac component is going to make this a lot simpler and more robust. I've also got the benefit of you, Grotius, and John as well as others who are very knowledgeable and incredibly patient and helpful on this forum. Thanks for all the input you have already provided!

I did look at the Ethercat information. While I'm sure it offers some advantages, I cannot see any reason I would need more than what the 7i76e offers for my hobby purposes.

Steven

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

- Posts: 2419

- Thank you received: 2348

For you it would be good to start with the Mesa board's.

If you want to go with less i/o and steppers, parport is perfect and cheap.

It has the same speed as a Mesa or Etercat in stepper speed output.

Linux time is the bastard. You will see no different on different systems when using all base thread on them. I tried it before.....

Don't think multicore has something to do with this.

Designing your machine i do in draftsight. I am old scool and do 3 sight's. Side, top and right view alway's. If you draw in Freecad you have some benefit's. Modern company's can do the job for you. They are based on this drawing input type for their production process from a to z. See www.mcdriessen.nl/

They do everything automated. Cutting, bending, all from one customer drawing. They even have a connection to order material automaticly. So this is future, but it's already here. Ftp connection's (file share) between company's all around the globe.

Grotius, That wasn't me. But its great to have such a prestigious client. You will be driving that Lamborgini in no time!

I have a nice car already. It's englisch and fast. It's not a Mclaren C12. It's the same as from the movie James Bond. Same age, same color inside and outside. Even the paraplu is available in the back. It has no rocket launchers at this moment, but that can be done when i need that option. I just go back to the factory for that option's.

The Italian company Soitaab was out of luck this week (the windows plc embedded company). We have sold a GR_LINUXCNC machine, plasma 60i fully digital connected with linux, with rotary axis (in water) and a second hd torch axis sold to Belgium yesterday. Swiftcut was also out of luck with their windows 7 machine on Mach0. So within one week. Say yes to the dress. Linuxcnc defeat's them all. Linux GPL2 = Power to the max.

Just look at the Linux Torvalds GPL2 licence. No Huawai modem's with their own software. Trump has made a good statement, when it's not GPL2 we do not import it. Let the chinese surveillance state rock and roll with their own spy surveillance software.

They are collecting sensitive data on massive scale.

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

- Posts: 2419

- Thank you received: 2348

I was wondering if your z-axis probe speed has increased for touch off in the past day's?

And if the x and y touch off distance is selectable at the gui?

I'd love to have a play with an ethercat drive but really the 7i76e and THCAD board are a very powerful combination.

One off the thing's i would change to a ethercat setup is the old-scool wire plugin type to be done by a standard multipole add-on connector.

And i say too you. It's a wonderfull idea to 3d print some standard multipole add-on ethercat connectors. Beckhoff will copy that idea in no time !

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 11737

- Thank you received: 3973

@Rod,

I was wondering if your z-axis probe speed has increased for touch off in the past day's?

And if the x and y touch off distance is selectable at the gui?

Yes, the probing speed is configurable in the Plasmac GUI. I did that THC test straight after I was checking the probe height so I had slowed it down for that and forgot to reset it. I have probed at 1000 mm/min quite OK.

And yes for X Y touchoff, it depends on the standard Gmocappy G54 touchoff buttons which are part of the GUI. I've been meaning to write some gcode that sets both X & Y offsets at the one time using a Gmocappy macro button.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 11737

- Thank you received: 3973

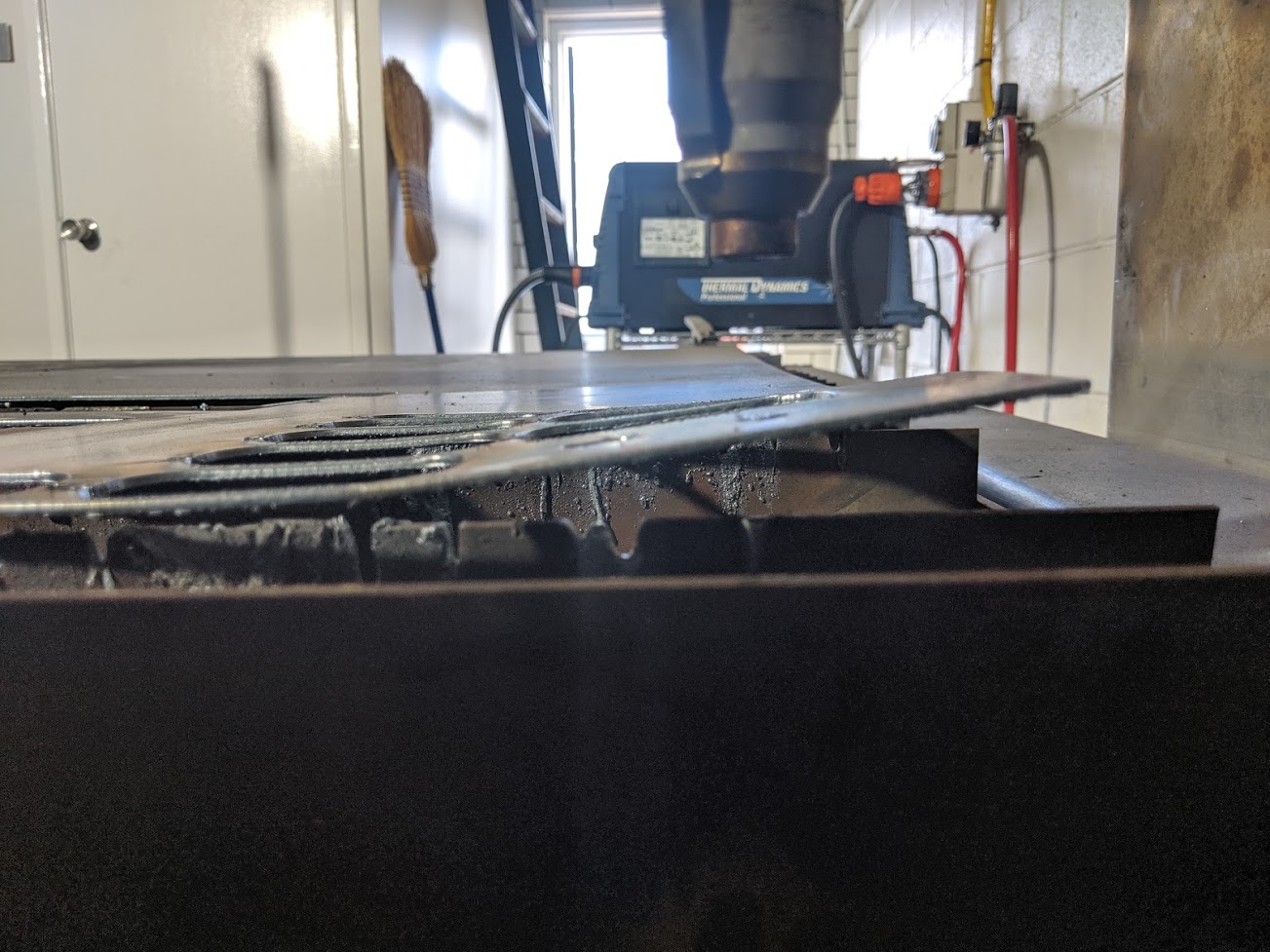

But even cutting at 40 amps, the warpage was similar. A couple of times near the end of the run on the far edge I held the material down for it to probe and plasmac kept the torch cutting even when I let it go and let it spring up 30mm or so. So its very responsive to changes in material height.

I'm still learning about Sheetcam. It would be good if it cut an array of parts in the X axis direction and I think it would warp less.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21376

- Thank you received: 7290

Mentally, that is the best thing with Linuxcnc, it just works.

Nice work.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 11737

- Thank you received: 3973

How does it feel to be able to turn the machine on and go grab a coffee or lunch or sleep and come back and find the parts ready?

Mentally, that is the best thing with Linuxcnc, it just works.

Nice work.

Nice. There are still some bugs in plasmac. I'm not sure if Phill has fixed them in later releases but its nothing you can't live with!

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Rod,Nice. There are still some bugs in plasmac. I'm not sure if Phill has fixed them in later releases but its nothing you can't live with!

When was your last update and what are the bugs?

I know kerf crossing is not right but I haven't had any feedback about the result if the kerf crossing override is increased.

I am also not 100% happy with probing.

Cheers, Phill.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 11737

- Thank you received: 3973

An example where it occurred.

I think I have some video I'll send you.

Attachments:

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Yes, I got the video.

That is quite a bit of warpage...

If you decrease Ohmic Probes in the Run tab it will fallback to float switch quicker. I probably should rename the Ohmic Attempts

That does show why I am not 100% happy with probing.

Cheers, Phill.

Please Log in or Create an account to join the conversation.