Rods "Spaceship" Scratch built Plasma Cutter build

- rodw

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 11654

- Thank you received: 3924

17 Jun 2019 21:38 #137163

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

I was hoping I could define a tool offset for this. T1 = plasma T2 = crosshairs so I'll just have to work it out once I get it wired in as an extension lead and a plug pack is not really appropriate.

Tommy, I did not receive any messages. you can email me direct " rodw at" my website. The lack of reliable forum messaging is why I suggest people contact via my website.

Software allows people to sell things at perceived value, not a markup on cost. In my last job, I purchased a couple of digital printing machines which were software limited by a licence key to just 160 pages per minute. They were capable of running at 320 copies per minute. We got behind while we only had one commissioned so we bought the go fast license for 1 month for $7k. My staff worked one Saturday shift and were back on track again. The permanent speed upgrade was $180k and they just typed in a Licence key. Grotius will be pleased to know these machines were built in Holland by Oce who were subsequently purchased by Canon for 0.9 billion Euros and after the purchase, Canon still had 1/3 of their cash reserves in the bank!

Tommy, I did not receive any messages. you can email me direct " rodw at" my website. The lack of reliable forum messaging is why I suggest people contact via my website.

Software allows people to sell things at perceived value, not a markup on cost. In my last job, I purchased a couple of digital printing machines which were software limited by a licence key to just 160 pages per minute. They were capable of running at 320 copies per minute. We got behind while we only had one commissioned so we bought the go fast license for 1 month for $7k. My staff worked one Saturday shift and were back on track again. The permanent speed upgrade was $180k and they just typed in a Licence key. Grotius will be pleased to know these machines were built in Holland by Oce who were subsequently purchased by Canon for 0.9 billion Euros and after the purchase, Canon still had 1/3 of their cash reserves in the bank!

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21213

- Thank you received: 7245

17 Jun 2019 22:18 #137166

by tommylight

Replied by tommylight on topic Rods "Spaceship" Scratch built Plasma Cutter build

Will do, thank you.

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

18 Jun 2019 05:44 #137175

by pl7i92

Replied by pl7i92 on topic Rods "Spaceship" Scratch built Plasma Cutter build

a laser beam on a plasma will that not be killed by missfirering EMI

we got in 2012 a small crosshair and it be killed within hours of work

as on letter cut it missfirerd trou to ED overrun of the Plasma

i guess it has been that newer got one since mounted

using Home for the sheet with fixed clamp to zero

we got in 2012 a small crosshair and it be killed within hours of work

as on letter cut it missfirerd trou to ED overrun of the Plasma

i guess it has been that newer got one since mounted

using Home for the sheet with fixed clamp to zero

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

20 Jun 2019 12:13 #137365

by andypugh

Use the LinuxCNC tool table to store an XY offset for your laser crosshair.

Then G43 H99 (or whatever) will offset the DRO.

Replied by andypugh on topic Rods "Spaceship" Scratch built Plasma Cutter build

So if anybody has any ideas on how to handle the offsets to use this, I would appreciate some pointers. I know what I have to do to calculate the offset and square it. but its the software stuff I'd like to know a bit more about.

Use the LinuxCNC tool table to store an XY offset for your laser crosshair.

Then G43 H99 (or whatever) will offset the DRO.

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2345

21 Jun 2019 18:16 - 21 Jun 2019 19:02 #137508

by Grotius

Replied by Grotius on topic Rods "Spaceship" Scratch built Plasma Cutter build

Rod,

Thank you for all your work so far to the plasma topic's and your own plasma topic !!

Thank's to your examples i made a c component earlyer.

You mailed me explaining code examples and so on. So i am thankfull to you !!

So credit's for cutting this 40mm thickness piece with bridge 6mm go's to you, it's cutted at 200 amps.

The picture is made during the plasma training course today.

Linuxcnc is used by Pon Catterpillar. They are very happy with linux.

It's cutted with a Thermal Dynamics XT200 today.

The big logo was cutted as a present for a 25 year employee.

We have official approval to use (integrate) the Thermal Dynamic's cutting chart's into open source software.

This approval is sent to me by in.linkedin.com/in/matthijs-piersma-61942a14

He can add Tommy to the OEM list. I have done some work for Tommy. They can sent to Kosovo.

Thank you for all your work so far to the plasma topic's and your own plasma topic !!

Thank's to your examples i made a c component earlyer.

You mailed me explaining code examples and so on. So i am thankfull to you !!

So credit's for cutting this 40mm thickness piece with bridge 6mm go's to you, it's cutted at 200 amps.

The picture is made during the plasma training course today.

Linuxcnc is used by Pon Catterpillar. They are very happy with linux.

It's cutted with a Thermal Dynamics XT200 today.

The big logo was cutted as a present for a 25 year employee.

We have official approval to use (integrate) the Thermal Dynamic's cutting chart's into open source software.

This approval is sent to me by in.linkedin.com/in/matthijs-piersma-61942a14

He can add Tommy to the OEM list. I have done some work for Tommy. They can sent to Kosovo.

Attachments:

Last edit: 21 Jun 2019 19:02 by Grotius.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 11654

- Thank you received: 3924

22 Jun 2019 10:09 #137574

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

Grotius. Thanks for the tribute. I think it is amazing that you have advanced so far with Linuxcnc to win such a powerful customer. It reminds me of a gentleman I once met here in Australia maybe 30 years ago who had 6 D10 bulldozers which then were worth $1.0m each. He broke a 6 tonne part on one of them. They apologised and said it should never have broken and said they would send one to Australia. So they put the part in a plane, and put as many other parts that would fit and flew it to Australia. The machine was down for a week and then Caterpillar did inservice modifications to every D10 in the world so it never happened again.

Anyway back on topic.

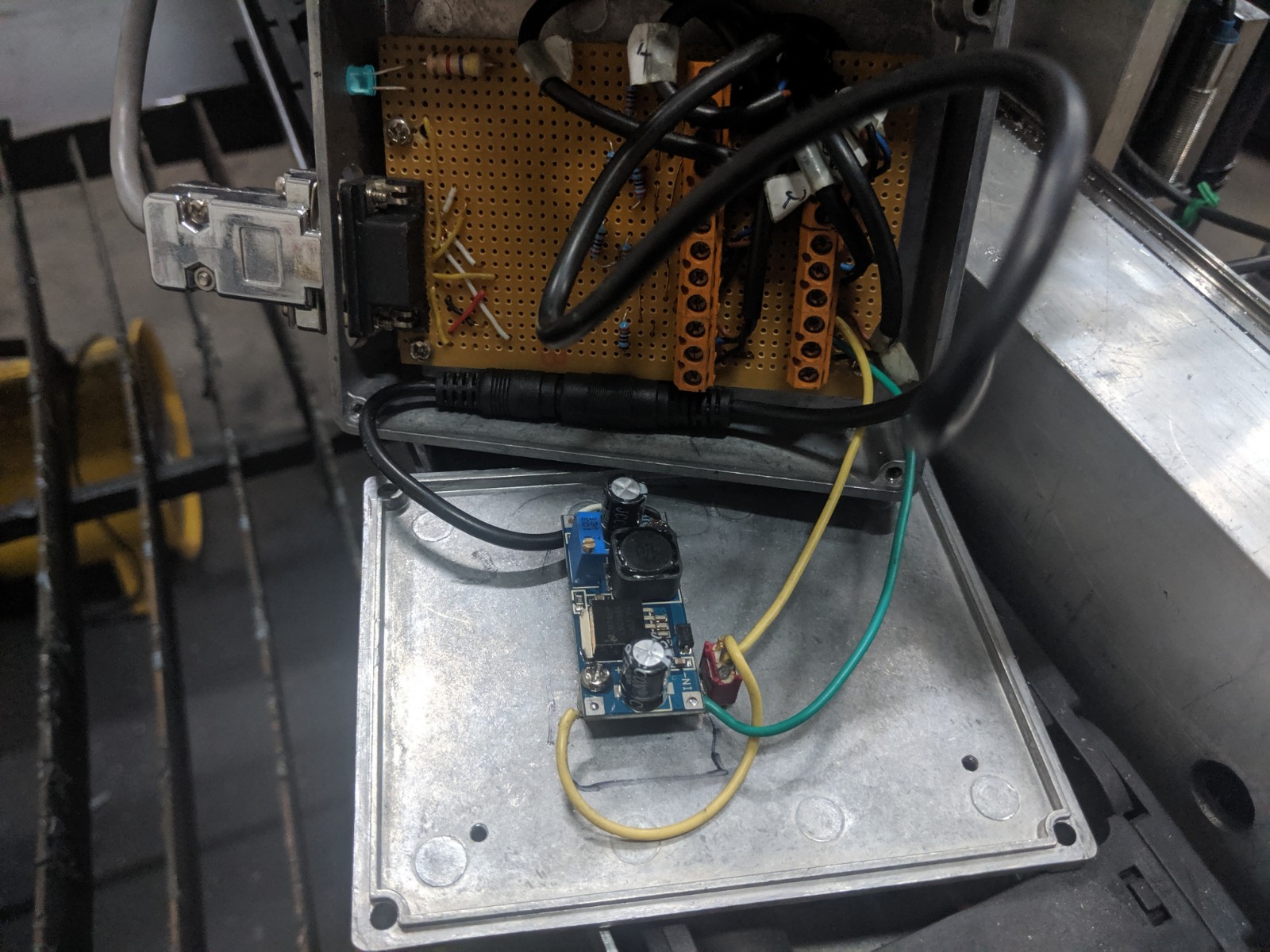

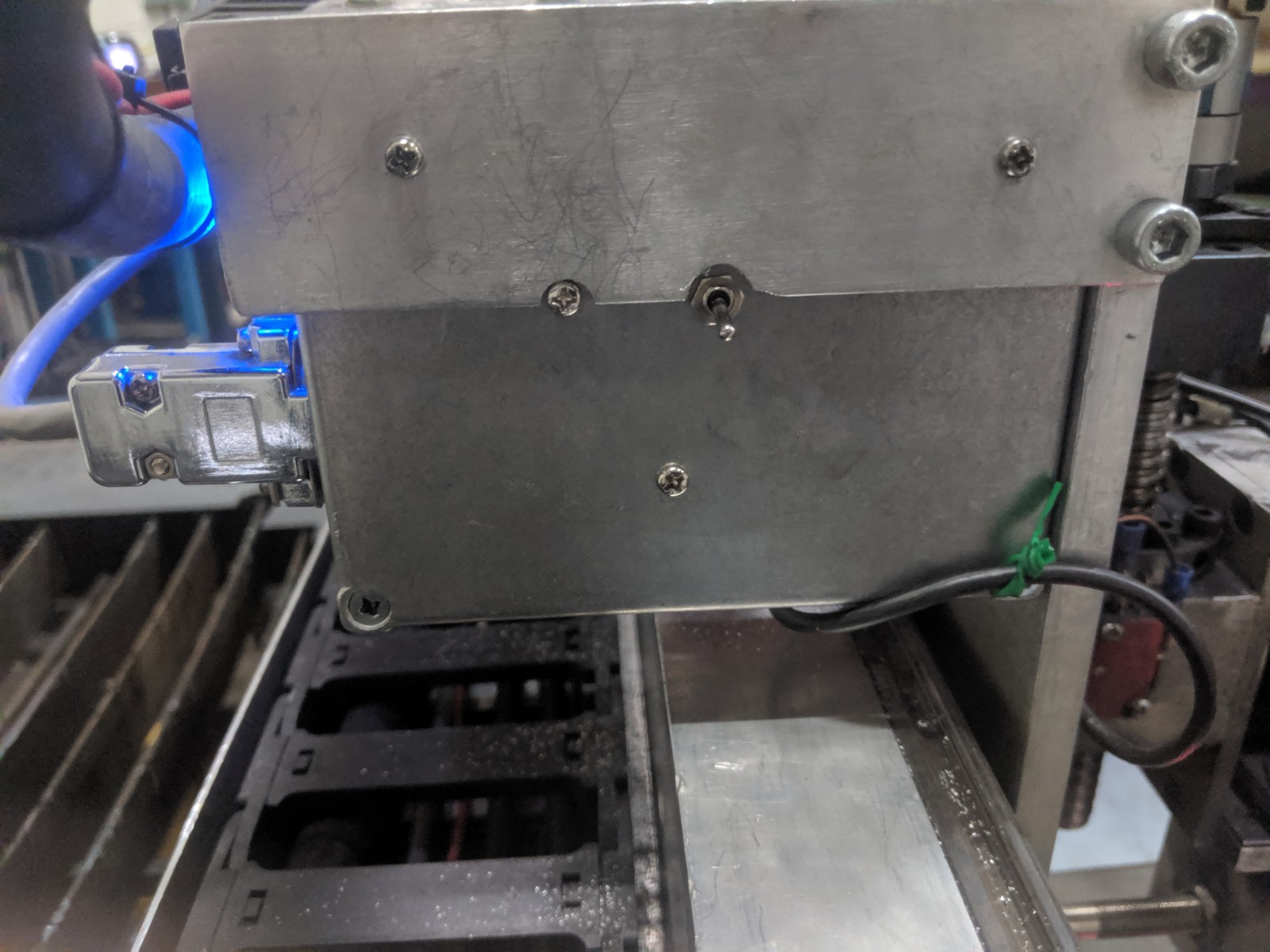

I decided to put a laser pointer on my plasma cutter so I needed to get 5 volts up on the gantry to power. As I had 24 volts up there in a metal breakout box for all of the sensors so the easiset way as to get a small buck power supply off ebay.

But I had no spare wires in the cable running up there so I had to add a manual switch instead of using an output on my 7i76e

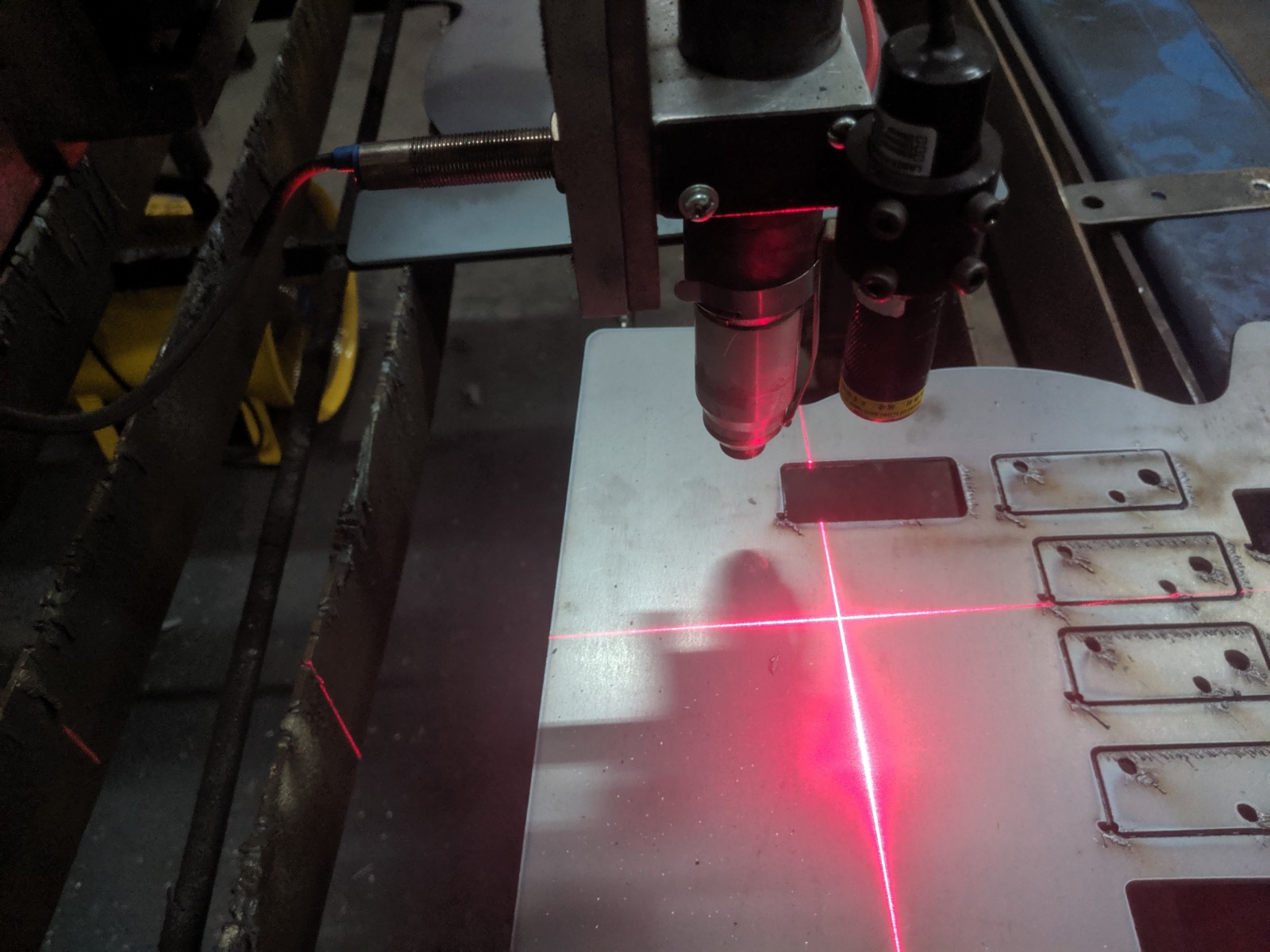

So now I have a crosshair pointer.

So to calibrate this, I burnt a spot at coordinates 0,0 and then jogged until the crosshairs were over the exact centre of it and recorded the offset. Then I added a couple of Gmocappy macro buttons that I called Laser_On and Laser_Off. By aligning the crosshairs where I want to cut, I just hit Laser_Off and it moves the torch to the crosshair position and then I just need to touch off in the usual way.

If I want the lasr to be at the crosshair position, I just need to press Laser_On.

Anyway back on topic.

I decided to put a laser pointer on my plasma cutter so I needed to get 5 volts up on the gantry to power. As I had 24 volts up there in a metal breakout box for all of the sensors so the easiset way as to get a small buck power supply off ebay.

But I had no spare wires in the cable running up there so I had to add a manual switch instead of using an output on my 7i76e

So now I have a crosshair pointer.

So to calibrate this, I burnt a spot at coordinates 0,0 and then jogged until the crosshairs were over the exact centre of it and recorded the offset. Then I added a couple of Gmocappy macro buttons that I called Laser_On and Laser_Off. By aligning the crosshairs where I want to cut, I just hit Laser_Off and it moves the torch to the crosshair position and then I just need to touch off in the usual way.

If I want the lasr to be at the crosshair position, I just need to press Laser_On.

Attachments:

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

22 Jun 2019 10:30 #137577

by phillc54

Replied by phillc54 on topic Rods "Spaceship" Scratch built Plasma Cutter build

Rod,

Looks good. You could probably get the macro to do the touch off as well using G10 L20.

Cheers, Phill.

Looks good. You could probably get the macro to do the touch off as well using G10 L20.

Cheers, Phill.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 11654

- Thank you received: 3924

22 Jun 2019 11:13 #137580

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

Phill, thanks, so if a the laser pointer X & Y offsets were 20mm and 30mm, would do something like:

G10 L20 P1 X20 Y30

so then would a G0 X0 Y0 put the torch where the pointer was?

I know there is a way, I just don't understand G code enough.

G10 L20 P1 X20 Y30

so then would a G0 X0 Y0 put the torch where the pointer was?

I know there is a way, I just don't understand G code enough.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

22 Jun 2019 11:22 #137582

by phillc54

Replied by phillc54 on topic Rods "Spaceship" Scratch built Plasma Cutter build

Yes, something like that. If you use P0 it will do the current co-ordinate system. Or you could move first then set it to X0 Y0.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 11654

- Thank you received: 3924

23 Jun 2019 23:55 #137682

by rodw

G10 L20 P0 X0 Y0 and I have an instant touchoff ready to start cutting.

I might add my choice of NPN prox sensors bit again as one more died on the weekend so I could not home until I replaced it. Thats the second of 5 sensors I've replaced. I think I probably should have added current limiting resistors.

Anyway, one step closer to finishing my machine!

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

Phill, thanks this did the trick for me nicely. After the torch moves to the crosshairs at the end of my macro, I addedYes, something like that. If you use P0 it will do the current co-ordinate system. Or you could move first then set it to X0 Y0.

G10 L20 P0 X0 Y0 and I have an instant touchoff ready to start cutting.

I might add my choice of NPN prox sensors bit again as one more died on the weekend so I could not home until I replaced it. Thats the second of 5 sensors I've replaced. I think I probably should have added current limiting resistors.

Anyway, one step closer to finishing my machine!

The following user(s) said Thank You: phillc54

Please Log in or Create an account to join the conversation.

Time to create page: 0.311 seconds