My Grizzly G0619 mill

- my1987toyota

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 959

- Thank you received: 417

08 Oct 2022 00:38 - 08 Oct 2022 00:40 #253722

by my1987toyota

Replied by my1987toyota on topic My Grizzly G0619 mill

I just got finished shooting video of the repairs to my stepper drivers. The Z axis was the most tricky

it turned out I had burned the 270 ohm resistor for the optoisolator the resistor had a value of

45-50Kohm yikes. Once I replaced that the driver worked fine. I had also purchased a new KL8060E.

Since I now have a spare stepper driver I will install it as well so if I want to use one in the future I

can drive a 4th axis.

it turned out I had burned the 270 ohm resistor for the optoisolator the resistor had a value of

45-50Kohm yikes. Once I replaced that the driver worked fine. I had also purchased a new KL8060E.

Since I now have a spare stepper driver I will install it as well so if I want to use one in the future I

can drive a 4th axis.

Last edit: 08 Oct 2022 00:40 by my1987toyota.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- my1987toyota

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 959

- Thank you received: 417

09 Oct 2022 23:44 #253831

by my1987toyota

Replied by my1987toyota on topic My Grizzly G0619 mill

Well editing took longer then expected. Is it just me or has the internet in general been

really slow today. I will have part 2 out later this week in the meantime here is part 1.

really slow today. I will have part 2 out later this week in the meantime here is part 1.

The following user(s) said Thank You: arvidb, tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21143

- Thank you received: 7221

10 Oct 2022 01:00 #253839

by tommylight

Replied by tommylight on topic My Grizzly G0619 mill

Watched it, nice.

But, the Z drive did not work, so check the opto again for soldering mishaps or cut vias.

Overvolting the opto will not destroy anything else, granted not exceeding the isolation voltage that is very high.

But, the Z drive did not work, so check the opto again for soldering mishaps or cut vias.

Overvolting the opto will not destroy anything else, granted not exceeding the isolation voltage that is very high.

The following user(s) said Thank You: my1987toyota

Please Log in or Create an account to join the conversation.

- my1987toyota

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 959

- Thank you received: 417

10 Oct 2022 01:46 - 10 Oct 2022 10:57 #253841

by my1987toyota

Replied by my1987toyota on topic My Grizzly G0619 mill

tommylight I actually got the Z drive working. It turned out to be a cooked current limit resistor

inline with the optoisolator.( it specs at 270 ohm but it tested at 45-50 Kohm )

though I will admit I never used the ENA. circuit with the mach 3 controller so it is possible

that it never worked on the Z drive anyway.

In PT.2 I don't show myself actually doing the repair too simple and boring

Plus dealing with matters concerning hurricane Ian. LOL . I do however show that the drive is

once again operational.

inline with the optoisolator.( it specs at 270 ohm but it tested at 45-50 Kohm )

though I will admit I never used the ENA. circuit with the mach 3 controller so it is possible

that it never worked on the Z drive anyway.

In PT.2 I don't show myself actually doing the repair too simple and boring

Plus dealing with matters concerning hurricane Ian. LOL . I do however show that the drive is

once again operational.

Last edit: 10 Oct 2022 10:57 by my1987toyota. Reason: adding info

Please Log in or Create an account to join the conversation.

- my1987toyota

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 959

- Thank you received: 417

10 Oct 2022 10:40 #253857

by my1987toyota

Replied by my1987toyota on topic My Grizzly G0619 mill

And here is part 2.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- my1987toyota

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 959

- Thank you received: 417

14 Jan 2023 20:17 - 14 Jan 2023 20:18 #261979

by my1987toyota

Replied by my1987toyota on topic My Grizzly G0619 mill

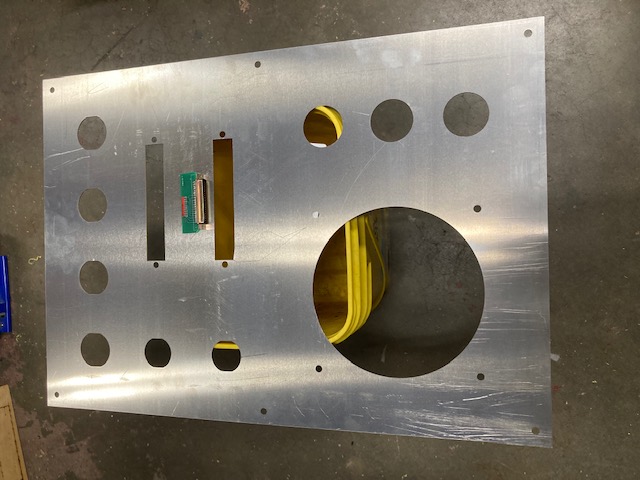

Boy time flies. It's hard to believe it's 2023 already. I had taken about a month to upgrade my

Anodizing line to make it more user friendly and more automatic. I can now get to work (5:30am) and

the tanks are either already at temp. or will be so when it's needed. On the G0619 I built most of

the external wiring . So I figured the next step was to cut out the I.O. plates . Unfortunately I ran into

an issue with my Autodesk Fusion 360 software. I sent a couple of DXF files to a company that does

water jet / laser cutting only to have the finished job be twice the size I had specd ( not their fault ).

Frustrating to say the least , more so at my self for not catching it and fixing it before I had sent it out.

Oh well it's always something.

Anodizing line to make it more user friendly and more automatic. I can now get to work (5:30am) and

the tanks are either already at temp. or will be so when it's needed. On the G0619 I built most of

the external wiring . So I figured the next step was to cut out the I.O. plates . Unfortunately I ran into

an issue with my Autodesk Fusion 360 software. I sent a couple of DXF files to a company that does

water jet / laser cutting only to have the finished job be twice the size I had specd ( not their fault ).

Frustrating to say the least , more so at my self for not catching it and fixing it before I had sent it out.

Oh well it's always something.

Last edit: 14 Jan 2023 20:18 by my1987toyota.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11600

- Thank you received: 3900

14 Jan 2023 20:35 #261980

by rodw

Replied by rodw on topic My Grizzly G0619 mill

That sucks. I always send a pdf drawing of the part with any DXFs we send out.

It might have let you blame them and not wear the recut!

Also the F360 DXF workflow I use is to:

1. Create a flat pattern and flatten it If sheetmetal

2. Add a new sketch on the flat pattern or surface of the part if not sheetmetal

3. Now in the tree, right click the sketch and save as DXF

4. Create a sketch showing outer dimensions and dimensions to any fold lines

5. send the pdf and dxf to supplier..

It might have let you blame them and not wear the recut!

Also the F360 DXF workflow I use is to:

1. Create a flat pattern and flatten it If sheetmetal

2. Add a new sketch on the flat pattern or surface of the part if not sheetmetal

3. Now in the tree, right click the sketch and save as DXF

4. Create a sketch showing outer dimensions and dimensions to any fold lines

5. send the pdf and dxf to supplier..

The following user(s) said Thank You: my1987toyota

Please Log in or Create an account to join the conversation.

- my1987toyota

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 959

- Thank you received: 417

15 Jan 2023 17:19 #262049

by my1987toyota

Replied by my1987toyota on topic My Grizzly G0619 mill

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11600

- Thank you received: 3900

15 Jan 2023 21:46 #262070

by rodw

Replied by rodw on topic My Grizzly G0619 mill

Ouch! and you paid money for that?

And it does not even seem to be a metric thing!

Send a dimensioned drawing with it next time! Or build a plasma table!

And it does not even seem to be a metric thing!

Send a dimensioned drawing with it next time! Or build a plasma table!

The following user(s) said Thank You: my1987toyota

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21143

- Thank you received: 7221

15 Jan 2023 22:19 #262074

by tommylight

Replied by tommylight on topic My Grizzly G0619 mill

Hmmm, did you pay for the small ones or large ones?

Please Log in or Create an account to join the conversation.

Time to create page: 0.161 seconds