DIY CNC router build

- Clive S

- Offline

- Platinum Member

-

Less

More

- Posts: 2202

- Thank you received: 482

04 Jan 2021 22:47 #194083

by Clive S

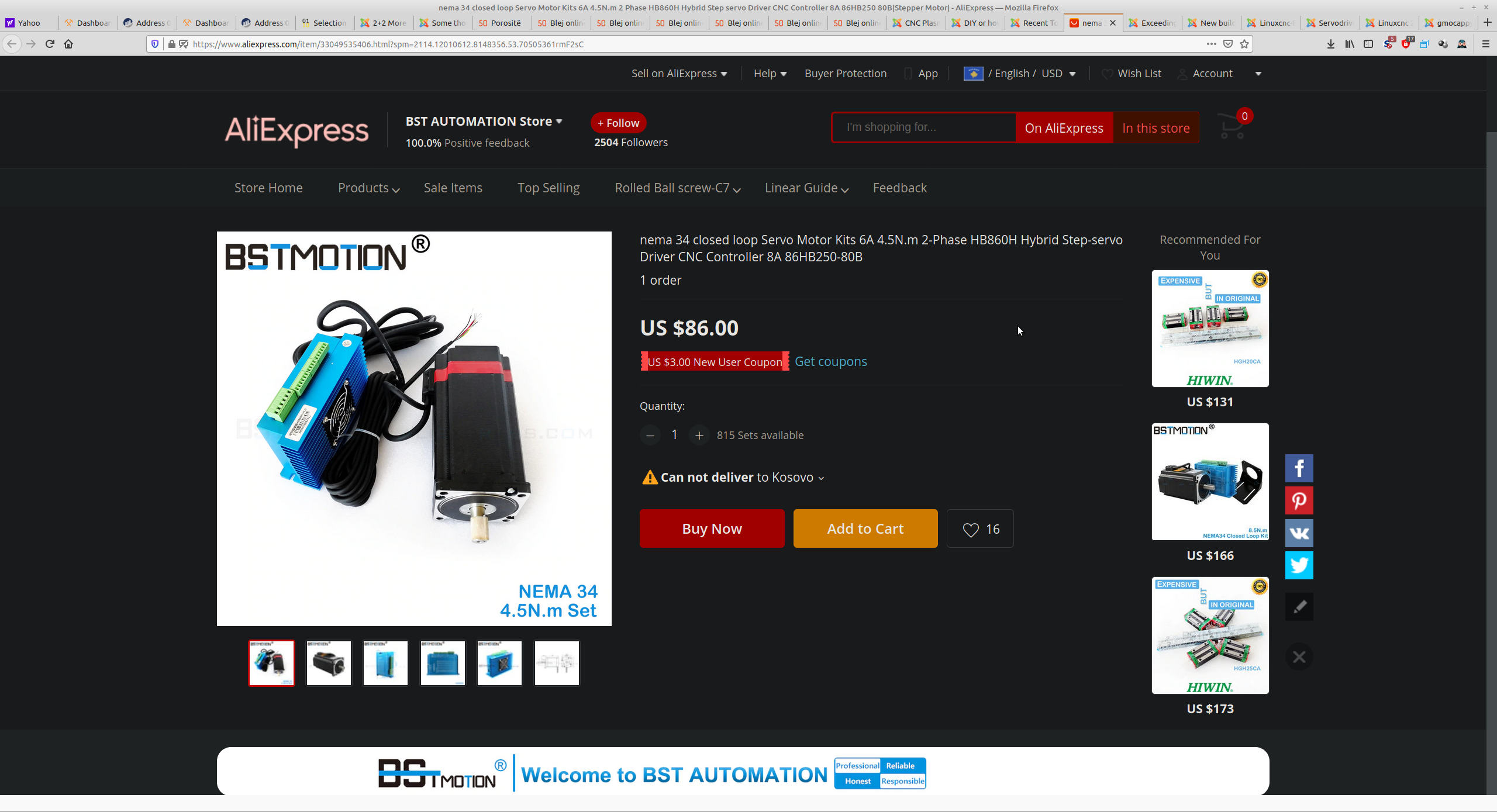

This is the link for the motors closed loop 4.5Nm nema 34 driven at 65V. The feed rate was 10mts/min

www.aliexpress.com/item/33049535406.html...56.53.70505361rmF2sC

The router was designed with a tall gantry and was designed to accept tall parts that had to have the top machined.

Replied by Clive S on topic DIY CNC router build

very nice

what steppers are u using ?

This is the link for the motors closed loop 4.5Nm nema 34 driven at 65V. The feed rate was 10mts/min

www.aliexpress.com/item/33049535406.html...56.53.70505361rmF2sC

The router was designed with a tall gantry and was designed to accept tall parts that had to have the top machined.

The following user(s) said Thank You: tommylight, shpatb

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21002

- Thank you received: 7161

04 Jan 2021 22:58 #194084

by tommylight

Replied by tommylight on topic DIY CNC router build

Attachments:

The following user(s) said Thank You: shpatb

Please Log in or Create an account to join the conversation.

- shpatb

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 87

- Thank you received: 62

04 Jan 2021 23:02 #194085

by shpatb

Replied by shpatb on topic DIY CNC router build

the fun part of living in balkans

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

Less

More

- Posts: 2202

- Thank you received: 482

04 Jan 2021 23:14 #194086

by Clive S

As a matter of interest Fred Lee at BST is a truly reliable and honest guy. I always email him direct . for ball screws and linear rails etc .

bstlinearxx#x@x??

x##gmail.com

Replied by Clive S on topic DIY CNC router build

Bugger .....

815 sets available, but i can not buy them! Bloody hell this has long past the point of being funny.

As a matter of interest Fred Lee at BST is a truly reliable and honest guy. I always email him direct . for ball screws and linear rails etc .

bstlinearxx#x@x??

x##gmail.com

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21002

- Thank you received: 7161

04 Jan 2021 23:42 #194093

by tommylight

Replied by tommylight on topic DIY CNC router build

Thank you Clive, i'll have a chat with him as soon as i can.

Please Log in or Create an account to join the conversation.

- shpatb

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 87

- Thank you received: 62

07 Jan 2021 20:40 #194412

by shpatb

Replied by shpatb on topic DIY CNC router build

everything was going ok until this happened...

installed the nut and moved the screw accidentally then it got blocked , had to remove the nut and install the balls inside then these plastic protectors ripped and balls dont stay inside anymore...

another 2 months of time wasted

installed the nut and moved the screw accidentally then it got blocked , had to remove the nut and install the balls inside then these plastic protectors ripped and balls dont stay inside anymore...

another 2 months of time wasted

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21002

- Thank you received: 7161

07 Jan 2021 23:18 #194429

by tommylight

Those plastic broke because the balls were not in their place, they have a very strict position where they should be located inside the nut.

You are lucky they did not bind, only an angle grinder would have set them free!

They can still be used without plastic rings but the dust will get in there and soon enough mess them up, in a year or 5 depending on use and dust.

If they are open type with a small black tube held by a screw:

-remove the screw and tube,

-insert the big screw and position the nut and the screw so the screw sits in the middle of the nut

-turn the nut so the holes are up

-turn the screw and peek through the holes till the grooves are aligned with both holes

-insert balls through one hole only till they start exiting at the other side

-put the metal lid on and insert any remaining balls under the lid

-tighten the lid

-enjoy.

If they are of the closed type, to fix them:

-find some engine grease, a flat head screwdriver, and a big clean cloth or table cover

-get the balls out and clean them properly one by one

-clean the nut inside and clean the grooves properly

-wash hands and clean screwdriver

-look inside the nut, there are deep grooves inside, only 3 of those groves are full rounds and they end on both sides where the "outside ball carrier"

-on both sides there is also another short grooved part, NO BALLS SHOULD GO THERE under any circumstances, it will lock the nut to the point that only angle grinder will work, or not because the nut will have to be cut open!!!

-make sure you got enough light to see inside the nut

-take the screwdriver and fill the grooves with grease, not the whole nut, just the gooves

-dip the tip of screwdriver in grease then grab only one ball with the greased tip and place it carefully in the groove

-repeat

-when done, DO NOT try to insert it in the srew

-find something round that can easily fit inside the nut, or make a tube out of thin cardboard or several sheets of paper

-slowly insert the tube inside the nut making sure the balls stay in place

-now slowly insert the screw, let the screw push the tube as it goes in

-enjoy.

Replied by tommylight on topic DIY CNC router build

Those plastic broke because the balls were not in their place, they have a very strict position where they should be located inside the nut.

You are lucky they did not bind, only an angle grinder would have set them free!

They can still be used without plastic rings but the dust will get in there and soon enough mess them up, in a year or 5 depending on use and dust.

If they are open type with a small black tube held by a screw:

-remove the screw and tube,

-insert the big screw and position the nut and the screw so the screw sits in the middle of the nut

-turn the nut so the holes are up

-turn the screw and peek through the holes till the grooves are aligned with both holes

-insert balls through one hole only till they start exiting at the other side

-put the metal lid on and insert any remaining balls under the lid

-tighten the lid

-enjoy.

If they are of the closed type, to fix them:

-find some engine grease, a flat head screwdriver, and a big clean cloth or table cover

-get the balls out and clean them properly one by one

-clean the nut inside and clean the grooves properly

-wash hands and clean screwdriver

-look inside the nut, there are deep grooves inside, only 3 of those groves are full rounds and they end on both sides where the "outside ball carrier"

-on both sides there is also another short grooved part, NO BALLS SHOULD GO THERE under any circumstances, it will lock the nut to the point that only angle grinder will work, or not because the nut will have to be cut open!!!

-make sure you got enough light to see inside the nut

-take the screwdriver and fill the grooves with grease, not the whole nut, just the gooves

-dip the tip of screwdriver in grease then grab only one ball with the greased tip and place it carefully in the groove

-repeat

-when done, DO NOT try to insert it in the srew

-find something round that can easily fit inside the nut, or make a tube out of thin cardboard or several sheets of paper

-slowly insert the tube inside the nut making sure the balls stay in place

-now slowly insert the screw, let the screw push the tube as it goes in

-enjoy.

The following user(s) said Thank You: shpatb

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19741

- Thank you received: 4578

08 Jan 2021 14:53 #194497

by andypugh

Replied by andypugh on topic DIY CNC router build

The wipers are not a particularly good solution anyway.

If you can fit spiral spring covers, that should work better and longer.

They are not cheap, but they are not horribly expensive either.

If you can fit spiral spring covers, that should work better and longer.

They are not cheap, but they are not horribly expensive either.

The following user(s) said Thank You: shpatb

Please Log in or Create an account to join the conversation.

- shpatb

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 87

- Thank you received: 62

08 Jan 2021 20:39 #194540

by shpatb

Replied by shpatb on topic DIY CNC router build

Tommy thank you, I have tried all of these you mentioned ,but none of them seem to work, took me like 3 hours to mount it , it moved smoothly as it came new, but this type of nut has that rubber thing like a spiral inside and its hold in place with some steel 1mm think wire and that is damaged , the nut moved smoothly but the vibration moving back and forward caused the balls to drop out, so the only solution is to get it brand new.

Please Log in or Create an account to join the conversation.

- shpatb

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 87

- Thank you received: 62

14 Jan 2021 15:36 #195323

by shpatb

Replied by shpatb on topic DIY CNC router build

some update if u can call it so.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

Time to create page: 0.132 seconds