- Hardware & Machines

- CNC Machines

- Milling Machines

- Retrofitting Mikron WF41C: Distance coded homing success

Retrofitting Mikron WF41C: Distance coded homing success

- mwinterm

- Offline

- Senior Member

-

Less

More

- Posts: 70

- Thank you received: 13

09 Apr 2021 19:26 #205460

by mwinterm

Retrofitting Mikron WF41C was created by mwinterm

Hello,

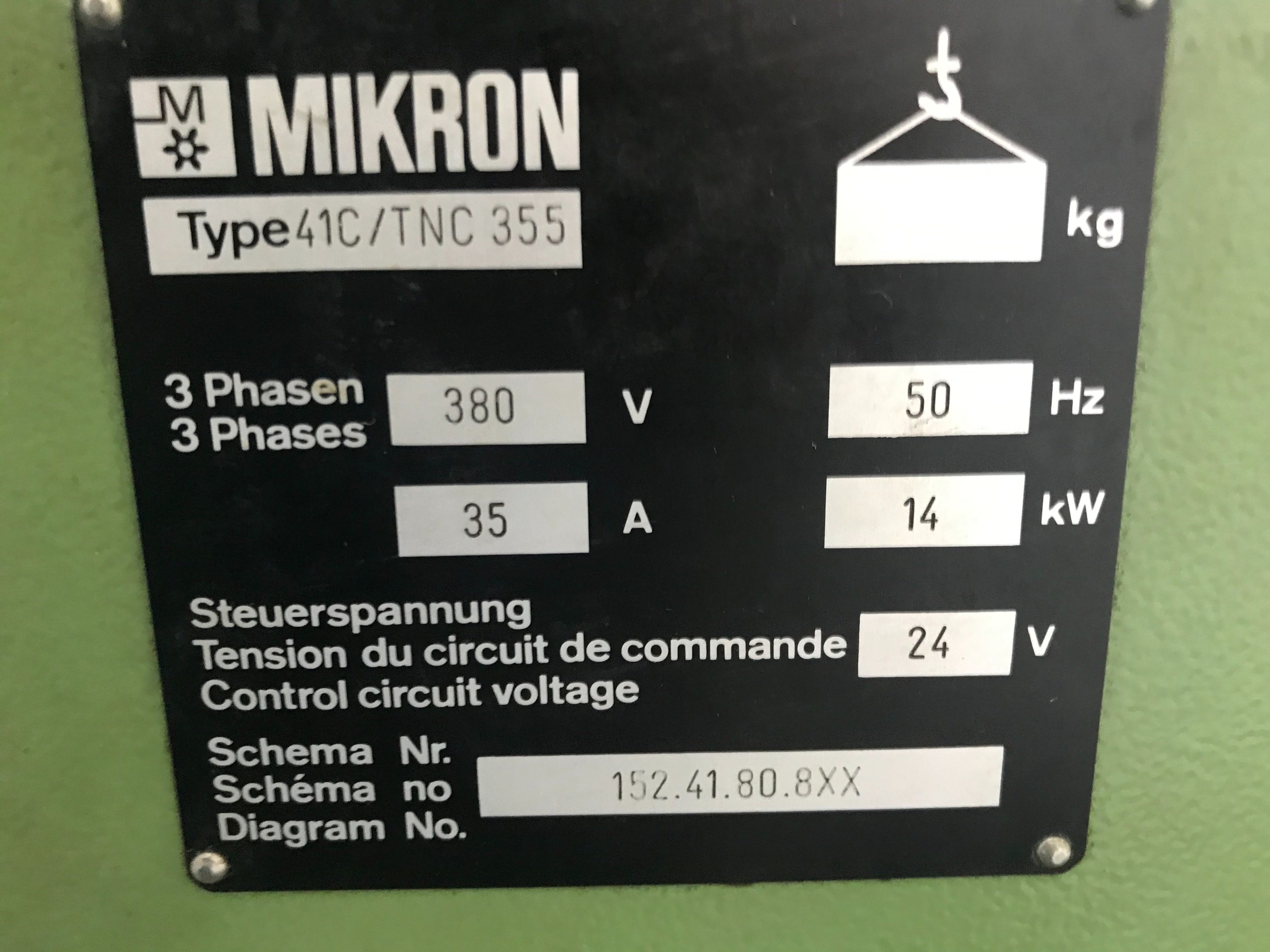

I'm sharing here some information on a retrofit project of a Mikron WF41C milling machine. The machine is from 1993, has a Heidenhain TNC355 control and is still fully functional and in daily use (currently on the pictures there is just the left glasscale removed temporarily for some testing in context of the retrofit project).

These machines from Mikron are very stiff and precise with glasscales on all three axes. My machine easily has a relative precision (repeatability) of 0.002-0.003mm. The machine has dovetail slides of very high quality in combination with automated lubrication. This makes the machine very robust on one side and the automated lubrication on the other side provides that there isn't really relevant wear-in even after decades of use (older models sometimes don't have automated lubrication therefore wear could potentially be more of an issue). My machine has 22 speed settings up to 4000RPM. The gearbox provides as well for huge amounts of torque at low RPMs. Finally my machine also comes with a Renishaw LP2 touchprobe which is very handy. The TNC355 is for me the oldest Heidenahin Control that still fits into our current workflows using CAE/CAM software for the generation of G-code. This is mainly due to three reasons it sets itself apart from even earlier Heidenhain controls:

1. The speed is good enough even today for most programming jobs given the CAM-software creates reasonable G-code (not just millions of little linear moves).

2. The TNC355 is to my knowledge the first Heidenhain to support a tool-table (even though only 99 tools which can be limiting in some circumstances).

3. The excellent drip-feed capabilities of Heidenhain controls. As you can see on the pictures there is a laptop connected to the machine via serial interface. On the laptop the Heidenhain TNCserver is running. To run a program just have to post the G-code into a specific directory on the laptop that is also used by the TNCserver. After that I can call the program from the Heidenhain control and run it. This is a better workflow than we even have with most more modern machines with network shares as no copying is involved.

The reason for retrofitting this still perfectly functional machine I will address in a next post.

Best regards,

Marc

I'm sharing here some information on a retrofit project of a Mikron WF41C milling machine. The machine is from 1993, has a Heidenhain TNC355 control and is still fully functional and in daily use (currently on the pictures there is just the left glasscale removed temporarily for some testing in context of the retrofit project).

These machines from Mikron are very stiff and precise with glasscales on all three axes. My machine easily has a relative precision (repeatability) of 0.002-0.003mm. The machine has dovetail slides of very high quality in combination with automated lubrication. This makes the machine very robust on one side and the automated lubrication on the other side provides that there isn't really relevant wear-in even after decades of use (older models sometimes don't have automated lubrication therefore wear could potentially be more of an issue). My machine has 22 speed settings up to 4000RPM. The gearbox provides as well for huge amounts of torque at low RPMs. Finally my machine also comes with a Renishaw LP2 touchprobe which is very handy. The TNC355 is for me the oldest Heidenahin Control that still fits into our current workflows using CAE/CAM software for the generation of G-code. This is mainly due to three reasons it sets itself apart from even earlier Heidenhain controls:

1. The speed is good enough even today for most programming jobs given the CAM-software creates reasonable G-code (not just millions of little linear moves).

2. The TNC355 is to my knowledge the first Heidenhain to support a tool-table (even though only 99 tools which can be limiting in some circumstances).

3. The excellent drip-feed capabilities of Heidenhain controls. As you can see on the pictures there is a laptop connected to the machine via serial interface. On the laptop the Heidenhain TNCserver is running. To run a program just have to post the G-code into a specific directory on the laptop that is also used by the TNCserver. After that I can call the program from the Heidenhain control and run it. This is a better workflow than we even have with most more modern machines with network shares as no copying is involved.

The reason for retrofitting this still perfectly functional machine I will address in a next post.

Best regards,

Marc

Attachments:

The following user(s) said Thank You: tommylight, J Green

Please Log in or Create an account to join the conversation.

- J Green

- Offline

- Elite Member

-

Less

More

- Posts: 164

- Thank you received: 24

09 Apr 2021 20:32 #205468

by J Green

Replied by J Green on topic Retrofitting Mikron WF41C

Marc

A big Thank You for sharing the venture and also the photos .

I will be very interested in reading your compare and contrast of Heidenhain vers LinuxCNC .

Also your ongoing details of the retrofitting .

Bob

A big Thank You for sharing the venture and also the photos .

I will be very interested in reading your compare and contrast of Heidenhain vers LinuxCNC .

Also your ongoing details of the retrofitting .

Bob

Please Log in or Create an account to join the conversation.

- mwinterm

- Offline

- Senior Member

-

Less

More

- Posts: 70

- Thank you received: 13

12 Apr 2021 14:47 #205719

by mwinterm

Replied by mwinterm on topic Retrofitting Mikron WF41C

Hello,

I now want to continue where I left on my first post and addressing why we want to retrofit the Mikron WF41C even though its original Heidenhain TNC355 is still doing a pretty good job up to today.

Looking at the WF41C at hand there is not really a good reason for doing this. The project actually started when I rather spontaneously bought in an auction a similar Mikron WF31C with an older TNC155 control for 1900€.

We had in mind to use a very high quality milling machine with a rather outdated CNC-control and convert it to LinuxCNC. Machines like the Mikrons (as well as similar Machines from Hermle, Maho and Deckel) in decent quality get more and more readily available here in Europe at prices sometimes significantly below 10'000€. Converted with an actual well integrated LinuxCNC control this promises to be a very attractive and in many aspects superior alternative to typical toolroom mills such as a Tormach or a Haas MiniMill (as long as manual tool change is acceptable).

So the project was kicked-off and we started looking into the electrics, wiring etc of the Mikron/Heidenhain. We found that the interface of the Heidenhain controls are pretty simple and clean and largely consistent even over several generations of the controls. For us the relevant interfaces basically are:

- 31 digital inputs (24V) on a d-sub 37

- 30 digital outputs (24V) on a d-sub 37

- 5 analog outputs (+/-10V) on a d-sub15 (only 3 used in our case) for the servos

- 5 inputs on some special connectors (I think Heidenhain calls them M22) for the linear glasscales

- 1 input for touch-probe

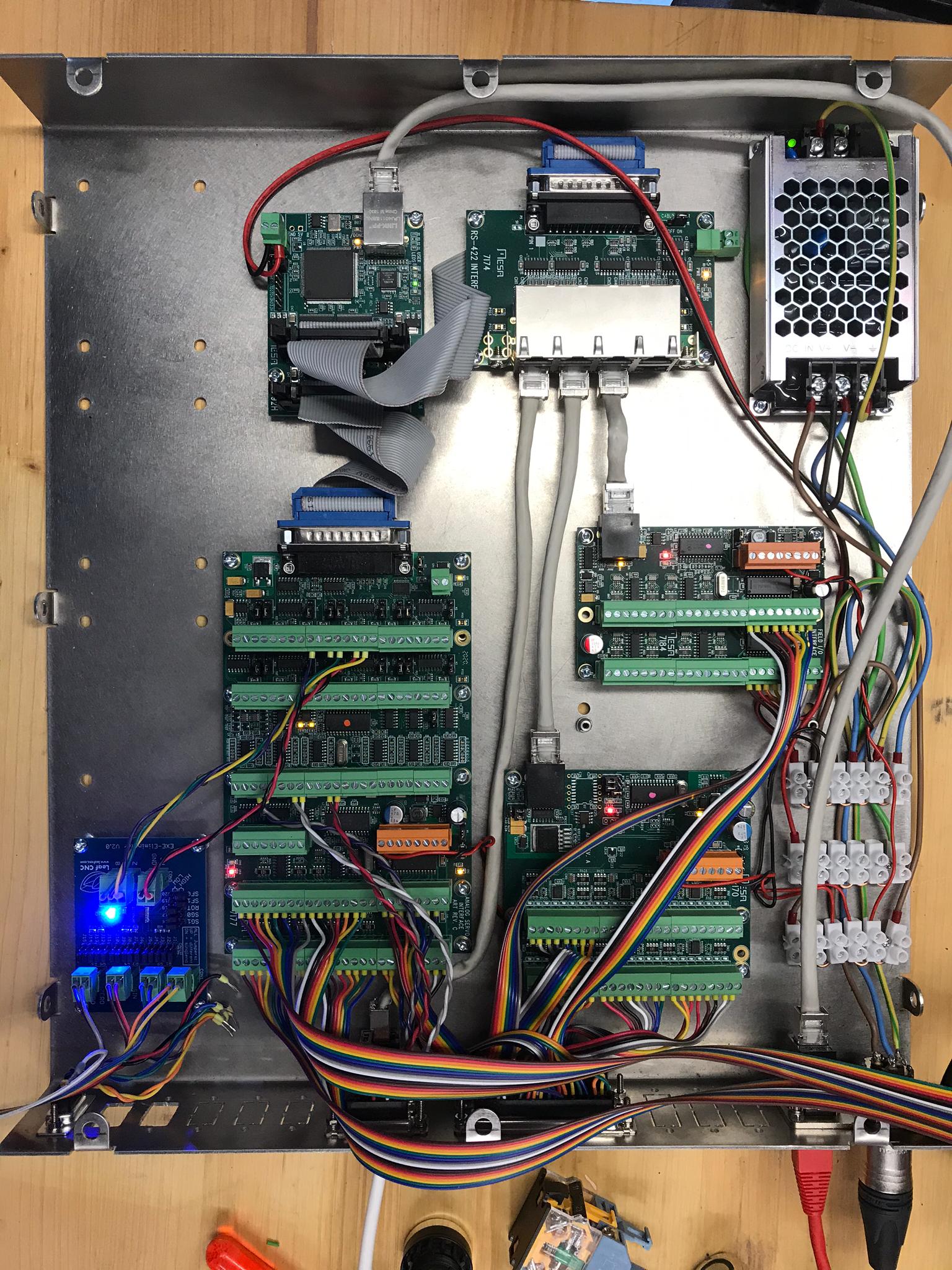

This can very easily be represented by a set of Mesa-Cards such as 7i77, 7i70 and 7i71 (plus something like 7i92 and 7i74 for connection to the computer and connection of the smart serial cards).

We further decided that we really don't want to re-wire the machine and designed a control unit containing the cards having virtually the same inputs and connectors and as the original Heidenhain control and a form-factor that easily fits in the volume that the original Heidenhain typically occupies.

In terms of connectors we only deviated from this strategy for the glasscales. There we decided to go for d-sub 9 connectors instead of the special Heidenhain types as the d-subs are more readily available and much cheaper. If there will be a future iteration of our design we probably will replace the d-sub 9 with d-sub 15 as we found out that later Heidenhain controls also chose d-sub 15 for the glasscales.

We also started designing a user-panel that should contain a 17" touch-screen, a number of physical controls connected to a 7i73 as well as the LinuxCNC controller computer itself (probably an Intel Nuc or somthing similar).

What happened then is that the owner of the auctioned Mikron WF31C reconsidered and managed to somehow sneak out of the auction deal. So we had no machine for our project.

Shortly we looked for another cheap Mikron but then we decided that we will use the WF41C we already own.

The reason behind this was that we realized that we did not really need to modify our WF41C. Rather we could plug-in our new LinuxCNC based control in the evening for testing and then for the daily operation, at least in the meantime, the TNC 355 would be reconnected. The only modification that we did was to cut the glasscale cables close to the connector and to mount a male and a female D-sub 9 respectively on both open ends. Like that we can use the new male d-sub 9 to connect to the LinuxCNC control and have little pig-tails with a female d-sub 9 connected to the TNC355 for switching back to it. This switching between controls works seamlessly so far.

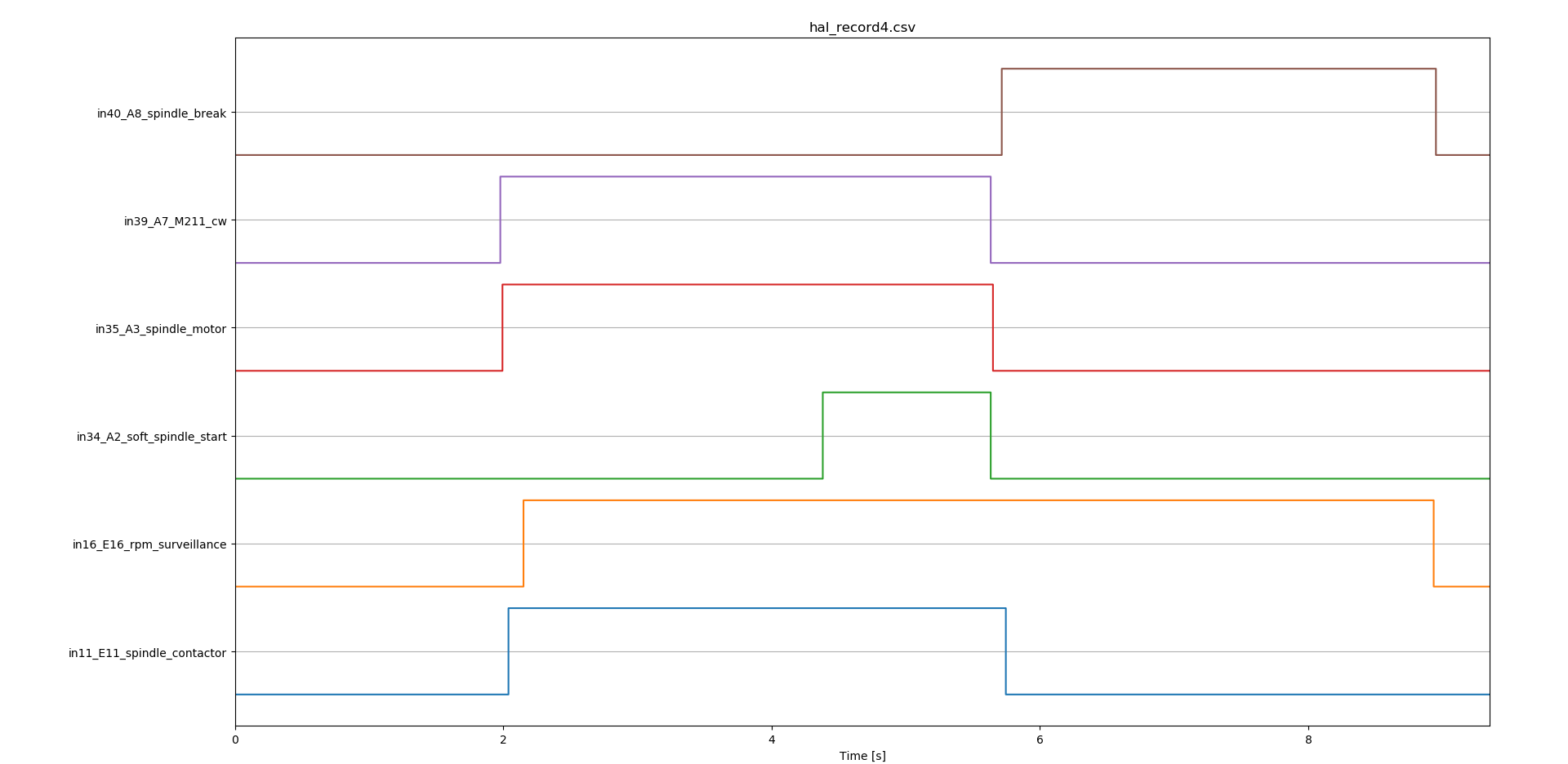

Further we also added little V-splitters to the between the Heidenhain digital inputs and outputs (d-sub 37 connectors). This allows us (since we have enough input channels with our cards) to tap into the digital input and output communication between the Heidenhain and the Mikron to learn better what is going on. So we basically use LinuxCNC as a recorder. I wrote a little python component that is recording all the signals with a time-stamp whenever a something is changing. Combined with another little tool employing matplotlib that can also hide channels with no activity this generates very handy graphs like this.

This helps tremendously to implement the gear-changes or the spindle start-stop etc. I'm currently working on.

So much for today. In a next post I will touch on how we try to process the Heidenhain glasscale inputs.

Best regards,

Marc

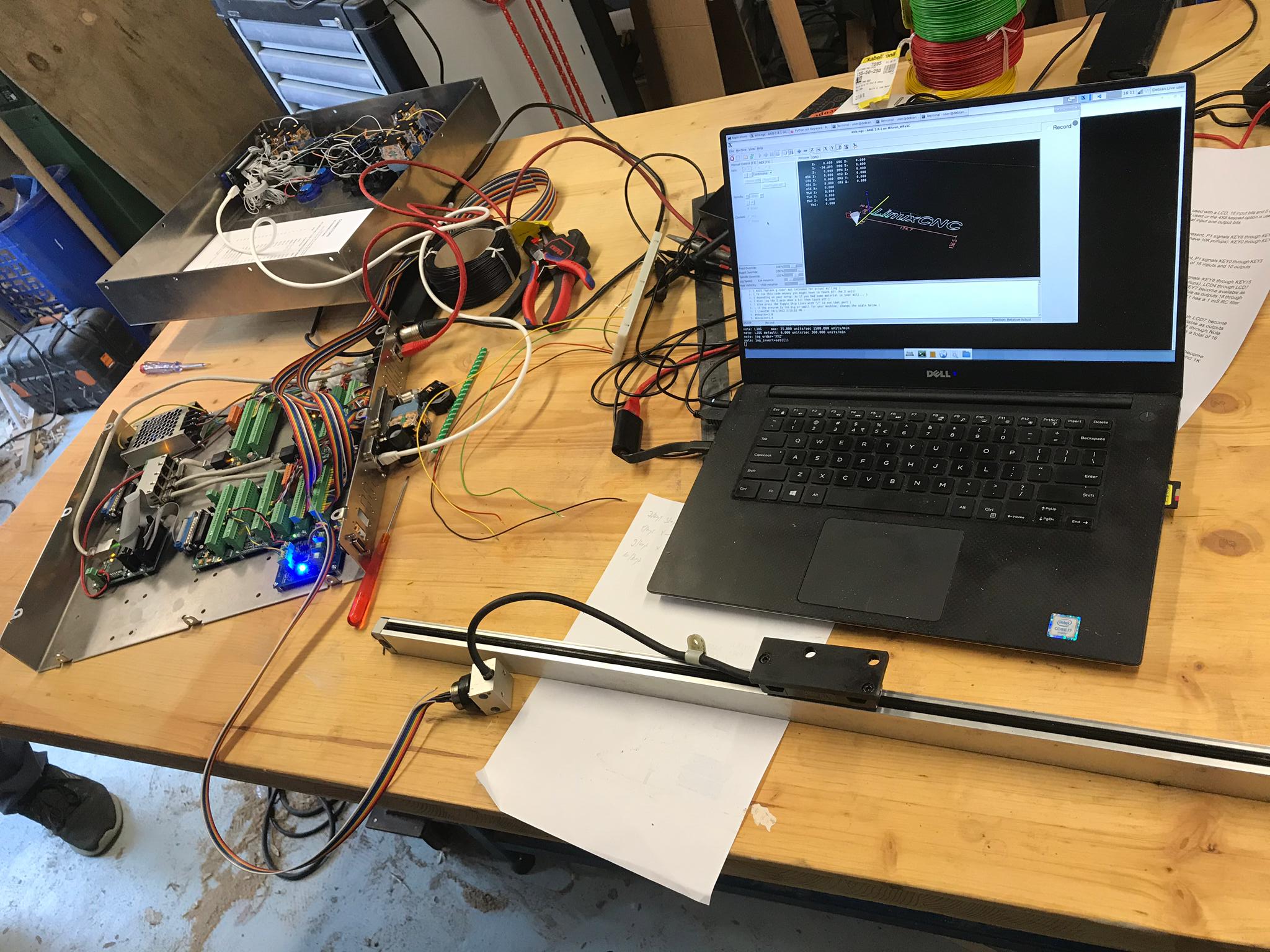

PS: Some comments on the photo of the control:

- There is a 7i84 instead of the planned 7i71 as the latter one was not available when we ordered

- There is currently only one glasscale interpolator board in as we are still testing it out.

- The ribbon cables coming out are providing additional inputs on a d-sub 37 to be able to listen to the inputs and outputs of the Heidenhain control as mentioned before.

I now want to continue where I left on my first post and addressing why we want to retrofit the Mikron WF41C even though its original Heidenhain TNC355 is still doing a pretty good job up to today.

Looking at the WF41C at hand there is not really a good reason for doing this. The project actually started when I rather spontaneously bought in an auction a similar Mikron WF31C with an older TNC155 control for 1900€.

We had in mind to use a very high quality milling machine with a rather outdated CNC-control and convert it to LinuxCNC. Machines like the Mikrons (as well as similar Machines from Hermle, Maho and Deckel) in decent quality get more and more readily available here in Europe at prices sometimes significantly below 10'000€. Converted with an actual well integrated LinuxCNC control this promises to be a very attractive and in many aspects superior alternative to typical toolroom mills such as a Tormach or a Haas MiniMill (as long as manual tool change is acceptable).

So the project was kicked-off and we started looking into the electrics, wiring etc of the Mikron/Heidenhain. We found that the interface of the Heidenhain controls are pretty simple and clean and largely consistent even over several generations of the controls. For us the relevant interfaces basically are:

- 31 digital inputs (24V) on a d-sub 37

- 30 digital outputs (24V) on a d-sub 37

- 5 analog outputs (+/-10V) on a d-sub15 (only 3 used in our case) for the servos

- 5 inputs on some special connectors (I think Heidenhain calls them M22) for the linear glasscales

- 1 input for touch-probe

This can very easily be represented by a set of Mesa-Cards such as 7i77, 7i70 and 7i71 (plus something like 7i92 and 7i74 for connection to the computer and connection of the smart serial cards).

We further decided that we really don't want to re-wire the machine and designed a control unit containing the cards having virtually the same inputs and connectors and as the original Heidenhain control and a form-factor that easily fits in the volume that the original Heidenhain typically occupies.

In terms of connectors we only deviated from this strategy for the glasscales. There we decided to go for d-sub 9 connectors instead of the special Heidenhain types as the d-subs are more readily available and much cheaper. If there will be a future iteration of our design we probably will replace the d-sub 9 with d-sub 15 as we found out that later Heidenhain controls also chose d-sub 15 for the glasscales.

We also started designing a user-panel that should contain a 17" touch-screen, a number of physical controls connected to a 7i73 as well as the LinuxCNC controller computer itself (probably an Intel Nuc or somthing similar).

What happened then is that the owner of the auctioned Mikron WF31C reconsidered and managed to somehow sneak out of the auction deal. So we had no machine for our project.

Shortly we looked for another cheap Mikron but then we decided that we will use the WF41C we already own.

The reason behind this was that we realized that we did not really need to modify our WF41C. Rather we could plug-in our new LinuxCNC based control in the evening for testing and then for the daily operation, at least in the meantime, the TNC 355 would be reconnected. The only modification that we did was to cut the glasscale cables close to the connector and to mount a male and a female D-sub 9 respectively on both open ends. Like that we can use the new male d-sub 9 to connect to the LinuxCNC control and have little pig-tails with a female d-sub 9 connected to the TNC355 for switching back to it. This switching between controls works seamlessly so far.

Further we also added little V-splitters to the between the Heidenhain digital inputs and outputs (d-sub 37 connectors). This allows us (since we have enough input channels with our cards) to tap into the digital input and output communication between the Heidenhain and the Mikron to learn better what is going on. So we basically use LinuxCNC as a recorder. I wrote a little python component that is recording all the signals with a time-stamp whenever a something is changing. Combined with another little tool employing matplotlib that can also hide channels with no activity this generates very handy graphs like this.

This helps tremendously to implement the gear-changes or the spindle start-stop etc. I'm currently working on.

So much for today. In a next post I will touch on how we try to process the Heidenhain glasscale inputs.

Best regards,

Marc

PS: Some comments on the photo of the control:

- There is a 7i84 instead of the planned 7i71 as the latter one was not available when we ordered

- There is currently only one glasscale interpolator board in as we are still testing it out.

- The ribbon cables coming out are providing additional inputs on a d-sub 37 to be able to listen to the inputs and outputs of the Heidenhain control as mentioned before.

Attachments:

The following user(s) said Thank You: J Green, cscegypt

Please Log in or Create an account to join the conversation.

- J Green

- Offline

- Elite Member

-

Less

More

- Posts: 164

- Thank you received: 24

12 Apr 2021 16:34 #205721

by J Green

Replied by J Green on topic Retrofitting Mikron WF41C

Marc

Another big Thank You for sharing further progress in the Micron conversion .

The user-panel ---- Will there be any provisions for USB keyboard ?

The control unit containing the MESA cards

What is the source of it's electrical power ? Also , what is the small power supply used for - 5Volt , 12Volt 24Volt ?

Eagerly awaiting more

Bob

Another big Thank You for sharing further progress in the Micron conversion .

The user-panel ---- Will there be any provisions for USB keyboard ?

The control unit containing the MESA cards

What is the source of it's electrical power ? Also , what is the small power supply used for - 5Volt , 12Volt 24Volt ?

Eagerly awaiting more

Bob

Please Log in or Create an account to join the conversation.

- mwinterm

- Offline

- Senior Member

-

Less

More

- Posts: 70

- Thank you received: 13

12 Apr 2021 18:21 #205724

by mwinterm

Replied by mwinterm on topic Retrofitting Mikron WF41C

Hello Bob,

Yes, we have an industrial USB keyboard that will be hinged to the user panel.

The Heidenhein control lives on 24V. So the input into the control unit is 24V that is also used as field power on the various Mesa cards. Beyond that the Mesa cards, the interpolator boards and the glasscales need 5V which is generated by a little 24V to 5V Meanwell DC/DC power supply.

Regards,

Marc

Yes, we have an industrial USB keyboard that will be hinged to the user panel.

The Heidenhein control lives on 24V. So the input into the control unit is 24V that is also used as field power on the various Mesa cards. Beyond that the Mesa cards, the interpolator boards and the glasscales need 5V which is generated by a little 24V to 5V Meanwell DC/DC power supply.

Regards,

Marc

The following user(s) said Thank You: J Green

Please Log in or Create an account to join the conversation.

- gaston48

- Offline

- Premium Member

-

Less

More

- Posts: 112

- Thank you received: 5

13 Apr 2021 08:17 #205766

by gaston48

Replied by gaston48 on topic Retrofitting Mikron WF41C

Hello Marc,

I finished a few months ago, a retrofit with mesa of a Mikron 31 D TNC 407.

forum.linuxcnc.org/9-installing-linuxcnc...7-15?start=10#199504

My question concerns the automatic lubrication of the slides and others of the machine.

The pump starts automatically when the machine is power on

as well as after a distance of 2000 mm traveled by the slides.

(I calculate this with a component inspired by integ.com)

I forgot to measure the running time of the pump?

you would have this information ?

Thank you and good continuation for your retrofit

gaston

I finished a few months ago, a retrofit with mesa of a Mikron 31 D TNC 407.

forum.linuxcnc.org/9-installing-linuxcnc...7-15?start=10#199504

My question concerns the automatic lubrication of the slides and others of the machine.

The pump starts automatically when the machine is power on

as well as after a distance of 2000 mm traveled by the slides.

(I calculate this with a component inspired by integ.com)

I forgot to measure the running time of the pump?

you would have this information ?

Thank you and good continuation for your retrofit

gaston

Please Log in or Create an account to join the conversation.

- mwinterm

- Offline

- Senior Member

-

Less

More

- Posts: 70

- Thank you received: 13

13 Apr 2021 12:13 #205776

by mwinterm

Replied by mwinterm on topic Retrofitting Mikron WF41C

Hello,

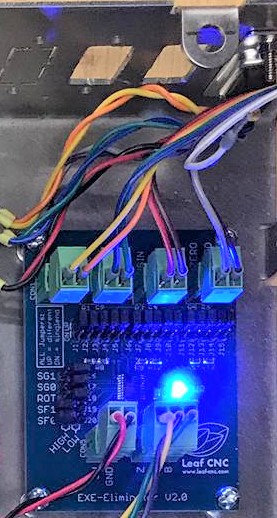

the next part on our journey to retrofit the Mikron WF41C is now dealing with the Heidenhain glasscales. These glasscales output two sinusoidal signals A and B that are offset to each other by 90deg. Depending on whether A is trailing B by 90 deg or the oposite way around the direction of the movement can be determinded. The period on the glasscales at hand (Heidenhain LS403C) is 0.02mm. The glasscales need to be provided with 5V and the resulting symmetric signal is around 1.3V and pretty weak/sensitive. Therefore there is some circuitary needed to process this signal up to TTL level as well as increase the resolution up to 0.001mm as provided by the original Heidenhain control.

Heidenhain provides such circuitary called EXEs. For non-Heidenhain controls they come in the form of small metal boxes. Older Heidenhain controls integrate them directly into the control unit as it is the case for our TNC355.

These EXE circuits basically interpolate the analog signal for higher resolution (in our case 5x) and output 5V TTL signals for A and B. These signals then can be read by e.g. a Mesa Card like the 7i77 on an encoder input and with quadrature enabeled in LinuxCNC (i.e. evaluating all the 4 zero-transitions of the A and B signal during a period) provide a 0.001mm resolution.

Further in the case of our LS403C there is a third index signal track. These index signals are arranged in two periodic series:

1. There is a signal every 20.00mm (let's say starting at absolut position 0mm)

2. There is also a signal every 20.02mm (starting at 10.00mm).

If you draw this up you can easily see how you can calculate the absolute position by the distance between two index signals and the relative distance traveled since passing the second index signal. Therfore the machine can be homed independent of its position after traveling a maximum of 20mm.

As we didn't want to rely on finding secondhand EXEs on eBay or similar we had to find another solution. In an old post from 2013 (forum.linuxcnc.org/27-driver-boards/2616...-7i33?start=10#31650) I found the reference to the icHaus iC-NV chip that seemed to do pretty much what we needed. So we bought some of those and designed a little PCB to host it.

About two weeks ago we tried it our for the first time. We tapped into the signal line going from the glasscales into the Heidenhain control. Looking at the signal on an oscilloscope showed some promise but we could not make any final conclusion if everything was working since we experienced two issues:

1. The Heidenhain control was even during constant moves makeing a lot of little ajustments which gave the oscilloscope a hard-time to properly trigger the signal.

2. Our taping into the weak signal from the glasscales quite often triggered glasscale errrors in the Heidenhain control which to our best knowledge could only be reset by restarting the Heidenhain control.

Therefore we decided to temporarily remove the y-Axis glasscale for testing. We were very pleased to find out that our little PCB just seems to work flawlessly. LinuxCNC showed the position with a resolution 0.001mm and also the index-signals were arriving as expected with the right spacing.

So the next step now is to find out how we can home the machine using these index signals. It looks to me that the the standard homeing sequences of LinuxCNC are not suited to home glasscales like the LS403C. Any help / suggestions are greatly appreciated.

Best regards,

Marc

the next part on our journey to retrofit the Mikron WF41C is now dealing with the Heidenhain glasscales. These glasscales output two sinusoidal signals A and B that are offset to each other by 90deg. Depending on whether A is trailing B by 90 deg or the oposite way around the direction of the movement can be determinded. The period on the glasscales at hand (Heidenhain LS403C) is 0.02mm. The glasscales need to be provided with 5V and the resulting symmetric signal is around 1.3V and pretty weak/sensitive. Therefore there is some circuitary needed to process this signal up to TTL level as well as increase the resolution up to 0.001mm as provided by the original Heidenhain control.

Heidenhain provides such circuitary called EXEs. For non-Heidenhain controls they come in the form of small metal boxes. Older Heidenhain controls integrate them directly into the control unit as it is the case for our TNC355.

These EXE circuits basically interpolate the analog signal for higher resolution (in our case 5x) and output 5V TTL signals for A and B. These signals then can be read by e.g. a Mesa Card like the 7i77 on an encoder input and with quadrature enabeled in LinuxCNC (i.e. evaluating all the 4 zero-transitions of the A and B signal during a period) provide a 0.001mm resolution.

Further in the case of our LS403C there is a third index signal track. These index signals are arranged in two periodic series:

1. There is a signal every 20.00mm (let's say starting at absolut position 0mm)

2. There is also a signal every 20.02mm (starting at 10.00mm).

If you draw this up you can easily see how you can calculate the absolute position by the distance between two index signals and the relative distance traveled since passing the second index signal. Therfore the machine can be homed independent of its position after traveling a maximum of 20mm.

As we didn't want to rely on finding secondhand EXEs on eBay or similar we had to find another solution. In an old post from 2013 (forum.linuxcnc.org/27-driver-boards/2616...-7i33?start=10#31650) I found the reference to the icHaus iC-NV chip that seemed to do pretty much what we needed. So we bought some of those and designed a little PCB to host it.

About two weeks ago we tried it our for the first time. We tapped into the signal line going from the glasscales into the Heidenhain control. Looking at the signal on an oscilloscope showed some promise but we could not make any final conclusion if everything was working since we experienced two issues:

1. The Heidenhain control was even during constant moves makeing a lot of little ajustments which gave the oscilloscope a hard-time to properly trigger the signal.

2. Our taping into the weak signal from the glasscales quite often triggered glasscale errrors in the Heidenhain control which to our best knowledge could only be reset by restarting the Heidenhain control.

Therefore we decided to temporarily remove the y-Axis glasscale for testing. We were very pleased to find out that our little PCB just seems to work flawlessly. LinuxCNC showed the position with a resolution 0.001mm and also the index-signals were arriving as expected with the right spacing.

So the next step now is to find out how we can home the machine using these index signals. It looks to me that the the standard homeing sequences of LinuxCNC are not suited to home glasscales like the LS403C. Any help / suggestions are greatly appreciated.

Best regards,

Marc

Attachments:

The following user(s) said Thank You: J Green

Please Log in or Create an account to join the conversation.

- mwinterm

- Offline

- Senior Member

-

Less

More

- Posts: 70

- Thank you received: 13

13 Apr 2021 12:58 #205789

by mwinterm

Replied by mwinterm on topic Retrofitting Mikron WF41C

Salut Gaston,

Nice machine!

To my knowledge the lubrication is turning on for about 20s on startup. After that shorter lubrication cycles are issued after a certain travel distance, a certain time, as well as a number of direction changes (whichever occurs first).

I did not yet record the lubrication cycles but will probably do next week (currently on vacation). I will share with you the results.

Best regards,

Marc

Nice machine!

To my knowledge the lubrication is turning on for about 20s on startup. After that shorter lubrication cycles are issued after a certain travel distance, a certain time, as well as a number of direction changes (whichever occurs first).

I did not yet record the lubrication cycles but will probably do next week (currently on vacation). I will share with you the results.

Best regards,

Marc

Please Log in or Create an account to join the conversation.

- gaston48

- Offline

- Premium Member

-

Less

More

- Posts: 112

- Thank you received: 5

13 Apr 2021 14:17 #205798

by gaston48

Replied by gaston48 on topic Retrofitting Mikron WF41C

Thank you Marc,

Exploiting "distance coded reference marks " by heidenhain was a old development project in linuxcnc

I also have coded marks, but my machine is also equipped with a spécifiq switch for a

standard homing cycle with one mark so not used by the tnc 407

(another switch with 2 stops is reserved for machine axis limits)

so after acting on this switch, I detect the first mark signal that arrives

I also use IC-NV

Exploiting "distance coded reference marks " by heidenhain was a old development project in linuxcnc

I also have coded marks, but my machine is also equipped with a spécifiq switch for a

standard homing cycle with one mark so not used by the tnc 407

(another switch with 2 stops is reserved for machine axis limits)

so after acting on this switch, I detect the first mark signal that arrives

I also use IC-NV

Attachments:

Please Log in or Create an account to join the conversation.

- mwinterm

- Offline

- Senior Member

-

Less

More

- Posts: 70

- Thank you received: 13

13 Apr 2021 14:32 #205800

by mwinterm

Replied by mwinterm on topic Retrofitting Mikron WF41C

Hello Gaston,

yes, my Machine also has additional homing switches that are even connected to the TNC355. Not yet sure what exactly they are used for. I would however like the use the index-mark for homing...

Nice to see that you used the same iC-NV. You have a second chip on your board right of the iC-NV. What is this one for?

Regards,

Marc

yes, my Machine also has additional homing switches that are even connected to the TNC355. Not yet sure what exactly they are used for. I would however like the use the index-mark for homing...

Nice to see that you used the same iC-NV. You have a second chip on your board right of the iC-NV. What is this one for?

Regards,

Marc

Please Log in or Create an account to join the conversation.

Moderators: piasdom

- Hardware & Machines

- CNC Machines

- Milling Machines

- Retrofitting Mikron WF41C: Distance coded homing success

Time to create page: 0.483 seconds