Padovani LE-200 Retrofit

- DoWerna

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 185

- Thank you received: 57

10 Jan 2022 10:10 #231295

by DoWerna

Padovani LE-200 Retrofit was created by DoWerna

Yay we have a new project

Bought myself a Padovani Teachin lathe

The machine is still in the shipping company

have so far only pictures.

Wanted to make it similar to the Maho,

and leave the original electrics as original as possible.

The machine has Siemens drives.

can you tell from the photos what they have for inputs?

+/-10V?

or are they already connected to a bus or something?

Bought myself a Padovani Teachin lathe

The machine is still in the shipping company

have so far only pictures.

Wanted to make it similar to the Maho,

and leave the original electrics as original as possible.

The machine has Siemens drives.

can you tell from the photos what they have for inputs?

+/-10V?

or are they already connected to a bus or something?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21342

- Thank you received: 7283

15 Jan 2022 07:48 #231867

by tommylight

Replied by tommylight on topic Padovani LE-200 Retrofit

Closeups ?

Schematics ?

Chances are very high it is analog, so Mesa 7i97 or 7i92/7i77 should do the job nicely.

Let us know when you get the machine so we can "poke" some more.

Schematics ?

Chances are very high it is analog, so Mesa 7i97 or 7i92/7i77 should do the job nicely.

Let us know when you get the machine so we can "poke" some more.

Please Log in or Create an account to join the conversation.

- DoWerna

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 185

- Thank you received: 57

19 Jan 2022 14:17 - 19 Jan 2022 14:18 #232438

by DoWerna

Replied by DoWerna on topic Padovani LE-200 Retrofit

slowly it will start  .

.

Yesterday I set up the future computer.

After your positive mention of the series here in the forum, I bought a used HP 8300.

It showed good latency values right away, without any further hacks.

I already have a 7i92 here,

Now I have to study the circuit diagrams to see which cards I still need.

have just unloaded the lathe here

Everything looks good so far.

But first I have to sort everything out and set up the lathe in the workshop.

Yesterday I set up the future computer.

After your positive mention of the series here in the forum, I bought a used HP 8300.

It showed good latency values right away, without any further hacks.

I already have a 7i92 here,

Now I have to study the circuit diagrams to see which cards I still need.

have just unloaded the lathe here

Everything looks good so far.

But first I have to sort everything out and set up the lathe in the workshop.

Attachments:

Last edit: 19 Jan 2022 14:18 by DoWerna.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- DoWerna

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 185

- Thank you received: 57

19 Jan 2022 18:27 #232464

by DoWerna

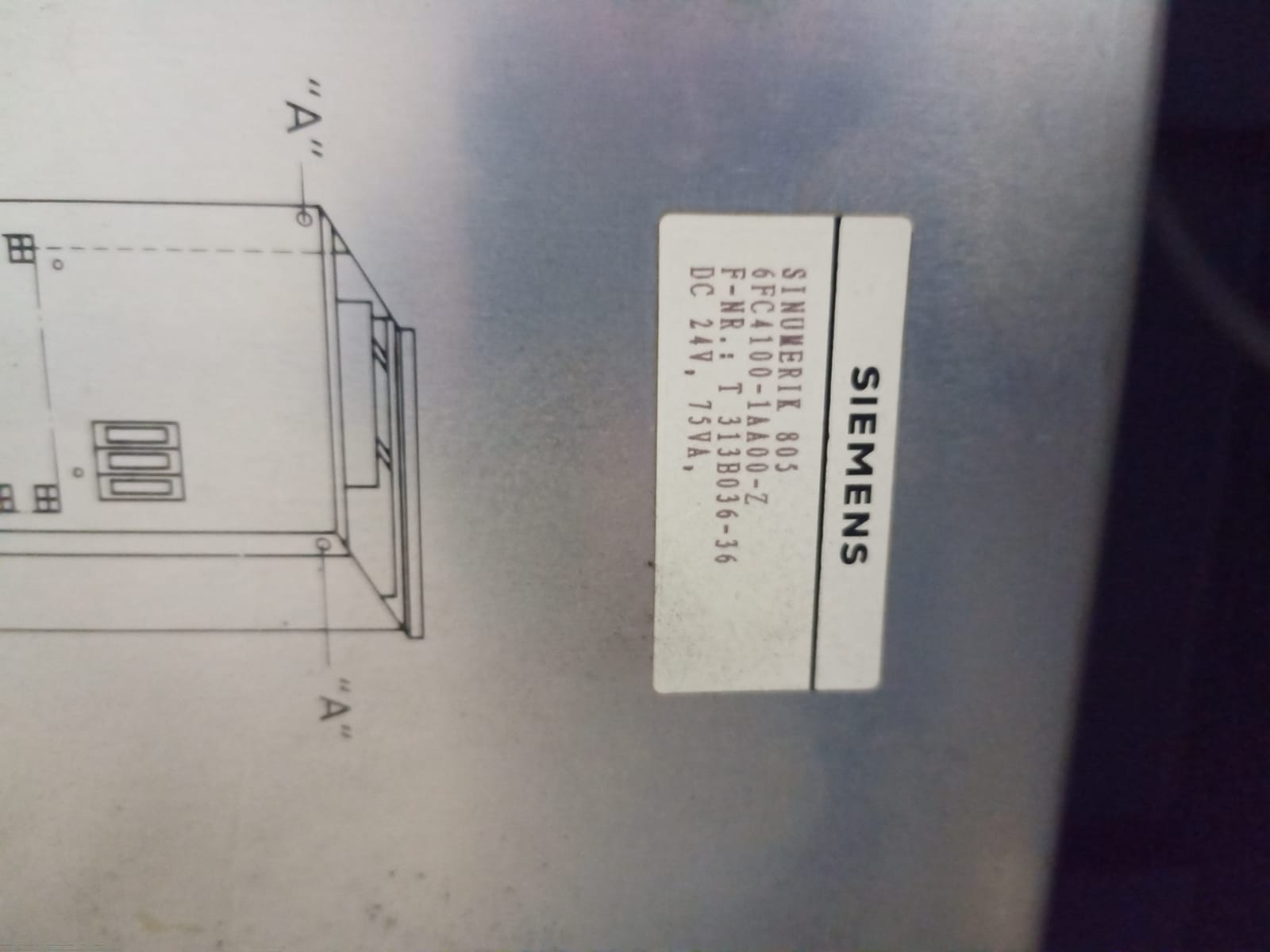

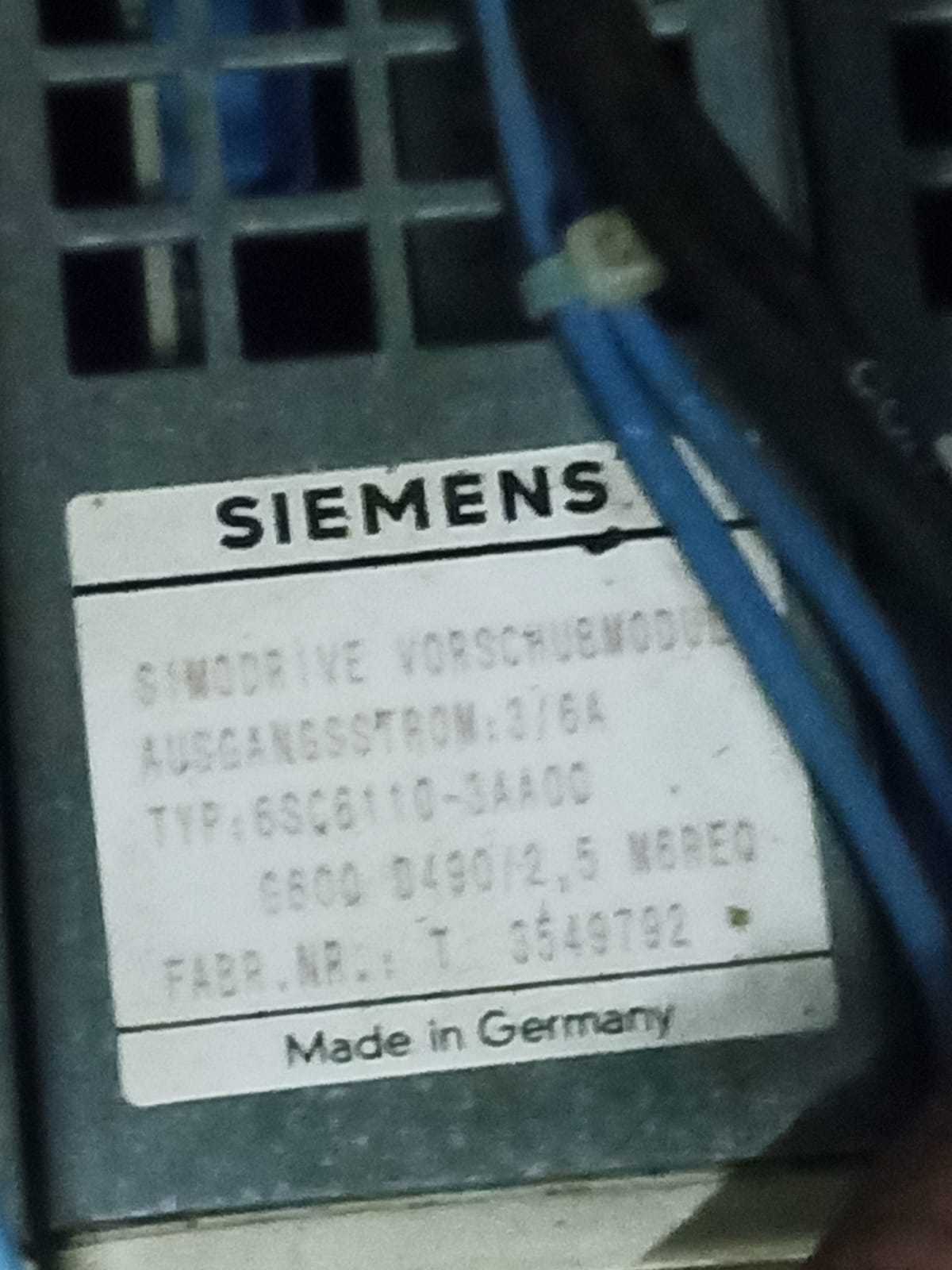

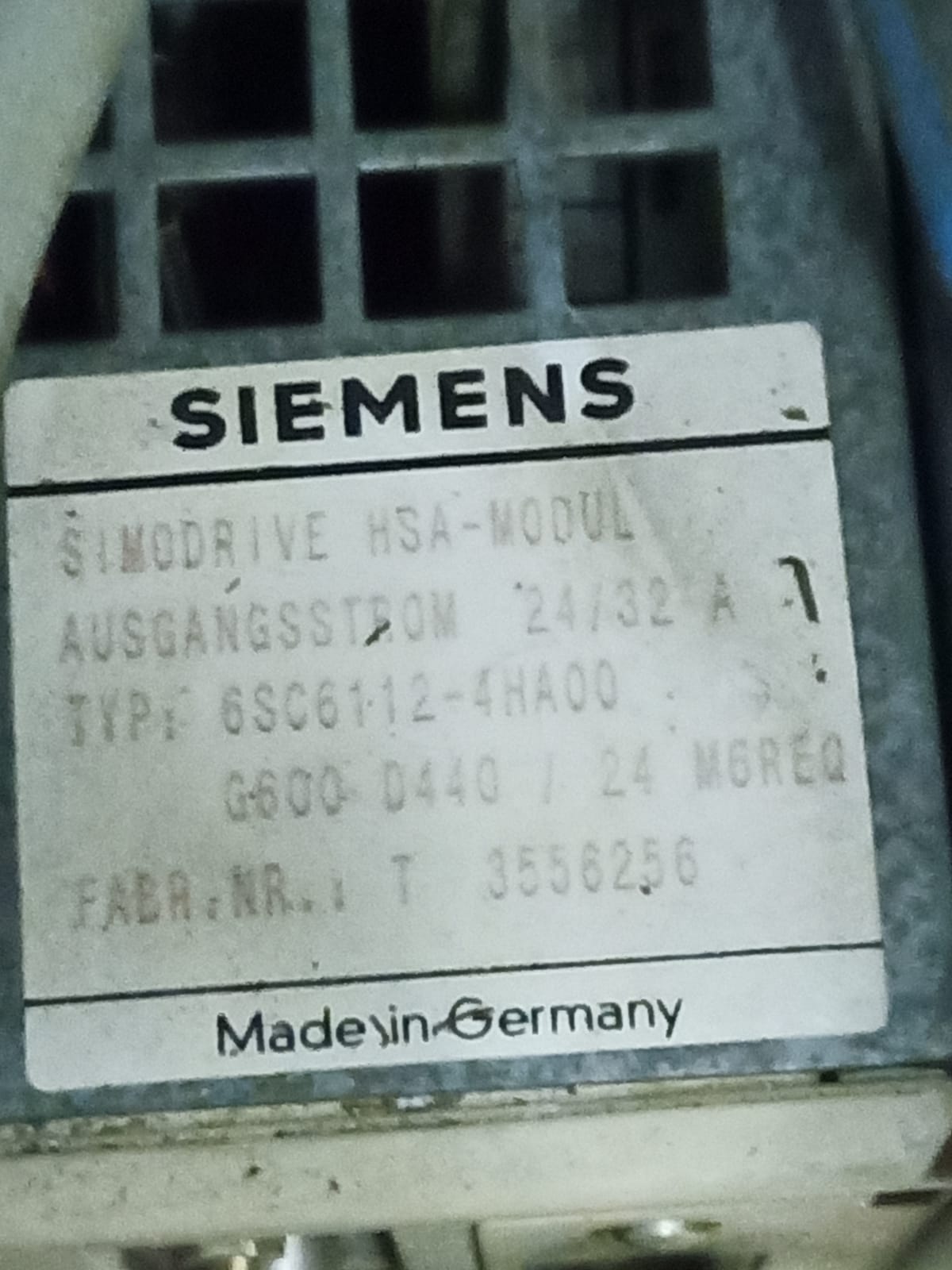

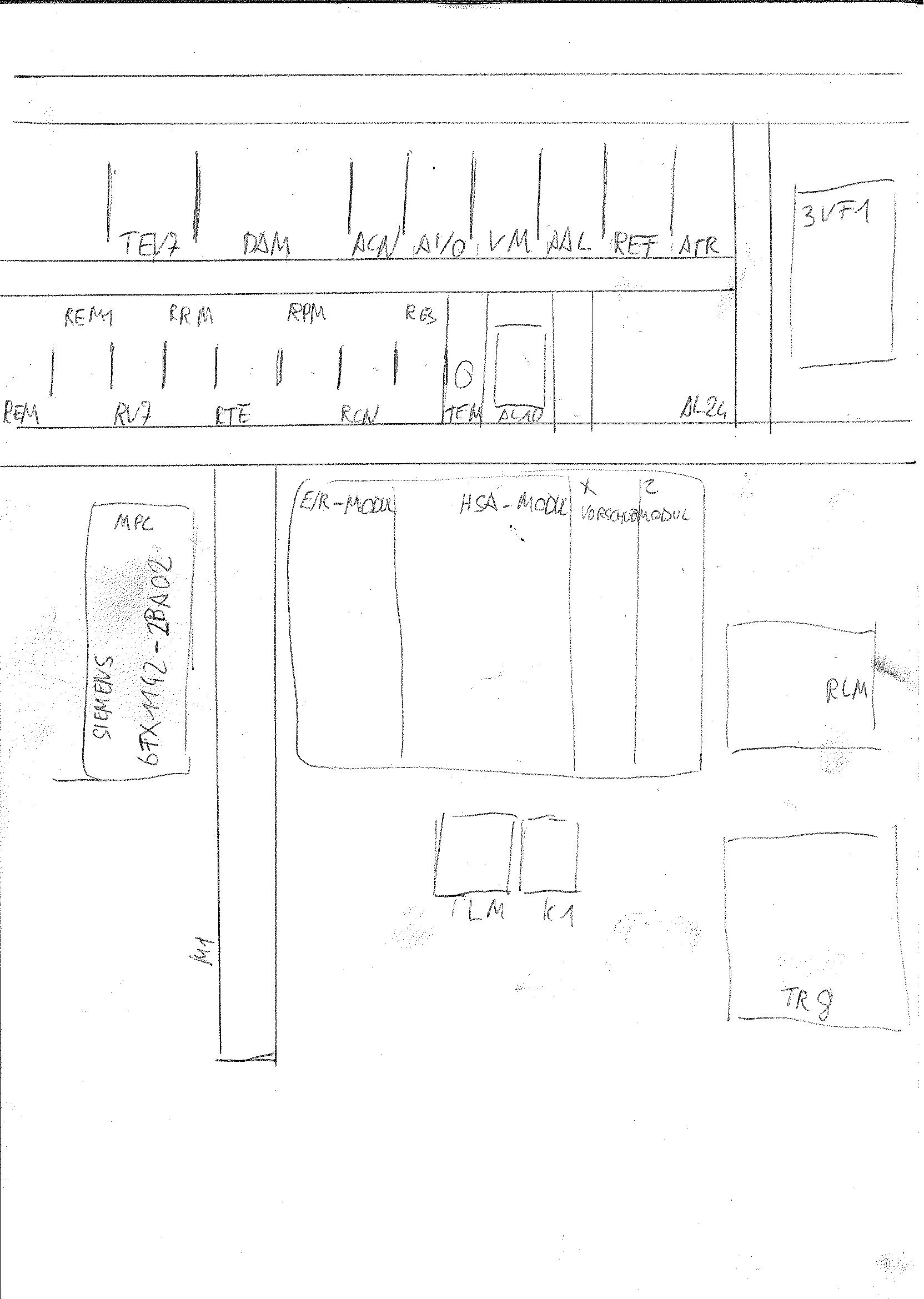

A wiring diagram of the electrics seems to be missing

would probably have been too easy.

In the appendix some more designations.

of the installed control system and drivers.

Replied by DoWerna on topic Padovani LE-200 Retrofit

Hmmm, I have looked through the manuals and file folders.I already have a 7i92 here,

Now I have to study the circuit diagrams to see which cards I still need.

A wiring diagram of the electrics seems to be missing

would probably have been too easy.

In the appendix some more designations.

of the installed control system and drivers.

Attachments:

Please Log in or Create an account to join the conversation.

- DoWerna

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 185

- Thank you received: 57

19 Jan 2022 18:31 - 19 Jan 2022 18:34 #232465

by DoWerna

Replied by DoWerna on topic Padovani LE-200 Retrofit

Attachments:

Last edit: 19 Jan 2022 18:34 by DoWerna.

Please Log in or Create an account to join the conversation.

- DoWerna

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 185

- Thank you received: 57

20 Jan 2022 10:50 #232506

by DoWerna

Replied by DoWerna on topic Padovani LE-200 Retrofit

to start somewhere

support.industry.siemens.com/cs/document...ungen?dti=0&lc=de-WW

this pdf describes the interfaces of the shoring control system.

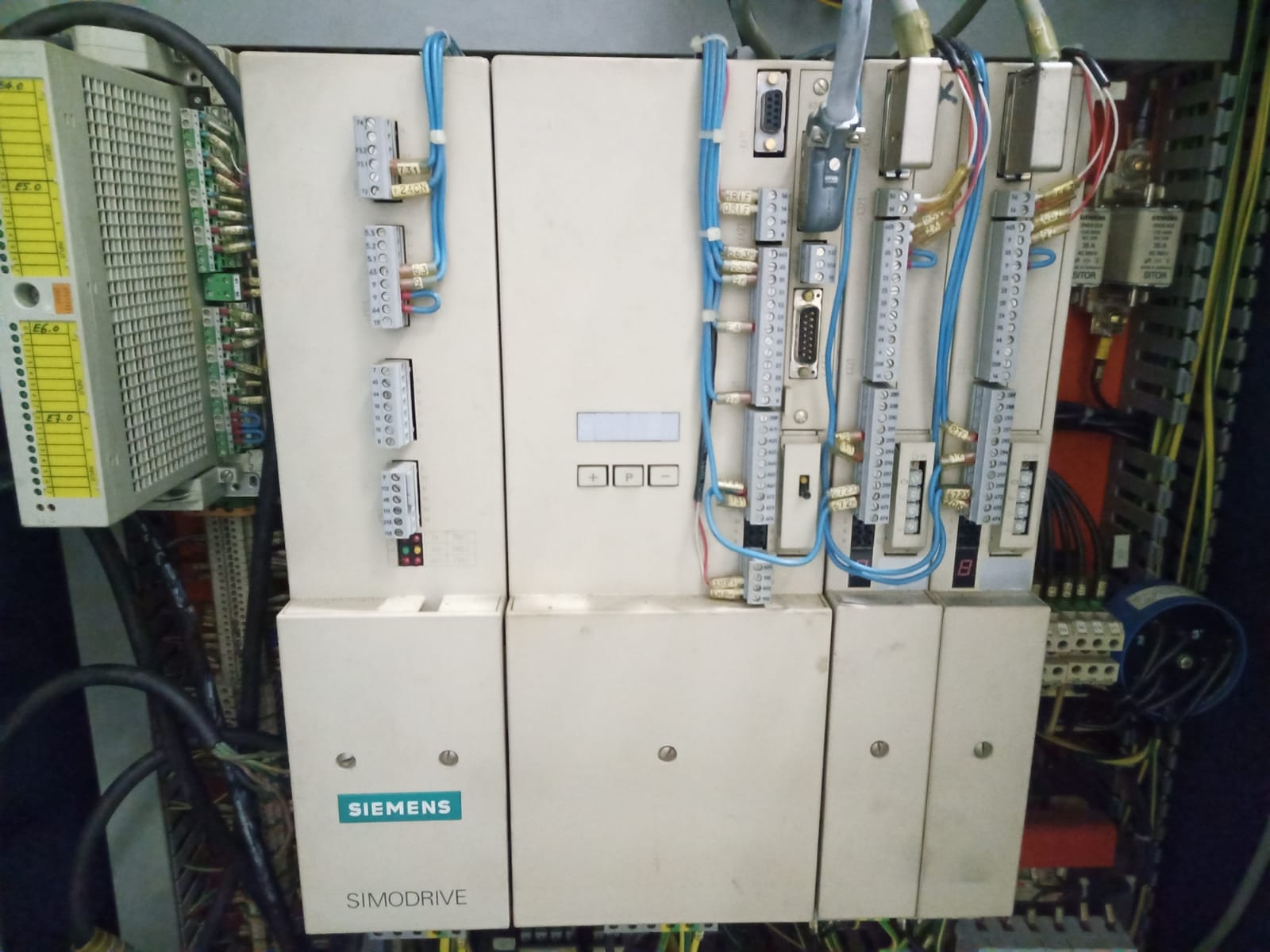

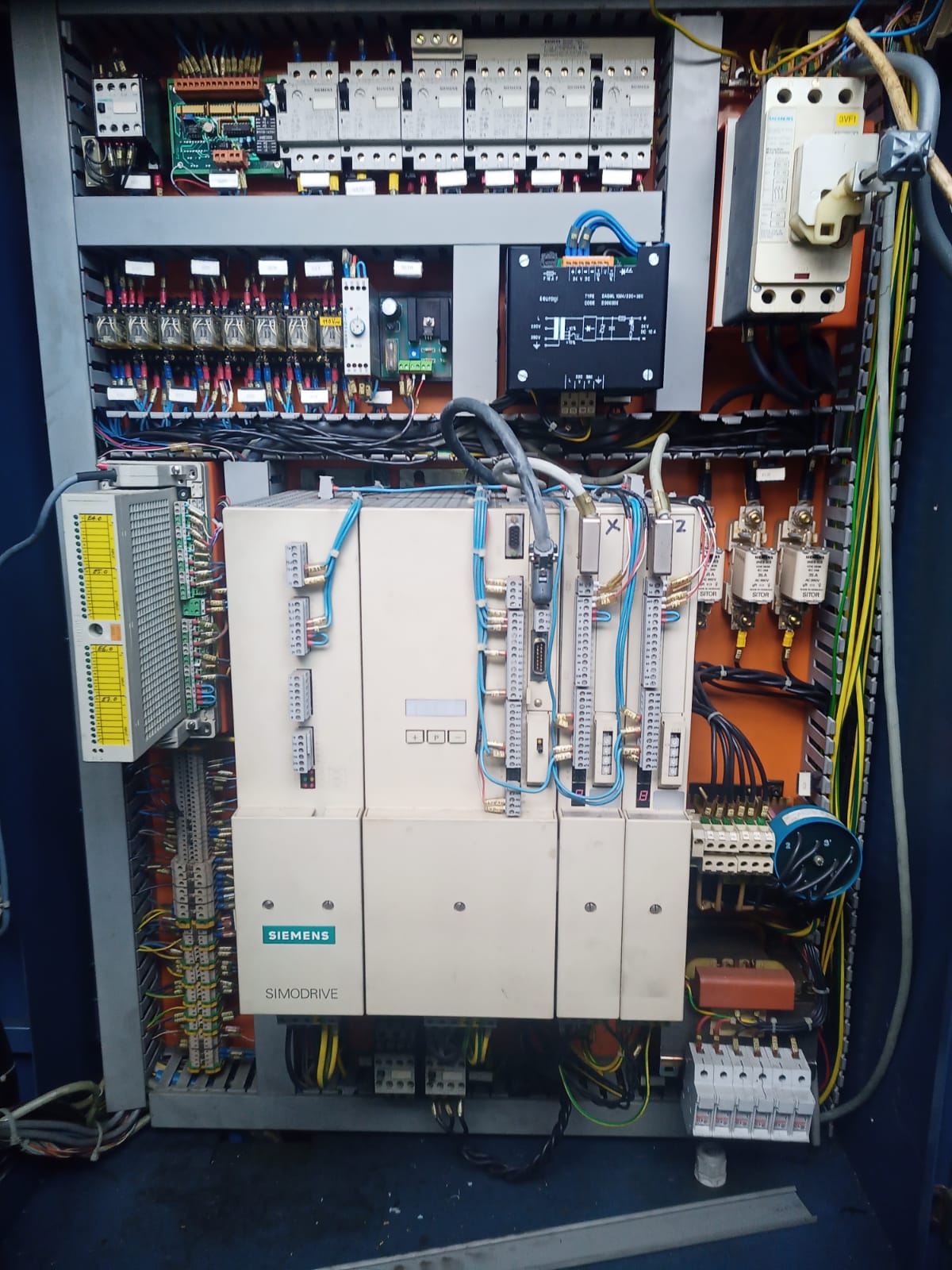

If I see this correctly, the machine really seems to have normal +-10V with encoder or glass scale feedback.

That would be already good

Outputs 24VDC, whether as sinking or sourcing I have to look yet

Connected to the central unit are the +-10V encoders and right PLC outputs as well as inputs, 24VDC.

The task of the so-called MPC module is unclear to me.

It is connected to the central unit via a serial data line.

Placed left next to the servo drives, 6FX1142-2BA02.

It also has many inputs and outputs, which are also connected.

Is the emergency stop chain possibly monitored with it?

Or hardware limit switches?

support.industry.siemens.com/cs/document...ungen?dti=0&lc=de-WW

this pdf describes the interfaces of the shoring control system.

If I see this correctly, the machine really seems to have normal +-10V with encoder or glass scale feedback.

That would be already good

Outputs 24VDC, whether as sinking or sourcing I have to look yet

Connected to the central unit are the +-10V encoders and right PLC outputs as well as inputs, 24VDC.

The task of the so-called MPC module is unclear to me.

It is connected to the central unit via a serial data line.

Placed left next to the servo drives, 6FX1142-2BA02.

It also has many inputs and outputs, which are also connected.

Is the emergency stop chain possibly monitored with it?

Or hardware limit switches?

Attachments:

Please Log in or Create an account to join the conversation.

- DoWerna

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 185

- Thank you received: 57

21 Jan 2022 07:50 #232605

by DoWerna

Replied by DoWerna on topic Padovani LE-200 Retrofit

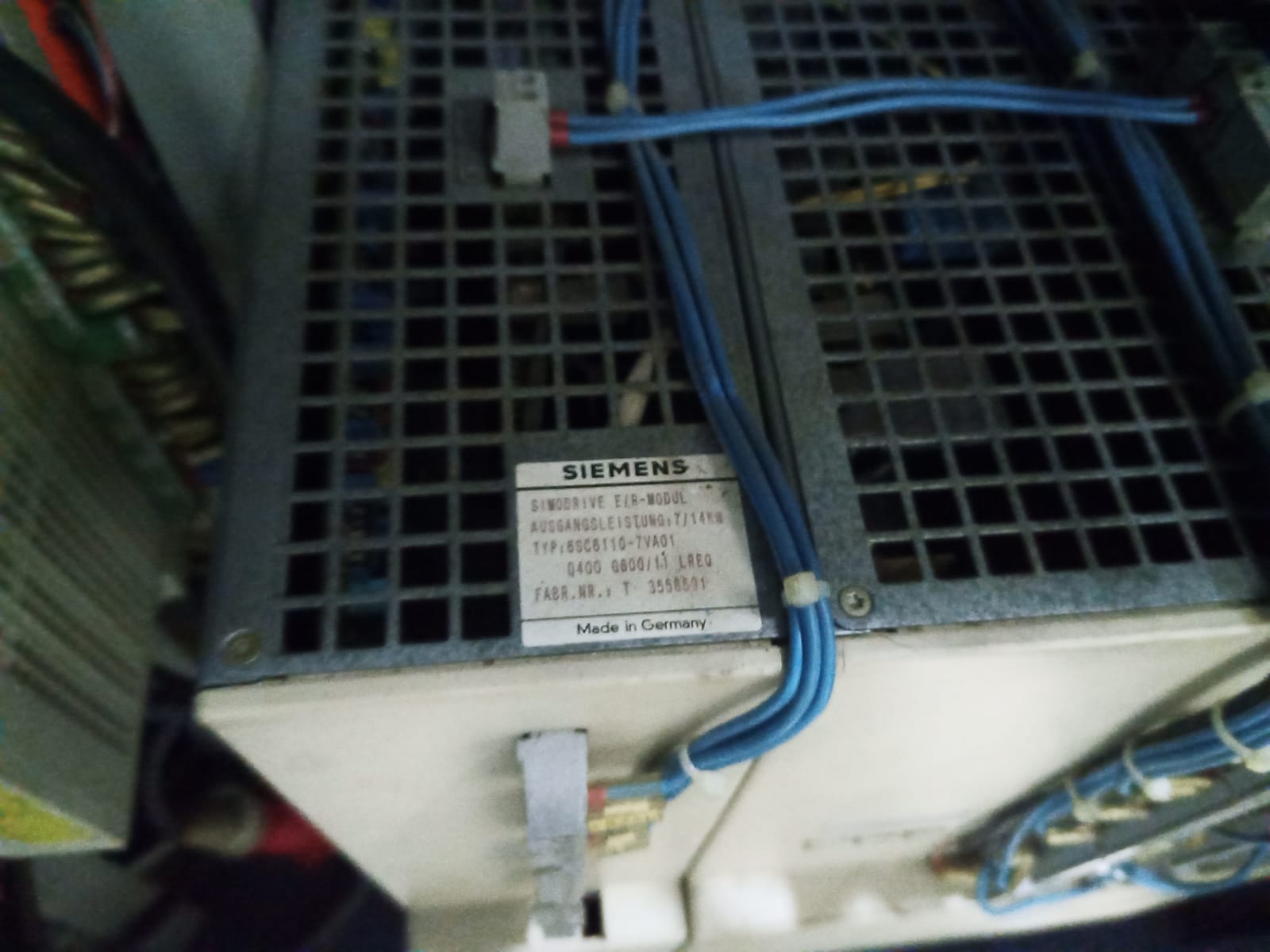

Since I don't have a wiring diagram for the lathe, I traced the path of the power current into the machine yesterday,

Some things are now clear, much is not yet

But will become already...

What I would like to do now.

I would like to trace the complete wiring of the Siemens servo drivers, and understand it.

So I can test the servos with a small variable voltage source and without belts.

Once the servos run, I can remove the existing control system

Unfortunately I have not found any manuals for the Siemens servo drivers so far

Translated with www.DeepL.com/Translator (free version)

Some things are now clear, much is not yet

But will become already...

What I would like to do now.

I would like to trace the complete wiring of the Siemens servo drivers, and understand it.

So I can test the servos with a small variable voltage source and without belts.

Once the servos run, I can remove the existing control system

Unfortunately I have not found any manuals for the Siemens servo drivers so far

Translated with www.DeepL.com/Translator (free version)

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4655

- Thank you received: 2078

21 Jan 2022 17:52 #232664

by Aciera

Replied by Aciera on topic Padovani LE-200 Retrofit

I'm not familiar with Sinumerik controllers but it likely has a PLC built in and the I/O-module on the left would interface all inputs and outputs like limit switches, coolant, and all that.

The following user(s) said Thank You: DoWerna

Please Log in or Create an account to join the conversation.

- DoWerna

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 185

- Thank you received: 57

21 Jan 2022 21:29 #232685

by DoWerna

Replied by DoWerna on topic Padovani LE-200 Retrofit

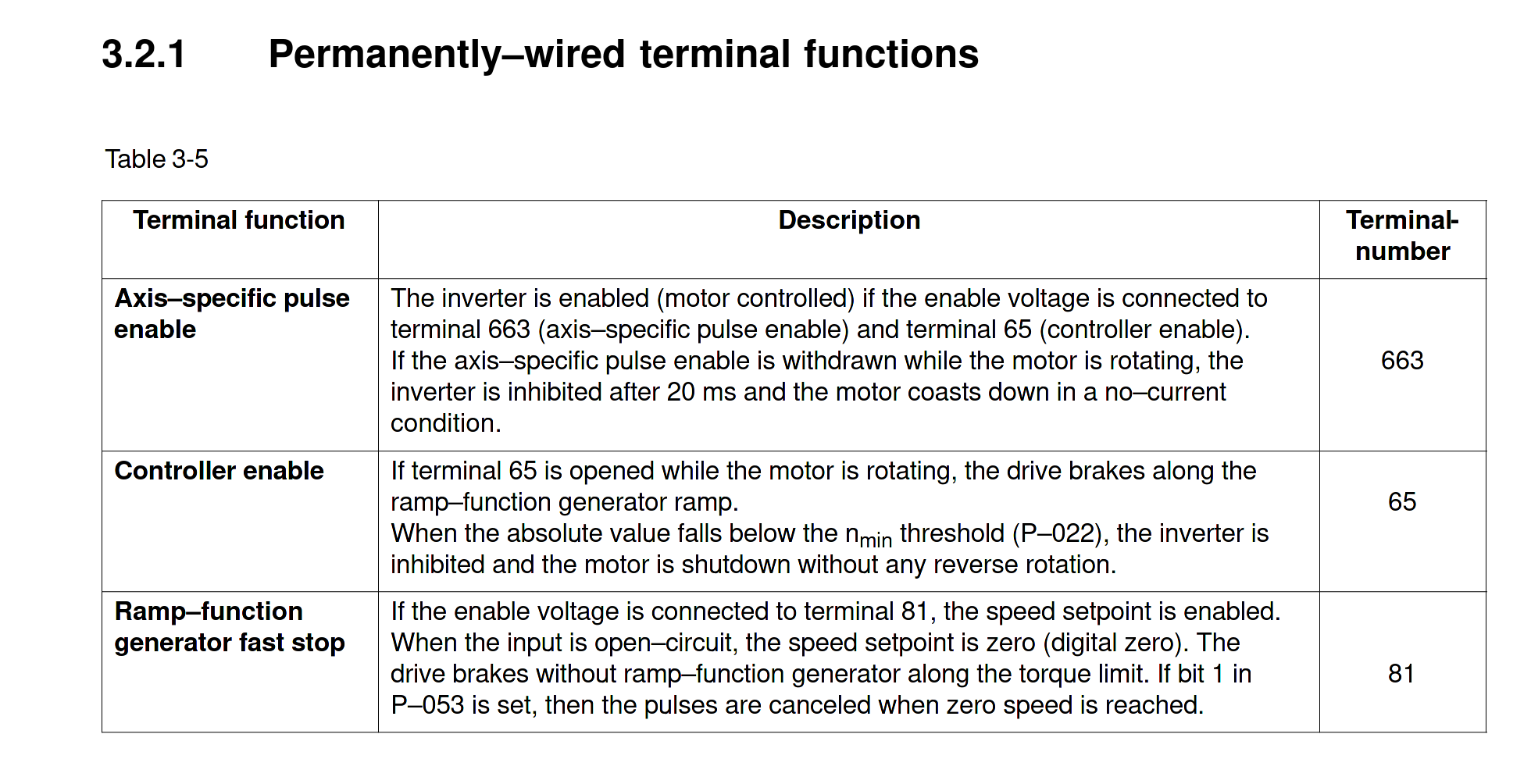

With the pdf from radom I could now assign all connected terminals of the Simodive.

forum.linuxcnc.org/30-cnc-machines/36886...he-retrofit?start=30

I am still unclear about the meaning of the individual enable connections on the spindle driver.

There we have a so called

"pulse enable" (663) and a

"controller enable" (65)

both separately switched via a relay.

and both refer only to the spindle motor.

Furthermore an input E4, also switched with a relay.

Freely programmable according to the manual.

forum.linuxcnc.org/30-cnc-machines/36886...he-retrofit?start=30

I am still unclear about the meaning of the individual enable connections on the spindle driver.

There we have a so called

"pulse enable" (663) and a

"controller enable" (65)

both separately switched via a relay.

and both refer only to the spindle motor.

Furthermore an input E4, also switched with a relay.

Freely programmable according to the manual.

Please Log in or Create an account to join the conversation.

- DoWerna

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 185

- Thank you received: 57

21 Jan 2022 22:26 #232692

by DoWerna

Replied by DoWerna on topic Padovani LE-200 Retrofit

Attachments:

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 2.515 seconds