Crusader II retrofit

- jamby

- Offline

- Elite Member

-

Less

More

- Posts: 235

- Thank you received: 6

04 Feb 2016 15:44 #69585

by jamby

Replied by jamby on topic Crusader II retrofit

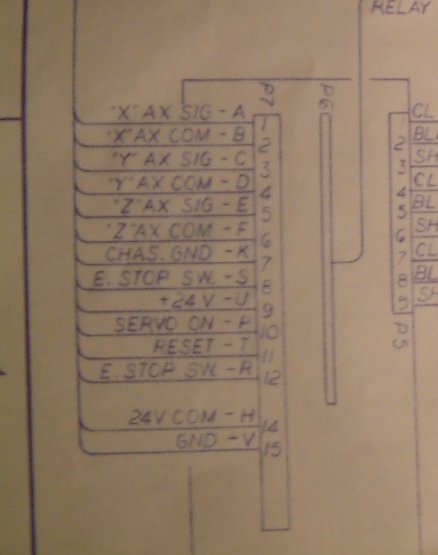

OOPS looks like I neglected to connect (6) important wires. Sig and Com to each of the axis at TB5.

So off to the big city to buy more supplies.

forgetful

Jim

So off to the big city to buy more supplies.

forgetful

Jim

Please Log in or Create an account to join the conversation.

- jamby

- Offline

- Elite Member

-

Less

More

- Posts: 235

- Thank you received: 6

04 Feb 2016 18:56 #69602

by jamby

Replied by jamby on topic Crusader II retrofit

Hey, on the drive to town I started thinking about the connections going into the Anilam Control Box. In the picture below I will be taking the first (6) wires "AX SIG and AX COM and rerouteing them to the TB5 connections on the 7i77. How hard would it be to take all the connections and route them through the 7i77's TB8 and completely remove the Anilam Control Box.

Thanks

Jim

Thanks

Jim

Please Log in or Create an account to join the conversation.

- punking

- Offline

- Junior Member

-

Less

More

- Posts: 35

- Thank you received: 1

04 Feb 2016 23:02 #69621

by punking

Replied by punking on topic Crusader II retrofit

Get it running first then you probably can redo the rest of the circuits to the 7i77

Please Log in or Create an account to join the conversation.

- jamby

- Offline

- Elite Member

-

Less

More

- Posts: 235

- Thank you received: 6

05 Feb 2016 18:32 #69659

by jamby

Replied by jamby on topic Crusader II retrofit

Okay

I jury rigged another wire from the A-B in the picture above to the ENA0 - COM on TB5. And X axis jogs back and forth in continuous and also moves 1.000 on the linuxcnc readout in increment 1.0. But there is the dreaded dither while holding location. The readout moves back and forth between 1.0002 and 0.9998 while the hand wheel moves slightly back and forth..

Should I test with the current setup moving the A-B feed into the other axis and try jogging them?

As side Note:

When I powered it back up the main relay was heard to engage but the drives didn't come on....panic. After much sole searching I noticed X was on the limit as I had move X and Y out for room to access the servo cabinet. Off limit try again ?! still no servo power uuurrrrr. Oh hello the Y axis also is at the limit... no that's not it.... Oh yeah I did some manual machining last night and switched to manual on the back of the servo box... FINAL the servos came up when the power switch on linuxcnc was pressed the motors started whining (almost as load as I am) and ....... It jogged...happy day (30mins later)

Jim

I jury rigged another wire from the A-B in the picture above to the ENA0 - COM on TB5. And X axis jogs back and forth in continuous and also moves 1.000 on the linuxcnc readout in increment 1.0. But there is the dreaded dither while holding location. The readout moves back and forth between 1.0002 and 0.9998 while the hand wheel moves slightly back and forth..

Should I test with the current setup moving the A-B feed into the other axis and try jogging them?

As side Note:

When I powered it back up the main relay was heard to engage but the drives didn't come on....panic. After much sole searching I noticed X was on the limit as I had move X and Y out for room to access the servo cabinet. Off limit try again ?! still no servo power uuurrrrr. Oh hello the Y axis also is at the limit... no that's not it.... Oh yeah I did some manual machining last night and switched to manual on the back of the servo box... FINAL the servos came up when the power switch on linuxcnc was pressed the motors started whining (almost as load as I am) and ....... It jogged...happy day (30mins later)

Jim

Please Log in or Create an account to join the conversation.

- punking

- Offline

- Junior Member

-

Less

More

- Posts: 35

- Thank you received: 1

05 Feb 2016 18:36 #69660

by punking

Replied by punking on topic Crusader II retrofit

My system does the same dithering . But, it holds position between tool changes and holds origin from one setup to the next. So in all it hasn't been a problem.

Please Log in or Create an account to join the conversation.

- jamby

- Offline

- Elite Member

-

Less

More

- Posts: 235

- Thank you received: 6

05 Feb 2016 20:35 #69665

by jamby

Replied by jamby on topic Crusader II retrofit

Tried it with all 3 axis wire in.

X slow drift in positive direction maybe a 1 in 10 min.

Y runaway in positive direction hits .5 ferror drifts to a halt. I think.

Z holding steady with slight dither.

X Z tested with Y disconnected.

Don't know where to go now. I've traced the wiring and don't see a problem but I may need to pull it apart and test each lead.

Jim

X slow drift in positive direction maybe a 1 in 10 min.

Y runaway in positive direction hits .5 ferror drifts to a halt. I think.

Z holding steady with slight dither.

X Z tested with Y disconnected.

Don't know where to go now. I've traced the wiring and don't see a problem but I may need to pull it apart and test each lead.

Jim

Please Log in or Create an account to join the conversation.

- jamby

- Offline

- Elite Member

-

Less

More

- Posts: 235

- Thank you received: 6

05 Feb 2016 21:04 #69667

by jamby

Replied by jamby on topic Crusader II retrofit

Yes it spits out a

joint 1 following error

joint 1 following error

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17728

- Thank you received: 5186

05 Feb 2016 21:05 #69668

by PCW

Sounds like X analog out is not connected (or P term is 0)

Likely means you need to reverse the analog out sign on Y

( Remember my list of 4 things needed to get the servo system working )

Replied by PCW on topic Crusader II retrofit

X slow drift in positive direction maybe a 1 in 10 min.

Sounds like X analog out is not connected (or P term is 0)

Y runaway in positive direction hits .5 ferror drifts to a halt. I think.

Likely means you need to reverse the analog out sign on Y

( Remember my list of 4 things needed to get the servo system working )

Please Log in or Create an account to join the conversation.

- jamby

- Offline

- Elite Member

-

Less

More

- Posts: 235

- Thank you received: 6

05 Feb 2016 21:11 #69670

by jamby

Replied by jamby on topic Crusader II retrofit

PCW

Ummm hate to admit it but X analog out and P term are subjects I am more then a bit foggy about. Are you referring to the ENA0 and COM at TB5 DRV0?

P term is that the P value in the ini file?

Thanks for your help

Jim

Ummm hate to admit it but X analog out and P term are subjects I am more then a bit foggy about. Are you referring to the ENA0 and COM at TB5 DRV0?

P term is that the P value in the ini file?

Thanks for your help

Jim

Please Log in or Create an account to join the conversation.

- punking

- Offline

- Junior Member

-

Less

More

- Posts: 35

- Thank you received: 1

05 Feb 2016 21:28 #69671

by punking

Replied by punking on topic Crusader II retrofit

Since you are running linuxCNC

Go up to tool bar and select machine>calibration

You'll se tune 0

Tune 1

Tune2

These are you axis'

These machines are running a pid (velocity) loop nested in a pid loop ( at least that the way I see it)

LinuxCNC allows us to fine tune the servos

P value on mine happen to be 45

I is 0

D is 0

Bias is 0

FF0 is 0

FF1 is 0.1

FF2 is 0

Try on all axis and see how it reacts

Go up to tool bar and select machine>calibration

You'll se tune 0

Tune 1

Tune2

These are you axis'

These machines are running a pid (velocity) loop nested in a pid loop ( at least that the way I see it)

LinuxCNC allows us to fine tune the servos

P value on mine happen to be 45

I is 0

D is 0

Bias is 0

FF0 is 0

FF1 is 0.1

FF2 is 0

Try on all axis and see how it reacts

The following user(s) said Thank You: jamby

Please Log in or Create an account to join the conversation.

Time to create page: 0.363 seconds