Emcoturn 120 lathe retrofit

- LutzTD

- Offline

- Elite Member

-

Less

More

- Posts: 216

- Thank you received: 1

28 Apr 2016 00:40 - 28 Apr 2016 00:41 #73976

by LutzTD

Replied by LutzTD on topic Emcoturn 120 lathe retrofit

I am a newb so forgive me if it sounds like I have my heart set on the smooth stepper or the C32 PCB. Its just what I know so I use that as a baseline. In addition to the above I/O I will need toolchanger control. Basically the toolchanger will use tome's Toolerator 3000 which has an onboard arduino so I think it just needs an additional output for the tool call and an input for the tool set signal. not sure what cc/ccw means. Does the vexta not use step and direction?

Last edit: 28 Apr 2016 00:41 by LutzTD.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

Less

More

- Posts: 4696

- Thank you received: 1439

28 Apr 2016 02:26 #73978

by Todd Zuercher

Replied by Todd Zuercher on topic Emcoturn 120 lathe retrofit

CW/CCW is an abbreviation for ClockWise/Counter ClockWise. and I think that those drives use that input system. The drives expect step pulses on the CW input to turn clockwise, and pulses on the CCW input to turn counter-clockwise.

I am completely ignorant of your tool changer arrangement, and the need for the "Toolerator 3000" and exactly what it does. How did the original control operate the tool changer, and what might be the difficulties of reusing the old systems?

I am completely ignorant of your tool changer arrangement, and the need for the "Toolerator 3000" and exactly what it does. How did the original control operate the tool changer, and what might be the difficulties of reusing the old systems?

Please Log in or Create an account to join the conversation.

- LutzTD

- Offline

- Elite Member

-

Less

More

- Posts: 216

- Thank you received: 1

28 Apr 2016 02:37 #73979

by LutzTD

Replied by LutzTD on topic Emcoturn 120 lathe retrofit

the toolerator 3000 is a PCBA and programming for linuxcnc ans arduino to operate the emco toolchanger done by user tome here on this board.. A more detailed explanation is here in this thread forum.linuxcnc.org/forum/26-turning/2928...-tool-turret-control . I have already sourced pcbs and built a toolerator 3000 pcba which I planned to use either with linxucnc or mach.

Please Log in or Create an account to join the conversation.

- tome

- Offline

- Premium Member

-

Less

More

- Posts: 116

- Thank you received: 11

28 Apr 2016 04:40 - 28 Apr 2016 04:51 #73984

by tome

The tool turret on the EMCO 120P uses a brushless DC motor connected to a worm gear that drives the turret. There is a gray code encoder that reads the tool position. The original controller would take the change tool command with tool number,, turn the turret just past that tool position (based on the reading of the encoder) and then back the DC motor up at which point a spring loaded pawl stops the turret at that position. The current to the motor is dropped to hold the motor in that position without overheating it.

The Toolerator 3000 is an Arduino and LMD18245 motor driver based version of that controller logic. It takes the tool change from Linuxcnc via USB port and reads the encoder and appropriately controls the motor. It is one of several controllers for the EMCO (and other) turret. It is specfically set up for Linuxcnc but I am sure it could easily be commanded from Mach if need be.

-Tom

Replied by tome on topic Emcoturn 120 lathe retrofit

I am completely ignorant of your tool changer arrangement, and the need for the "Toolerator 3000" and exactly what it does. How did the original control operate the tool changer, and what might be the difficulties of reusing the old systems?

The tool turret on the EMCO 120P uses a brushless DC motor connected to a worm gear that drives the turret. There is a gray code encoder that reads the tool position. The original controller would take the change tool command with tool number,, turn the turret just past that tool position (based on the reading of the encoder) and then back the DC motor up at which point a spring loaded pawl stops the turret at that position. The current to the motor is dropped to hold the motor in that position without overheating it.

The Toolerator 3000 is an Arduino and LMD18245 motor driver based version of that controller logic. It takes the tool change from Linuxcnc via USB port and reads the encoder and appropriately controls the motor. It is one of several controllers for the EMCO (and other) turret. It is specfically set up for Linuxcnc but I am sure it could easily be commanded from Mach if need be.

-Tom

Last edit: 28 Apr 2016 04:51 by tome.

Please Log in or Create an account to join the conversation.

- tome

- Offline

- Premium Member

-

Less

More

- Posts: 116

- Thank you received: 11

28 Apr 2016 04:42 - 28 Apr 2016 04:47 #73985

by tome

The Vexta drives take step/dir. I can post my config files if you'd like to see them. I am using a different set of hardware (6i25, 7i84 and 7i85s) but they would give you the idea...

-Tom

Replied by tome on topic Emcoturn 120 lathe retrofit

CW/CCW is an abbreviation for ClockWise/Counter ClockWise. and I think that those drives use that input system. The drives expect step pulses on the CW input to turn clockwise, and pulses on the CCW input to turn counter-clockwise.

The Vexta drives take step/dir. I can post my config files if you'd like to see them. I am using a different set of hardware (6i25, 7i84 and 7i85s) but they would give you the idea...

-Tom

Last edit: 28 Apr 2016 04:47 by tome.

Please Log in or Create an account to join the conversation.

- tome

- Offline

- Premium Member

-

Less

More

- Posts: 116

- Thank you received: 11

28 Apr 2016 04:59 #73987

by tome

Replied by tome on topic Emcoturn 120 lathe retrofit

BTW, I don't know how much information you have on your lathe but I have accumulated a significant amount of information (much in PDF form). If you'd like I can post it here (or elsewhere)...

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19797

- Thank you received: 4606

28 Apr 2016 09:26 #73992

by andypugh

Thinking about this a little further, you should definitely use LinuxCNC for this lathe, because it is a lathe. Mach3 is perfectly adequate for milling machines, but has well-known shortcomings for lathe control. This is why Tormach switched to LinuxCNC when they started to make a lathe. The main difference is that Mach3 does not slave the Z axis to the spindle encoder when threading. This means that even if the spindle slows during a threading pass the thread pitch is unaffected. You can even stop the spindle during the threading pass and it keeps synch:

Mach3 can do external threading reasonably well as long as the spindle speed does not change, but it can't really do rigid-tapping. which is where the spindle is reversed at the bottom of the pass and the tap is backed-out. Mach3 can "fake" this with a servo spindle by making coordinated spindle and Z moves, but I don't think that the Emcoturn has this degree of spindle control.

Normally I don't make any specific recommendation between LinuxCNC or Mach3, the choice should be down to the user, but for a lathe I believe there are good arguments that LinuxCNC works better.

Replied by andypugh on topic Emcoturn 120 lathe retrofit

I am a newb so forgive me if it sounds like I have my heart set on the smooth stepper or the C32 PCB. Its just what I know so I use that as a baseline.

Thinking about this a little further, you should definitely use LinuxCNC for this lathe, because it is a lathe. Mach3 is perfectly adequate for milling machines, but has well-known shortcomings for lathe control. This is why Tormach switched to LinuxCNC when they started to make a lathe. The main difference is that Mach3 does not slave the Z axis to the spindle encoder when threading. This means that even if the spindle slows during a threading pass the thread pitch is unaffected. You can even stop the spindle during the threading pass and it keeps synch:

Mach3 can do external threading reasonably well as long as the spindle speed does not change, but it can't really do rigid-tapping. which is where the spindle is reversed at the bottom of the pass and the tap is backed-out. Mach3 can "fake" this with a servo spindle by making coordinated spindle and Z moves, but I don't think that the Emcoturn has this degree of spindle control.

Normally I don't make any specific recommendation between LinuxCNC or Mach3, the choice should be down to the user, but for a lathe I believe there are good arguments that LinuxCNC works better.

Please Log in or Create an account to join the conversation.

- LutzTD

- Offline

- Elite Member

-

Less

More

- Posts: 216

- Thank you received: 1

28 Apr 2016 11:15 #73999

by LutzTD

Would be nice for me to have any info attached here. I have a few things but not much of the detailed stuff. Of course since its gutted maybe most of the detail no longer applies but it would be good reference for system architecture. Along with that anything you want to share in the way of your retrofit setup and linuxcnc code certainly would help. It sounds so far like I can get better functionality at a lower initial cost with a linuxcnc system, Im just worried that 5 years from now if something goes wrong I will need to relearn everything., but it sounds like its worth the risk. Maybe the next lathe or mill retrofit (id like to do a large vmc with a toolchanger if I can find a dead control HAAS or mazak for cheap) will keep me up to date or even increase my knowledge base instead of forgetting it later.

Replied by LutzTD on topic Emcoturn 120 lathe retrofit

BTW, I don't know how much information you have on your lathe but I have accumulated a significant amount of information (much in PDF form). If you'd like I can post it here (or elsewhere)...

Would be nice for me to have any info attached here. I have a few things but not much of the detailed stuff. Of course since its gutted maybe most of the detail no longer applies but it would be good reference for system architecture. Along with that anything you want to share in the way of your retrofit setup and linuxcnc code certainly would help. It sounds so far like I can get better functionality at a lower initial cost with a linuxcnc system, Im just worried that 5 years from now if something goes wrong I will need to relearn everything., but it sounds like its worth the risk. Maybe the next lathe or mill retrofit (id like to do a large vmc with a toolchanger if I can find a dead control HAAS or mazak for cheap) will keep me up to date or even increase my knowledge base instead of forgetting it later.

Please Log in or Create an account to join the conversation.

- LutzTD

- Offline

- Elite Member

-

Less

More

- Posts: 216

- Thank you received: 1

28 Apr 2016 13:13 #74000

by LutzTD

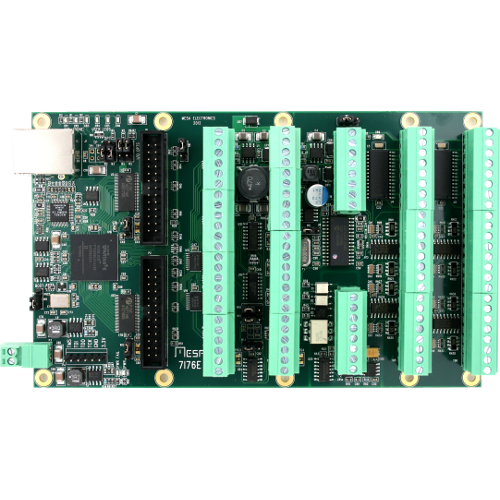

Im liking the Mesa 7i76e ethernet i/o board. If I were to go that route I could keep the dell fx170 thinclient, would I need any other boards with this as it is also cheaper than the pci io and 2 daughter cards from mesa.

Replied by LutzTD on topic Emcoturn 120 lathe retrofit

For little more than your C32 board you could get a mesa 7i76E, and eliminate items 2,3 and 4 from your shopping list. (it is the breakout, spindle encoder counter, vfd control, and hardware step-generator, all in one.

But if you already have your heart set on, or already have that other stuff a configuration could probably be put together that could directly replace a smoothstepper using a 7i92.

One benifit of using Linuxcnc over Mach might be that Linuxcnc can generate other step output paterns than just step/dir. CW/CCW and quadrature as well as a few more obscure options are available. (I think those vexta drives may use CW/CCW.)

Im liking the Mesa 7i76e ethernet i/o board. If I were to go that route I could keep the dell fx170 thinclient, would I need any other boards with this as it is also cheaper than the pci io and 2 daughter cards from mesa.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19797

- Thank you received: 4606

28 Apr 2016 13:23 #74001

by andypugh

You might need a USB Network dongle of some sort, the 7i76 will occupy the only ethernet port. However, you should have more than enough stepgens and GPIO for the lathe on the 7i76, and I would expect that the spindle interface can operate the spindle.

Replied by andypugh on topic Emcoturn 120 lathe retrofit

Im liking the Mesa 7i76e ethernet i/o board. If I were to go that route I could keep the dell fx170 thinclient, would I need any other boards with this as it is also cheaper than the pci io and 2 daughter cards from mesa.

You might need a USB Network dongle of some sort, the 7i76 will occupy the only ethernet port. However, you should have more than enough stepgens and GPIO for the lathe on the 7i76, and I would expect that the spindle interface can operate the spindle.

Please Log in or Create an account to join the conversation.

Time to create page: 0.137 seconds