- Hardware & Machines

- CNC Machines

- Plasma & Laser

- Anyone Actually Using External Offsets Branch for THC?

Anyone Actually Using External Offsets Branch for THC?

- islander261

- Offline

- Platinum Member

-

Less

More

- Posts: 757

- Thank you received: 216

28 Jan 2018 00:09 #105090

by islander261

Replied by islander261 on topic Anyone Actually Using External Offsets Branch for THC?

Hello

Well I have made some progress towards having working THC using the eoffsets branch. I have looked at the source code (I'm not a programmer) till my eyes bugged out get my head wrapped around this thing. I have cut nearly 100 test lines in the shop trying to find a configuration the works well. Thanks to Dewey for all the hard work he put in getting it this far.

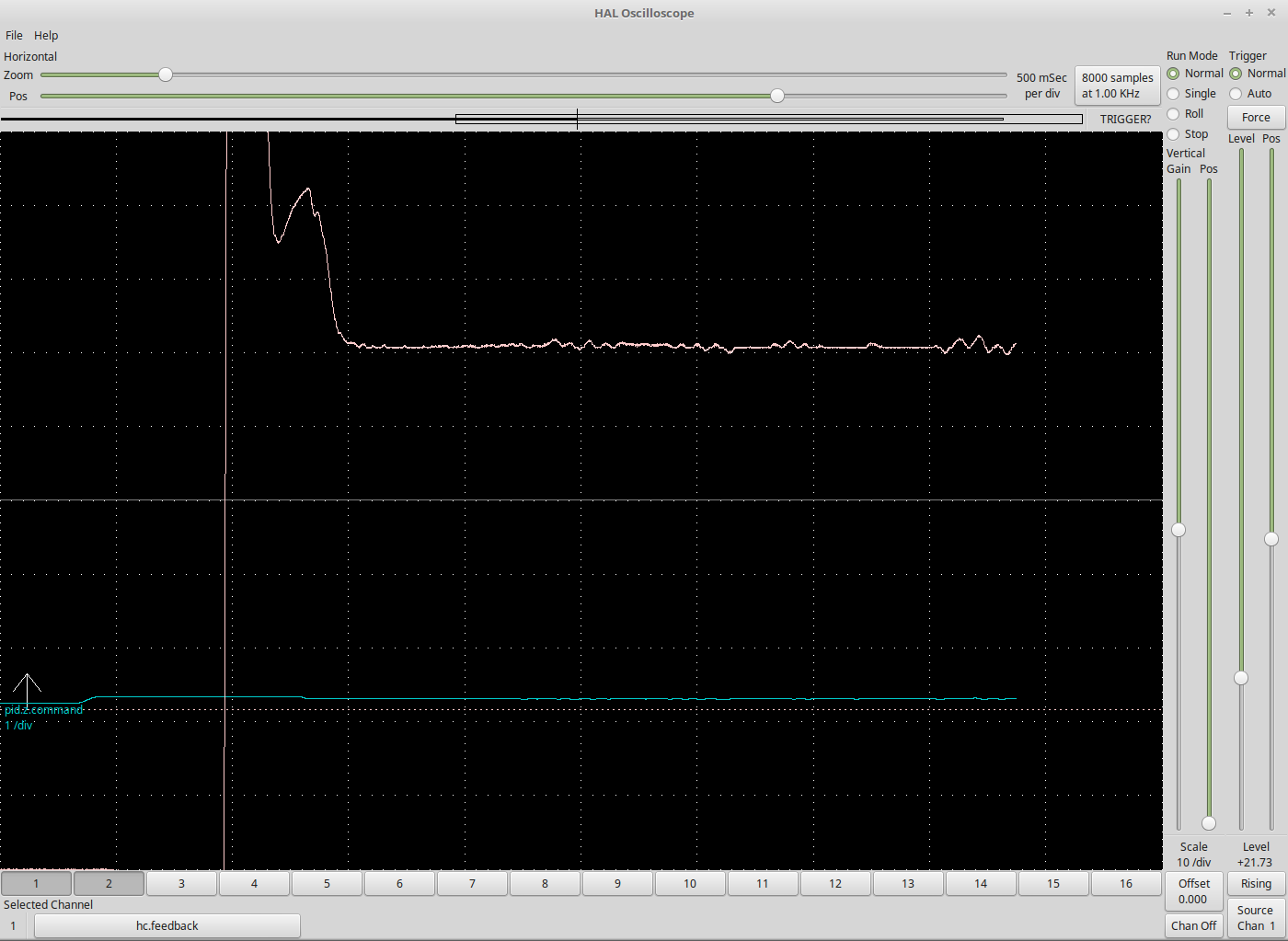

What I have now is THC in a straight line with no corner hold or kerf crossing tested. The torch holds 2v (.010") pk-pk or better position while following gently bending sheet. The height control is still a little "nervous" for my tastes but much better than previously. The cut is good with no noticeable variation in taper or kerf width. I have even gotten to test many of the extra features I added to my GUI. I think I will have a total rebuild of my GUI before putting this into production use. I also need to reinstall the eoffsets branch because it has been rebased since my last install.

My configuration is not the standard one for testing the eoffsets branch. I am using eoffsets_pid Pgain =1 and Dgain =.1. My machine is an inch units machine. My z axis is set to maximum velocity of 220 ipm with an acceleration of .15g. Here are the deviations from the standard test configuration files that I have.

During my testing I found that it would have been really nice to have separate scaling factors for both axis velocity and acceleration.

Tonight I have to reinstall my old commercial controller so I can get back into production. It will be a month or more before I get a chance to dive back into this, maybe someone else can clear more of the path in that time.

John

Well I have made some progress towards having working THC using the eoffsets branch. I have looked at the source code (I'm not a programmer) till my eyes bugged out get my head wrapped around this thing. I have cut nearly 100 test lines in the shop trying to find a configuration the works well. Thanks to Dewey for all the hard work he put in getting it this far.

What I have now is THC in a straight line with no corner hold or kerf crossing tested. The torch holds 2v (.010") pk-pk or better position while following gently bending sheet. The height control is still a little "nervous" for my tastes but much better than previously. The cut is good with no noticeable variation in taper or kerf width. I have even gotten to test many of the extra features I added to my GUI. I think I will have a total rebuild of my GUI before putting this into production use. I also need to reinstall the eoffsets branch because it has been rebased since my last install.

My configuration is not the standard one for testing the eoffsets branch. I am using eoffsets_pid Pgain =1 and Dgain =.1. My machine is an inch units machine. My z axis is set to maximum velocity of 220 ipm with an acceleration of .15g. Here are the deviations from the standard test configuration files that I have.

#net z-vel-cmd <= joint.2.vel-cmd

#net z-vel-cmd => pid.z.command-deriv

setp hc.k 57

setp axis.z.eoffset-scale .0001During my testing I found that it would have been really nice to have separate scaling factors for both axis velocity and acceleration.

Tonight I have to reinstall my old commercial controller so I can get back into production. It will be a month or more before I get a chance to dive back into this, maybe someone else can clear more of the path in that time.

John

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11722

- Thank you received: 3968

28 Jan 2018 00:42 #105091

by rodw

Replied by rodw on topic Anyone Actually Using External Offsets Branch for THC?

John, great you have made some progress. You prompted me to read the whole thread again.

When you say this:

You are referring to being able to alter the velocity and acceleration values in the ini file right?

The hpid GUI provides a window for this and you can implement it in your config by adding this to your ini file (update the path)

I found I had to add the complete path to sim_pin but for some reasons the sims don't need to. I've never worked out if sim_pin is something added by Dewey on this branch or if its included in LinuxCNC. It is very handy though.

When you say this:

Hello

During my testing I found that it would have been really nice to have separate scaling factors for both axis velocity and acceleration.

You are referring to being able to alter the velocity and acceleration values in the ini file right?

The hpid GUI provides a window for this and you can implement it in your config by adding this to your ini file (update the path)

[APPLICATIONS]

# delay because some pins are postgui

DELAY = 3

APP = /home/plasma/linuxcnc-dev/scripts/sim_pin --title "INI A/V" \

APP = sim_pin --title "INI A/V" \

ini.z.max_velocity \

ini.z.max_accelerationI found I had to add the complete path to sim_pin but for some reasons the sims don't need to. I've never worked out if sim_pin is something added by Dewey on this branch or if its included in LinuxCNC. It is very handy though.

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

Less

More

- Posts: 757

- Thank you received: 216

28 Jan 2018 01:03 #105092

by islander261

Replied by islander261 on topic Anyone Actually Using External Offsets Branch for THC?

Rod

Well I was actually thinking about this snippet:

OFFSET_AV_RATIO = .5

MAX_VELOCITY = 7.7776

MAX_ACCELERATION = 110

Having one ratio for A and on for V. I will look at what you posted, it may do the same thing. Though I doubt it is needed for a production machine.

John

Well I was actually thinking about this snippet:

OFFSET_AV_RATIO = .5

MAX_VELOCITY = 7.7776

MAX_ACCELERATION = 110

Having one ratio for A and on for V. I will look at what you posted, it may do the same thing. Though I doubt it is needed for a production machine.

John

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11722

- Thank you received: 3968

28 Jan 2018 01:26 #105093

by rodw

Replied by rodw on topic Anyone Actually Using External Offsets Branch for THC?

John, it only lets you change these 2 on the fly

I don't think we need to change OFFSET_AV_RATIO

MAX_VELOCITY = 7.7776

MAX_ACCELERATION = 110I don't think we need to change OFFSET_AV_RATIO

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

Less

More

- Posts: 757

- Thank you received: 216

28 Jan 2018 01:38 #105095

by islander261

Replied by islander261 on topic Anyone Actually Using External Offsets Branch for THC?

Rod

What I want to do is have independent ratios for each velocity and acceleration. By using the ratio and the max value I can tune the different response between operating under gcode control (planning) and eoffset control. I always want near maximum under gcode but for testing and trouble shooting it is nice to slow down the eoffset control.

John

What I want to do is have independent ratios for each velocity and acceleration. By using the ratio and the max value I can tune the different response between operating under gcode control (planning) and eoffset control. I always want near maximum under gcode but for testing and trouble shooting it is nice to slow down the eoffset control.

John

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11722

- Thank you received: 3968

28 Jan 2018 02:03 - 28 Jan 2018 02:04 #105097

by rodw

Replied by rodw on topic Anyone Actually Using External Offsets Branch for THC?

You can't do that as OFFSET_AV_RATIO is part of the internal external offset code, not part of your config or the component without rewriting the core code. (eg. uses axis.eoffset-scale pin)

Remember, the original intent was to give up a fraction of your velocity and acceleration so it could be used independently for the external offsets without the knowledge of the trajectory planner. The result is your machine slows down. I bastardised it by setting up a config that used 100% of the velocity and acceleration for THC and jogging/touchoff applications (which was only possible because these operations are both mutually exclusive). I did this by doubling the values for velocity and acceleration in my ini file

What you could do is revert to the original intent, (eg. don't double your velocity and acceleration values) to achieve your goal. But THC needs a lot of horsepower (OFFSET_AV_RATIO = 0.8 is suggested). Try it by all means but touch offs will take forever (limited to 20% of the maximum)

Remember, the original intent was to give up a fraction of your velocity and acceleration so it could be used independently for the external offsets without the knowledge of the trajectory planner. The result is your machine slows down. I bastardised it by setting up a config that used 100% of the velocity and acceleration for THC and jogging/touchoff applications (which was only possible because these operations are both mutually exclusive). I did this by doubling the values for velocity and acceleration in my ini file

What you could do is revert to the original intent, (eg. don't double your velocity and acceleration values) to achieve your goal. But THC needs a lot of horsepower (OFFSET_AV_RATIO = 0.8 is suggested). Try it by all means but touch offs will take forever (limited to 20% of the maximum)

Last edit: 28 Jan 2018 02:04 by rodw.

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

Less

More

- Posts: 757

- Thank you received: 216

28 Jan 2018 02:33 - 28 Jan 2018 02:37 #105098

by islander261

Replied by islander261 on topic Anyone Actually Using External Offsets Branch for THC?

Rod

You hit my intent right on the head. Change the underlying code to support one ratio for velocity and one for acceleration. I have no intent on trying it myself. I actually don't know if you need it for a production machine. It sure is nice while homing in on the correct tuning to slow things down. My use actual would be in the other direction, values >0 and <.5. The difference between (1-r) and r can really help to skew response.

Power on the Z axis isn't a problem for me, I have a spare 490oz/in stepper driving it with .1" per rev two start (.2" effective) lead screw.

John

You hit my intent right on the head. Change the underlying code to support one ratio for velocity and one for acceleration. I have no intent on trying it myself. I actually don't know if you need it for a production machine. It sure is nice while homing in on the correct tuning to slow things down. My use actual would be in the other direction, values >0 and <.5. The difference between (1-r) and r can really help to skew response.

Power on the Z axis isn't a problem for me, I have a spare 490oz/in stepper driving it with .1" per rev two start (.2" effective) lead screw.

John

Last edit: 28 Jan 2018 02:37 by islander261.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11722

- Thank you received: 3968

28 Jan 2018 03:55 #105100

by rodw

Replied by rodw on topic Anyone Actually Using External Offsets Branch for THC?

Its nothing about power. Its about making the thc as responsive as possible (eg. fast). But I do get your point about changing the velocity as part of the tuning process.

I did some maths but never did implement it. It is possible to vary my 0.5 ratio and change the maximums in such a way to keep maximum velocities for touch off but run a slower velocity on the THC but it can get confusing with the virtual velocity and accelerations

I did some maths but never did implement it. It is possible to vary my 0.5 ratio and change the maximums in such a way to keep maximum velocities for touch off but run a slower velocity on the THC but it can get confusing with the virtual velocity and accelerations

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

- Hardware & Machines

- CNC Machines

- Plasma & Laser

- Anyone Actually Using External Offsets Branch for THC?

Time to create page: 0.126 seconds