Another plasma component...

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

29 Aug 2019 01:30 - 29 Aug 2019 01:32 #143513

by phillc54

I am not sure how much more to add to the PlasmaC preprocessor, most of these features probably do belong in a CAM postprocessor although they are nice to have for users who either don't have CAM or a postprocesser with that ability and I do like what you did.

In the meantime while I procrastinate, now that PlasmaC has its own section in the forum it may be worthwhile if I make a sticky locked thread that has user donated postprocessors.

Edit: A question for Tom, if someone posts in the PlasmaC section can I move that post to a sticky thread?

Replied by phillc54 on topic Another plasma component...

That is very nice, it looks good in a sim.Phill,

As you know, I've had to do quite a bit of work to get the Fusion 360 post processor working with PlasmaC. I've really worked on the small hole cutting more than anything. I have now managed to get the post processor to create a lead-in arc from the center of a hole similar to what Hypertherm recommends. I think, based on the plasmac_gcode_arcs.py file you posted in the past, that you could accomplish this same thing (i.e. you have the variables needed for the calculations). If you want to put this into plasmac, I'll share with you the way that I did it.

I am not sure how much more to add to the PlasmaC preprocessor, most of these features probably do belong in a CAM postprocessor although they are nice to have for users who either don't have CAM or a postprocesser with that ability and I do like what you did.

In the meantime while I procrastinate, now that PlasmaC has its own section in the forum it may be worthwhile if I make a sticky locked thread that has user donated postprocessors.

Edit: A question for Tom, if someone posts in the PlasmaC section can I move that post to a sticky thread?

Last edit: 29 Aug 2019 01:32 by phillc54.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21370

- Thank you received: 7288

29 Aug 2019 08:19 #143537

by tommylight

Replied by tommylight on topic Another plasma component...

Never tried it, but it should work.Edit: A question for Tom, if someone posts in the PlasmaC section can I move that post to a sticky thread?

The following user(s) said Thank You: phillc54

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

31 Aug 2019 09:58 #143719

by rodw

Replied by rodw on topic Another plasma component...

Just a heads up that Phill is still on the ball! A couple of days ago while conducting my own experiments, I observed by accident that a very short plasma pulse (maybe a millisecond or two) produced a very fine punch mark. I mentioned this to Phill so in less than a week, Phill has pushed an update that uses a third spindle (plasma, scribe and now centre punching) and he's included a variable on the GUI to set the time the torch remains on.

I have to say I can't wait to experiment with this new feature because my current spotting process is to wait until I get an ArcOK. I think this is pretty brutal by comparison!

I have to say I can't wait to experiment with this new feature because my current spotting process is to wait until I get an ArcOK. I think this is pretty brutal by comparison!

The following user(s) said Thank You: tommylight, mkardasi

Please Log in or Create an account to join the conversation.

- JTknives

-

- Offline

- Elite Member

-

Less

More

- Posts: 243

- Thank you received: 32

31 Aug 2019 14:14 - 31 Aug 2019 14:20 #143721

by JTknives

Replied by JTknives on topic Another plasma component...

How are you marking holes? I just use the drill function in sheet cam and have zero delay. It does a super fast pulse and makes a mark that looks almost identical to a center punch mark. Here is s video showing it in action. I think where I might be different is I have a very low arc OK voltage set.

Last edit: 31 Aug 2019 14:20 by JTknives.

The following user(s) said Thank You: phillc54

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

31 Aug 2019 20:19 - 31 Aug 2019 20:21 #143746

by rodw

Probably where we differ is that we are relying on the machine to give us an ArcOK and you are synthesising yours as your machine does not have a CNC interface.

Currently, for spotting I turn the torch off as soon as it sees an ArcOK but that is enough to pierce 2mm steel at 40 amps. It is more brutal at 120 amps on 16mm.

How this came about is I had a bug in my new ohmic sensing component and a probe signal was left enabled which Linuxcnc sees as an error. I suspect the torch was turned off on the next servo cycle.

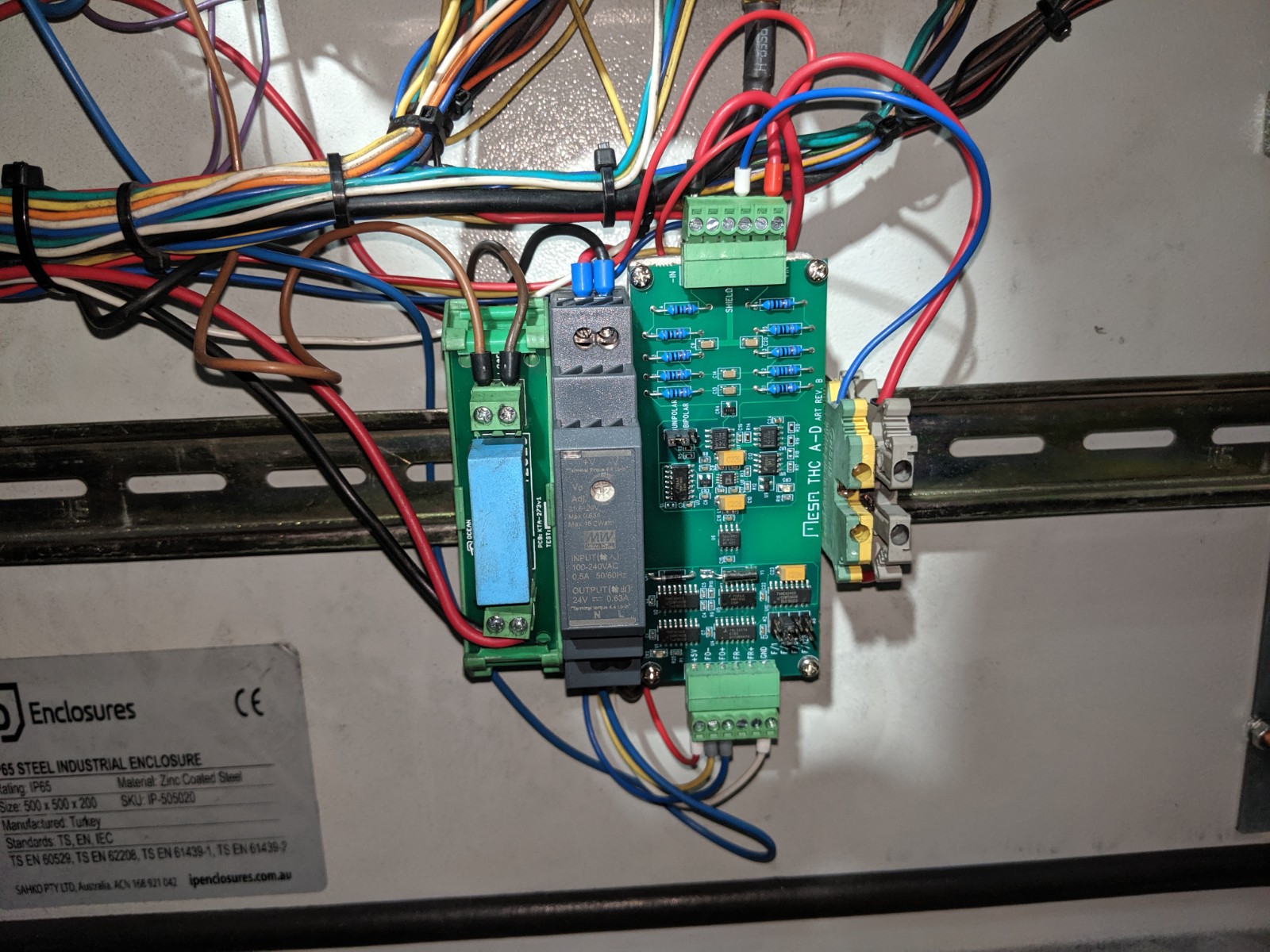

I've been working on a new Ohmic sensing method which uses a Mesa THCAD-5 kindly donated by PCW to sense the voltage in the 24 volt circuit for the probe signal. The higher isolation afforded by the THCAD means there is no need to add relays and diodes to the circuit to protect things. In fact, its perfectly safe to leave the power supply connected all of the time but I've added an AC relay (blue one) to power off the power supply when not in use more to protect against any consumable corrosion that might occur on a water table.

Replied by rodw on topic Another plasma component...

How are you marking holes? I just use the drill function in sheet cam and have zero delay. It does a super fast pulse and makes a mark that looks almost identical to a center punch mark. Here is s video showing it in action. I think where I might be different is I have a very low arc OK voltage set.

Probably where we differ is that we are relying on the machine to give us an ArcOK and you are synthesising yours as your machine does not have a CNC interface.

Currently, for spotting I turn the torch off as soon as it sees an ArcOK but that is enough to pierce 2mm steel at 40 amps. It is more brutal at 120 amps on 16mm.

How this came about is I had a bug in my new ohmic sensing component and a probe signal was left enabled which Linuxcnc sees as an error. I suspect the torch was turned off on the next servo cycle.

I've been working on a new Ohmic sensing method which uses a Mesa THCAD-5 kindly donated by PCW to sense the voltage in the 24 volt circuit for the probe signal. The higher isolation afforded by the THCAD means there is no need to add relays and diodes to the circuit to protect things. In fact, its perfectly safe to leave the power supply connected all of the time but I've added an AC relay (blue one) to power off the power supply when not in use more to protect against any consumable corrosion that might occur on a water table.

Last edit: 31 Aug 2019 20:21 by rodw.

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

31 Aug 2019 23:40 #143751

by phillc54

Replied by phillc54 on topic Another plasma component...

Plus one for voltage derived Arc OKHow are you marking holes? I just use the drill function in sheet cam and have zero delay. It does a super fast pulse and makes a mark that looks almost identical to a center punch mark. Here is s video showing it in action. I think where I might be different is I have a very low arc OK voltage set.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

02 Sep 2019 05:46 #143879

by thefabricator03

Replied by thefabricator03 on topic Another plasma component...

I have changed the default pid-p gain back to 10 today and ran out a sheet of parts I had a problem with last time and they are cutting perfectly.

Please Log in or Create an account to join the conversation.

- Franklin

- Offline

- Senior Member

-

Less

More

- Posts: 47

- Thank you received: 19

10 Sep 2019 17:54 #144725

by Franklin

Replied by Franklin on topic Another plasma component...

Hi, help please. I can’t use the Center Spot function, the machine goes to the spotting coordinates, makes a center mark and repeats this operation endlessly on one place until I stop the program.

What could be wrong?

The ARK-OK signal arrives. I still use the external THC from Proma.

I use installation from the LinuxCNC buildbot.

Thanks.

What could be wrong?

The ARK-OK signal arrives. I still use the external THC from Proma.

I use installation from the LinuxCNC buildbot.

Thanks.

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

10 Sep 2019 23:26 #144751

by phillc54

Replied by phillc54 on topic Another plasma component...

Could you post the GCode file.

Please Log in or Create an account to join the conversation.

- Franklin

- Offline

- Senior Member

-

Less

More

- Posts: 47

- Thank you received: 19

11 Sep 2019 09:12 #144797

by Franklin

Replied by Franklin on topic Another plasma component...

I used the sample GCode from the documentation

And tried other GCodes, the result is the same.

How should this function work, the plasmac should wait for the arcOK?

It seems like the plasmac does not see the signal of the arcOK and repeats attempts many times.

Warning: Spoiler!

G21 (metric)

F99999 (high feed rate)

g0 x10 y10

m3 $2 s1 (centre Spot on)

g91 (relative distance mode)

g1 x0.000001

g90 (absolute distance mode)

m5 (centre punch off)

g0 x0 y0

g90

m30

F99999 (high feed rate)

g0 x10 y10

m3 $2 s1 (centre Spot on)

g91 (relative distance mode)

g1 x0.000001

g90 (absolute distance mode)

m5 (centre punch off)

g0 x0 y0

g90

m30

And tried other GCodes, the result is the same.

How should this function work, the plasmac should wait for the arcOK?

It seems like the plasmac does not see the signal of the arcOK and repeats attempts many times.

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.293 seconds