PlasmaC torch starting problem (Solved with help from the famous three)

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

17 Mar 2020 22:45 #160600

by phillc54

Replied by phillc54 on topic PlasmaC torch starting problem

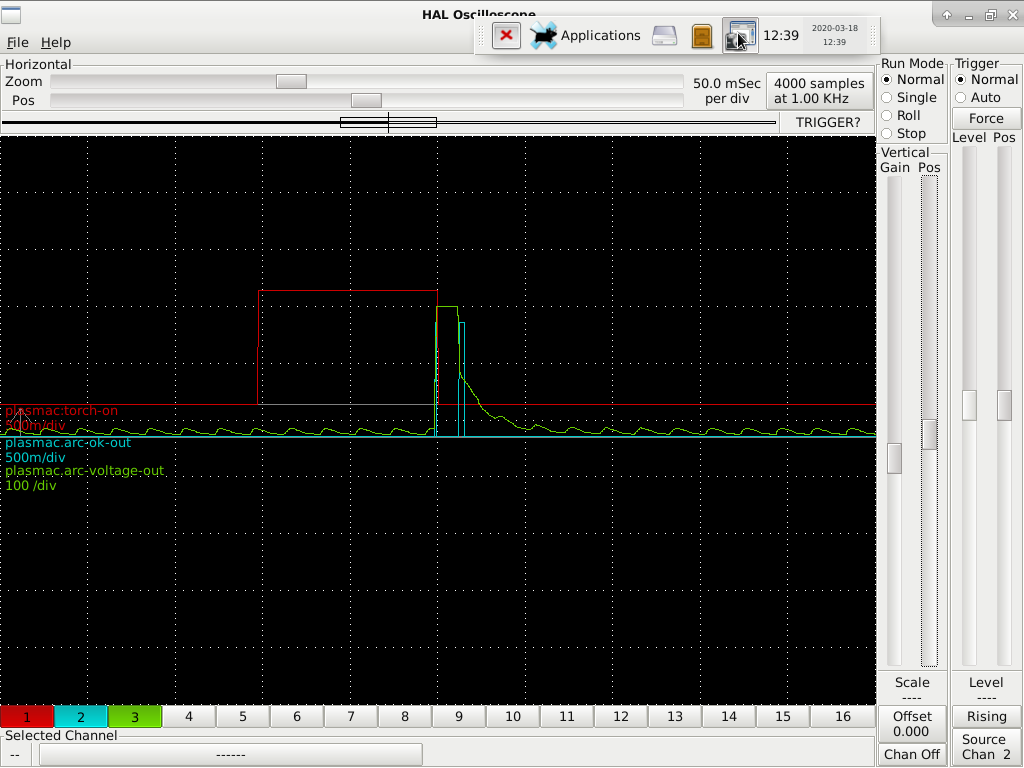

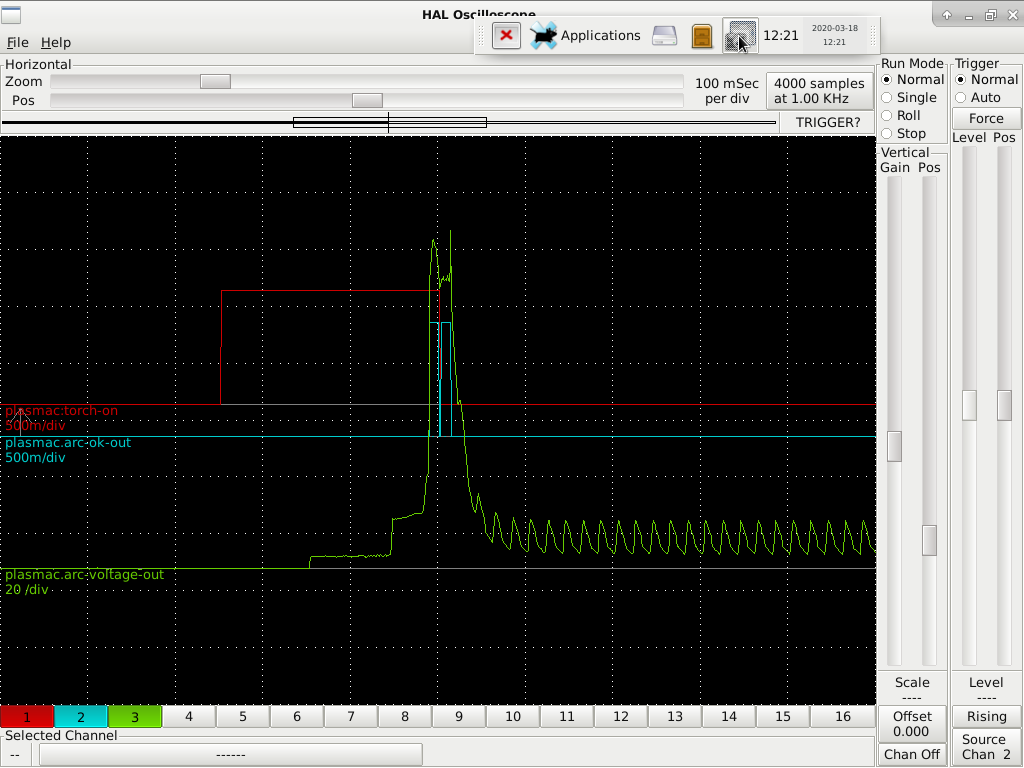

Wow, that is a mean spike you get 100mS after torch on for the second cut.

I can see that it gives an Arc OK then shoots past Arc OK High so turns Arc OK off and you lose the Torch On signal.

It is interesting that it doesn't occur on the first cut nor does the 20 odd V sawtooth pattern appear before the first cut.

So there a maybe a few different ways around this.

I can see that it gives an Arc OK then shoots past Arc OK High so turns Arc OK off and you lose the Torch On signal.

It is interesting that it doesn't occur on the first cut nor does the 20 odd V sawtooth pattern appear before the first cut.

So there a maybe a few different ways around this.

- install a current sensor in the torch lead and use that for an Arc OK signal

- I could add a Arc OK on delay so the arc voltage needs to be within limits for nnn amount of time before Arc OK is true

- I could add a Arc OK off delay so the arc voltage needs to be outside limits for nnn amount of time before Arc OK is false

- I could add a Arc OK High inhibit so Arc OK won't go false if the arc voltage is too high

The following user(s) said Thank You: Clive S

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17698

- Thank you received: 5175

17 Mar 2020 23:03 #160602

by PCW

Replied by PCW on topic PlasmaC torch starting problem

Looks like the arc voltage may exceed your arc-ok high threshold

can you change the scaling and post it again?

can you change the scaling and post it again?

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

Less

More

- Posts: 2203

- Thank you received: 482

18 Mar 2020 16:11 #160653

by Clive S

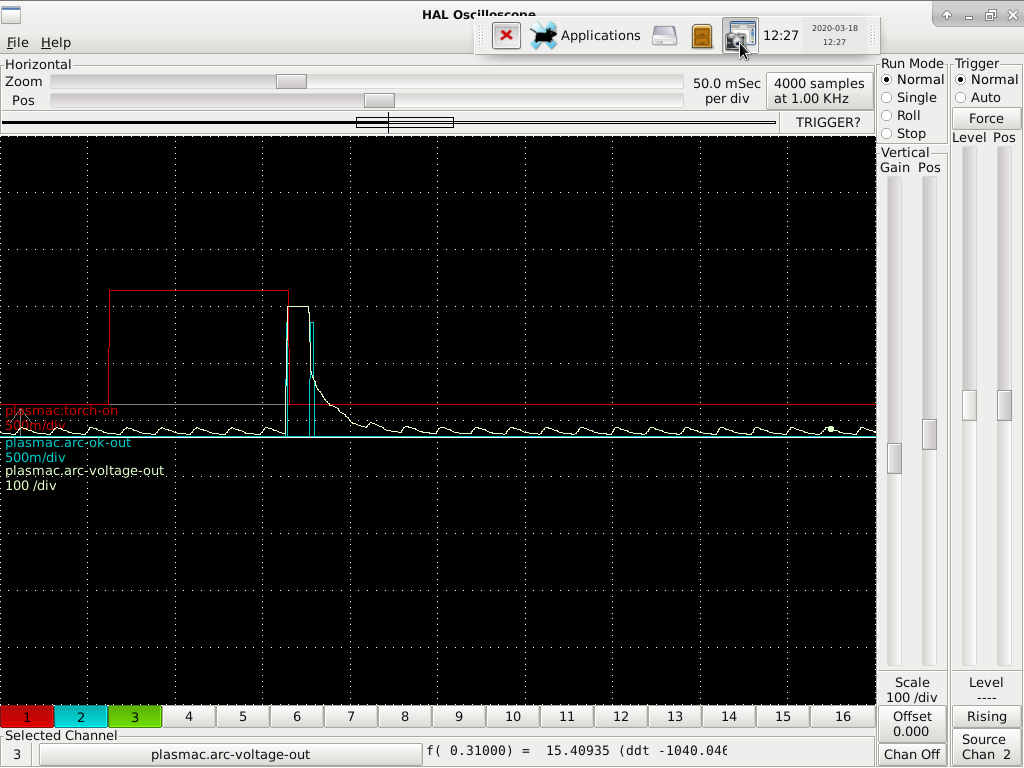

OK is this better: Fail cut with air

fail cut

Fail cut started after the air stopped purging : no 50hz before start

Replied by Clive S on topic PlasmaC torch starting problem

Looks like the arc voltage may exceed your arc-ok high threshold

can you change the scaling and post it again?

OK is this better: Fail cut with air

fail cut

Fail cut started after the air stopped purging : no 50hz before start

Attachments:

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

Less

More

- Posts: 2203

- Thank you received: 482

18 Mar 2020 16:17 #160654

by Clive S

That would be very helpful Phil.

Could we try 4) first . I take it I would have to modify the code somewhere If so how?

If so how?

Replied by Clive S on topic PlasmaC torch starting problem

Wow, that is a mean spike you get 100mS after torch on for the second cut.

So there a maybe a few different ways around this.

- install a current sensor in the torch lead and use that for an Arc OK signal

- I could add a Arc OK on delay so the arc voltage needs to be within limits for nnn amount of time before Arc OK is true

- I could add a Arc OK off delay so the arc voltage needs to be outside limits for nnn amount of time before Arc OK is false

- I could add a Arc OK High inhibit so Arc OK won't go false if the arc voltage is too high

That would be very helpful Phil.

Could we try 4) first . I take it I would have to modify the code somewhere

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11712

- Thank you received: 3963

18 Mar 2020 20:41 #160677

by rodw

Thats not 100 ms! Its one second.

The division is the minor tick. 10 minor ticks per vertical line.

So Is plasmac not waiting long enough for the arc to establish?

This machine has significant lag from the torch on signal to actually igniting the arc. Much more than the two machines I have used.

All cuts are atypical against the hundreds of plots I've done and the failed cuts are clearly caused by Plasmac turning off the torch during the establishment phase.

When an arc commences it rapidly spikes up to 130% to 150% (sometimes even 200% or more) above the desired cutting volts. Then it should drop back to the cut voltage. on its own without THC action. This can take some time, maybe 1.5 seconds. This is natural, native behaviour and you need to set your cut volts to agree with that naturally occurring voltage. Even in the cutting example on the previous page I don't see this and it seems that the cut volts is significantly below this natural voltage so it steps down as the THC is enabled (I think this is what happened in the absence of a signal to say when the THC turned on). Thats by the by, the thing I see is that the gradual ramp up without a spike is unusual. A more typical result is the spikes Plasmac is failing.

If Plasmac fails ArcOK becasue a high voltage threshold is exceeded, then its algorithm is totally wrong as it fails to allow for this voltage spike which occurs naturally.

Plus Plasmac needs to allow for the significant lag from torch on to arc commencement on this machine. I don't know how Plasmac works there.

I still think this is another example of why synthesising ArcOK from a voltage is a bad idea. If you don't have an ArcOK signal, then you should add one that is based on current sensing. Eventually you will come unstuck as many have already but this is a more extreme example.

Replied by rodw on topic PlasmaC torch starting problem

Wow, that is a mean spike you get 100mS after torch on for the second cut.

Thats not 100 ms! Its one second.

The division is the minor tick. 10 minor ticks per vertical line.

So Is plasmac not waiting long enough for the arc to establish?

This machine has significant lag from the torch on signal to actually igniting the arc. Much more than the two machines I have used.

All cuts are atypical against the hundreds of plots I've done and the failed cuts are clearly caused by Plasmac turning off the torch during the establishment phase.

When an arc commences it rapidly spikes up to 130% to 150% (sometimes even 200% or more) above the desired cutting volts. Then it should drop back to the cut voltage. on its own without THC action. This can take some time, maybe 1.5 seconds. This is natural, native behaviour and you need to set your cut volts to agree with that naturally occurring voltage. Even in the cutting example on the previous page I don't see this and it seems that the cut volts is significantly below this natural voltage so it steps down as the THC is enabled (I think this is what happened in the absence of a signal to say when the THC turned on). Thats by the by, the thing I see is that the gradual ramp up without a spike is unusual. A more typical result is the spikes Plasmac is failing.

If Plasmac fails ArcOK becasue a high voltage threshold is exceeded, then its algorithm is totally wrong as it fails to allow for this voltage spike which occurs naturally.

Plus Plasmac needs to allow for the significant lag from torch on to arc commencement on this machine. I don't know how Plasmac works there.

I still think this is another example of why synthesising ArcOK from a voltage is a bad idea. If you don't have an ArcOK signal, then you should add one that is based on current sensing. Eventually you will come unstuck as many have already but this is a more extreme example.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17698

- Thank you received: 5175

18 Mar 2020 21:08 - 18 Mar 2020 21:08 #160678

by PCW

Replied by PCW on topic PlasmaC torch starting problem

Sounds like if it not already done, simply masking the high voltage test for

a settable period of time after the torch on command would fix the issue.

Also just setting the high threshold to a bit under the open circuit voltage

when waiting for arc OK seems like it would also fix the issue

a settable period of time after the torch on command would fix the issue.

Also just setting the high threshold to a bit under the open circuit voltage

when waiting for arc OK seems like it would also fix the issue

Last edit: 18 Mar 2020 21:08 by PCW.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11712

- Thank you received: 3963

18 Mar 2020 21:36 - 18 Mar 2020 21:39 #160680

by rodw

Fix the algorithm, instead of this at line 469 in plasmac.comp

Try this:

recompile and install the comp with halcompile

My typos excluded, this should set the arcOK when it exceeds high voltage

and turn it off when it falls below low voltage.

Try high = 50% of cut voltage, low = 30% cut voltage.

You may need to reset ac_ok_out to FALSE at the end of the cut

Replied by rodw on topic PlasmaC torch starting problem

Sounds like if it not already done, simply masking the high voltage test for

a settable period of time after the torch on command would fix the issue.

Also just setting the high threshold to a bit under the open circuit voltage

when waiting for arc OK seems like it would also fix the issue

Fix the algorithm, instead of this at line 469 in plasmac.comp

/* set arc ok from either arc ok input of from actual arc voltage

* if using arc ok input, set arc_ok_low_in and/or arc_ok_high_in to 0 */

if(mode > 0){

arc_ok_out = arc_ok_in;

}else if(arc_voltage_out >= arc_ok_low && arc_voltage_out <= arc_ok_high){

arc_ok_out = TRUE;

}else{

arc_ok_out = FALSE;

}Try this:

/* set arc ok from either arc ok input of from actual arc voltage

* if using arc ok input, set arc_ok_low_in and/or arc_ok_high_in to 0 *

if(mode > 0){

arc_ok_out = arc_ok_in;

}

else{

if(!arc_ok_out){

if(arc_voltage_out > arc_ok_high)

arc_ok_out = TRUE;

}

else{

if(arc_voltage_out < arc_ok_low)

ac_ok_out = FALSE;

}

}

recompile and install the comp with halcompile

My typos excluded, this should set the arcOK when it exceeds high voltage

and turn it off when it falls below low voltage.

Try high = 50% of cut voltage, low = 30% cut voltage.

You may need to reset ac_ok_out to FALSE at the end of the cut

Last edit: 18 Mar 2020 21:39 by rodw.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11712

- Thank you received: 3963

18 Mar 2020 21:44 #160681

by rodw

Replied by rodw on topic PlasmaC torch starting problem

And Arc Fail timeout of at least 2 seconds due to laggy torch start.

The following user(s) said Thank You: Clive S

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

Less

More

- Posts: 2203

- Thank you received: 482

18 Mar 2020 23:33 #160685

by Clive S

Rod I do thank you for looking into this. But I am not sure what you are asking me to do, and how to do it.

Is the code aimed at me or Phil ?

Phil has suggested some options here:

So there a maybe a few different ways around this.

install a current sensor in the torch lead and use that for an Arc OK signal

I could add a Arc OK on delay so the arc voltage needs to be within limits for nnn amount of time before Arc OK is true

I could add a Arc OK off delay so the arc voltage needs to be outside limits for nnn amount of time before Arc OK is false

I could add a Arc OK High inhibit so Arc OK won't go false if the arc voltage is too high

I don't want to meddle in the dark and break the system.

Replied by Clive S on topic PlasmaC torch starting problem

And Arc Fail timeout of at least 2 seconds due to laggy torch start.

Rod I do thank you for looking into this. But I am not sure what you are asking me to do, and how to do it.

Is the code aimed at me or Phil ?

Phil has suggested some options here:

So there a maybe a few different ways around this.

install a current sensor in the torch lead and use that for an Arc OK signal

I could add a Arc OK on delay so the arc voltage needs to be within limits for nnn amount of time before Arc OK is true

I could add a Arc OK off delay so the arc voltage needs to be outside limits for nnn amount of time before Arc OK is false

I could add a Arc OK High inhibit so Arc OK won't go false if the arc voltage is too high

I don't want to meddle in the dark and break the system.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7266

19 Mar 2020 00:00 #160688

by tommylight

Replied by tommylight on topic PlasmaC torch starting problem

I did see Clive's post about 20 minutes after he posted it and as usual i went on to reply to it, but, as i was looking at his graphs something does not add up, well a lot of things.

To be clear, i went to reply the same thing all of you did reply, but, and again a big but, that does not seem to be the case.

The first thing is the noise, to much of it at 50Hz is a sure sign of grounding failure, or a miss wiring.

Then there is the instant torch off after an arcok, normally assumed to be from to much voltage, but it looks more like failure due to a spike in voltage, and not just the torch voltage.

@Clive,

Does the plasma still have hand trigger ? Can you do a voltage trace by activating it by hand while cutting something, once while the THC shows 0V, and once while it is still fluctuating between 0 and 20V ?

I would like to see if there is a difference in voltage between two readings.

To be clear, i went to reply the same thing all of you did reply, but, and again a big but, that does not seem to be the case.

The first thing is the noise, to much of it at 50Hz is a sure sign of grounding failure, or a miss wiring.

Then there is the instant torch off after an arcok, normally assumed to be from to much voltage, but it looks more like failure due to a spike in voltage, and not just the torch voltage.

@Clive,

Does the plasma still have hand trigger ? Can you do a voltage trace by activating it by hand while cutting something, once while the THC shows 0V, and once while it is still fluctuating between 0 and 20V ?

I would like to see if there is a difference in voltage between two readings.

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.240 seconds