Some thoughts and some findings using PlasmaC

- Franklin

- Offline

- Senior Member

-

Less

More

- Posts: 47

- Thank you received: 19

07 Nov 2020 09:04 #188578

by Franklin

Replied by Franklin on topic Some thoughts and some findings using PlasmaC

Hi, yesterday I updated the plasmac and cut several sheets, and there were no problems with the float-switch sensor triggering when the torch ignition.

So the update "disable ohmic and float fault sensing until arc ok" works fine.

Thanks Phill

So the update "disable ohmic and float fault sensing until arc ok" works fine.

Thanks Phill

The following user(s) said Thank You: phillc54, tommylight, snowgoer540

Please Log in or Create an account to join the conversation.

- Talon2006

- Offline

- New Member

-

Less

More

- Posts: 5

- Thank you received: 2

12 Nov 2020 13:31 #189105

by Talon2006

Replied by Talon2006 on topic Some thoughts and some findings using PlasmaC

I just got my plasmac machine up and running and seems to have tons of little bugs... mostly with torch starts now but I was having float switch issues.

Reading through this thread it seems most of my issues should be resolved with this update! Super new to Linux so I’m glad there is a large support base here to help newbies like me.

Reading through this thread it seems most of my issues should be resolved with this update! Super new to Linux so I’m glad there is a large support base here to help newbies like me.

The following user(s) said Thank You: snowgoer540

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21084

- Thank you received: 7197

12 Nov 2020 16:16 - 12 Nov 2020 21:18 #189120

by tommylight

Replied by tommylight on topic Some thoughts and some findings using PlasmaC

We got stuck at 0.180 !

For some reason the master build for Stretch and Buster is not happening since 27 of October .

Just did a post in the Moderator part of the forum, so should be OK soon.

BTW, the 2.8 official release is all good.

For some reason the master build for Stretch and Buster is not happening since 27 of October .

Just did a post in the Moderator part of the forum, so should be OK soon.

BTW, the 2.8 official release is all good.

Last edit: 12 Nov 2020 21:18 by tommylight. Reason: wrong month

The following user(s) said Thank You: snowgoer540

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11566

- Thank you received: 3884

12 Nov 2020 20:42 #189151

by rodw

December???? Did I miss Christmas???

Replied by rodw on topic Some thoughts and some findings using PlasmaC

We got stuck at 0.180 !

For some reason the master build for Stretch and Buster is not happening since 27 of December.

Just did a post in the Moderator part of the forum, so should be OK soon.

BTW, the 2.8 official release is all good.

December???? Did I miss Christmas???

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21084

- Thank you received: 7197

12 Nov 2020 21:18 #189154

by tommylight

Fixed it, thank you Rod.

Replied by tommylight on topic Some thoughts and some findings using PlasmaC

Ooops ! My bad.

We got stuck at 0.180 !

For some reason the master build for Stretch and Buster is not happening since 27 of December.

Just did a post in the Moderator part of the forum, so should be OK soon.

BTW, the 2.8 official release is all good.

December???? Did I miss Christmas???

Fixed it, thank you Rod.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21084

- Thank you received: 7197

19 Nov 2020 00:08 #189740

by tommylight

Replied by tommylight on topic Some thoughts and some findings using PlasmaC

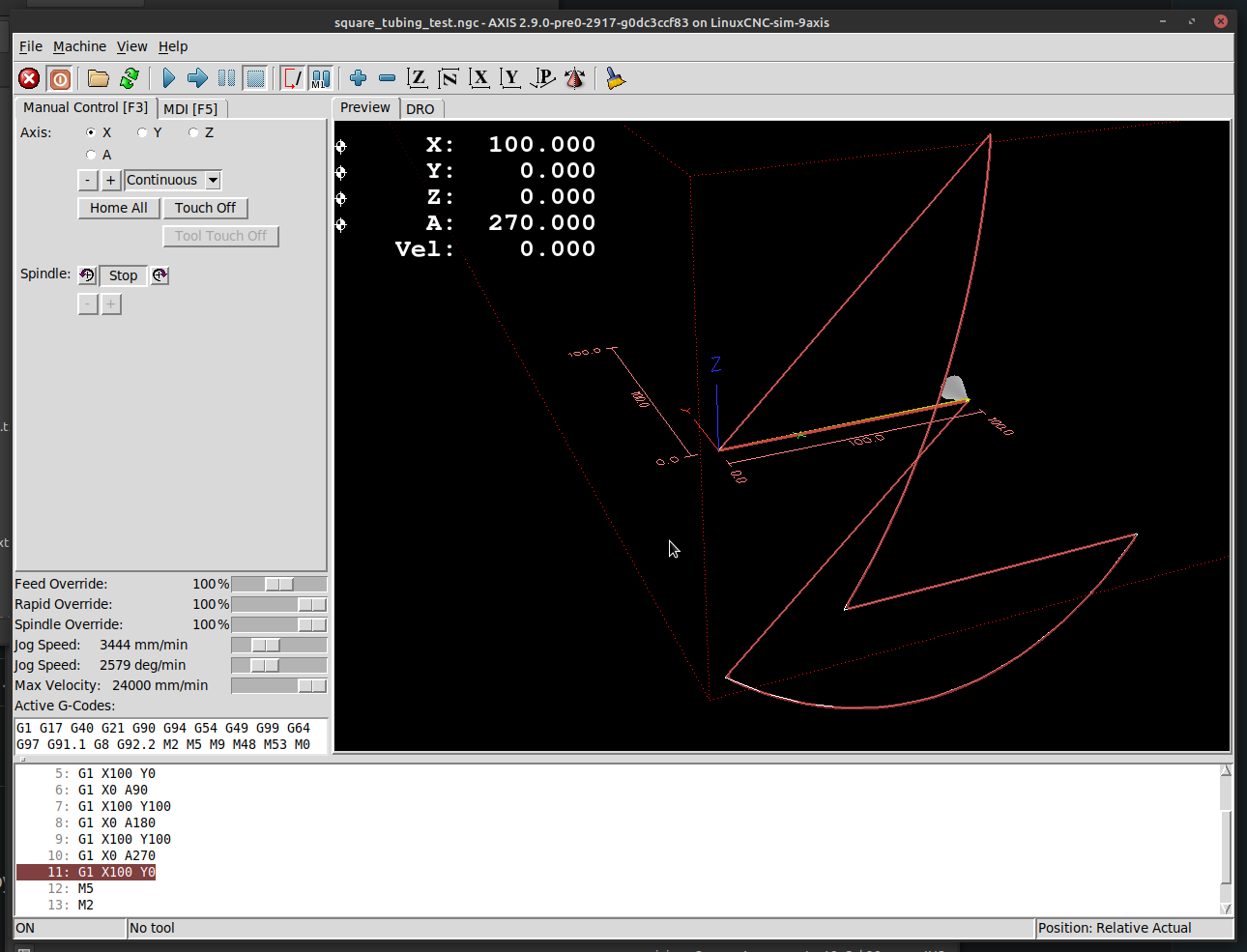

Did some thinking today ..... (pause till the laughing subsides  ) about the square tube cutter as i finally had about an hour of time to do nothing ... well think about how it should function and how the hardware is going to be set for what i need it to do, so while doing that i was thinking of how the gcode should look and work as this will be basically a 3 axis machine with the possibility of rotating the work piece so there are always 4 pieces of 2D cutting to do, or 4 XY planes. In this mode the A axis will do exclusively 0, 90, 180, and 270 degrees.

) about the square tube cutter as i finally had about an hour of time to do nothing ... well think about how it should function and how the hardware is going to be set for what i need it to do, so while doing that i was thinking of how the gcode should look and work as this will be basically a 3 axis machine with the possibility of rotating the work piece so there are always 4 pieces of 2D cutting to do, or 4 XY planes. In this mode the A axis will do exclusively 0, 90, 180, and 270 degrees.

I'll try to use an example, i did say TRY:

-square tube 100x100mm

-need to cut it at 45 degree angle

===if everything is set up correctly regarding the X and A axis speeds, meaning the time it takes for X axis to move from 100mm to 0mm position should be the same as for the A axis to turn 90 degrees, so the move will go in unison with the torch following the tip of the tube.

-here is the gcode i came up with on short notice and did some tests in a sim and it seems to do just that:-More explaining or trying to:

-the machine should be looked from the front, tube pointing at you - "looking at the barrel of a gun", X moves perpendicular to tube, Y moves along the tube,

-machine at 0 torch should be on the left edge of the tube

-m3 = fire something, launch a missile, do some damage ...

-make a perpendicular line to the other edge of tube G1 X100 Y0

-move the torch back to 0 at the same time turning the tube 90 degrees, THC takes care of the change in height, on thin walled tubing might need raising the feed rate,

-now the machine is again at x0 y0

-move the torch to x100 y100 to do a 45 degree cut on the second XY plane

- move the torch back to 0 at the same time turning the tube 90 degrees

-now the machine is at X0Y100

-move the torch to X100 Y100 making a straight cut on the third XY plane

--machine again at x0 y100

-Move the torch to x100 y0 making a reverse 45 degree cut on the fourth plane.

Easy enough, although it took much more to write this down than to thing, power up the pc and watch some AMD Radeon 6800XT tests, make a sim config for 4 axis (there are none, i am pretty sure there was one in the early days), writing and rewriting the gcode and testing the Display section of Axis GUI to force it to show something useful, but no luck there, this is the best it could do:

Regards,

Tom.

I'll try to use an example, i did say TRY:

-square tube 100x100mm

-need to cut it at 45 degree angle

===if everything is set up correctly regarding the X and A axis speeds, meaning the time it takes for X axis to move from 100mm to 0mm position should be the same as for the A axis to turn 90 degrees, so the move will go in unison with the torch following the tip of the tube.

-here is the gcode i came up with on short notice and did some tests in a sim and it seems to do just that:

G0 X0 Y0 Z0 A0

F2000

G1 X0 Y0

M3 $0 S1

G1 X100 Y0

G1 X0 A90

G1 X100 Y100

G1 X0 A180

G1 X100 Y100

G1 X0 A270

G1 X100 Y0

M5

M2-the machine should be looked from the front, tube pointing at you - "looking at the barrel of a gun", X moves perpendicular to tube, Y moves along the tube,

-machine at 0 torch should be on the left edge of the tube

-m3 = fire something, launch a missile, do some damage ...

-make a perpendicular line to the other edge of tube G1 X100 Y0

-move the torch back to 0 at the same time turning the tube 90 degrees, THC takes care of the change in height, on thin walled tubing might need raising the feed rate,

-now the machine is again at x0 y0

-move the torch to x100 y100 to do a 45 degree cut on the second XY plane

- move the torch back to 0 at the same time turning the tube 90 degrees

-now the machine is at X0Y100

-move the torch to X100 Y100 making a straight cut on the third XY plane

--machine again at x0 y100

-Move the torch to x100 y0 making a reverse 45 degree cut on the fourth plane.

Easy enough, although it took much more to write this down than to thing, power up the pc and watch some AMD Radeon 6800XT tests, make a sim config for 4 axis (there are none, i am pretty sure there was one in the early days), writing and rewriting the gcode and testing the Display section of Axis GUI to force it to show something useful, but no luck there, this is the best it could do:

Regards,

Tom.

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21084

- Thank you received: 7197

19 Nov 2020 23:01 #189835

by tommylight

Replied by tommylight on topic Some thoughts and some findings using PlasmaC

Just gave it a shot at editing some python files and created another wizard for the conversational and ..... no go, need to recompile a pyc file.

Waiting for Phill's wrath to come down on me !

Waiting for Phill's wrath to come down on me !

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

19 Nov 2020 23:06 #189837

by phillc54

Replied by phillc54 on topic Some thoughts and some findings using PlasmaC

It "should" do that automatically.Just gave it a shot at editing some python files and created another wizard for the conversational and ..... no go, need to recompile a pyc file.

I can have a look at it this afternoon (my time) if you want.Waiting for Phill's wrath to come down on me !

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21084

- Thank you received: 7197

19 Nov 2020 23:22 #189842

by tommylight

Replied by tommylight on topic Some thoughts and some findings using PlasmaC

Nah, no worries, just needed some brain workout, given the load it got last few weeks, this is like a walk in the park !

I just need it to do the above explanation, or lack thereof. I can code that in gcode in about a minute, but if someone has the sudden urge to buy the machine, i will have to do something about it.

Thank you for everything.

I just need it to do the above explanation, or lack thereof. I can code that in gcode in about a minute, but if someone has the sudden urge to buy the machine, i will have to do something about it.

Thank you for everything.

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21084

- Thank you received: 7197

08 Dec 2020 23:37 #191450

by tommylight

Replied by tommylight on topic Some thoughts and some findings using PlasmaC

Been using the machines a lot lately, so here are some more thoughts:

forum.linuxcnc.org/show-your-stuff/38547...ild?start=250#191262

forum.linuxcnc.org/show-your-stuff/38547...ild?start=250#191262

The following user(s) said Thank You: phillc54

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.102 seconds