Rods "Spaceship" Scratch built Plasma Cutter build

- denhen89

-

- Offline

- Elite Member

-

Less

More

- Posts: 298

- Thank you received: 26

30 May 2020 08:37 #169397

by denhen89

Replied by denhen89 on topic Rods "Spaceship" Scratch built Plasma Cutter build

Thank you very much Rod.

I created a new Thread and did what you wrote. I build a truth table for every switch position.

All i have explained as good as possible the new thread:

forum.linuxcnc.org/24-hal-components/392...e-and-scale-settings

I created a new Thread and did what you wrote. I build a truth table for every switch position.

All i have explained as good as possible the new thread:

forum.linuxcnc.org/24-hal-components/392...e-and-scale-settings

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

03 Jun 2020 01:47 #169902

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

Well finally I have all of the stuff here to have a play. Some parts are not optimal but its what I could find in Australia.

Recapping, the enlcosed Lam drives are DS1076A 65 volts AC input, 6 amps ( 8 amps peak) output (approx 90v DC to motor)

The open frame driver is a LS1073A 65 volts AC input, 3amps (4.2 amp peak) A naked version of the DS1073A

The encoder is all I could find in Australia. Cost me $100. I did get a quote on a quality one at $550 that would bolt on to the back of the motor! I want to play with Tommy's boost setting (initially on a test rig turning a cast iron flywheel to add some load/inertia.

The toroids from Tortech are multi tapped but configured for 32 volts 20 amp. So in series I will get 64 volts AC, 20 amps or I can be a bit gentler on the smaller motors and just give them 32 volts AC ... (50 volts DC to the motor).

I queried them about the inrush current popping the circuit breaker and they included a couple of thermistors which when put on the AC input will gradually allow the current to ramp up over a second or so which should prevent this.

I'm hoping only the Z axis will need an encoder. I'm pretty sure I can write a component to apply boost only while the motor is accelerating and decelerating. On X & Y this will be a low duty cycle becasue we should get to cutting speed in < 50 ms if our model is right but on the Z axis, it could revert to a triangular motion profile so could be 100% duty cycle...

Recapping, the enlcosed Lam drives are DS1076A 65 volts AC input, 6 amps ( 8 amps peak) output (approx 90v DC to motor)

The open frame driver is a LS1073A 65 volts AC input, 3amps (4.2 amp peak) A naked version of the DS1073A

The encoder is all I could find in Australia. Cost me $100. I did get a quote on a quality one at $550 that would bolt on to the back of the motor! I want to play with Tommy's boost setting (initially on a test rig turning a cast iron flywheel to add some load/inertia.

The toroids from Tortech are multi tapped but configured for 32 volts 20 amp. So in series I will get 64 volts AC, 20 amps or I can be a bit gentler on the smaller motors and just give them 32 volts AC ... (50 volts DC to the motor).

I queried them about the inrush current popping the circuit breaker and they included a couple of thermistors which when put on the AC input will gradually allow the current to ramp up over a second or so which should prevent this.

I'm hoping only the Z axis will need an encoder. I'm pretty sure I can write a component to apply boost only while the motor is accelerating and decelerating. On X & Y this will be a low duty cycle becasue we should get to cutting speed in < 50 ms if our model is right but on the Z axis, it could revert to a triangular motion profile so could be 100% duty cycle...

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

12 Jun 2020 23:55 - 12 Jun 2020 23:55 #171345

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

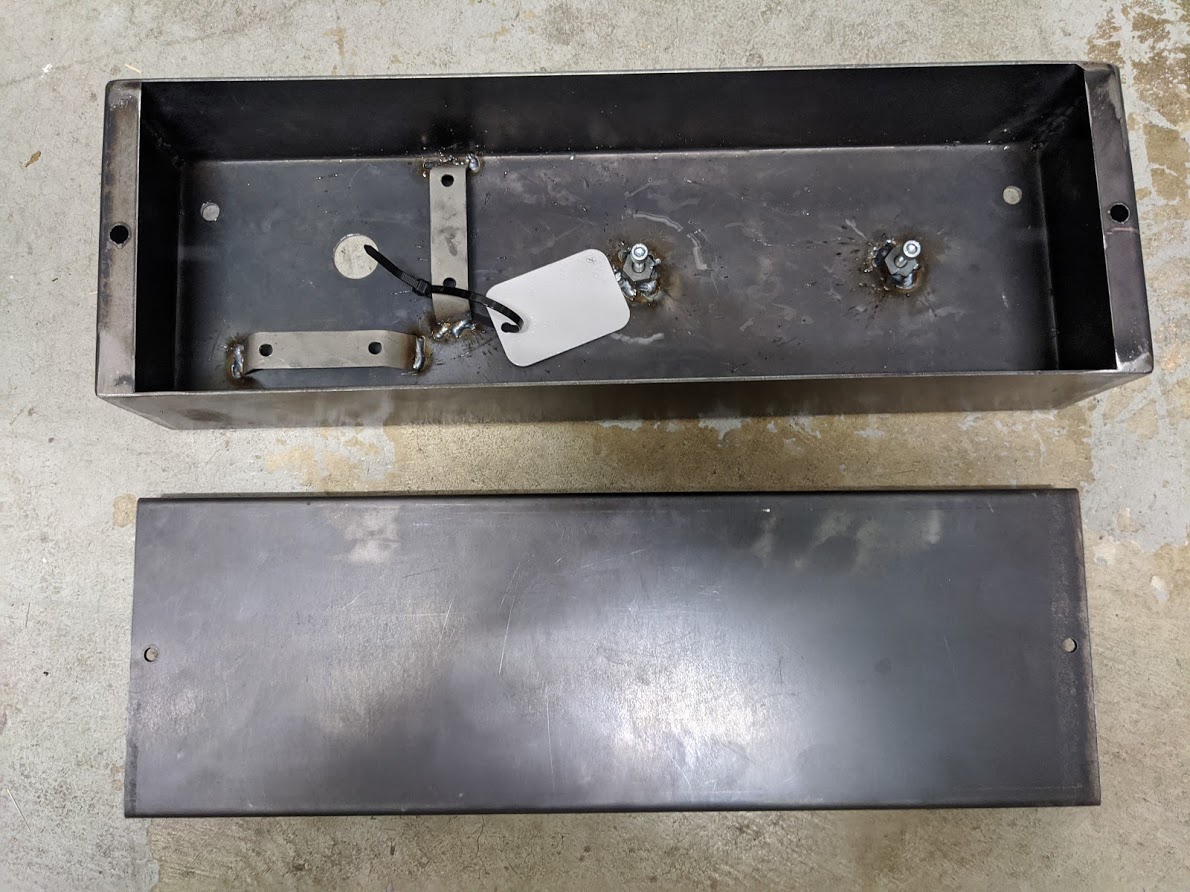

Well its taken a while to get everything here. The first thing I had to get somewhere to mount the toroids so I came up with a piggybank box that will mount behind the control box. This went off to powder coating yesterday. I'm sure they won't be any faster than Tommy's paint shop. The job I gave them early in the week was still sitting on the ground outside their office. It should come back the colour of the sample cable tied on.

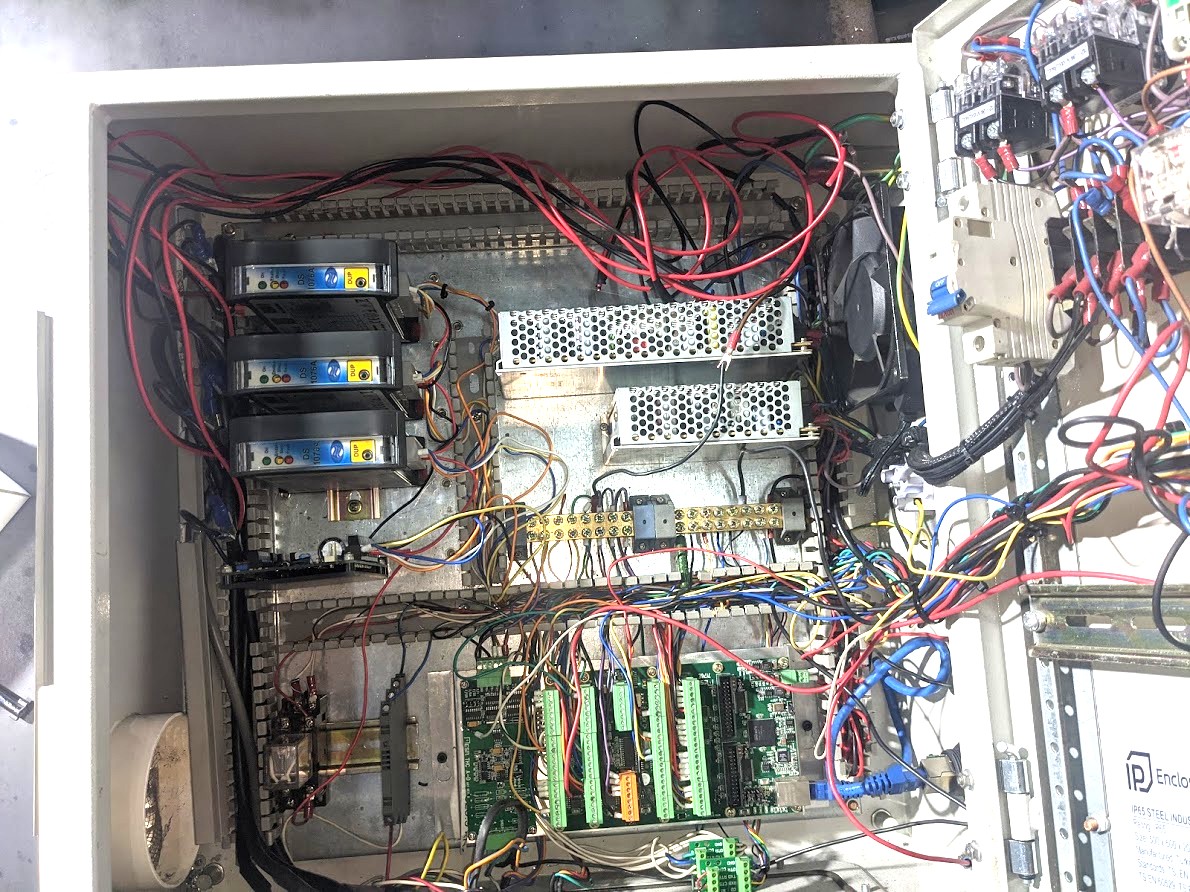

Lam suggests that every AC wire going to the stepper drives has a fuse on them and I found some DIN rail fuse holders. So all up I think there will be about 24 DIN rail terminals squeezed into the box. Hence the standoff mounts.

And I mounted up the LAM drives yesterday too. Man I've got some wiring to tidy up! If you look closely, there is a 25mm hole in the top right above the power supplies which will let wires pass into the toroid box.

Th Z axis drive below the three DS 1076A's is an open frame LS1073A. Which is what they had in the country. Its tiny! The LS series is cheaper but I think I'd stick to the enclosed DS series as the LS does not have any removable connectors so not as convenient to wire up.

I also lucked onto a lot of 5 high quality Sanyo Denki NEMA23 drives. They didn't have any wiring harnesses with them but I found some so I've ended up with $200 steppers at < $30 a piece!

While my machine is off the air, I think I'll clean it up and paint the frame.

Lam suggests that every AC wire going to the stepper drives has a fuse on them and I found some DIN rail fuse holders. So all up I think there will be about 24 DIN rail terminals squeezed into the box. Hence the standoff mounts.

And I mounted up the LAM drives yesterday too. Man I've got some wiring to tidy up! If you look closely, there is a 25mm hole in the top right above the power supplies which will let wires pass into the toroid box.

Th Z axis drive below the three DS 1076A's is an open frame LS1073A. Which is what they had in the country. Its tiny! The LS series is cheaper but I think I'd stick to the enclosed DS series as the LS does not have any removable connectors so not as convenient to wire up.

I also lucked onto a lot of 5 high quality Sanyo Denki NEMA23 drives. They didn't have any wiring harnesses with them but I found some so I've ended up with $200 steppers at < $30 a piece!

While my machine is off the air, I think I'll clean it up and paint the frame.

Attachments:

Last edit: 12 Jun 2020 23:55 by rodw.

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4661

- Thank you received: 2078

13 Jun 2020 06:53 #171375

by Aciera

Replied by Aciera on topic Rods "Spaceship" Scratch built Plasma Cutter build

No kidding.Man I've got some wiring to tidy up!

Please Log in or Create an account to join the conversation.

- bbsr_5a

- Offline

- Platinum Member

-

Less

More

- Posts: 544

- Thank you received: 105

13 Jun 2020 09:41 #171386

by bbsr_5a

Replied by bbsr_5a on topic Rods "Spaceship" Scratch built Plasma Cutter build

belive me you will wire all at the first EMI shoutdown SMILE

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

13 Jun 2020 09:53 #171391

by thefabricator03

What are the symptoms of a EMI shutdown?

Replied by thefabricator03 on topic Rods "Spaceship" Scratch built Plasma Cutter build

belive me you will wire all at the first EMI shoutdown SMILE

What are the symptoms of a EMI shutdown?

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

Less

More

- Posts: 2203

- Thank you received: 482

13 Jun 2020 10:01 #171392

by Clive S

Rod. I think you know but don't connect any earth wires etc to the top studs on the toroidal tx ,as doing so will give you a shorted turn and might warm thee tx up.

Replied by Clive S on topic Rods "Spaceship" Scratch built Plasma Cutter build

Well its taken a while to get everything here. The first thing I had to get somewhere to mount the toroids so I came up with a piggybank box that will mount behind the control box. This went off to powder coating yesterday. I'm sure they won't be any faster than Tommy's paint shop. The job I gave them early in the week was still sitting on the ground outside their office. It should come back the colour of the sample cable tied on.

While my machine is off the air, I think I'll clean it up and paint the frame.

Rod. I think you know but don't connect any earth wires etc to the top studs on the toroidal tx ,as doing so will give you a shorted turn and might warm thee tx up.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

13 Jun 2020 10:55 #171397

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

Don't worry guys, its still very much a messy work in progress. The Lam drivers are much more compact than what I had so hopefully, I can get it all back nice and neat once I know its working.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

13 Jun 2020 10:57 #171398

by rodw

YEs, its all good. I will use an earth clamp on the DIN rail..

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

Rod. I think you know but don't connect any earth wires etc to the top studs on the toroidal tx ,as doing so will give you a shorted turn and might warm thee tx up.

YEs, its all good. I will use an earth clamp on the DIN rail..

Please Log in or Create an account to join the conversation.

- bbsr_5a

- Offline

- Platinum Member

-

Less

More

- Posts: 544

- Thank you received: 105

13 Jun 2020 11:54 #171409

by bbsr_5a

Replied by bbsr_5a on topic Rods "Spaceship" Scratch built Plasma Cutter build

Attachments:

The following user(s) said Thank You: dvn4life1972

Please Log in or Create an account to join the conversation.

Time to create page: 0.416 seconds