Rods "Spaceship" Scratch built Plasma Cutter build

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

25 Jul 2020 06:36 #175711

by phillc54

Replied by phillc54 on topic Rods "Spaceship" Scratch built Plasma Cutter build

It is amazing how a drive (or ride) can get the brain back in focus...Clearly, there was a fault tin the plasma cutter so I went home in disgust only to realise half way home that I had not bothered to connect the work clamp!

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

25 Jul 2020 06:43 #175712

by rodw

The silly thing, I wasn't even thinking about it at the time!

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

It is amazing how a drive (or ride) can get the brain back in focus...Clearly, there was a fault tin the plasma cutter so I went home in disgust only to realise half way home that I had not bothered to connect the work clamp!

The silly thing, I wasn't even thinking about it at the time!

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

Less

More

- Posts: 2203

- Thank you received: 482

25 Jul 2020 07:18 #175714

by Clive S

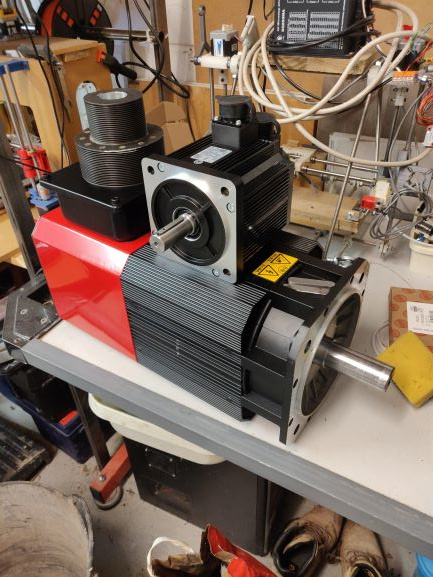

Rod you need bigger motors.

Replied by Clive S on topic Rods "Spaceship" Scratch built Plasma Cutter build

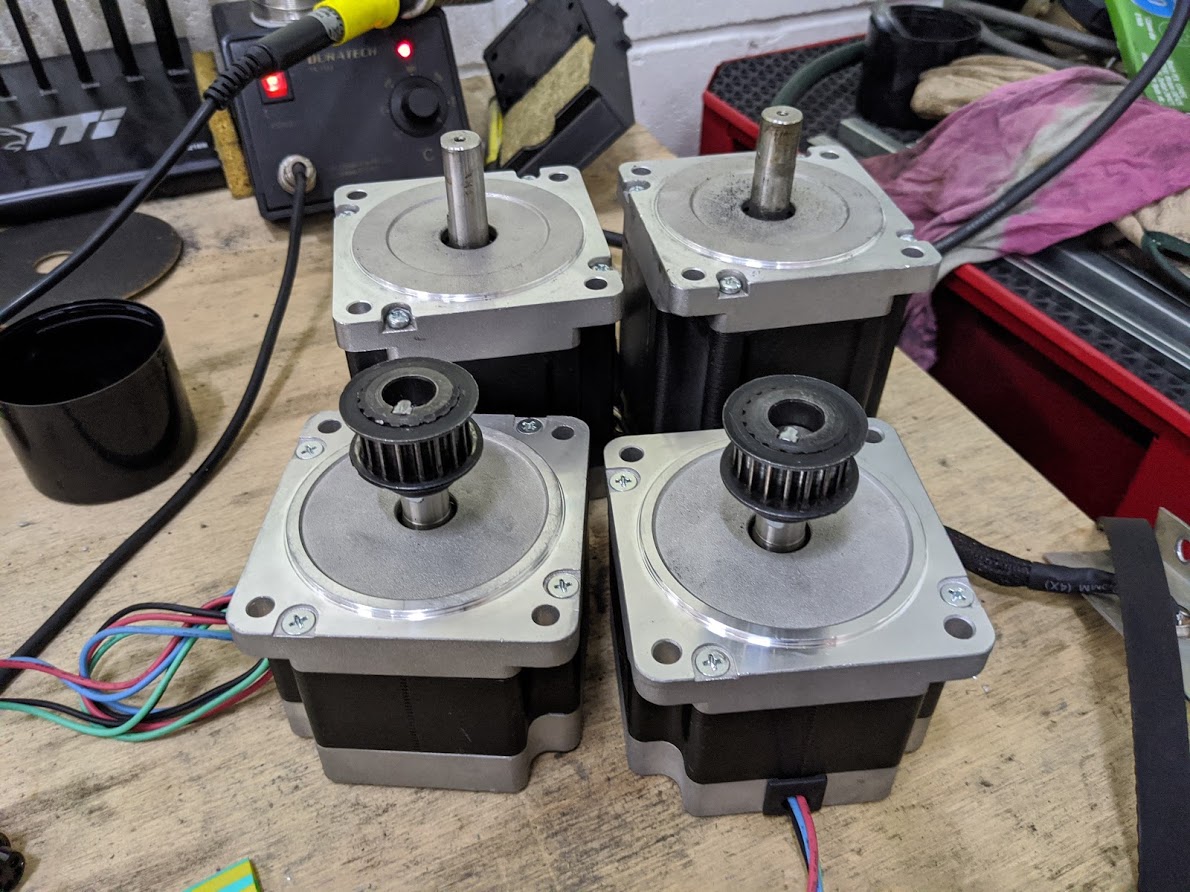

This weekend, I replaced the two Y axis motors

The new motors are the smaller ones with the pulleys on them. With shipping these cost about 4x what the other cheap ones are and are 7 amp vs the larges 4.2 amp motors. ANyway a bit of wight saving to offset the proposed braces.

The Z axis motor is still to be replaced!

Rod you need bigger motors.

Attachments:

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

25 Jul 2020 07:34 #175715

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

Nah, Clive the Spaceship will get into orbit quite nicely with what it has...

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21372

- Thank you received: 7289

25 Jul 2020 16:54 #175749

by tommylight

Now, do not tell that to anyone !

Replied by tommylight on topic Rods "Spaceship" Scratch built Plasma Cutter build

Pssst....i did the same thing a while back, wondering if there is enough air from the crappy compressor. It was the next day that i realised the error of my ways. Not a nice feeling, at all.

It is amazing how a drive (or ride) can get the brain back in focus...Clearly, there was a fault tin the plasma cutter so I went home in disgust only to realise half way home that I had not bothered to connect the work clamp!

The silly thing, I wasn't even thinking about it at the time!

Now, do not tell that to anyone !

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

26 Jul 2020 04:59 - 26 Jul 2020 04:59 #175854

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

I got caught again today with ArcOK! This time the circuit breaker had tripped on the air compressor part way through a job. I was sitting htere scratching my head until I saw all the low air pressure warning lights flashing on the plasma cutter.

I also made some revisions to my Ohmic component as it was not behaving for me. A loose wire on the power supply DC output did not help!

Followers of thins build might remember on the first few pages of this thread, I shared a render that included a material rest for full sheets. I am pleased to say I have finally built it!

Its made from 32NB water pipe (1 1/4" for the laggards) with some 25NB (1") water pipe telescoped inside and clamped off with a M8 bolt for some height adjustment. I was going to add some casters to the legs but I don't think its necessary. The sliding rails are pretty long so they act as a counterbalance and lift the legs off the ground when slid right in. You pick it up and lift the legs to move it back and then they drop down. Works quite nice really.

I also made some revisions to my Ohmic component as it was not behaving for me. A loose wire on the power supply DC output did not help!

Followers of thins build might remember on the first few pages of this thread, I shared a render that included a material rest for full sheets. I am pleased to say I have finally built it!

Its made from 32NB water pipe (1 1/4" for the laggards) with some 25NB (1") water pipe telescoped inside and clamped off with a M8 bolt for some height adjustment. I was going to add some casters to the legs but I don't think its necessary. The sliding rails are pretty long so they act as a counterbalance and lift the legs off the ground when slid right in. You pick it up and lift the legs to move it back and then they drop down. Works quite nice really.

Last edit: 26 Jul 2020 04:59 by rodw.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21372

- Thank you received: 7289

26 Jul 2020 09:18 #175874

by tommylight

Replied by tommylight on topic Rods "Spaceship" Scratch built Plasma Cutter build

Not adjustable ???

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

26 Jul 2020 09:55 #175879

by rodw

Yeh, it slides out about 1500mm and the legs are also adjustable. But the height isn't because its fixed by the table height. Took me a while to work out how it needed to work.

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

Not adjustable ???

Yeh, it slides out about 1500mm and the legs are also adjustable. But the height isn't because its fixed by the table height. Took me a while to work out how it needed to work.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21372

- Thank you received: 7289

26 Jul 2020 10:17 #175880

by tommylight

Replied by tommylight on topic Rods "Spaceship" Scratch built Plasma Cutter build

Nice, that should be more that enough.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

26 Jul 2020 11:01 #175884

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

Yes, mostly I cut full sheets (2400 x 1200) and previously propped it up on a piece of SHS which would fall down. I bought the tube when I last bought some steel but I needed to buy a notcher (Cheap Chinese drill press one) which I did last weekend. I won't say its my favourite tool but it got the job done after I worked out how to mount it up becasue it did not really work well on my bench drill press.

Today was much easier.

Today was much easier.

Please Log in or Create an account to join the conversation.

Time to create page: 0.423 seconds