Rods "Spaceship" Scratch built Plasma Cutter build

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

31 Jul 2020 10:52 - 31 Jul 2020 10:56 #176642

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

What a monster project this week!

I've been struggling to learn Fusion360 becasue I grabbed a 3 year licence while it was on special. So then I needed a new computer so I bought an Intel NUC with a Radeon graphics card built in. Then I decided I should get two monitors while I was at it but had no room on my desk for the second, so I had to buy a new desk while I was at it!

Its actually a pleasure to go to work now! I also bought a license to Adobe Photoshop and Lightroom so finally, the two non cloud based apps (CAD and photo processing) are also in the cloud. Its just a shame they are not OS agnostic like me! Any hardcopy invoices I receive are scanned to Google Drive with the white scanner so my new bookkeeper can take over.

So today, I managed to design some parts in Fusion to do a few jobs around the shop! The first was a couple of wall brackets to hold a roll of backdrop paper in my little product studio. I needed to do this to get rid of a couple of light stands and repurpose my old desk/table into photo duties. While I was in F360, I decided to put a notch on the fold line to line up the part when I folded it (in my 6": wide vice brake press!). Thats when I found out how much flex I have in my gantry ends. Look at the oscillations in the cut with acceleration of 5 m/s^2!

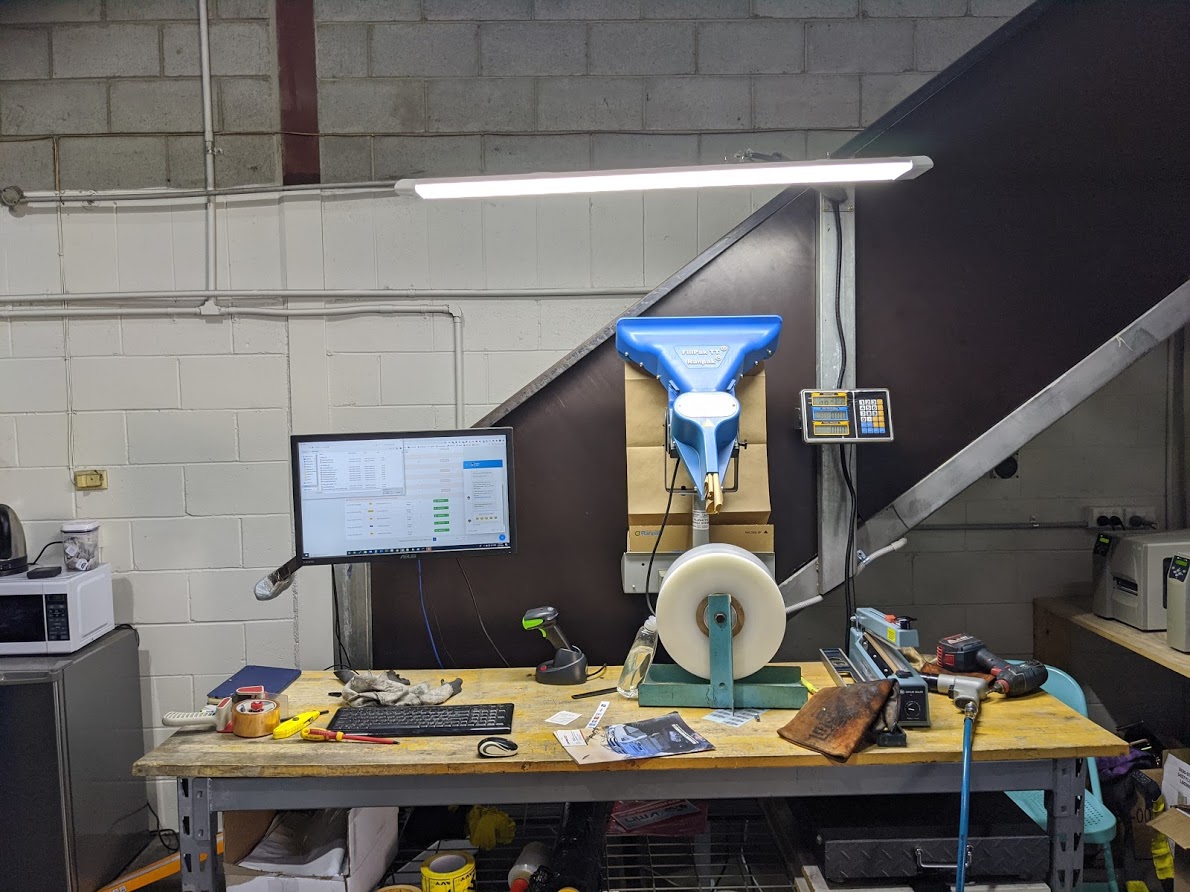

Also last week, I had a lot of electrical work done and the new high bay lights were super bright but left my keyboard in shadow on my packing bench. The other job I did today was to build an air hook to put a LED light over the packing bench.

I just have to tweak it a bit so it sits straight but with 90 watts of LEDs over the bench, let me tell you the shadows are banished forever! Hmm, now I look at that, I should have put a few tools away, Nutsert inserter, welding gloves, drill among heat sealers, barcode scanner and void fill machine... Its actually a very efficient (and super bright) workspace.

I've been struggling to learn Fusion360 becasue I grabbed a 3 year licence while it was on special. So then I needed a new computer so I bought an Intel NUC with a Radeon graphics card built in. Then I decided I should get two monitors while I was at it but had no room on my desk for the second, so I had to buy a new desk while I was at it!

Its actually a pleasure to go to work now! I also bought a license to Adobe Photoshop and Lightroom so finally, the two non cloud based apps (CAD and photo processing) are also in the cloud. Its just a shame they are not OS agnostic like me! Any hardcopy invoices I receive are scanned to Google Drive with the white scanner so my new bookkeeper can take over.

So today, I managed to design some parts in Fusion to do a few jobs around the shop! The first was a couple of wall brackets to hold a roll of backdrop paper in my little product studio. I needed to do this to get rid of a couple of light stands and repurpose my old desk/table into photo duties. While I was in F360, I decided to put a notch on the fold line to line up the part when I folded it (in my 6": wide vice brake press!). Thats when I found out how much flex I have in my gantry ends. Look at the oscillations in the cut with acceleration of 5 m/s^2!

Also last week, I had a lot of electrical work done and the new high bay lights were super bright but left my keyboard in shadow on my packing bench. The other job I did today was to build an air hook to put a LED light over the packing bench.

I just have to tweak it a bit so it sits straight but with 90 watts of LEDs over the bench, let me tell you the shadows are banished forever! Hmm, now I look at that, I should have put a few tools away, Nutsert inserter, welding gloves, drill among heat sealers, barcode scanner and void fill machine... Its actually a very efficient (and super bright) workspace.

Attachments:

Last edit: 31 Jul 2020 10:56 by rodw.

The following user(s) said Thank You: tommylight, snowgoer540

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21372

- Thank you received: 7289

31 Jul 2020 11:43 #176647

by tommylight

Replied by tommylight on topic Rods "Spaceship" Scratch built Plasma Cutter build

Nice, nice and very nice, not necessarily in that order !

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

31 Jul 2020 12:20 #176653

by rodw

Thanks.

You liked my acceleration induced ripple then? I'm sure all my customers will want one of those in their parts

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

Nice, nice and very nice, not necessarily in that order !

Thanks.

You liked my acceleration induced ripple then? I'm sure all my customers will want one of those in their parts

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21372

- Thank you received: 7289

31 Jul 2020 12:50 #176658

by tommylight

Replied by tommylight on topic Rods "Spaceship" Scratch built Plasma Cutter build

It adds something unique to their parts !

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- Mike_Eitel

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1052

- Thank you received: 183

01 Aug 2020 11:30 #176771

by Mike_Eitel

Replied by Mike_Eitel on topic Rods "Spaceship" Scratch built Plasma Cutter build

Is the biggest "hick" where you start? Otherwise i can not see whay you have that strange oscillation. If not i would look for a y statement in you g code.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

01 Aug 2020 13:29 #176781

by rodw

Nah, its a physical issue, I've replaced my motors and drivers so now rapids have moved from 20 m/s^2 to 36 m/s^2 and acceleration is now 5 m/s^2 (up from 2 m/s^2). Its 100% due to the inertia and flex due to the massive acceleration. There is a 3mm leadin direct into a 3mm V notch which would be far enough to get to 2.2 m/s cut speed and that combined with the sudden reversal of direction, caused the gantry to oscillate along the X axis while we travel along the Y axis.

I still have to stiffen up the gantry ends. In fact I have a couple of videos of the 400+kg table dancing on its 300 kg casters and one with a dial indicator against the gantry end, I'm too embarrassed to share!

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

Is the biggest "hick" where you start? Otherwise i can not see whay you have that strange oscillation. If not i would look for a y statement in you g code.

Nah, its a physical issue, I've replaced my motors and drivers so now rapids have moved from 20 m/s^2 to 36 m/s^2 and acceleration is now 5 m/s^2 (up from 2 m/s^2). Its 100% due to the inertia and flex due to the massive acceleration. There is a 3mm leadin direct into a 3mm V notch which would be far enough to get to 2.2 m/s cut speed and that combined with the sudden reversal of direction, caused the gantry to oscillate along the X axis while we travel along the Y axis.

I still have to stiffen up the gantry ends. In fact I have a couple of videos of the 400+kg table dancing on its 300 kg casters and one with a dial indicator against the gantry end, I'm too embarrassed to share!

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21372

- Thank you received: 7289

01 Aug 2020 16:28 #176796

by tommylight

Replied by tommylight on topic Rods "Spaceship" Scratch built Plasma Cutter build

We would not be embarrassed to watch it at all !............ I'm too embarrassed to share!

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- bevins

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

01 Aug 2020 18:25 - 01 Aug 2020 18:26 #176806

by bevins

I'm going to have to read this thread/book of yours one day...

Replied by bevins on topic Rods "Spaceship" Scratch built Plasma Cutter build

We would not be embarrassed to watch it at all !............ I'm too embarrassed to share!

I'm going to have to read this thread/book of yours one day...

Last edit: 01 Aug 2020 18:26 by bevins.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

19 Aug 2020 11:19 #178699

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

Well I bought a small accessory for my plasma cutter at an online auction which got delivered on Monday.

Then they poked it under a vehicle hoist

and extended the boom and placed it right against the back wall!

I even scored a bonus pallet of tooling which was not in the listing.

This is a 2.0 metre, 50 tonne Amada press brake with NC control. Its been retrofitted with a Presstek touch screen 2-3 years ago and there was a business card for the guy that did it on the machine so he's been helpful. It was also fitted with light guards at that time which replaced an old guarding system so there are a lot of spare wires floating around in the control panel... It was only a mile or so from work, so I figured I'd never get a cheaper one.

I saw it powered up before I bought it but they disconnected it before I saw it after the sale. The power connection was not easy to find so its taken a while to sort it out but I have an electrician booked tomorrow. There is some dodgy mains wiring in the cabinet that I will get cleaned up while we are at it. It was never wired in according to the manufacturer's directions so I'll get the power away from the logic.

Amada also have been very helpful. He said he wanted to get me to upgrade my spaceship to his laser!

So hopefully this does not end in tears tomrrow!

Then they poked it under a vehicle hoist

and extended the boom and placed it right against the back wall!

I even scored a bonus pallet of tooling which was not in the listing.

This is a 2.0 metre, 50 tonne Amada press brake with NC control. Its been retrofitted with a Presstek touch screen 2-3 years ago and there was a business card for the guy that did it on the machine so he's been helpful. It was also fitted with light guards at that time which replaced an old guarding system so there are a lot of spare wires floating around in the control panel... It was only a mile or so from work, so I figured I'd never get a cheaper one.

I saw it powered up before I bought it but they disconnected it before I saw it after the sale. The power connection was not easy to find so its taken a while to sort it out but I have an electrician booked tomorrow. There is some dodgy mains wiring in the cabinet that I will get cleaned up while we are at it. It was never wired in according to the manufacturer's directions so I'll get the power away from the logic.

Amada also have been very helpful. He said he wanted to get me to upgrade my spaceship to his laser!

So hopefully this does not end in tears tomrrow!

Attachments:

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

19 Aug 2020 13:45 #178708

by machinedude

Replied by machinedude on topic Rods "Spaceship" Scratch built Plasma Cutter build

hard part is out of the way now  getting it in the building is most of the battle the rest is just time consuming

getting it in the building is most of the battle the rest is just time consuming

keep your fingers out of the way that machine will most likely do some damage

keep your fingers out of the way that machine will most likely do some damage

Please Log in or Create an account to join the conversation.

Time to create page: 0.520 seconds