Hurco KMB-IS CNC update

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

02 Aug 2020 22:42 - 03 Aug 2020 04:04 #176952

by CORBETT

Leith,

LOL I could not afford a Porsche... In 1983 I was 13 and went saw my first movie without my parents.... "Return of the Jedi"... will never forget that.... at 13, Princess Leia was really hot when at Jabba the Hutt's palace... LOL

Yeah that sounds like a aftermarket upgrade. I can tell you that Hurco would not have sent out a piece of machinery with something just hanging off the back as I have looked at practically all the different years and models of this machine and never saw anything outside of a cabinet. Plus the liability of someone getting electrocuted would have kept them from doing so also.

Ok you should be able to look at the transformer and see how many wires are powering it on the primary side to see if it is single or three phase. If single, then you will not need the VFD installed to fire up the servos, as you can wire up and get power to the transformer, You shouldn't need the VFD for the servos anyway as the VFD will ONLY be for your spindle 3ph motor and not powering other things down the line. I believe the OEM transformer was single phase 110-220, but not sure of that at all as I would need to take a look. I never had to mess with the wiring, and that is why I am not sure. It would make sense as I have not seen any secondary VFD in any machine to get 3ph for the transformers. I don't think Hurco would have taken a 3ph transformer and wired for single phase input as that is dangerous from what I remember, but I could be wrong about that... but seems like the other 2 windings are live and dangerous, which once again for a company is liability.

Be aware that the Primary could very well be 110-120V and I would not send a lot of voltage to it until confirming what you have. You can get away with powering with the lower voltage to check first (110V), but if you put too much (220V) then obviously get the "magic smoke" LOL Worst case, since it could be aftermarket, it may be 220-440V - 3PH on the primary side with 220V on the LV and 440V for HV and 80-85V - 1PH on the secondary. I would need to take a look at what I have and see if I can help. Pus I would find it odd that they are using a 3PH transformer to step to 80V - 1PH, but I have seen some crazy transformers up in the north east of USA to match OLD OLD electrical systems that were done when Edison and Westinghouse first put electricity in the factories and there was no set standard yet.

ADDING THIS EDIT TO CLARIFY THIS PART ABOUT TRANSFORMER

I know I probably got a little confusing about the transformer when I said 3ph in and 1ph out would be odd, because there are plenty of machines that have step down transformers with 3ph in and 1ph out to the controller, but what I was trying to state was for this particular machine I believe that transformer is single phase. As I would think they did 1PH to 1PH on this particular transformer. I am pretty sure there are 2 transformers in the back, one is for the servos and the other is step down. I will check mine out as I have only opened those compartments one time ever and that was many years ago. Hope I did not confuse you earlier.

]END OF EDIT

2ND EDIT ABOUT TRANSFORMER

Ok I went and looked online and it does appear that the servo transformer is single phase (I never made it to shop today, sorry). The one I saw was 240V primary and 60V secondary. I will take a look at mine and see if the same. I believe all of them were single phase as this would keep continuity for all the machines with only the input voltage and step down transformer being the only thing Hurco would have to deal with per each customers voltage requirements. I did go pull my manuals to the first machine and looks like it is a 1981 model and the other is a 1983 model. So all of the pics I have sent so far should be from the 1981 model. The 81 manual shows that there was 8 different input voltages that could be ordered from 200V - 575V in 50 and 60hz. So this would make sense of only having to deal with just one transformer per machine before shipping to the customer (step down transformer), Not sure about servo transformer having a 240V primary with the machine only getting 200V input as that would reduce the output from the secondary, but what I saw online could have been from a later model and my earlier 81 model may be a low primary voltage. Will find out and let you know, but at least hopefully it is single phase and you can keep moving in the right direction.

Once again though, if yours is aftermarket, then yours may be a different primary and possibly 3phase

END EDIT

Yes the left cabinet is usually gutted and only a VFD and disconnect. I will upload a picture of the OEM cabinet and you can see what it originally looked like. Once the parajust board and the connector board above is taken out, there is nothing left but the disconnect. The cabinet looks odd so empty, but that is because the parajust board was so big.

Ok if the pendant is one screen then yes you probably do have a older model and closer to my wiring type. The newer models were pretty close, but a little different. Hurco like any other big manufacture had to keep most all of the controls and electrical pretty much the same between their own machines, because if there was a lot of crazy different designs, then it would have been a nightmare for the tech guy going out in the field and performing warranty repairs or for money service calls. Speed is the name of the game in repairs as the customer needs to be back up and running, so they tried to keep all the stuff reasonably the same to minimize parts stock and not have to get something exotic shipped in. Plus they did not need the tech guy's stopping to check manuals for different designs when they could keep one style and train the guy's for that design. Multiple styles increase chances of mistakes in the field.

On a tangent, you may want to retrieve that tape out of the drive and see if it is one of the Hurco parameter tapes. I doubt it is and probably just some program to run for a project, but if the parameter tape some guy out there may be super happy to get it. I would have been that guy 2 years ago LOL.

Ok yeah if you are not comfortable trying to run the old control then yeah go for it on retrofit, I simply wanted to tell you just in case you wanted to try and get the machine up and running quickly. I was unsure of what your time frame was and that was a option for speed.

Ok one last thing, I would completely stay away from a laptop (my opinion LOL). There are people that run laptops, but I have seen way more problems over the years of research when using a laptop. I am sure someone is going chime in and tell me I am wrong, but once again, I am all about reliability. Anytime there is a possibility that something could go wrong with the computer side and crash the machine, makes me stay on the side of reliability by using a desktop style computer. Things do change and I have not researched using LCNC with a laptop in the last few years, but years ago I know it was frowned upon.

Ok I may not have answered everything, but I will be back in a bit and get more info for you.

Robert

Replied by CORBETT on topic Hurco KMB-IS CNC update

Leith,

LOL I could not afford a Porsche... In 1983 I was 13 and went saw my first movie without my parents.... "Return of the Jedi"... will never forget that.... at 13, Princess Leia was really hot when at Jabba the Hutt's palace... LOL

Yeah that sounds like a aftermarket upgrade. I can tell you that Hurco would not have sent out a piece of machinery with something just hanging off the back as I have looked at practically all the different years and models of this machine and never saw anything outside of a cabinet. Plus the liability of someone getting electrocuted would have kept them from doing so also.

Ok you should be able to look at the transformer and see how many wires are powering it on the primary side to see if it is single or three phase. If single, then you will not need the VFD installed to fire up the servos, as you can wire up and get power to the transformer, You shouldn't need the VFD for the servos anyway as the VFD will ONLY be for your spindle 3ph motor and not powering other things down the line. I believe the OEM transformer was single phase 110-220, but not sure of that at all as I would need to take a look. I never had to mess with the wiring, and that is why I am not sure. It would make sense as I have not seen any secondary VFD in any machine to get 3ph for the transformers. I don't think Hurco would have taken a 3ph transformer and wired for single phase input as that is dangerous from what I remember, but I could be wrong about that... but seems like the other 2 windings are live and dangerous, which once again for a company is liability.

Be aware that the Primary could very well be 110-120V and I would not send a lot of voltage to it until confirming what you have. You can get away with powering with the lower voltage to check first (110V), but if you put too much (220V) then obviously get the "magic smoke" LOL Worst case, since it could be aftermarket, it may be 220-440V - 3PH on the primary side with 220V on the LV and 440V for HV and 80-85V - 1PH on the secondary. I would need to take a look at what I have and see if I can help. Pus I would find it odd that they are using a 3PH transformer to step to 80V - 1PH, but I have seen some crazy transformers up in the north east of USA to match OLD OLD electrical systems that were done when Edison and Westinghouse first put electricity in the factories and there was no set standard yet.

ADDING THIS EDIT TO CLARIFY THIS PART ABOUT TRANSFORMER

I know I probably got a little confusing about the transformer when I said 3ph in and 1ph out would be odd, because there are plenty of machines that have step down transformers with 3ph in and 1ph out to the controller, but what I was trying to state was for this particular machine I believe that transformer is single phase. As I would think they did 1PH to 1PH on this particular transformer. I am pretty sure there are 2 transformers in the back, one is for the servos and the other is step down. I will check mine out as I have only opened those compartments one time ever and that was many years ago. Hope I did not confuse you earlier.

]END OF EDIT

2ND EDIT ABOUT TRANSFORMER

Ok I went and looked online and it does appear that the servo transformer is single phase (I never made it to shop today, sorry). The one I saw was 240V primary and 60V secondary. I will take a look at mine and see if the same. I believe all of them were single phase as this would keep continuity for all the machines with only the input voltage and step down transformer being the only thing Hurco would have to deal with per each customers voltage requirements. I did go pull my manuals to the first machine and looks like it is a 1981 model and the other is a 1983 model. So all of the pics I have sent so far should be from the 1981 model. The 81 manual shows that there was 8 different input voltages that could be ordered from 200V - 575V in 50 and 60hz. So this would make sense of only having to deal with just one transformer per machine before shipping to the customer (step down transformer), Not sure about servo transformer having a 240V primary with the machine only getting 200V input as that would reduce the output from the secondary, but what I saw online could have been from a later model and my earlier 81 model may be a low primary voltage. Will find out and let you know, but at least hopefully it is single phase and you can keep moving in the right direction.

Once again though, if yours is aftermarket, then yours may be a different primary and possibly 3phase

END EDIT

Yes the left cabinet is usually gutted and only a VFD and disconnect. I will upload a picture of the OEM cabinet and you can see what it originally looked like. Once the parajust board and the connector board above is taken out, there is nothing left but the disconnect. The cabinet looks odd so empty, but that is because the parajust board was so big.

Ok if the pendant is one screen then yes you probably do have a older model and closer to my wiring type. The newer models were pretty close, but a little different. Hurco like any other big manufacture had to keep most all of the controls and electrical pretty much the same between their own machines, because if there was a lot of crazy different designs, then it would have been a nightmare for the tech guy going out in the field and performing warranty repairs or for money service calls. Speed is the name of the game in repairs as the customer needs to be back up and running, so they tried to keep all the stuff reasonably the same to minimize parts stock and not have to get something exotic shipped in. Plus they did not need the tech guy's stopping to check manuals for different designs when they could keep one style and train the guy's for that design. Multiple styles increase chances of mistakes in the field.

On a tangent, you may want to retrieve that tape out of the drive and see if it is one of the Hurco parameter tapes. I doubt it is and probably just some program to run for a project, but if the parameter tape some guy out there may be super happy to get it. I would have been that guy 2 years ago LOL.

Ok yeah if you are not comfortable trying to run the old control then yeah go for it on retrofit, I simply wanted to tell you just in case you wanted to try and get the machine up and running quickly. I was unsure of what your time frame was and that was a option for speed.

Ok one last thing, I would completely stay away from a laptop (my opinion LOL). There are people that run laptops, but I have seen way more problems over the years of research when using a laptop. I am sure someone is going chime in and tell me I am wrong, but once again, I am all about reliability. Anytime there is a possibility that something could go wrong with the computer side and crash the machine, makes me stay on the side of reliability by using a desktop style computer. Things do change and I have not researched using LCNC with a laptop in the last few years, but years ago I know it was frowned upon.

Ok I may not have answered everything, but I will be back in a bit and get more info for you.

Robert

Last edit: 03 Aug 2020 04:04 by CORBETT. Reason: To clarify my post on the transformer 2 different times

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21230

- Thank you received: 7249

02 Aug 2020 23:24 #176961

by tommylight

Had to do some explaining the next day, but was bloody worth it.

Had to do some explaining the next day, but was bloody worth it.

BTW, thanks for all the help you are offering, it is becoming quite the knowledge base.

Replied by tommylight on topic Hurco KMB-IS CNC update

So was i, 13, went on a brake from school to my apartment ( literally 30 meters far ) saw Star Wars on TV just started so i did not go back to school that day!In 1983 I was 13 and went saw my first movie without my parents.... "Return of the Jedi"... will never forget that.... at 13, Princess Leia was really hot when at Jabba the Hutt's palace... LOL

BTW, thanks for all the help you are offering, it is becoming quite the knowledge base.

The following user(s) said Thank You: CORBETT

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

02 Aug 2020 23:42 #176966

by CORBETT

Leith,

One quick clarification when I was speaking previously about the OEM transformer being single phase. The machines were 3 phase from the factory as most all customers would have been using 440-480V and some at 220V. Another thing for a machine shop is electricity cost and most all customers would have been trying to use 440V to save money. 440V 3ph is seven times more efficient that 220V 1ph, so it does not take much math to figure out the cost saved, especially running the machine nearly non-stop.

I didn't have to make changes to my transformer as the previous company had already put the VFD in and had the input wiring working for 220V. I will need to check my setup out and see how it was wired as I know the original transformers were in the machine.

Control cabinets here in the USA take low voltage 110V A/C and never a HIGH voltage. I am sure this is a NEMA requirement as every control cabinet that I have ever been into was 110V single phase, with most of the control being 24V DC. The only HIGH voltage will be the input going to the step down transformer to get 110V for the controller, and to the contactors/magnetic starters for the spindle motor and coolant pump. Other than the step down, coolant pump, and spindle motor I am not aware of anything else needing 3ph in this style of machine. Now of course on the big VMC's we had extra 3ph equipment such as hydraulic power unit, coolant pump, and coolant pump cleaners, but you wanted 3ph for all of the motors to keep power cost down. The servos are DC and not part of the equation as the supply transformer would be the only thing that may be 3ph as downstream will be the 80-85V single phase going to the amps.

I know I probably got a little confusing about the transformer when I said 3ph in and 1ph out would be odd, because there are plenty of machines that have step down transformers with 3ph in and 1ph out to the controller, but what I was trying to state was for this particular machine I believe that transformer is single phase. Hope I did not confuse you earlier.

We had 3 large Monarch VMC's and even on the largest we had (VMC 150), it was single phase to the controller. The only thing that is 3 phase is the spindle motor, coolant motor, etc... That machine had a 25hp motor for the spindle with CAT 50 tooling. Anyway, a lot of HP for the spindle and nice big 3' x 5' table, but still only 110V to the Allen-Bradley controller.

Just wanted to try and clear things up before I muddied the water about the transformer in and out.

Robert

Replied by CORBETT on topic Hurco KMB-IS CNC update

Leith,

One quick clarification when I was speaking previously about the OEM transformer being single phase. The machines were 3 phase from the factory as most all customers would have been using 440-480V and some at 220V. Another thing for a machine shop is electricity cost and most all customers would have been trying to use 440V to save money. 440V 3ph is seven times more efficient that 220V 1ph, so it does not take much math to figure out the cost saved, especially running the machine nearly non-stop.

I didn't have to make changes to my transformer as the previous company had already put the VFD in and had the input wiring working for 220V. I will need to check my setup out and see how it was wired as I know the original transformers were in the machine.

Control cabinets here in the USA take low voltage 110V A/C and never a HIGH voltage. I am sure this is a NEMA requirement as every control cabinet that I have ever been into was 110V single phase, with most of the control being 24V DC. The only HIGH voltage will be the input going to the step down transformer to get 110V for the controller, and to the contactors/magnetic starters for the spindle motor and coolant pump. Other than the step down, coolant pump, and spindle motor I am not aware of anything else needing 3ph in this style of machine. Now of course on the big VMC's we had extra 3ph equipment such as hydraulic power unit, coolant pump, and coolant pump cleaners, but you wanted 3ph for all of the motors to keep power cost down. The servos are DC and not part of the equation as the supply transformer would be the only thing that may be 3ph as downstream will be the 80-85V single phase going to the amps.

I know I probably got a little confusing about the transformer when I said 3ph in and 1ph out would be odd, because there are plenty of machines that have step down transformers with 3ph in and 1ph out to the controller, but what I was trying to state was for this particular machine I believe that transformer is single phase. Hope I did not confuse you earlier.

We had 3 large Monarch VMC's and even on the largest we had (VMC 150), it was single phase to the controller. The only thing that is 3 phase is the spindle motor, coolant motor, etc... That machine had a 25hp motor for the spindle with CAT 50 tooling. Anyway, a lot of HP for the spindle and nice big 3' x 5' table, but still only 110V to the Allen-Bradley controller.

Just wanted to try and clear things up before I muddied the water about the transformer in and out.

Robert

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

02 Aug 2020 23:49 #176968

by CORBETT

@tommylight

Tom,

Yeah I was hooked on Star Wars when I was a kid... To this day I can still remember watching the movie commercials on TV and begging my parents to go see them. My parents wouldn't let me go see the first 2 movies, but finally relented on the 3rd one LOL.

Much obliged to you and Albert on giving me help in the past, as you guys helped me and this is the way I can pay it back.

Robert

Replied by CORBETT on topic Hurco KMB-IS CNC update

@tommylight

Tom,

Yeah I was hooked on Star Wars when I was a kid... To this day I can still remember watching the movie commercials on TV and begging my parents to go see them. My parents wouldn't let me go see the first 2 movies, but finally relented on the 3rd one LOL.

Much obliged to you and Albert on giving me help in the past, as you guys helped me and this is the way I can pay it back.

Robert

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21230

- Thank you received: 7249

03 Aug 2020 08:13 #177010

by tommylight

Replied by tommylight on topic Hurco KMB-IS CNC update

I still am !

Yeah I was hooked on Star Wars when I was a kid...

The following user(s) said Thank You: CORBETT

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

03 Aug 2020 22:45 #177119

by CORBETT

Replied by CORBETT on topic Hurco KMB-IS CNC update

I am still also LOL

I will say that I like the original first 3 movies the best... Ahh, nostalgia... gonna have to sit and watch them again soon...

I will say that I like the original first 3 movies the best... Ahh, nostalgia... gonna have to sit and watch them again soon...

Please Log in or Create an account to join the conversation.

- _big_

- Offline

- Premium Member

-

Less

More

- Posts: 87

- Thank you received: 13

04 Aug 2020 03:13 #177161

by _big_

Replied by _big_ on topic Hurco KMB-IS CNC update

Got a bunch of pictures. Forum seems to get cranky if you post too many at once. I'll break it up into several replys.

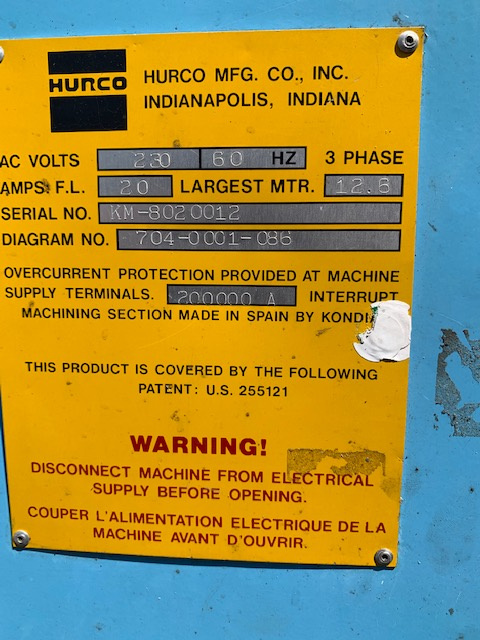

Nameplate says 220V 3 phase. Quill motor says 220440V 3 phase. Eventual landing place for machine is a shop with 440V 3 phase. Probably with the exception of the quill motor, machine ran off of a single phase of the 220V 3 phase. Biggest problem with the 440V is then stepping it down to 220V. Not a big deal though.

Looked more closely at the rear mounted transformer. Single core and hence single phase. Two input wires and two output wires. All the MAX-430 servos AC power inputs are bussed together. Probably the transformer steps a single phase of the 220V down to ~85 VAC.

Photo of the nameplate. If we had the right secret decoder ring, we could probably tell exactly when the beast was made.

Nameplate says 220V 3 phase. Quill motor says 220440V 3 phase. Eventual landing place for machine is a shop with 440V 3 phase. Probably with the exception of the quill motor, machine ran off of a single phase of the 220V 3 phase. Biggest problem with the 440V is then stepping it down to 220V. Not a big deal though.

Looked more closely at the rear mounted transformer. Single core and hence single phase. Two input wires and two output wires. All the MAX-430 servos AC power inputs are bussed together. Probably the transformer steps a single phase of the 220V down to ~85 VAC.

Photo of the nameplate. If we had the right secret decoder ring, we could probably tell exactly when the beast was made.

Please Log in or Create an account to join the conversation.

- _big_

- Offline

- Premium Member

-

Less

More

- Posts: 87

- Thank you received: 13

04 Aug 2020 03:16 #177162

by _big_

Replied by _big_ on topic Hurco KMB-IS CNC update

Please Log in or Create an account to join the conversation.

- _big_

- Offline

- Premium Member

-

Less

More

- Posts: 87

- Thank you received: 13

04 Aug 2020 03:18 #177163

by _big_

Replied by _big_ on topic Hurco KMB-IS CNC update

Attachments:

Please Log in or Create an account to join the conversation.

- _big_

- Offline

- Premium Member

-

Less

More

- Posts: 87

- Thank you received: 13

04 Aug 2020 03:19 #177164

by _big_

Replied by _big_ on topic Hurco KMB-IS CNC update

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.644 seconds