Optimum Optimill MH50V CNC conversion

- Unlogic

- Offline

- Elite Member

-

Less

More

- Posts: 238

- Thank you received: 118

09 Mar 2025 21:26 #323567

by Unlogic

Replied by Unlogic on topic Optimum Optimill MH50V CNC conversion

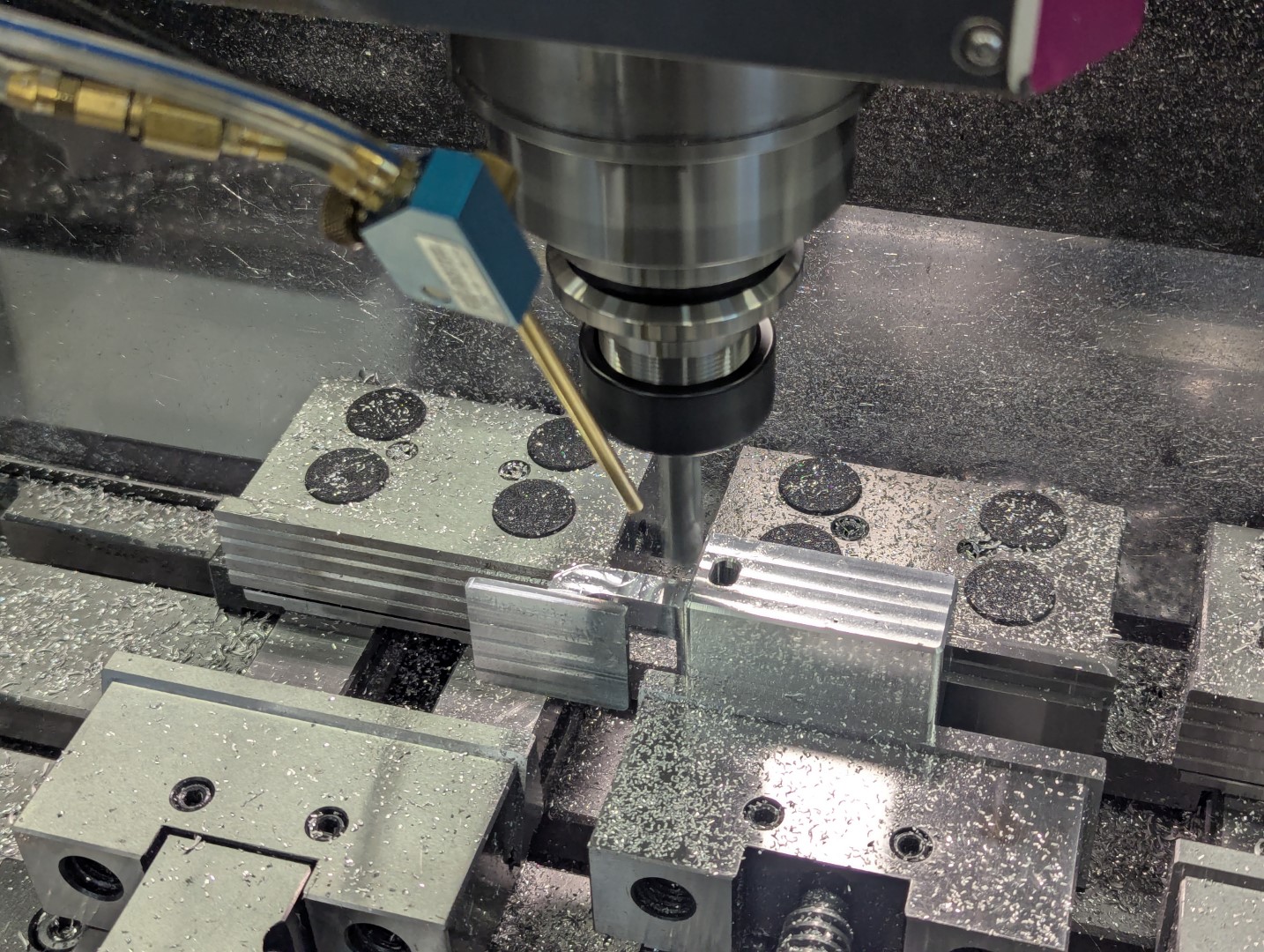

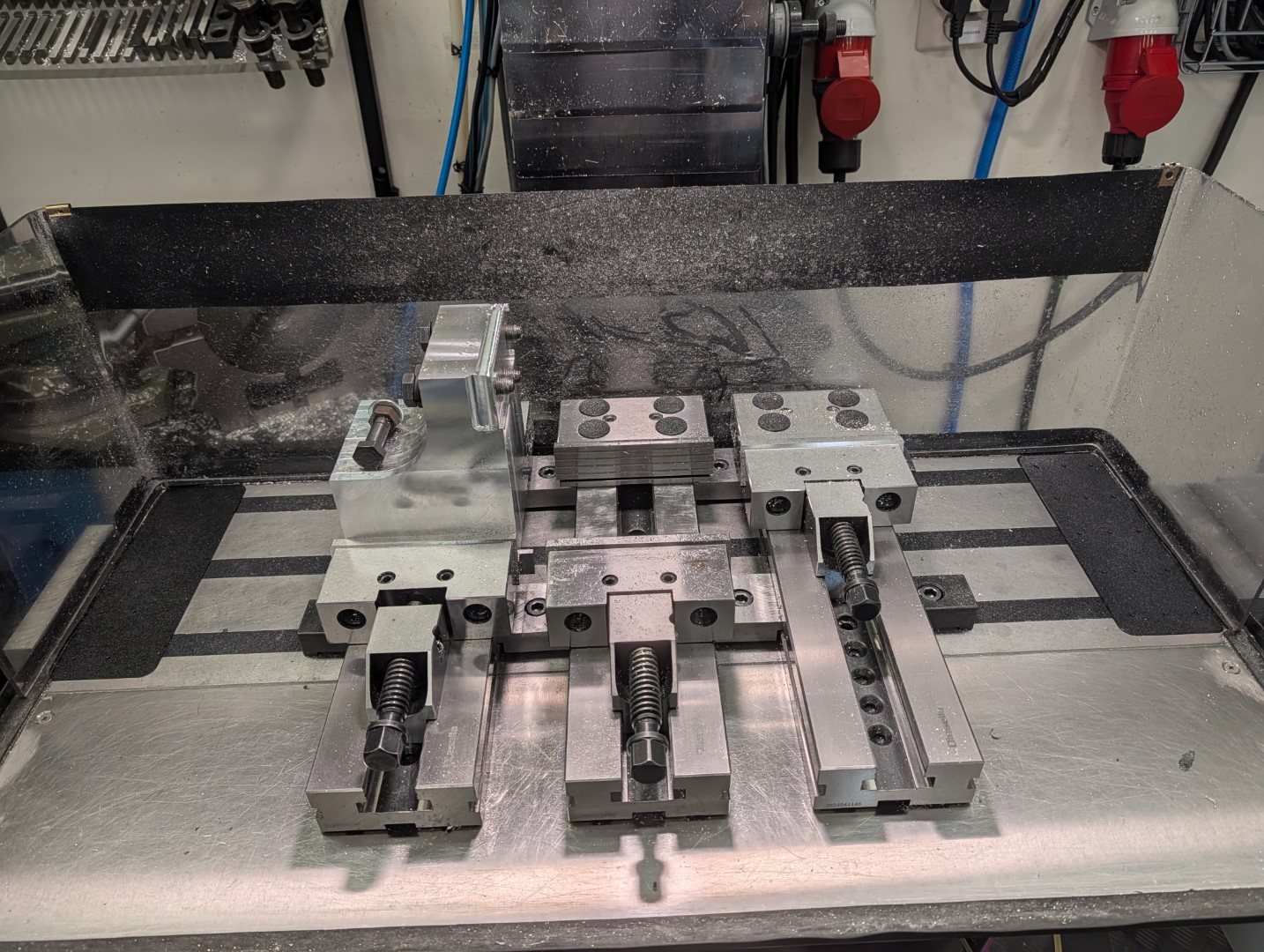

I've done some more parts on the mill and it's working great apart from the slow spindle speeds I have to run.

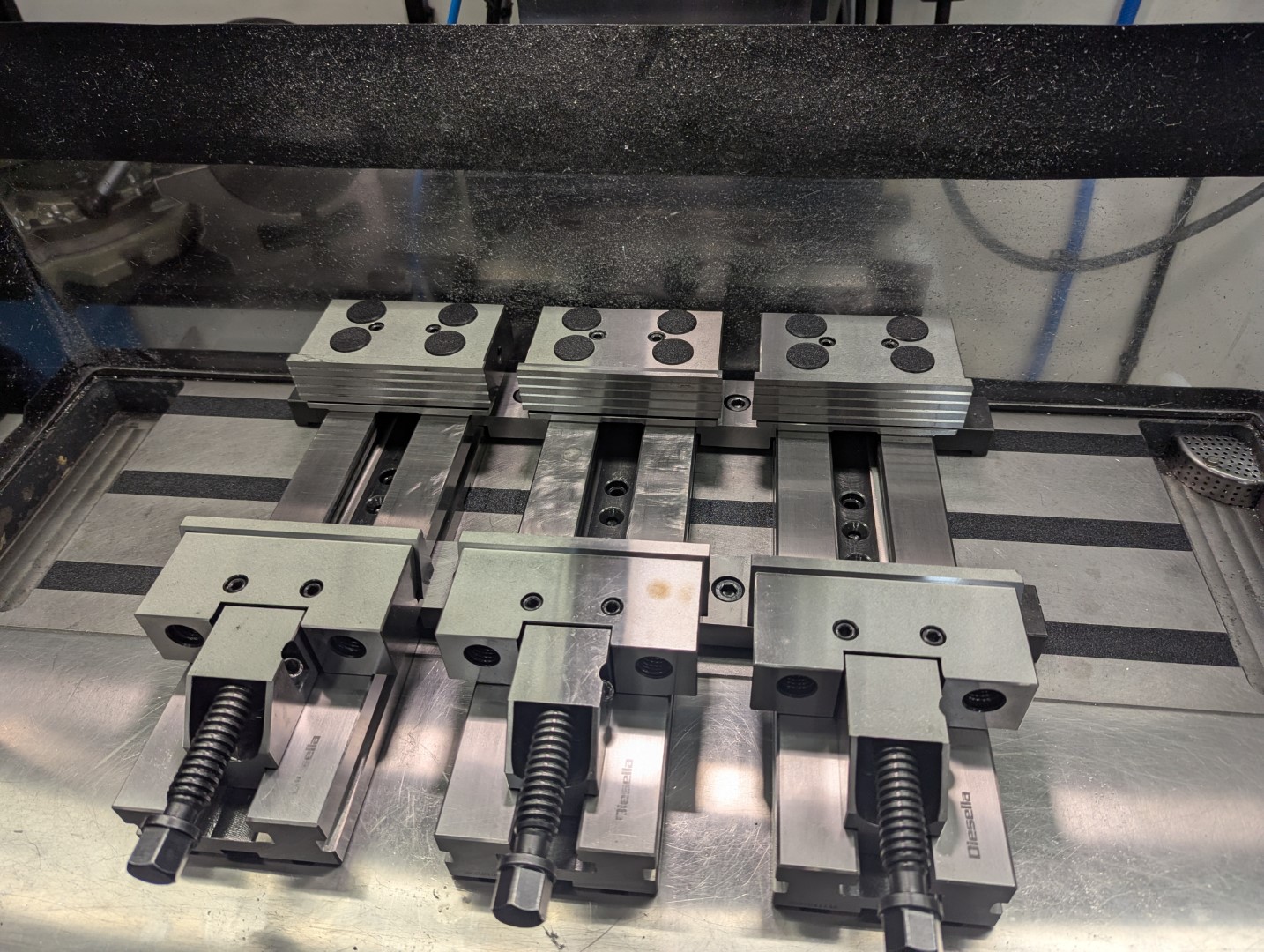

Here is a short video of two aluminum mounting brackets that I designed for the rear sway bar of my race car.

The mounting brackets came out really nice but I can't wait until I have a new spindle so that I can increase the speeds and feeds a bit.

I'm also considering expanding my enclosure a bit as the one I have at the moment allows a bit too many chips too escape during some operations.

Here is a short video of two aluminum mounting brackets that I designed for the rear sway bar of my race car.

The mounting brackets came out really nice but I can't wait until I have a new spindle so that I can increase the speeds and feeds a bit.

I'm also considering expanding my enclosure a bit as the one I have at the moment allows a bit too many chips too escape during some operations.

The following user(s) said Thank You: tommylight, rodw

Please Log in or Create an account to join the conversation.

- Unlogic

- Offline

- Elite Member

-

Less

More

- Posts: 238

- Thank you received: 118

15 Aug 2025 13:13 #333465

by Unlogic

Replied by Unlogic on topic Optimum Optimill MH50V CNC conversion

The milling machine has been working great so I haven't done any changes to it for several months. However one thing that has been on my mind for a while is that I have no idea how hot it gets inside of the control cabinet during long milling sessions.

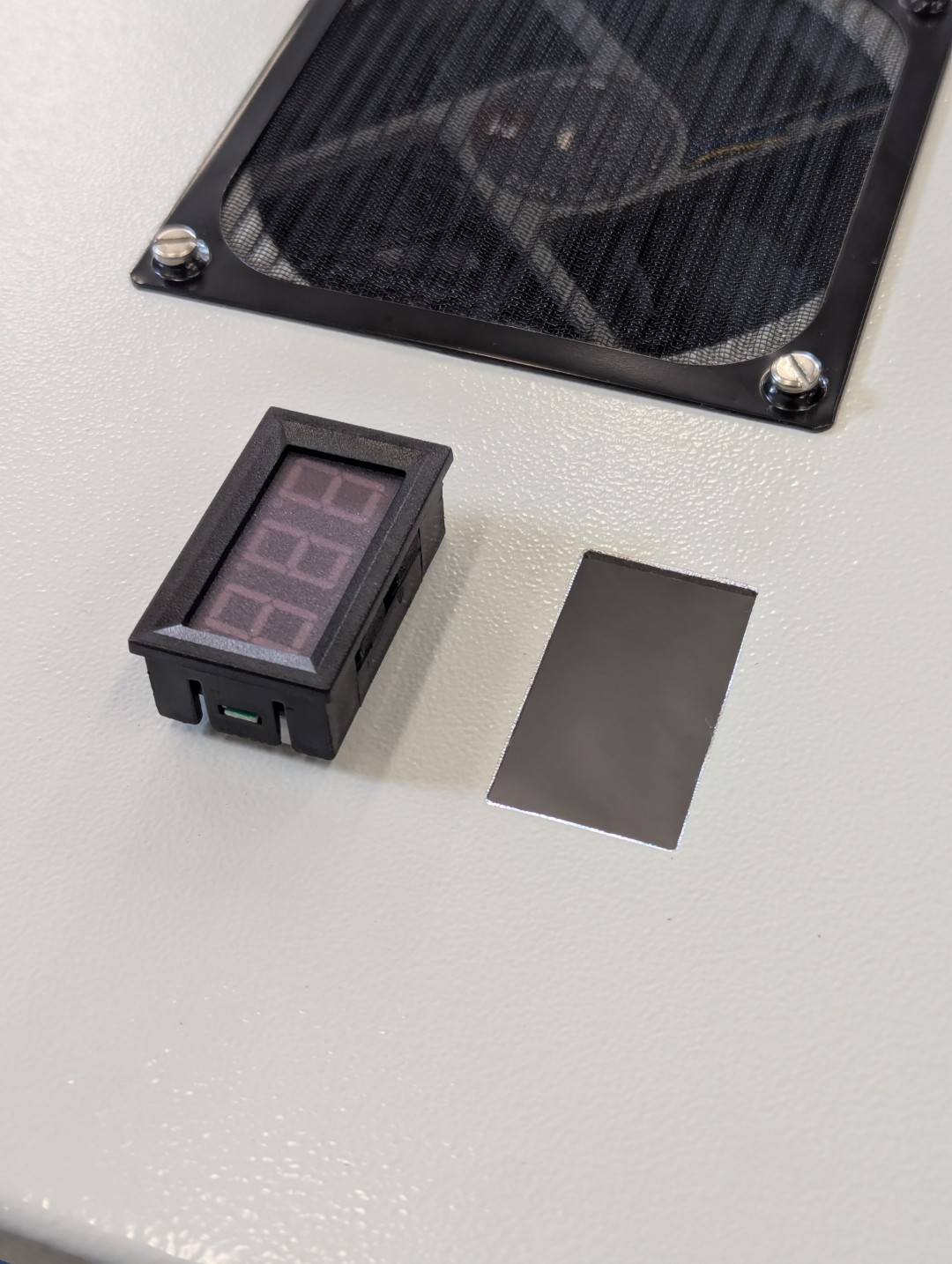

A quick search for temperature display brought up this unit on AliExpress for a very low price:

www.aliexpress.com/item/1005005993184685.html

I bought one and it arrived a couple weeks later, here is how it looks installed in the cabinet.

It's gonna be interesting to see how hot it actually gets inside the cabinet.

A quick search for temperature display brought up this unit on AliExpress for a very low price:

www.aliexpress.com/item/1005005993184685.html

I bought one and it arrived a couple weeks later, here is how it looks installed in the cabinet.

It's gonna be interesting to see how hot it actually gets inside the cabinet.

Attachments:

The following user(s) said Thank You: tommylight, Surmetall

Please Log in or Create an account to join the conversation.

- Unlogic

- Offline

- Elite Member

-

Less

More

- Posts: 238

- Thank you received: 118

07 Sep 2025 20:26 - 07 Sep 2025 20:50 #334591

by Unlogic

Replied by Unlogic on topic Optimum Optimill MH50V CNC conversion

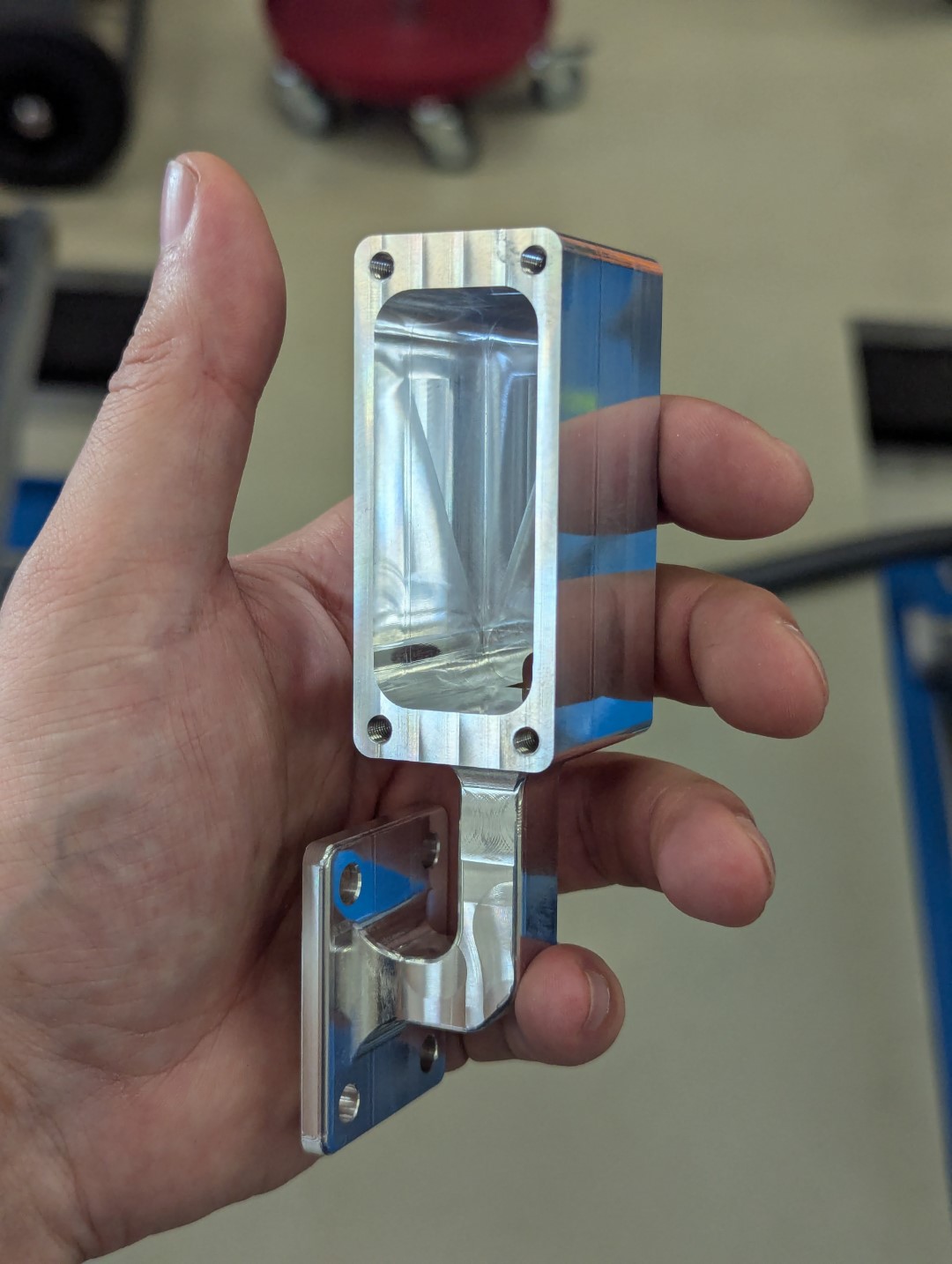

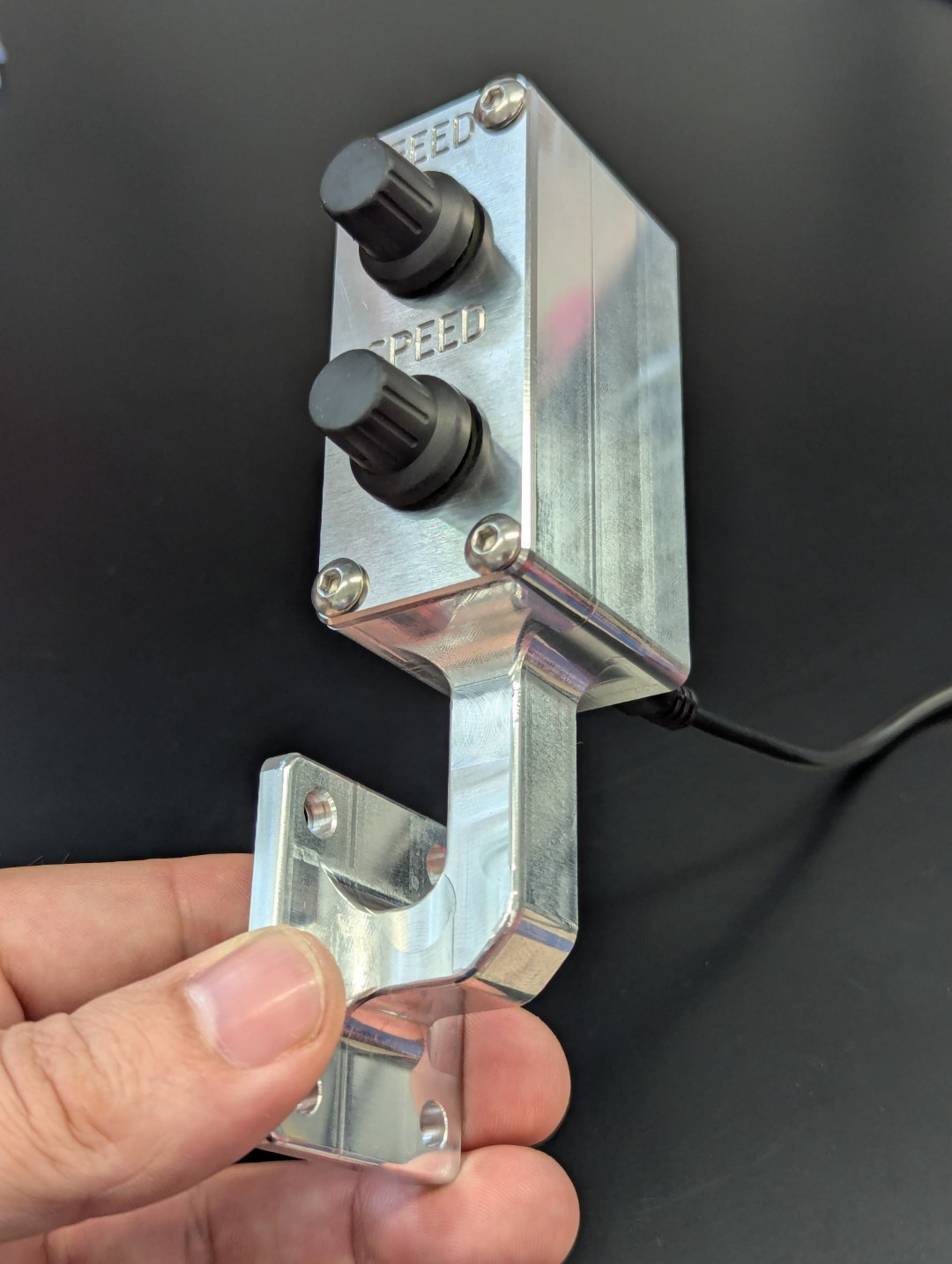

I spent the last week with a really bad cold and while being bored by the need to rest and stay calm I decided to design a small addon for the control panel on the mill.

When I first designed the control panel I had never touched a CNC mill so I had no real idea which physical buttons that I would need.

After using the machine for a while I have realized that having rotary encoders for controlling feed and speed override would be very useful as it would mean that they could be operated while wearing gloves which does not work very well with the touch screen.

As I had plenty of time to kill this addon might have gone a bit over the top but it's very sturdy and works really well.

I started by milling the body out of some 6082 aluminum.

I then milled a face plate from a 2 mm thick scrap piece of stainless plate that I had laying around.

When I first designed the control panel I had never touched a CNC mill so I had no real idea which physical buttons that I would need.

After using the machine for a while I have realized that having rotary encoders for controlling feed and speed override would be very useful as it would mean that they could be operated while wearing gloves which does not work very well with the touch screen.

As I had plenty of time to kill this addon might have gone a bit over the top but it's very sturdy and works really well.

I started by milling the body out of some 6082 aluminum.

I then milled a face plate from a 2 mm thick scrap piece of stainless plate that I had laying around.

Attachments:

Last edit: 07 Sep 2025 20:50 by Unlogic. Reason: Figthing with the editor *argh*

Please Log in or Create an account to join the conversation.

- Unlogic

- Offline

- Elite Member

-

Less

More

- Posts: 238

- Thank you received: 118

07 Sep 2025 20:39 #334594

by Unlogic

Replied by Unlogic on topic Optimum Optimill MH50V CNC conversion

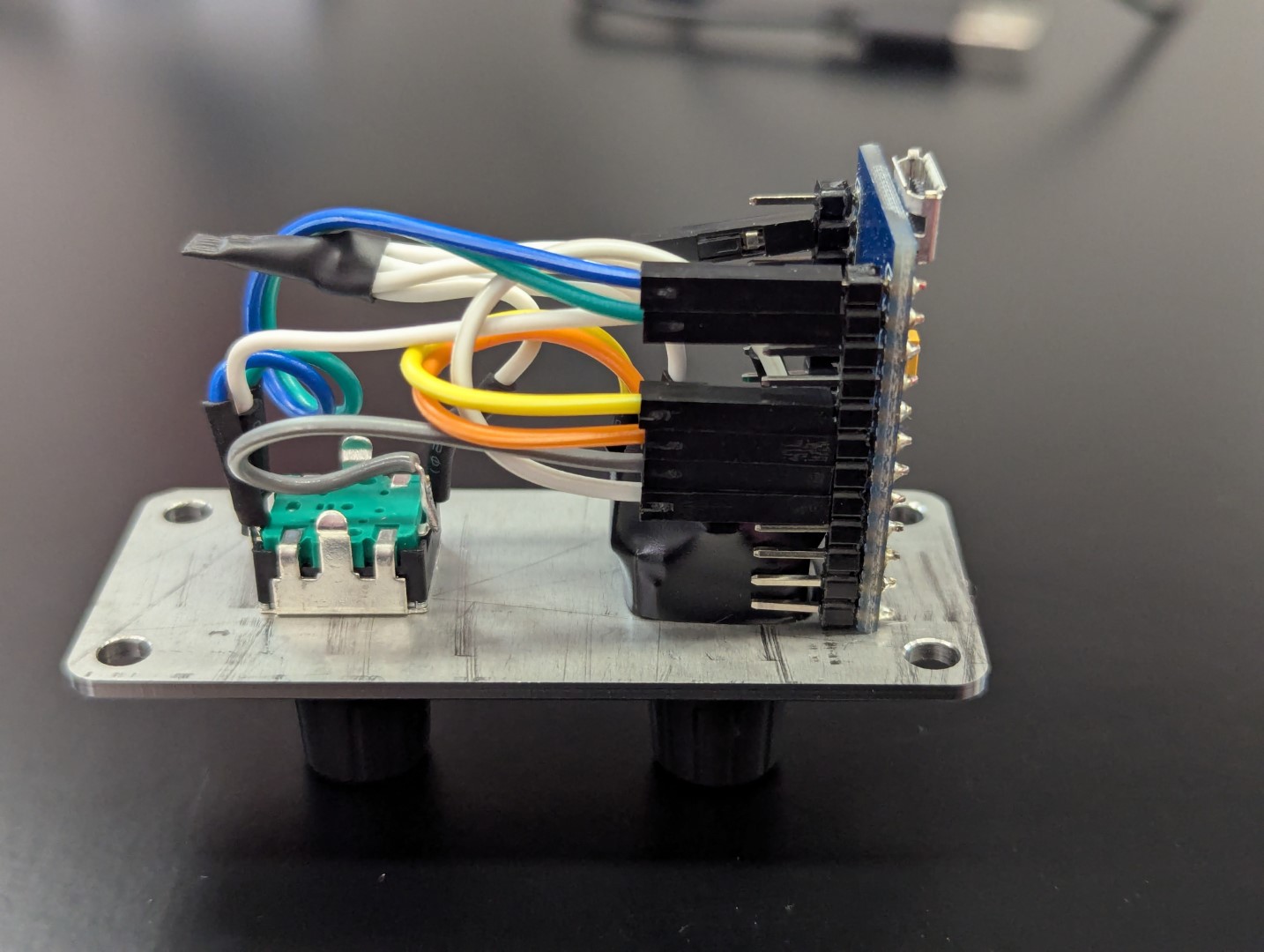

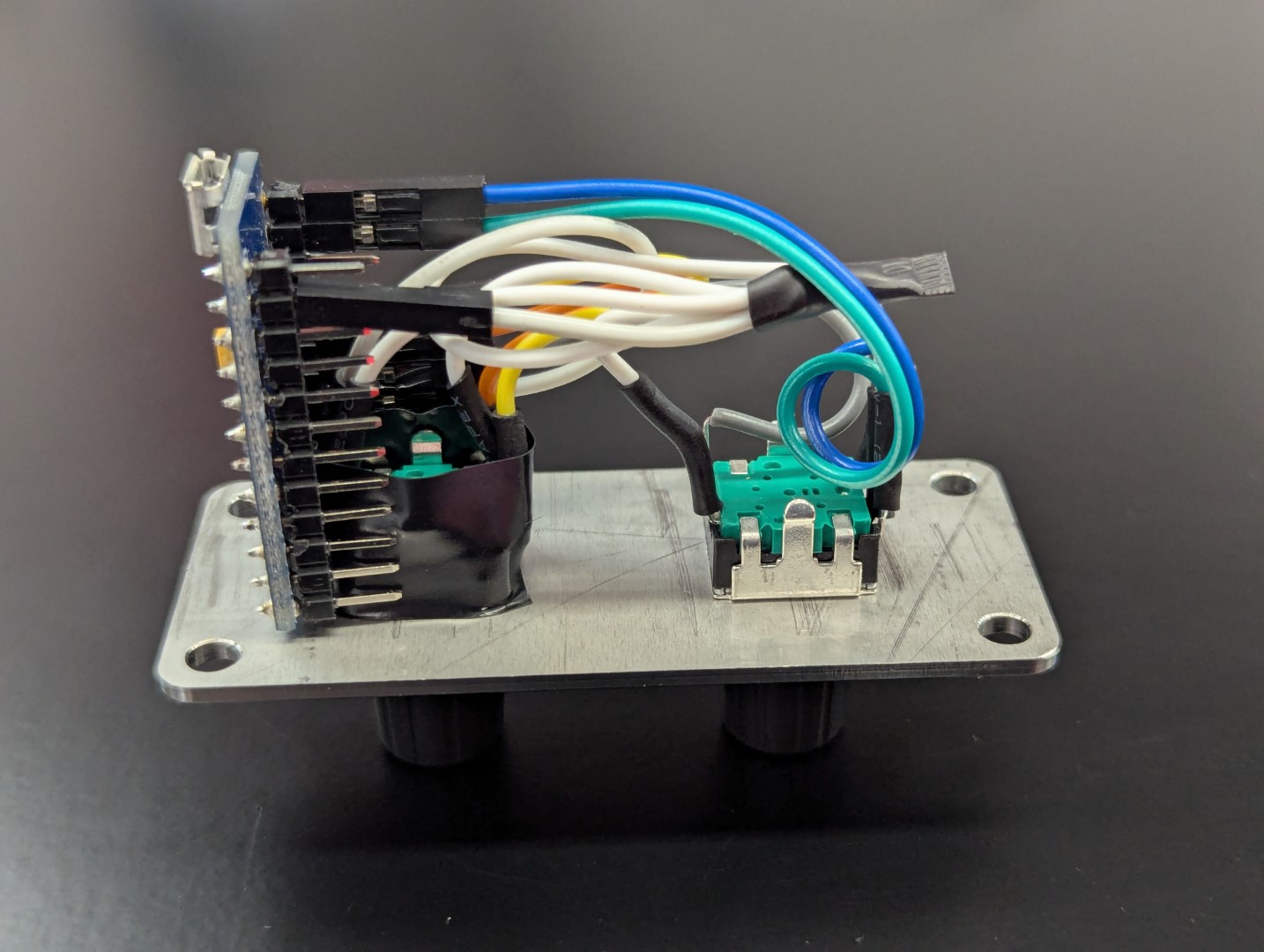

With all the milling down I turned my attention to the electronics, consisting of a small Arduino micro clone and two rotary encoders with built in push buttons.

Here is how the complete assembly looks.

Here it is installed on the side of the control panel.

And here is a short video showing how the two rotary encoders work in LinuxCNC with the Probe Basic user interface.

The LinuxCNC ArduinoConnector by Alexander Richter worked surprisingly smoothly. However I did find a bug in the Python code when it came to using the encoders in up/down mode instead of counter mode. I'm going to report that bug in the forum thread for the Arduino connector, however it was not a show stopper as I simply switched to counter mode instead.

Here is how the complete assembly looks.

Here it is installed on the side of the control panel.

And here is a short video showing how the two rotary encoders work in LinuxCNC with the Probe Basic user interface.

The LinuxCNC ArduinoConnector by Alexander Richter worked surprisingly smoothly. However I did find a bug in the Python code when it came to using the encoders in up/down mode instead of counter mode. I'm going to report that bug in the forum thread for the Arduino connector, however it was not a show stopper as I simply switched to counter mode instead.

Attachments:

The following user(s) said Thank You: tommylight, Clive S, pommen

Please Log in or Create an account to join the conversation.

- Unlogic

- Offline

- Elite Member

-

Less

More

- Posts: 238

- Thank you received: 118

10 Sep 2025 07:54 #334757

by Unlogic

Replied by Unlogic on topic Optimum Optimill MH50V CNC conversion

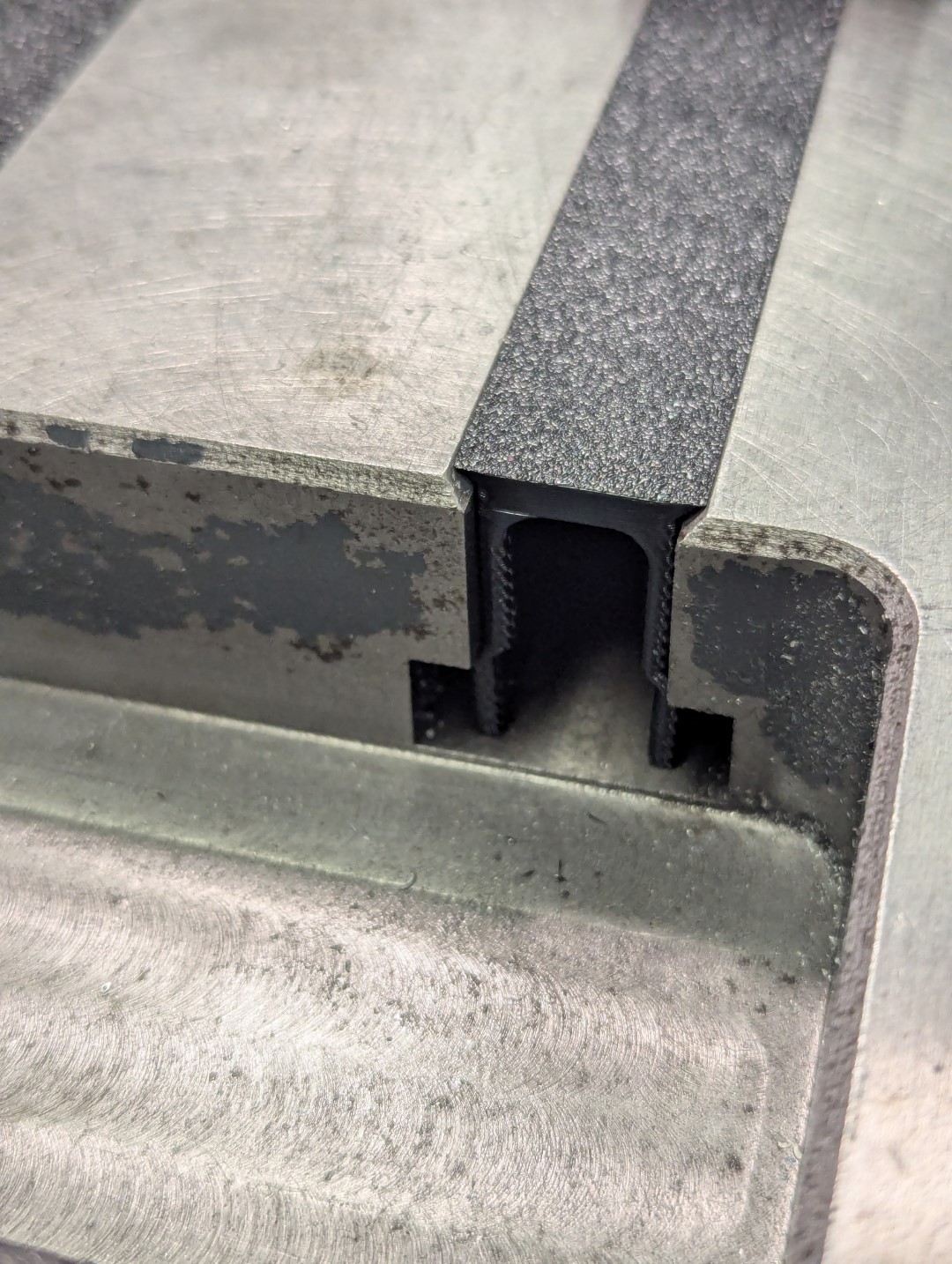

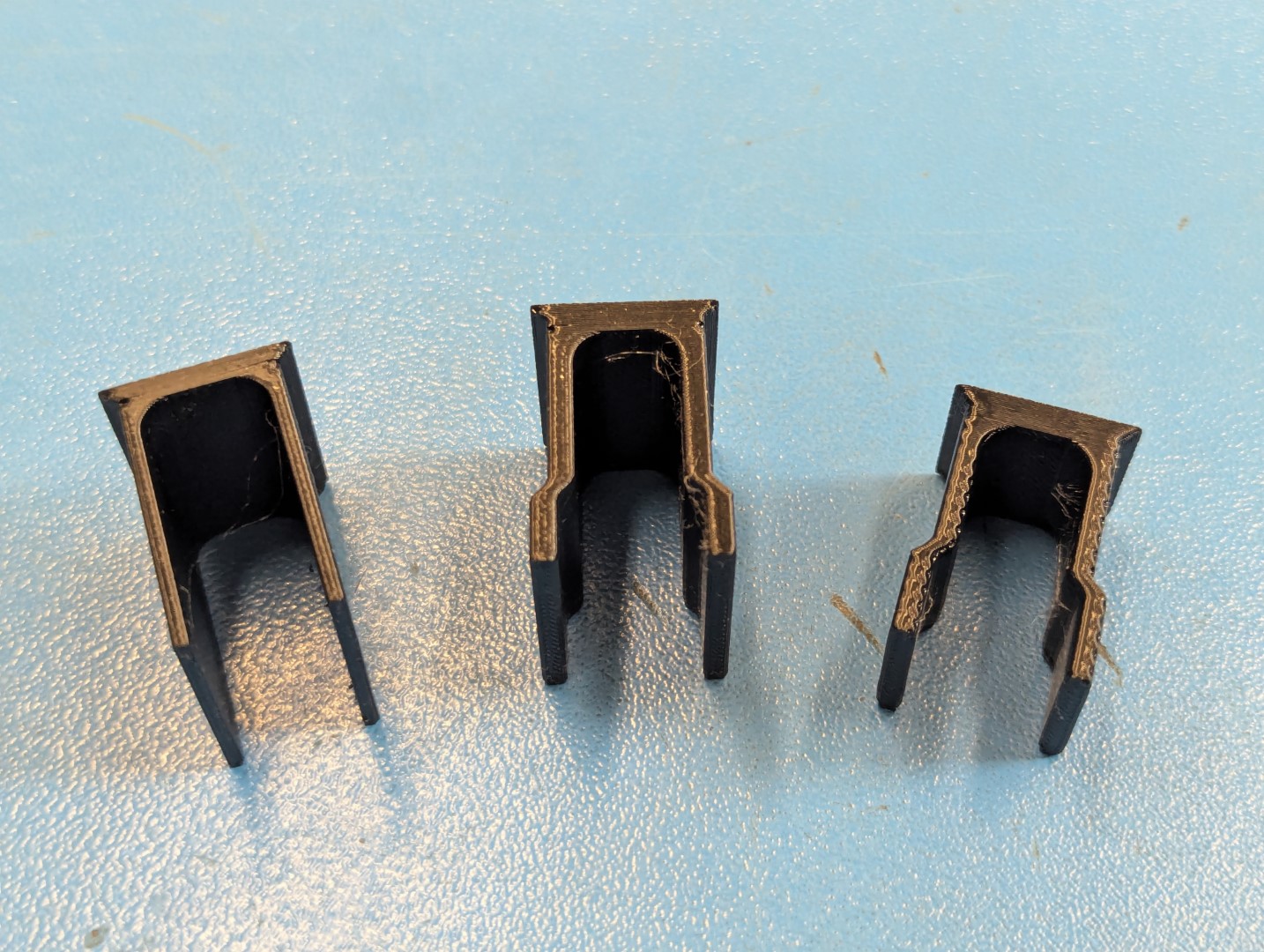

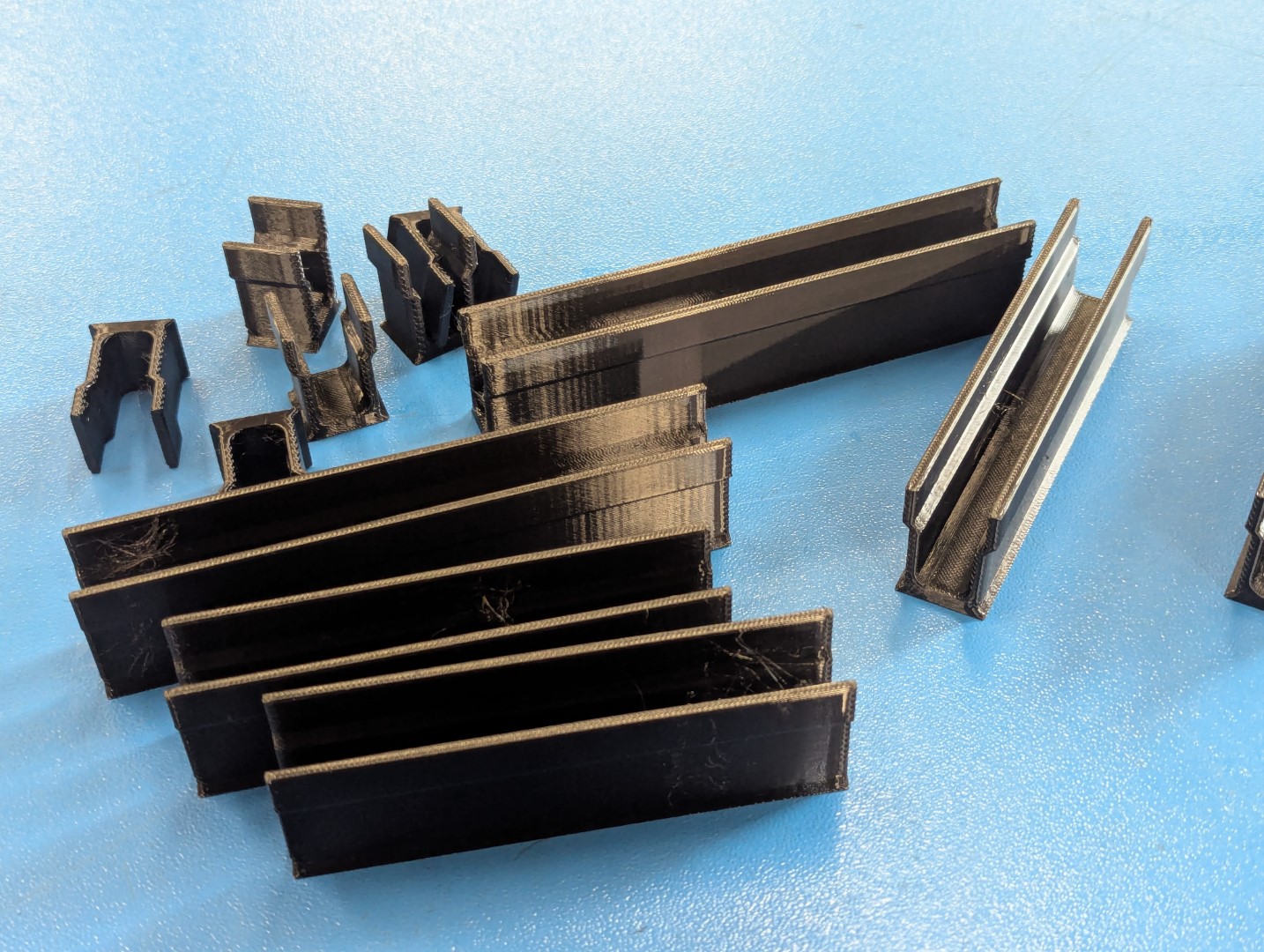

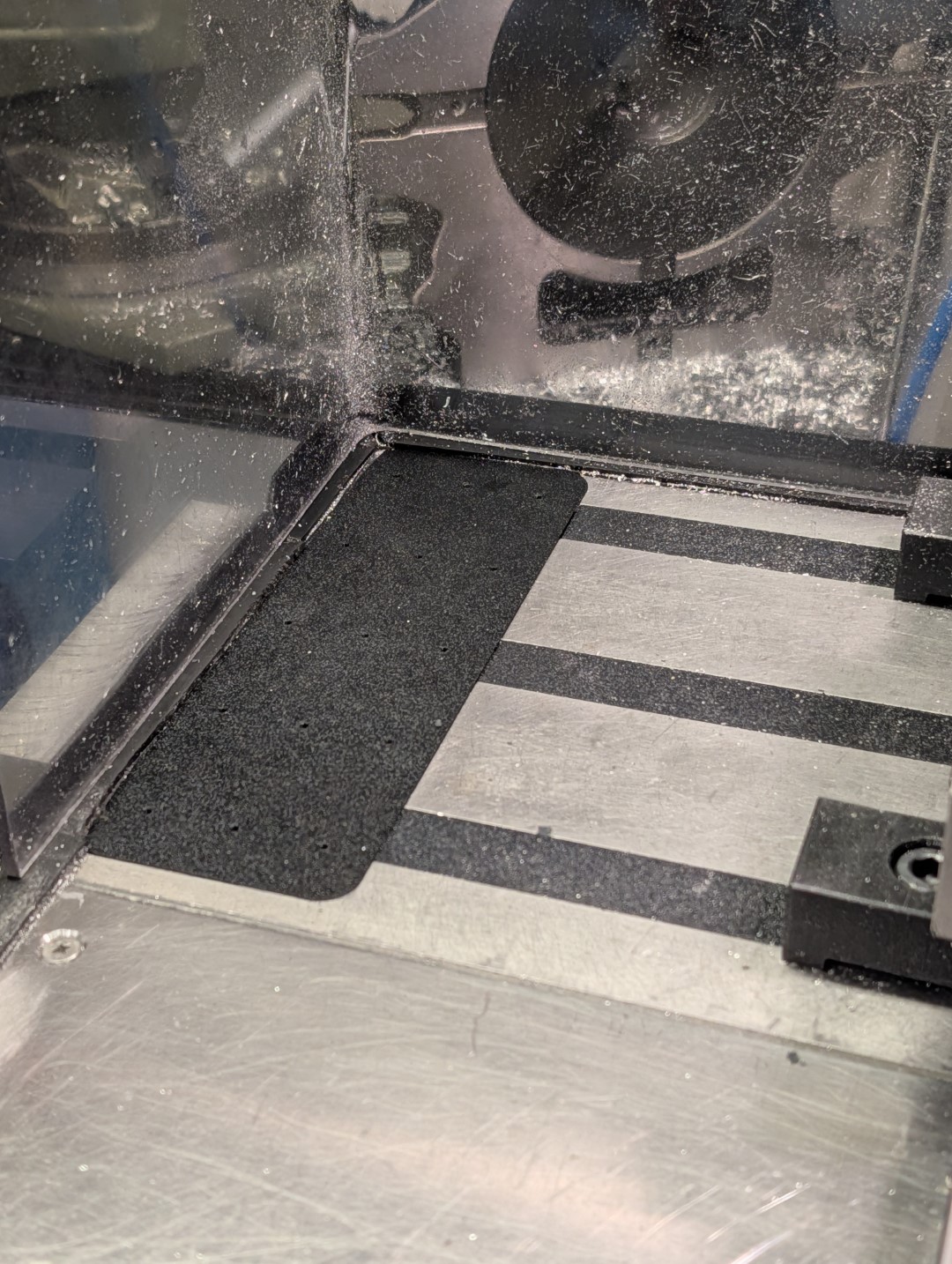

This is not really LinuxCNC related but something I should have done years ago, 3D-printed T-slot covers. It makes it much easier to vacuum up all the chips of the table.

It took three iterations to get the profile right, here are the test pieces I went through.

Here is the complete set that I installed.

They are printed out of flexible TPU filament and took about 4,5 hours to print on a Bambulab P1S printer.

It took three iterations to get the profile right, here are the test pieces I went through.

Here is the complete set that I installed.

They are printed out of flexible TPU filament and took about 4,5 hours to print on a Bambulab P1S printer.

Attachments:

The following user(s) said Thank You: tommylight, pommen

Please Log in or Create an account to join the conversation.

- Unlogic

- Offline

- Elite Member

-

Less

More

- Posts: 238

- Thank you received: 118

17 Sep 2025 15:40 - 17 Sep 2025 15:42 #335128

by Unlogic

Replied by Unlogic on topic Optimum Optimill MH50V CNC conversion

I'm still using the BT40 spindle that this machine came with. However getting the preload right for the spindle and getting the upper bearings for the quill drive to like high rpm milling for prolonged periods has been a challenge. I've been planning to replace the spindle for quite some time but not really taken leap yet.

However after fiddling with the spindle for sometime I've realized that I have to set the preload when the spindle is really warm in order to get a preload that works.

This in turn requires me to do few minutes of spindle warmup at lower rpm when the spindle is cold before I can crank up the rpm. Else I get a really nasty oscillating sound from one of the upper bearings.

Here is a video of the spindle at 3200 rpm roughing 6082 aluminum with a long 24 mm indexed end mill.

This has became a favorite tool for roughing aluminum as it has good reach, removes material at a decent rate and the 1003 inserts are cheap and readily available from many vendors.

However after fiddling with the spindle for sometime I've realized that I have to set the preload when the spindle is really warm in order to get a preload that works.

This in turn requires me to do few minutes of spindle warmup at lower rpm when the spindle is cold before I can crank up the rpm. Else I get a really nasty oscillating sound from one of the upper bearings.

Here is a video of the spindle at 3200 rpm roughing 6082 aluminum with a long 24 mm indexed end mill.

This has became a favorite tool for roughing aluminum as it has good reach, removes material at a decent rate and the 1003 inserts are cheap and readily available from many vendors.

Last edit: 17 Sep 2025 15:42 by Unlogic. Reason: Fixed embeddning of video

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- Unlogic

- Offline

- Elite Member

-

Less

More

- Posts: 238

- Thank you received: 118

21 Sep 2025 10:14 #335237

by Unlogic

Replied by Unlogic on topic Optimum Optimill MH50V CNC conversion

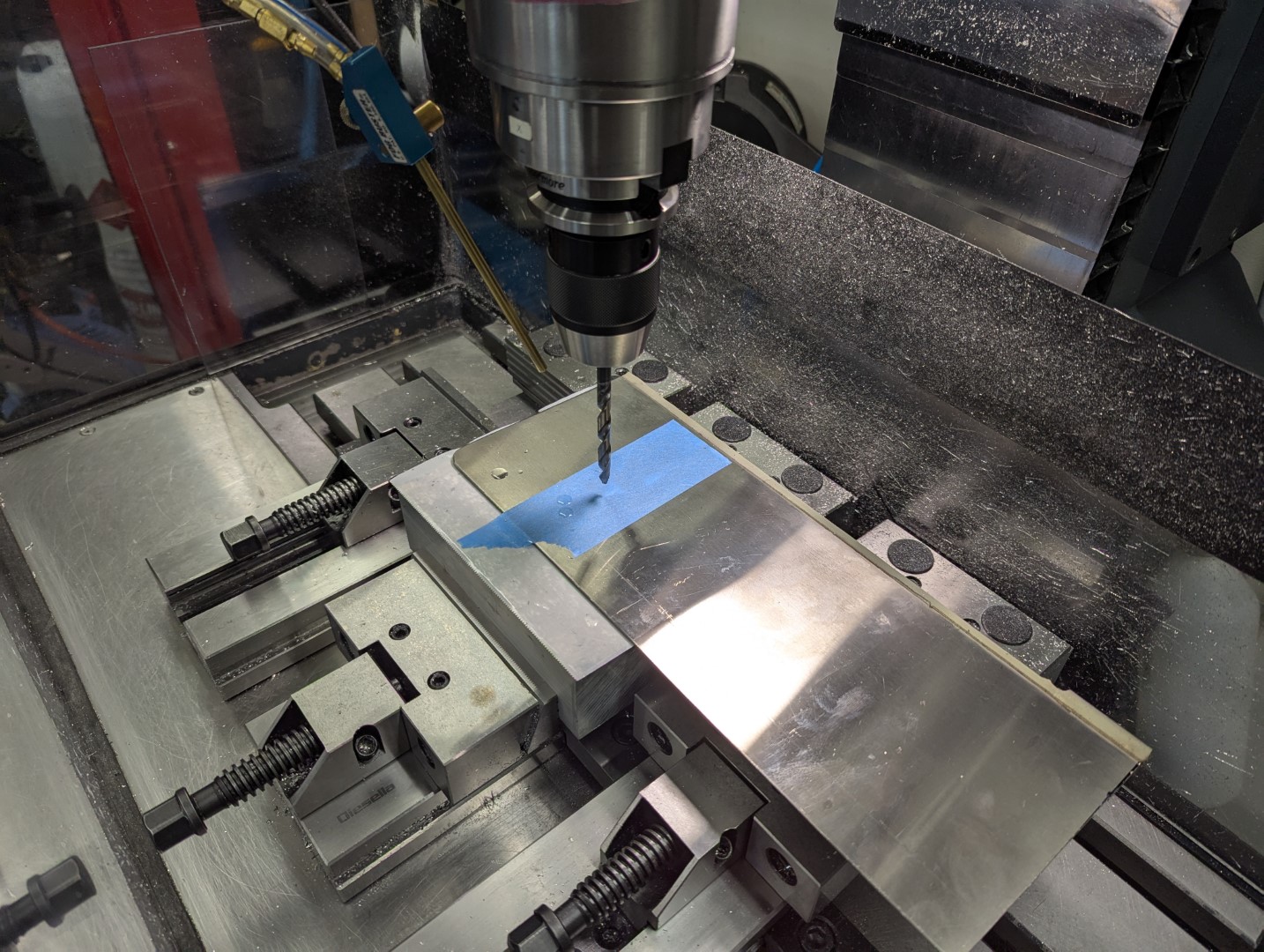

The way covers I made recently greatly simplified the removal of chips from the table. So inspired by that success I decided to make a set of covers for the pockets at the ends of the table too.

I won't use these together with flood coolant but to make sure that any moisture that gets trapped under them still has a chance to escape I added some 2 mm holes.

I won't use these together with flood coolant but to make sure that any moisture that gets trapped under them still has a chance to escape I added some 2 mm holes.

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- Unlogic

- Offline

- Elite Member

-

Less

More

- Posts: 238

- Thank you received: 118

22 Oct 2025 12:43 - 22 Oct 2025 13:32 #336872

by Unlogic

Replied by Unlogic on topic Optimum Optimill MH50V CNC conversion

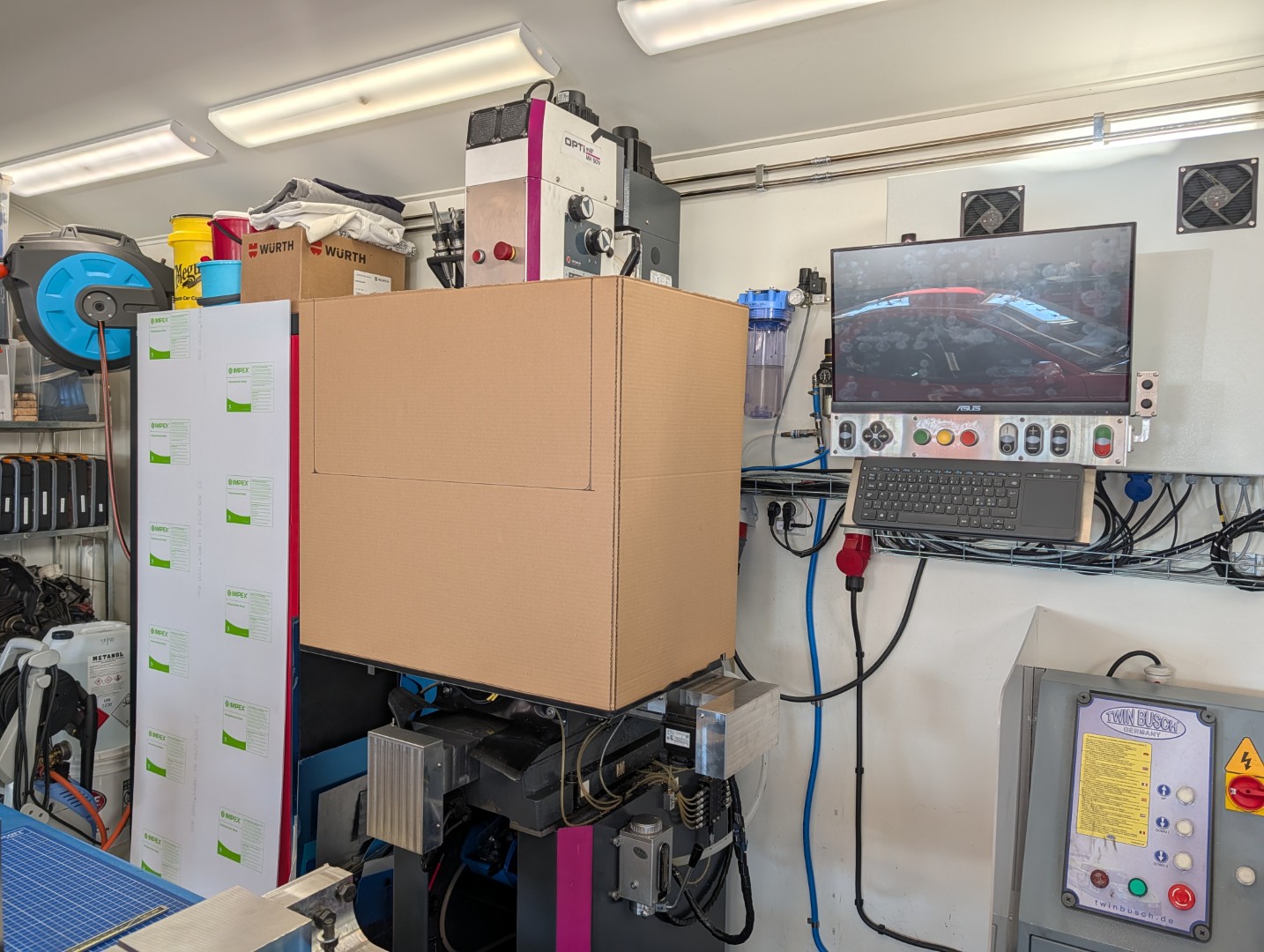

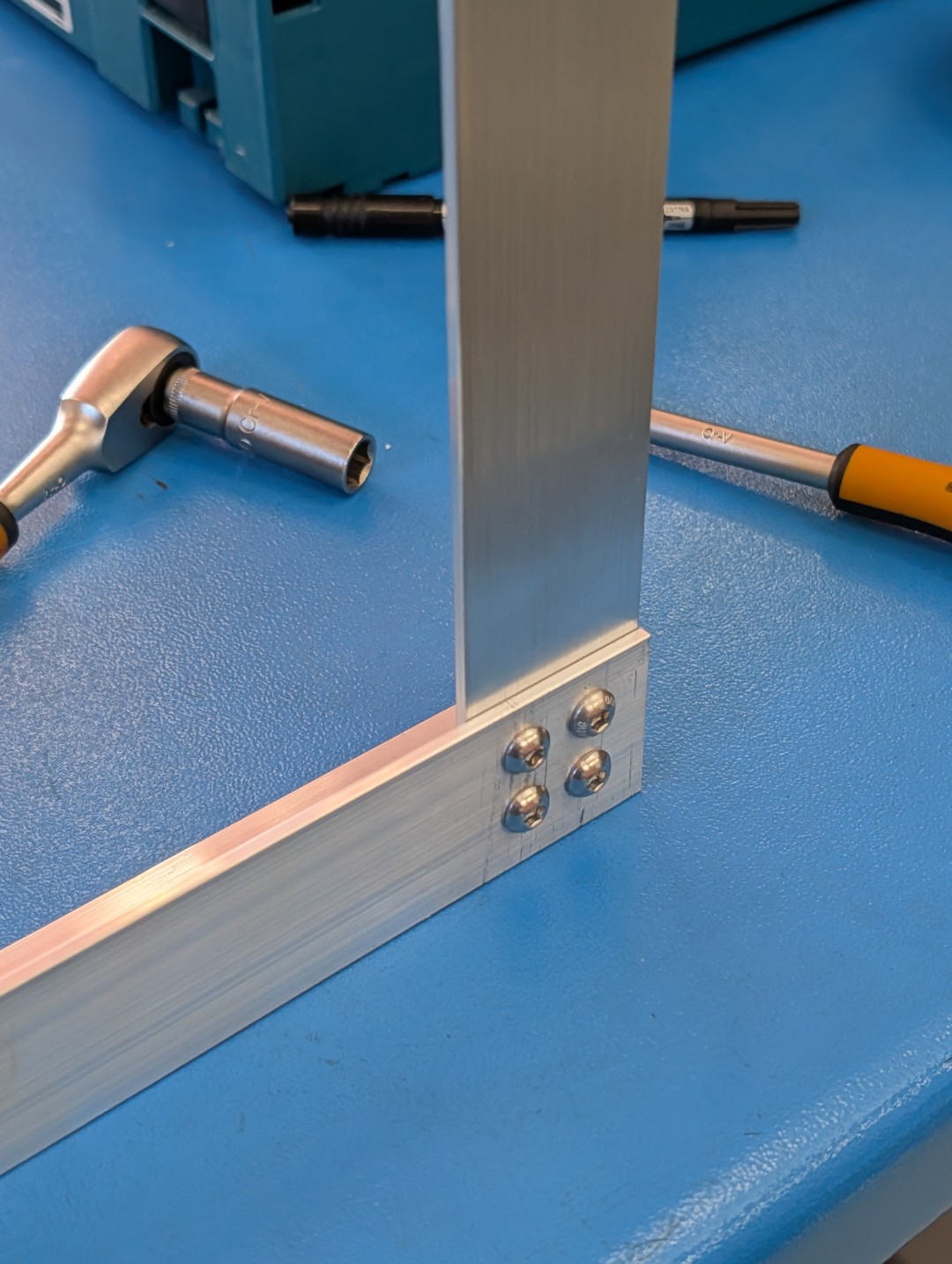

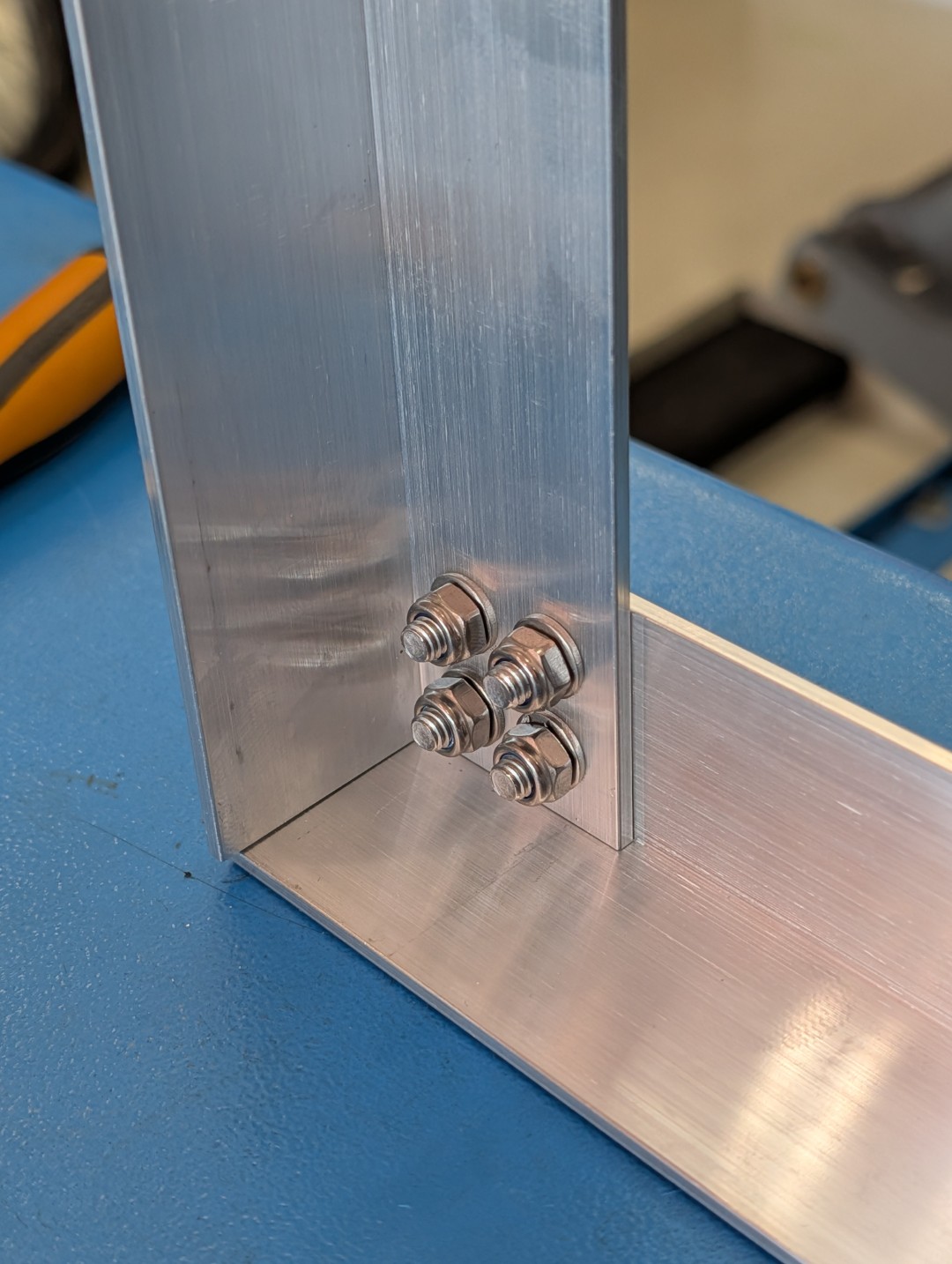

The mill has continued to work great but as I started to mill larger parts and use the full 50 cm z-height of the machine my existing chip cover proved to be inadequate with chips ending up all over my garage.

I had already increased the size of the polycarbonate chip guard once before because of this reason so this time I decided to do "the final chip guard". In all honesty a full enclosure would probably be the way to go but I don't have space for that which is why I'm sticking to chip guards that sit on the table instead.

To get started I ordered a large sheet of 4 mm polycarbonate.

I then started a very analog process of designing the actual size and shape using the cardboard box that the polycarbonate sheet was delivered in.

Once I hade the decided size and shape I purchased some aluminum extrusions which I cut slightly too long and then milled to size in order to get square corners.

While at it I decided to add some more polycarbonate on each side of the column to protect everything behind the machine from chips. They attach with magnets so that they can be removed just by pulling them off.

Here is how it looks all assembled.

The door took a bit of thought to figure out what would be the best solution so that it wouldn't be in the way for operations which don't require it to be in place.

In the end I decided to go with this design so that it's very easy to remove. When removed I just set it down on the floor in front of the machine leaning against the stand.

I had already increased the size of the polycarbonate chip guard once before because of this reason so this time I decided to do "the final chip guard". In all honesty a full enclosure would probably be the way to go but I don't have space for that which is why I'm sticking to chip guards that sit on the table instead.

To get started I ordered a large sheet of 4 mm polycarbonate.

I then started a very analog process of designing the actual size and shape using the cardboard box that the polycarbonate sheet was delivered in.

Once I hade the decided size and shape I purchased some aluminum extrusions which I cut slightly too long and then milled to size in order to get square corners.

While at it I decided to add some more polycarbonate on each side of the column to protect everything behind the machine from chips. They attach with magnets so that they can be removed just by pulling them off.

Here is how it looks all assembled.

The door took a bit of thought to figure out what would be the best solution so that it wouldn't be in the way for operations which don't require it to be in place.

In the end I decided to go with this design so that it's very easy to remove. When removed I just set it down on the floor in front of the machine leaning against the stand.

Attachments:

Last edit: 22 Oct 2025 13:32 by Unlogic. Reason: Fixed typo

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 1.039 seconds