Light Machine Corp. Benchman XTr (retrofit)

- MacGalempsy

- Offline

- Senior Member

-

Less

More

- Posts: 68

- Thank you received: 2

18 Dec 2016 02:33 #84349

by MacGalempsy

Replied by MacGalempsy on topic Light Machine Corp. Benchman XTr (retrofit)

Here it is. Ultraware v1.60 with a pdf of the original printout from this drive. I was able to get it going on a windows XP machine, but not sure about anything else. To successfully access the drive, a cross-over serial cable is required. I highly recommend saving a copy of your drive .PAR file before making any changes. Also, look at starting the program in Administrator mode. It allows you to access a few more menus for setting up the motor properly. Opening every window and doing a screenshot helped me out when the VFD was replaced with a refurbished unit. If your VFD is bad and you do not have a .PAR file, hit me up and I'll give you the one I am using.

Here is the manual for the drive.

Ultra 100 Drive Manual

There is also a device that plugs into the serial port on the VFD that is made to forego the whole computer setup. The instructions on it are in the manual. I was able to pick one of these up from ebay a few years ago, and it wasn't cheap. If someone would like to buy it from me, shoot me a msg in the Freenode channel #linuxcnc.

Electro-Craft Servo Products

MMI-001

9101-1386

H000834

PS if anyone has the original model number of the Electro-craft AC servo, please post it. The label on mine has faded to blank.

Here is the manual for the drive.

Ultra 100 Drive Manual

There is also a device that plugs into the serial port on the VFD that is made to forego the whole computer setup. The instructions on it are in the manual. I was able to pick one of these up from ebay a few years ago, and it wasn't cheap. If someone would like to buy it from me, shoot me a msg in the Freenode channel #linuxcnc.

Electro-Craft Servo Products

MMI-001

9101-1386

H000834

PS if anyone has the original model number of the Electro-craft AC servo, please post it. The label on mine has faded to blank.

Attachment not found

Attachment not found

Please Log in or Create an account to join the conversation.

- MacGalempsy

- Offline

- Senior Member

-

Less

More

- Posts: 68

- Thank you received: 2

18 Dec 2016 03:15 #84350

by MacGalempsy

Replied by MacGalempsy on topic Light Machine Corp. Benchman XTr (retrofit)

try 2

Please Log in or Create an account to join the conversation.

- steve_a

- Offline

- Senior Member

-

Less

More

- Posts: 75

- Thank you received: 2

18 Dec 2016 18:04 - 18 Dec 2016 18:06 #84366

by steve_a

Replied by steve_a on topic Light Machine Corp. Benchman XTr (retrofit)

The Model number is DDM-019. Thanks for posting that Mac... I'll try it on my machine later. I can't open it on my home computer because I'm running Windows 7 but with any luck this will work on the XT computer I have hooked up.

Last edit: 18 Dec 2016 18:06 by steve_a.

Please Log in or Create an account to join the conversation.

- MacGalempsy

- Offline

- Senior Member

-

Less

More

- Posts: 68

- Thank you received: 2

18 Dec 2016 20:48 #84372

by MacGalempsy

Replied by MacGalempsy on topic Light Machine Corp. Benchman XTr (retrofit)

Azik1 if the 500rpm spindle does not work, you might check the vfd for a ICP error when you go to enable it. If you get that, then the drive is toast. Mine had to be replaced, which an ebay seller was willing to take a core on my broken unit and sell me his refurbished unit for a few hundred bucks.

Please Log in or Create an account to join the conversation.

- MacGalempsy

- Offline

- Senior Member

-

Less

More

- Posts: 68

- Thank you received: 2

18 Dec 2016 21:00 #84373

by MacGalempsy

Replied by MacGalempsy on topic Light Machine Corp. Benchman XTr (retrofit)

A few revelations were made along the way.

1. Copley controls are set to torque mode.

2. I was able to setup a signal to the VFD to enable torque mode, and get signals to lcnc for current output and drive enabled.

3. The copley controls run on a 3kHz bandwidth. For the xyz axes, I was able to get them tuned at 1kHz and when I went to 3kHz they sounded better.

4. Trying to tune the 4th axis has become a PITA. I would really like to figure out an easier way to tune it correctly.

5. Currently, I am working again on a xml file for more controls and readouts for the purpose of running the VFD in torque mode, for the purpose of controlled spindle orientation and indexing.

Steve, did you end up getting a mesa card combo for your mill? (im running a 5i25, 7i77 and 7i84) Also, you mentioned making cuts. what kind of cutting depths are you getting?

1. Copley controls are set to torque mode.

2. I was able to setup a signal to the VFD to enable torque mode, and get signals to lcnc for current output and drive enabled.

3. The copley controls run on a 3kHz bandwidth. For the xyz axes, I was able to get them tuned at 1kHz and when I went to 3kHz they sounded better.

4. Trying to tune the 4th axis has become a PITA. I would really like to figure out an easier way to tune it correctly.

5. Currently, I am working again on a xml file for more controls and readouts for the purpose of running the VFD in torque mode, for the purpose of controlled spindle orientation and indexing.

Steve, did you end up getting a mesa card combo for your mill? (im running a 5i25, 7i77 and 7i84) Also, you mentioned making cuts. what kind of cutting depths are you getting?

Please Log in or Create an account to join the conversation.

- Azik1

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 2

18 Dec 2016 21:05 #84374

by Azik1

Replied by Azik1 on topic Light Machine Corp. Benchman XTr (retrofit)

Mac, thank you. I did replace Ultra 100 with Ultra3000, there is quite a few of them on ebay and they quite cheaper and more capable unit. Had to make small PCB breakout adapters to convert Ultra 100 plug into Ultra 3000 so that i did not have to cut and replace existing connectors on motor wires.

Please Log in or Create an account to join the conversation.

- TGTROPIC

- Offline

- Junior Member

-

Less

More

- Posts: 26

- Thank you received: 4

19 Dec 2016 14:22 #84411

by TGTROPIC

Replied by TGTROPIC on topic Light Machine Corp. Benchman XTr (retrofit)

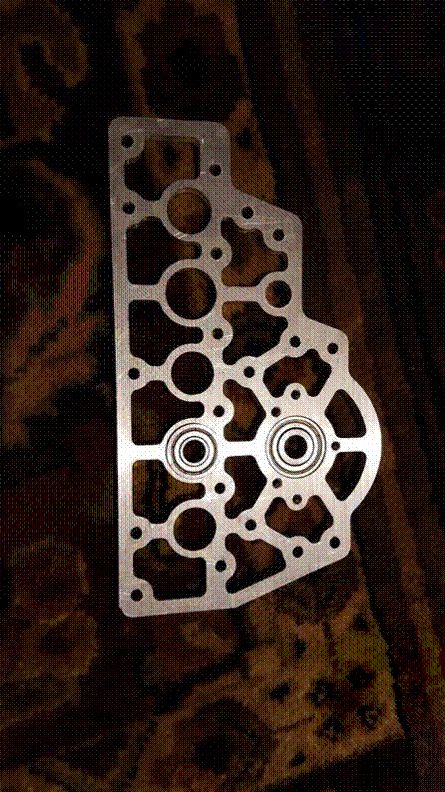

24,

Looks like the exact same board.

I have one component missing from C14 that is present on your board.

Would you be willing to part with this board?

TG

Looks like the exact same board.

I have one component missing from C14 that is present on your board.

Would you be willing to part with this board?

TG

Please Log in or Create an account to join the conversation.

- steve_a

- Offline

- Senior Member

-

Less

More

- Posts: 75

- Thank you received: 2

20 Dec 2016 00:02 - 20 Dec 2016 00:03 #84441

by steve_a

Replied by steve_a on topic Light Machine Corp. Benchman XTr (retrofit)

Mac,

I went with the Kflop/Kannaolg because of the Mesa supply problem. I gave up waiting for them to be able to send me a card. At the time I think they were in the middle of supplying someone with a commercial application so my order was constantly being bumped.

I have everything but the tool changer working. I made this part using a .25", 2 flute end mill, running at about 2500 RPM and 4 IPM. It takes about 2 hours for all the operations but I'm really happy with the accuracy. The bearings are press fit and that was what I was after. However, the numbers say I should be able to run about 4000 RPM at 12 IPM... The piece complains a lot and running it over 11 IPM I experience a spindle shut down that I believe is something in the Ultra 100. I used the application you shared and finally was able to talk to the unit! Now I just have to learn what it all means.

I went with the Kflop/Kannaolg because of the Mesa supply problem. I gave up waiting for them to be able to send me a card. At the time I think they were in the middle of supplying someone with a commercial application so my order was constantly being bumped.

I have everything but the tool changer working. I made this part using a .25", 2 flute end mill, running at about 2500 RPM and 4 IPM. It takes about 2 hours for all the operations but I'm really happy with the accuracy. The bearings are press fit and that was what I was after. However, the numbers say I should be able to run about 4000 RPM at 12 IPM... The piece complains a lot and running it over 11 IPM I experience a spindle shut down that I believe is something in the Ultra 100. I used the application you shared and finally was able to talk to the unit! Now I just have to learn what it all means.

Last edit: 20 Dec 2016 00:03 by steve_a.

Please Log in or Create an account to join the conversation.

- steve_a

- Offline

- Senior Member

-

Less

More

- Posts: 75

- Thank you received: 2

20 Dec 2016 04:58 #84444

by steve_a

Replied by steve_a on topic Light Machine Corp. Benchman XTr (retrofit)

OOOPS! Forgot to mention... the cut depth per pass, .0625".... Should be able to do twice that according to the numbers.... must be for Bridgeport sized machines.

Please Log in or Create an account to join the conversation.

- Azik1

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 2

21 Dec 2016 05:28 #84483

by Azik1

Replied by Azik1 on topic Light Machine Corp. Benchman XTr (retrofit)

Does any one know good method to tram head along X/Y axis ? Seems like it has just 4 bolts holding spindle no adjustments visible.

Thanks!

Thanks!

Please Log in or Create an account to join the conversation.

Time to create page: 0.383 seconds