Emcoturn 120 lathe retrofit

- Muzzer

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 41

04 Jun 2016 16:42 #75495

by Muzzer

Replied by Muzzer on topic Emcoturn 120 lathe retrofit

Andy - that would be rather excellent and would save me some beer vouchers. £50 + postage would be great. If you could let me know how much, I could pay you with Paypal if that suits.

I had my eye on one of those assorted kits with crimp tool for £30 as I have a variety of wire sizes. Of course, I have loads of ferrules and a large box full of proper crimp tools somewhere at my mother's so feel reluctant to fork out all over again. However, I don't want to use Toytown tools either. Do you know if yours is better than the thing that comes in the kits?

As ever you can't get everything you want from one source, so I will have to get some stuff from RS, some from Farnell and some from Rapid, even connector shells from the same series have to come from multiple sources. I've also managed to find useful stuff on ebay and Amazon. Most of the mechanical stuff is direct from China.

I had my eye on one of those assorted kits with crimp tool for £30 as I have a variety of wire sizes. Of course, I have loads of ferrules and a large box full of proper crimp tools somewhere at my mother's so feel reluctant to fork out all over again. However, I don't want to use Toytown tools either. Do you know if yours is better than the thing that comes in the kits?

As ever you can't get everything you want from one source, so I will have to get some stuff from RS, some from Farnell and some from Rapid, even connector shells from the same series have to come from multiple sources. I've also managed to find useful stuff on ebay and Amazon. Most of the mechanical stuff is direct from China.

Please Log in or Create an account to join the conversation.

- LutzTD

- Offline

- Elite Member

-

Less

More

- Posts: 216

- Thank you received: 1

04 Jun 2016 17:26 - 04 Jun 2016 17:27 #75496

by LutzTD

Hi Tom,

I found the Rasmi filter for about $60 that will fit. Can you give me some info on the ferrite beads?

Hey Andy,

For control cable I am using shielded cat6a or the cable that was on the component from the lathe. For example, the steppers, the home switches, the tool changer already had very long cables so I assume they are of adequate quality. The new encoder will be a cat6a run as well. I'm going to look at the DC motor cable and see if it is OK, If not the motor cable will be the only one I need to source.

thanx

Replied by LutzTD on topic Emcoturn 120 lathe retrofit

I crammed all my electronics (incl VFD) into a relatively small box on the side of my machine in order to save space and get the machine through doorways. I was very careful to keep the VFD and it's wiring as far from the rest as I could. When I first got things running I had what appeared to be bad noise issues and spent a bunch of time trying to diagnose and correct it. I ended up installing a Rasmi input filter (Andy's suggestion) and large ferrite beads on the output cable to the motor. Neither of these things fixed the particular problem I was having. I borrowed a friends spectrum analyzer to see if I could trace the noise to tie it to some event and while I could see plenty of noise and where it occurred in the cabinet it didn't help to find how to eliminate it. Ultimately I found the problem as I began to re-route various wires to provide further isolation and I discovered that the USB keyboard I was using was unusually susceptible to noise on its input wire and was generating spurious characters. Simply replacing the keyboard solved the problem.

I am not sorry I put the filters on the VFD, it did reduce noise overall according to what I could see on the spectrum analyzer and is suggested practice in general and also specifically shown in the automation direct manual for the VFD. I recall that the Rasmi filter and ferrite beads I found only added about $50 total to the build. But in the end it was other random issue that bit me. Just be as careful as you can with routing wiring, shield where appropriate, and you may be fine.

My last resort was going to be to move the VFD out of the electronics cabinet but it didn't come to that and the lathe has been working great.

-Tom

Hi Tom,

I found the Rasmi filter for about $60 that will fit. Can you give me some info on the ferrite beads?

Hey Andy,

For control cable I am using shielded cat6a or the cable that was on the component from the lathe. For example, the steppers, the home switches, the tool changer already had very long cables so I assume they are of adequate quality. The new encoder will be a cat6a run as well. I'm going to look at the DC motor cable and see if it is OK, If not the motor cable will be the only one I need to source.

thanx

Last edit: 04 Jun 2016 17:27 by LutzTD.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

04 Jun 2016 17:48 #75497

by andypugh

Just be aware that ordinary Cat6a (and ordinary Cat5) might not resist oil and coolant very well. That concern is why I chose the PUR sheathed stuff, despite it being rather more expensive. But then the runs inside a machine tool are short compared to wiring a building.

Replied by andypugh on topic Emcoturn 120 lathe retrofit

For control cable I am using shielded cat6a or the cable that was on the component from the lathe.

Just be aware that ordinary Cat6a (and ordinary Cat5) might not resist oil and coolant very well. That concern is why I chose the PUR sheathed stuff, despite it being rather more expensive. But then the runs inside a machine tool are short compared to wiring a building.

Please Log in or Create an account to join the conversation.

- LutzTD

- Offline

- Elite Member

-

Less

More

- Posts: 216

- Thank you received: 1

04 Jun 2016 17:48 - 04 Jun 2016 17:49 #75498

by LutzTD

Replied by LutzTD on topic Emcoturn 120 lathe retrofit

bummer. So bigger isnt always better. I tried hooking up the contactor/estop today. Nogo. So I finally go and read the instructions, of course thats the last resort. The contactor needs 24VDC 200W to close when cold. Of course my awesome 24VDC PSU is only rated to 96W. My bad. I looked and found another smaller contactor that only draws 3.5W. Live and Learn. that cost me $35. Anybody need a 80A 4 pole contactor?

Last edit: 04 Jun 2016 17:49 by LutzTD.

Please Log in or Create an account to join the conversation.

- LutzTD

- Offline

- Elite Member

-

Less

More

- Posts: 216

- Thank you received: 1

04 Jun 2016 17:53 - 04 Jun 2016 17:55 #75499

by LutzTD

mostly the cat6a is from the Mesa to the drivers and to the Dell. I think the only run outside the control is for the encoder, albeit the dirtiest place on the lathe, it is behind a wall. I will see if I can come up with a jacket for it. The encoder has a military 7 pin connector on it maybe I can run it inside a silicon tube from that termination. Thanks for the heads up.

Replied by LutzTD on topic Emcoturn 120 lathe retrofit

For control cable I am using shielded cat6a or the cable that was on the component from the lathe.

Just be aware that ordinary Cat6a (and ordinary Cat5) might not resist oil and coolant very well. That concern is why I chose the PUR sheathed stuff, despite it being rather more expensive. But then the runs inside a machine tool are short compared to wiring a building.

mostly the cat6a is from the Mesa to the drivers and to the Dell. I think the only run outside the control is for the encoder, albeit the dirtiest place on the lathe, it is behind a wall. I will see if I can come up with a jacket for it. The encoder has a military 7 pin connector on it maybe I can run it inside a silicon tube from that termination. Thanks for the heads up.

Last edit: 04 Jun 2016 17:55 by LutzTD.

Please Log in or Create an account to join the conversation.

- LutzTD

- Offline

- Elite Member

-

Less

More

- Posts: 216

- Thank you received: 1

05 Jun 2016 01:12 - 05 Jun 2016 01:13 #75515

by LutzTD

Replied by LutzTD on topic Emcoturn 120 lathe retrofit

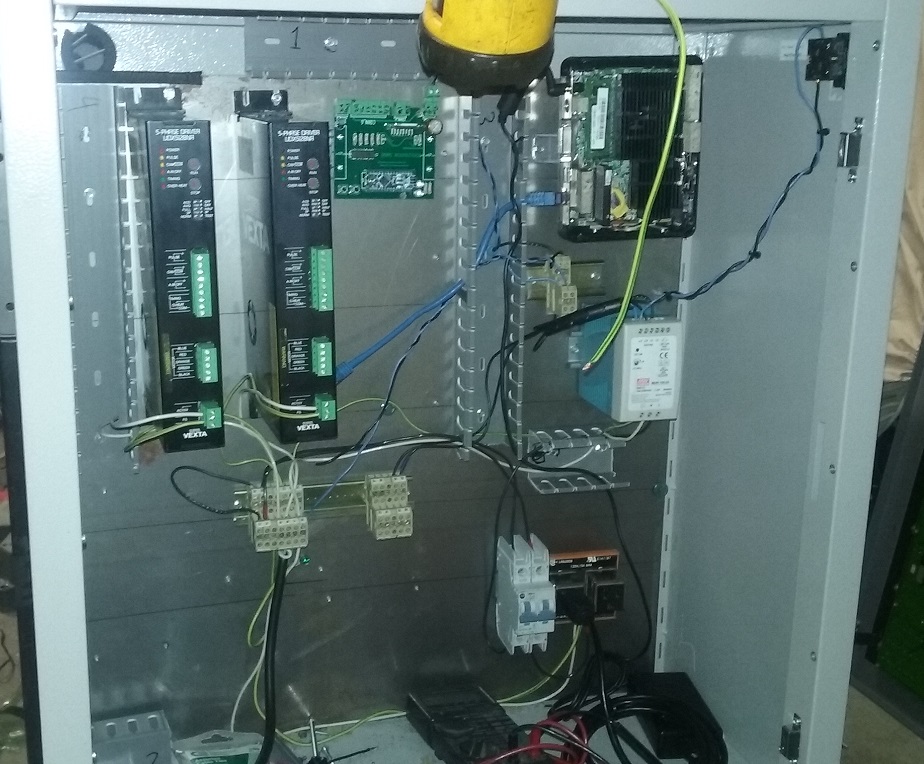

ran most of the power wires today. It looks a mess but I will jacket all of the loose runs that are there now. Removed the big contactor and stole the piece of din rail to mount the 3amp double pole breaker and the outlet which arrived yesterday this let me wire the 24vdc psu and the computer, which I also mounted using a short piece of 1x1 aluminum tube. I need to make a mount for the mesa board, and then figure out all of the control wires. I have a 240V plug coming but I will still need to wire an outlet in the garage for 4 wire and get an extension cord to go from the wall outlet to the lathe plug. Still lots to do. I also need to wait for the encoder plug and make that wire, along with a shaft adapter and modified mount.

Last edit: 05 Jun 2016 01:13 by LutzTD.

Please Log in or Create an account to join the conversation.

- tome

- Offline

- Premium Member

-

Less

More

- Posts: 116

- Thank you received: 11

05 Jun 2016 04:08 - 05 Jun 2016 04:11 #75516

by tome

I bought four of these and put them inline on the output according to the section on RF filtering in the Automation Direct manual for the VFD. I used an SO cord for my output to the motor so inline was easier than wrapping the individual wires.

www.digikey.com/product-detail/en/wurth-.../732-3092-ND/2626031

-Tom

Replied by tome on topic Emcoturn 120 lathe retrofit

Can you give me some info on the ferrite beads?

I bought four of these and put them inline on the output according to the section on RF filtering in the Automation Direct manual for the VFD. I used an SO cord for my output to the motor so inline was easier than wrapping the individual wires.

www.digikey.com/product-detail/en/wurth-.../732-3092-ND/2626031

-Tom

Last edit: 05 Jun 2016 04:11 by tome.

Please Log in or Create an account to join the conversation.

- LutzTD

- Offline

- Elite Member

-

Less

More

- Posts: 216

- Thank you received: 1

06 Jun 2016 12:27 #75552

by LutzTD

Replied by LutzTD on topic Emcoturn 120 lathe retrofit

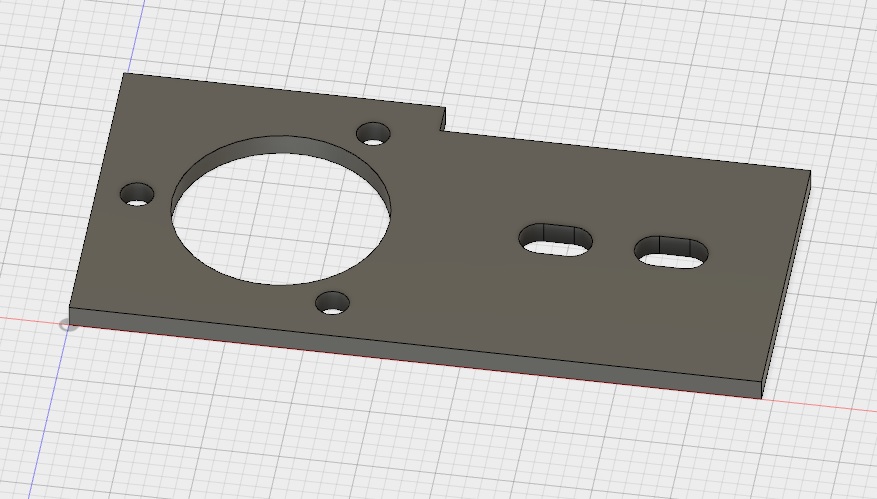

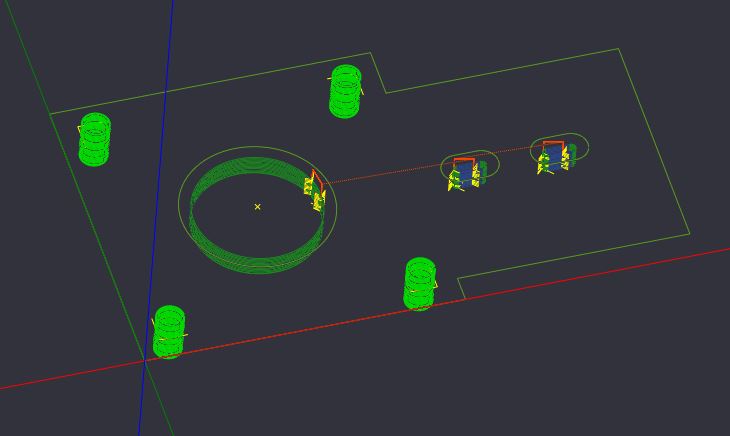

Sunday I made a shaft adapter. since the difference is not enough to put in a set screw I just ended up splitting it to use the pulley set screw for both diameters. this doesn't have a lot of torque on it so it should be fine. The mounting bracket will have to be remade. Im looking for a decent shareware 2D cad package so I can do this at home, I can do it in Solidworks or Pro/E Creo at work but at home I'm limited to Cambam which I don't like very much as a drawing package.

Please Log in or Create an account to join the conversation.

- tome

- Offline

- Premium Member

-

Less

More

- Posts: 116

- Thank you received: 11

06 Jun 2016 12:40 #75553

by tome

Check out Autodesk Fusion 360. It is free for enthusiasts and businesses making less than $100k/yr on designs drawn in Fusion.

-Tom

Replied by tome on topic Emcoturn 120 lathe retrofit

Im looking for a decent shareware 2D cad package so I can do this at home, I can do it in Solidworks or Pro/E Creo at work but at home I'm limited to Cambam which I don't like very much as a drawing package.

Check out Autodesk Fusion 360. It is free for enthusiasts and businesses making less than $100k/yr on designs drawn in Fusion.

-Tom

The following user(s) said Thank You: LutzTD

Please Log in or Create an account to join the conversation.

- LutzTD

- Offline

- Elite Member

-

Less

More

- Posts: 216

- Thank you received: 1

06 Jun 2016 14:46 - 06 Jun 2016 16:40 #75556

by LutzTD

Replied by LutzTD on topic Emcoturn 120 lathe retrofit

thanx Ill check that out. So far I downloaded one from dessalt ( maker of solidworks it was terrible), and also LibreCad which is similarly bad.

EDIT: yeah this isnt too bad. took me about an hour to do this, would have been a couple minutes in SW but theres a learning curve. It looks pretty much exactly what I was wanting for a home CAD software. Thanx again

MODIFIED

DXF out to CamBam

EDIT: yeah this isnt too bad. took me about an hour to do this, would have been a couple minutes in SW but theres a learning curve. It looks pretty much exactly what I was wanting for a home CAD software. Thanx again

MODIFIED

DXF out to CamBam

Last edit: 06 Jun 2016 16:40 by LutzTD.

Please Log in or Create an account to join the conversation.

Time to create page: 0.330 seconds