Emcoturn 120 lathe retrofit

- LutzTD

- Offline

- Elite Member

-

Less

More

- Posts: 216

- Thank you received: 1

09 Jun 2016 14:15 - 09 Jun 2016 14:16 #75730

by LutzTD

Replied by LutzTD on topic Emcoturn 120 lathe retrofit

but since it buzzes, isnt that a sign it is not new either? I bought it as "new in box" now I know its not the right box so maybe its more like "used in a box". can I clean it or something to get rid of the buzz? Or do I not need to worry about the buzz?

Last edit: 09 Jun 2016 14:16 by LutzTD.

Please Log in or Create an account to join the conversation.

- LutzTD

- Offline

- Elite Member

-

Less

More

- Posts: 216

- Thank you received: 1

11 Jun 2016 03:01 #75799

by LutzTD

Replied by LutzTD on topic Emcoturn 120 lathe retrofit

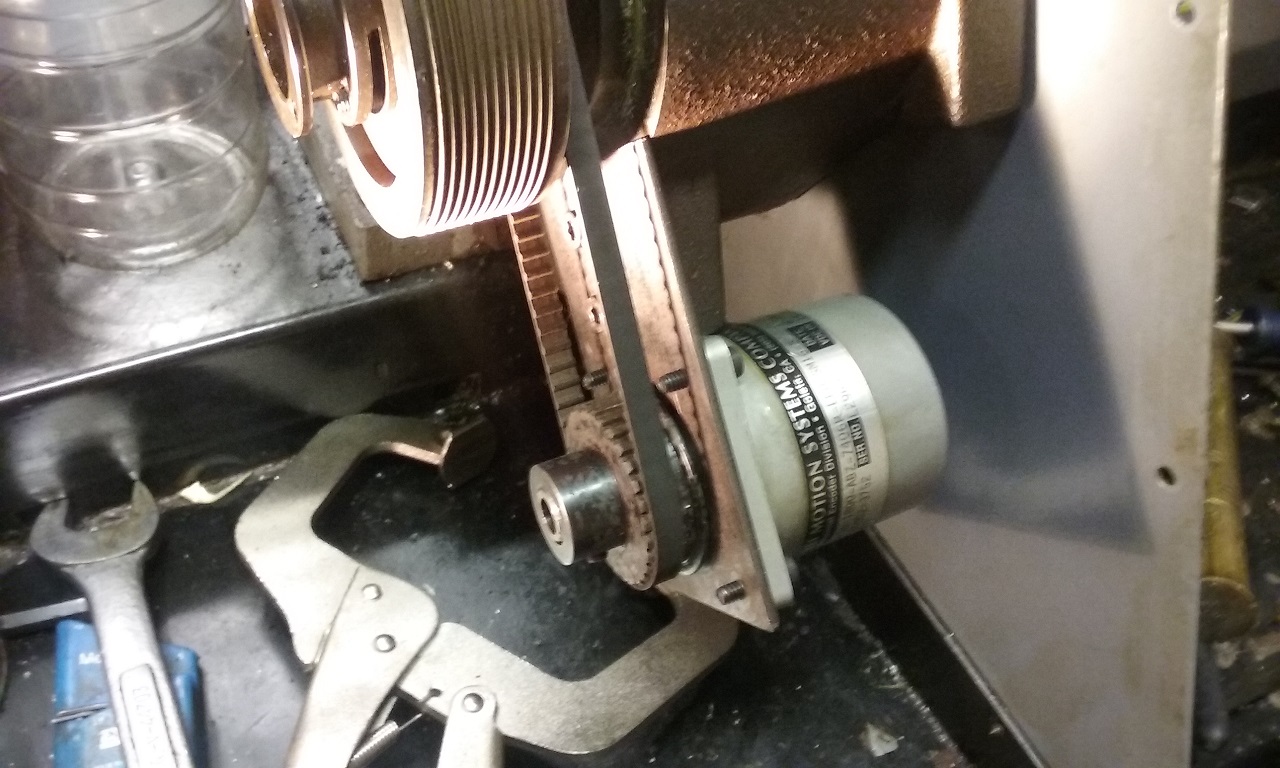

worked a little bit on the encoder plate while I wait for more control parts. I cut the hole for the encoder locating bore. Likely I will just do the rest with the manual bridgeport and with a transfer punch, I dont have a mill cutter small enough to do a proper cnc cut and Im wanting to get this done so the old fashioned way will have to do.

Please Log in or Create an account to join the conversation.

- LutzTD

- Offline

- Elite Member

-

Less

More

- Posts: 216

- Thank you received: 1

11 Jun 2016 17:04 #75827

by LutzTD

Replied by LutzTD on topic Emcoturn 120 lathe retrofit

got the encoder mount plate finished. It interfered slightly with an ear on the lathe, rather than cut the lathe spindle housing I notched the BEI encoder just enough to give good belt tension. Once mounted it works good, I did remove it again and shorten the screws, the belt drifts in and rides on the spindle plate, but it did this before as well. Doesn't seem to effect anything.

Please Log in or Create an account to join the conversation.

- LutzTD

- Offline

- Elite Member

-

Less

More

- Posts: 216

- Thank you received: 1

13 Jun 2016 02:35 #75895

by LutzTD

Replied by LutzTD on topic Emcoturn 120 lathe retrofit

worked on a couple things today. I used one of the many extra cables from the emco to make a new encoder cable. The BEI encoder had a 7 pin military style connector, I found a new mate and soldered the connector and mounted it. I also flipped the wire box on the spindle motor as it was close to the Z-axis stepper travel envelope, now its zero problem. I also figured out a way to turn on the Dell computer from outside the control box. The green button is a standard industrial control butto, (actually a $2 chinese copy) I removed the switch and turned a dowel rod to fit tight in the back of the button. It has a very small travel and with a belt sander I modified the length to just push the on button on the dell at the end of the green button travel. Works very nice.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

13 Jun 2016 09:19 - 13 Jun 2016 09:21 #75901

by andypugh

You could have unplugged the case button from the MB

Actually, looking more carefully, you can't can you?.

Replied by andypugh on topic Emcoturn 120 lathe retrofit

Actually, looking more carefully, you can't can you?.

Last edit: 13 Jun 2016 09:21 by andypugh.

Please Log in or Create an account to join the conversation.

- LutzTD

- Offline

- Elite Member

-

Less

More

- Posts: 216

- Thank you received: 1

13 Jun 2016 11:06 - 13 Jun 2016 12:10 #75911

by LutzTD

Replied by LutzTD on topic Emcoturn 120 lathe retrofit

no, that was the deal, I would have had to desolder the button leads (SMT) from the motherboard and then solder on wires to make the switch, in the end the mechanical solution was the least painful. I know it looks kinda kluged, but it actually works quite well and it saves me opening the control box every time I start up.

Last edit: 13 Jun 2016 12:10 by LutzTD.

Please Log in or Create an account to join the conversation.

- LutzTD

- Offline

- Elite Member

-

Less

More

- Posts: 216

- Thank you received: 1

23 Jun 2016 20:36 #76515

by LutzTD

Replied by LutzTD on topic Emcoturn 120 lathe retrofit

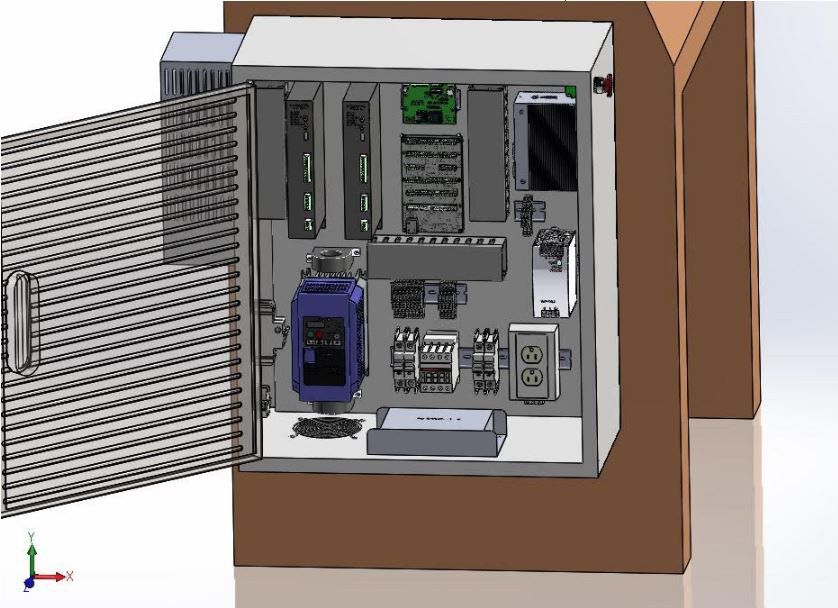

haven't had time to get out to the shop. But I have ordered a few more components. Here is an updated control cabinet layout with line reactors, emi filter, resistive brake, cabinet fan and updated layout per my weeks of assembly. I may end pu moving the brake as it would be a bump hazard if it sticks out that far. I was hoping to place it over the cabinet air exit to give it some moving air but I may have to change that plan so it will fit through a 3ft door.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

24 Jun 2016 12:34 #76545

by andypugh

Replied by andypugh on topic Emcoturn 120 lathe retrofit

If that is the brake resistor on the left of the view it looks massively oversized. It doesn't have to be continuously rated.

Please Log in or Create an account to join the conversation.

- LutzTD

- Offline

- Elite Member

-

Less

More

- Posts: 216

- Thank you received: 1

24 Jun 2016 13:29 - 24 Jun 2016 13:31 #76554

by LutzTD

Replied by LutzTD on topic Emcoturn 120 lathe retrofit

yes it is the brake resistor. The literature for the VFD said to use a 40 Ohm 400 Watt. The size is based on the literature I could find on the new old stock one I bought, it might be modeled wrong. But I'll admit I didn't even think about duty cycle. Oh well, I think its going to get tucked up under the lathe frame so size wont hurt me for any other reason will it?

Sadly on the flip side the VFD is 2X the one in the picture, so the entire layout will need to be "adjusted"

Sadly on the flip side the VFD is 2X the one in the picture, so the entire layout will need to be "adjusted"

Last edit: 24 Jun 2016 13:31 by LutzTD.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

24 Jun 2016 13:37 #76556

by andypugh

It looks like 200x60x30mm is about right:

docs-europe.electrocomponents.com/webdoc...0900766b80fecc81.pdf

So, they are a fair size, but could possibly just go on the outside of the box. In non-industrial use I doubt that it will get hot enough to need a safety cover.

Replied by andypugh on topic Emcoturn 120 lathe retrofit

yes it is the brake resistor. The literature for the VFD said to use a 40 Ohm 400 Watt. The size is based on the literature I could find on the new old stock one I bought, it might be modeled wrong."

It looks like 200x60x30mm is about right:

docs-europe.electrocomponents.com/webdoc...0900766b80fecc81.pdf

So, they are a fair size, but could possibly just go on the outside of the box. In non-industrial use I doubt that it will get hot enough to need a safety cover.

Please Log in or Create an account to join the conversation.

Time to create page: 0.422 seconds