Bridgeport Torq Cut 22 Retrofit

- Michael

- Offline

- Platinum Member

-

Less

More

- Posts: 335

- Thank you received: 59

15 Dec 2020 03:39 #192027

by Michael

Replied by Michael on topic Bridgeport Torq Cut 22 Retrofit

The drives internal settings are main gain, speed gain, integration gain. The main and speed are set to 40 (of 127) anything higher causes the motor to chatter. I have been all over the board with the integration and DMM told me it"usually doesn't effect anything".

Other than that, toque filter is off and there is an acceleration (smoothing) setting that is at 90 (127 is off, 1 is highest).

Here is some verbage from their website:

Main Gain: As load inertia increases, Main Gain should be increased correspondingly to make sure the servo has higher stability, increased stiffness and faster response. If set too high, high frequency noise is introduced because control loop frequency domain conflicts with torque servo loop. If set too low, servo loop may become unstable - low frequency oscillations introduced.

Speed Gain: As load inertia further increases, Speed Gain should be correspondingly increased to increase the servo stability. Speed Gain also has the effect of smoothing servo motor's motion. If set too high relative to load, servo response may become slower, high frequency noise may be introduced.

Integration Gain: Used to increase the servo stiffness and keeping servo accuracy. Generally should be lowered as load inertia increase as larger loads should not have high dynamic ability (rapid acceleration/deceleration). Higher integration gain will decrease the servo stability. For large inertia loads, integration should be decreased.

Other than that, toque filter is off and there is an acceleration (smoothing) setting that is at 90 (127 is off, 1 is highest).

Here is some verbage from their website:

Main Gain: As load inertia increases, Main Gain should be increased correspondingly to make sure the servo has higher stability, increased stiffness and faster response. If set too high, high frequency noise is introduced because control loop frequency domain conflicts with torque servo loop. If set too low, servo loop may become unstable - low frequency oscillations introduced.

Speed Gain: As load inertia further increases, Speed Gain should be correspondingly increased to increase the servo stability. Speed Gain also has the effect of smoothing servo motor's motion. If set too high relative to load, servo response may become slower, high frequency noise may be introduced.

Integration Gain: Used to increase the servo stiffness and keeping servo accuracy. Generally should be lowered as load inertia increase as larger loads should not have high dynamic ability (rapid acceleration/deceleration). Higher integration gain will decrease the servo stability. For large inertia loads, integration should be decreased.

Please Log in or Create an account to join the conversation.

- Michael

- Offline

- Platinum Member

-

Less

More

- Posts: 335

- Thank you received: 59

17 Dec 2020 04:17 - 06 Feb 2021 16:40 #192221

by Michael

Replied by Michael on topic Bridgeport Torq Cut 22 Retrofit

Edit, removed incorrect information

Attachments:

Last edit: 06 Feb 2021 16:40 by Michael.

Please Log in or Create an account to join the conversation.

- Michael

- Offline

- Platinum Member

-

Less

More

- Posts: 335

- Thank you received: 59

06 Feb 2021 17:30 #197851

by Michael

Replied by Michael on topic Bridgeport Torq Cut 22 Retrofit

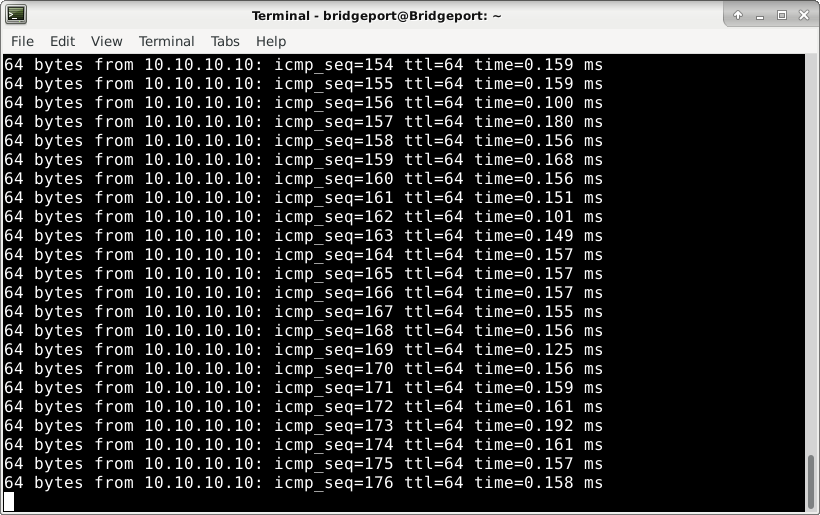

After dealing with the DMM servo issues of overcurrent at speed and delayed response in encoder feedback while in analog speed mode I have decided to take the project a different direction. I ordered a 7i78 to go along with the 7i92, 7i77 and 7i84. I have also installed the standard ISO Debian 10 Buster with 2.8. I will be reflashing the 7i92 with a different bit file later today to match configuration change. This is probably not the most ideal combo but it was affordable and I need to get the machine moving along. Once I clear the back log of work I will probably source some Yaskawa Sigma 5's and go back to analog control.

I would like to go over the math of the pulse settings to make sure I am in the right ball park.

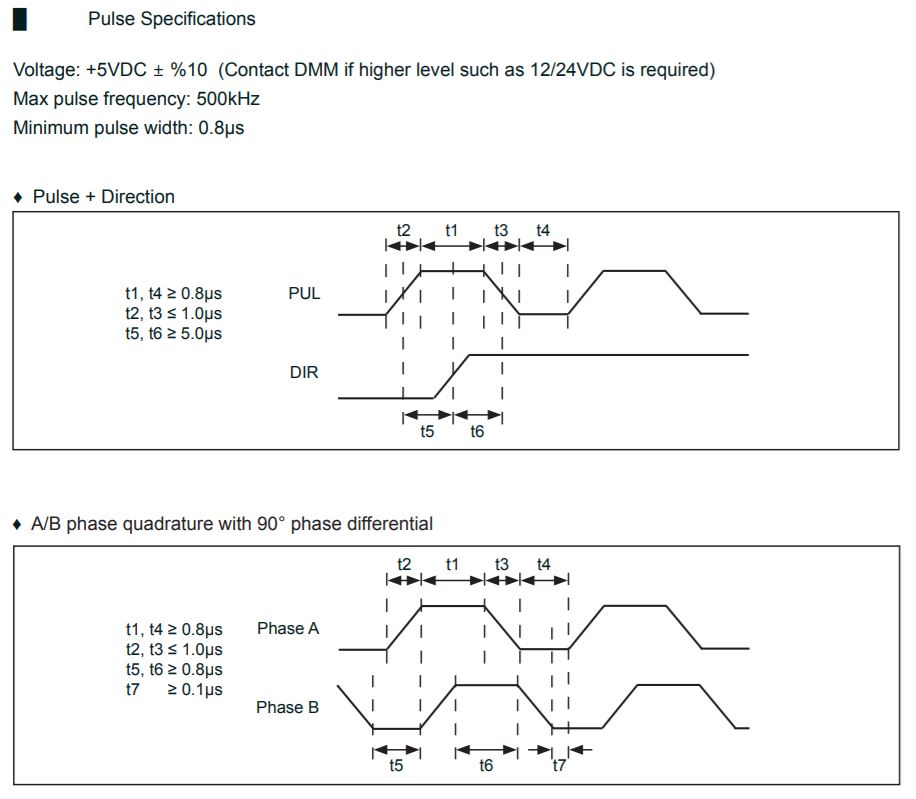

Going over step/direction signal timing in the manual I have this page:

Max motor speed is 3000 rpm which makes it 50rps

Max pulse cycles read to be 500kHz which gives me 10000 us per revolution for pulses.

minimum pulse width is .8 us so it looks like to get max motor speed I would need 12500 pulses per revolution to achieve that.

The drive gearing can produce anywhere from 2000 to 65536 pulses per revolution.

Resolution wise this provides me with .000015ish" per pulse X/Y and .000009ish" in Z (geared 40 to 24 and 8mm and 5mm screws respectively)

Any thoughts on the math and the adequacy of the resolution? I probably wont be trying for full speed but closer to 90%.

I would like to go over the math of the pulse settings to make sure I am in the right ball park.

Going over step/direction signal timing in the manual I have this page:

Max motor speed is 3000 rpm which makes it 50rps

Max pulse cycles read to be 500kHz which gives me 10000 us per revolution for pulses.

minimum pulse width is .8 us so it looks like to get max motor speed I would need 12500 pulses per revolution to achieve that.

The drive gearing can produce anywhere from 2000 to 65536 pulses per revolution.

Resolution wise this provides me with .000015ish" per pulse X/Y and .000009ish" in Z (geared 40 to 24 and 8mm and 5mm screws respectively)

Any thoughts on the math and the adequacy of the resolution? I probably wont be trying for full speed but closer to 90%.

Attachments:

Please Log in or Create an account to join the conversation.

- Michael

- Offline

- Platinum Member

-

Less

More

- Posts: 335

- Thank you received: 59

08 Feb 2021 15:13 #198008

by Michael

Replied by Michael on topic Bridgeport Torq Cut 22 Retrofit

Please Log in or Create an account to join the conversation.

- arsenix

-

- Offline

- New Member

-

Less

More

- Posts: 15

- Thank you received: 1

21 Jun 2022 06:25 #245516

by arsenix

Replied by arsenix on topic Bridgeport Torq Cut 22 Retrofit

How is this project going? I have a TC22. Still using the old control!

Did you get rid of your original servo amps? I've been looking for a spare to use as a 4th axis controller.

Did you get rid of your original servo amps? I've been looking for a spare to use as a 4th axis controller.

Please Log in or Create an account to join the conversation.

- Nineteen75

- Offline

- New Member

-

Less

More

- Posts: 1

- Thank you received: 0

17 Jan 2024 02:19 #290922

by Nineteen75

Replied by Nineteen75 on topic Bridgeport Torq Cut 22 Retrofit

Hello, I'm new here.

I have a Bridgeport torqcutt 22

The hardrive crapped out.

Does anyone have back discs where I can buy a new hardive and reinstall the software so I can be back up and running?

Any help would be more than appreciated!

I have a Bridgeport torqcutt 22

The hardrive crapped out.

Does anyone have back discs where I can buy a new hardive and reinstall the software so I can be back up and running?

Any help would be more than appreciated!

Please Log in or Create an account to join the conversation.

Time to create page: 0.122 seconds