Error message "Radius to end of arc differs....etc etc"

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

06 May 2019 15:41 #132974

by pl7i92

Replied by pl7i92 on topic Error message "Radius to end of arc differs....etc etc"

he shoudt use a Fanuc postprocesor for the output

Please Log in or Create an account to join the conversation.

- Jocman

- Offline

- Premium Member

-

Less

More

- Posts: 111

- Thank you received: 11

08 May 2019 11:46 #133129

by Jocman

Do you mean to put:

G21 G40 G49 G90 G91.1 G64 P0.03 M6 T1

instead of

G21 G40 G49 G90.1 G64 P0.03 M6 T1

(commands G90.0 and G91.1) ?

This case, If I modify my PP settings so to keep these changes, do you think I could have problems for other kind of jobs?

Fanuc can work with LinuxCNC with no issues?

Replied by Jocman on topic Error message "Radius to end of arc differs....etc etc"

Your old G-code works fine if you change the first line.

Do you mean to put:

G21 G40 G49 G90 G91.1 G64 P0.03 M6 T1

instead of

G21 G40 G49 G90.1 G64 P0.03 M6 T1

(commands G90.0 and G91.1) ?

This case, If I modify my PP settings so to keep these changes, do you think I could have problems for other kind of jobs?

he shoudt use a Fanuc postprocesor for the output

Fanuc can work with LinuxCNC with no issues?

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4704

- Thank you received: 1443

08 May 2019 14:21 - 08 May 2019 14:22 #133145

by Todd Zuercher

Replied by Todd Zuercher on topic Error message "Radius to end of arc differs....etc etc"

Yes, change that line.

No, I don't see how you would have any problems with other g-code from the same post processor.

Most general Fanuc G-code should run fine. The big differences for Fanuc code comes when you start using Custom Macro (B or A), sub programs, and maybe some canned cycles. Most of which usually are not an issue with CAM generated code. There can also be some issues with machine coordinate systems, tool table handling and M-codes, but that starts to get very machine specific and will vary as much between different Fanuc controlled machines from different manufacturers as much as between Linuxcnc.

No, I don't see how you would have any problems with other g-code from the same post processor.

Most general Fanuc G-code should run fine. The big differences for Fanuc code comes when you start using Custom Macro (B or A), sub programs, and maybe some canned cycles. Most of which usually are not an issue with CAM generated code. There can also be some issues with machine coordinate systems, tool table handling and M-codes, but that starts to get very machine specific and will vary as much between different Fanuc controlled machines from different manufacturers as much as between Linuxcnc.

Last edit: 08 May 2019 14:22 by Todd Zuercher.

Please Log in or Create an account to join the conversation.

- Jocman

- Offline

- Premium Member

-

Less

More

- Posts: 111

- Thank you received: 11

09 May 2019 06:48 #133229

by Jocman

Replied by Jocman on topic Error message "Radius to end of arc differs....etc etc"

Well, I made the changes you suggested, and tried that gcode and a new exemple one.

Everithing was fine, no more error messages.

I provided to modify the PP file to put the same startline everytime.

About the Fanuc PP, well, there's no risk at all to have any issues: I'm just a "sunday miller" (as we say in Italy, don't know if in USA it sounds same way...), meaning I just mill wood and plastic for hobbies, in the easiest way as possible.

Thanks a lot to everyone for the help.

Andrea

Everithing was fine, no more error messages.

I provided to modify the PP file to put the same startline everytime.

About the Fanuc PP, well, there's no risk at all to have any issues: I'm just a "sunday miller" (as we say in Italy, don't know if in USA it sounds same way...), meaning I just mill wood and plastic for hobbies, in the easiest way as possible.

Thanks a lot to everyone for the help.

Andrea

Please Log in or Create an account to join the conversation.

- Marfil

- Offline

- Senior Member

-

Less

More

- Posts: 48

- Thank you received: 3

25 Mar 2021 23:20 #203650

by Marfil

Replied by Marfil on topic Error message "Radius to end of arc differs....etc etc"

Hi Jocman. Im Marfil.

Could you give me a hand please? Where I can find the "2.4. [RS274NGC] Section"

I want to change the arc tolerance but I don,t know how

Thanks in advance.

Could you give me a hand please? Where I can find the "2.4. [RS274NGC] Section"

I want to change the arc tolerance but I don,t know how

Thanks in advance.

Please Log in or Create an account to join the conversation.

- Jocman

- Offline

- Premium Member

-

Less

More

- Posts: 111

- Thank you received: 11

26 Mar 2021 08:05 #203676

by Jocman

Replied by Jocman on topic Error message "Radius to end of arc differs....etc etc"

Hi Marfil.

You should check the .ini file related to your machine.

Is the same .ini file where you set such Displays and so on.

In case is not present in your .ini file, you can create it simply by inserting it

Anyway check it out here:

linuxcnc.org/docs/html/config/ini-config...sec:rs274ngc-section

Hope it will help

Andrea

You should check the .ini file related to your machine.

Is the same .ini file where you set such Displays and so on.

In case is not present in your .ini file, you can create it simply by inserting it

Anyway check it out here:

linuxcnc.org/docs/html/config/ini-config...sec:rs274ngc-section

Hope it will help

Andrea

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4704

- Thank you received: 1443

26 Mar 2021 12:59 #203704

by Todd Zuercher

Replied by Todd Zuercher on topic Error message "Radius to end of arc differs....etc etc"

I'm not sure that version 2.4 had the option of easily adjusting the arc tolerance. That may not have been added until v2.5.

Please Log in or Create an account to join the conversation.

- Marfil

- Offline

- Senior Member

-

Less

More

- Posts: 48

- Thank you received: 3

27 Mar 2021 22:12 #203850

by Marfil

Replied by Marfil on topic Error message "Radius to end of arc differs....etc etc"

Hi Andrea. It' s me again.

Here you have a print screen from my PC.

Same drawing in both case, one of them is in fault.

The big diference are in decimals qty (I, J) as you can see.

In post_config.cfg from DXF2Gcode app. I changed it

[Number_Format]

pre_decimals = 4

post_decimals = 3

That's all and it's working.

thanks a lot.

Here you have a print screen from my PC.

Same drawing in both case, one of them is in fault.

The big diference are in decimals qty (I, J) as you can see.

In post_config.cfg from DXF2Gcode app. I changed it

[Number_Format]

pre_decimals = 4

post_decimals = 3

That's all and it's working.

thanks a lot.

The following user(s) said Thank You: Jocman

Please Log in or Create an account to join the conversation.

- Jocman

- Offline

- Premium Member

-

Less

More

- Posts: 111

- Thank you received: 11

29 Mar 2021 06:38 #203980

by Jocman

Replied by Jocman on topic Error message "Radius to end of arc differs....etc etc"

Glad to ear everything went fine.

BTW, at that time I fixed my problem by editing the setting for the postprocessor to linuxcnc output, more or less same as you did.

Andrea

BTW, at that time I fixed my problem by editing the setting for the postprocessor to linuxcnc output, more or less same as you did.

Andrea

Please Log in or Create an account to join the conversation.

- gekonko

-

- Offline

- New Member

-

Less

More

- Posts: 17

- Thank you received: 3

15 Jan 2025 21:42 #319052

by gekonko

Replied by gekonko on topic Error message "Radius to end of arc differs....etc etc"

Hello,

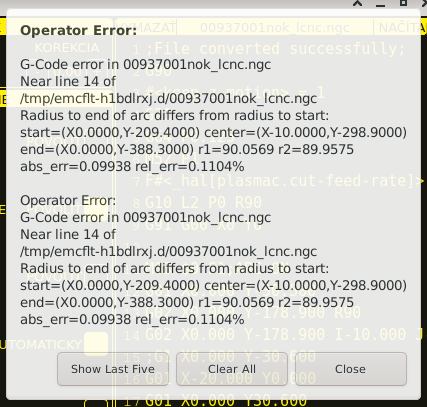

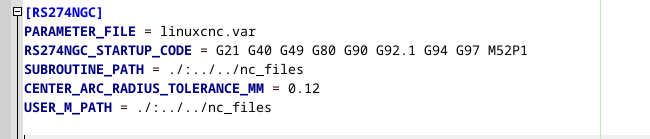

i get the same error in QtplasmaC v2.9-238.314 RIP with EN (and SK) locale and Metric system. I have tryed to change CENTER_ARC_RADIUS_TOLERANCE_MM for my machine, but without luck. It seems that this tolerance stays default and does not change. Unfortunately, I cannot change generated tolerance from this cad/cam. This software is prahistoric but I am bound to it because it has functions for generating custom hvac components and nesting. Problem is that generated files from this cad/cam are only with 0.1mm accuracy.

the error is reasonably small for my application

changed ini file, I have also tried to use bigger tolerance = 0.5

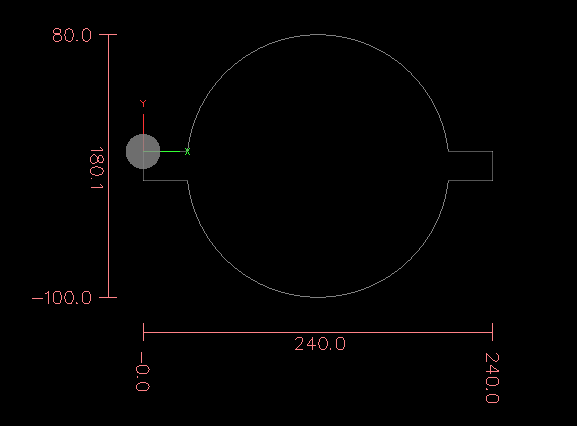

this is how the workpiece should look like.

i get the same error in QtplasmaC v2.9-238.314 RIP with EN (and SK) locale and Metric system. I have tryed to change CENTER_ARC_RADIUS_TOLERANCE_MM for my machine, but without luck. It seems that this tolerance stays default and does not change. Unfortunately, I cannot change generated tolerance from this cad/cam. This software is prahistoric but I am bound to it because it has functions for generating custom hvac components and nesting. Problem is that generated files from this cad/cam are only with 0.1mm accuracy.

the error is reasonably small for my application

changed ini file, I have also tried to use bigger tolerance = 0.5

this is how the workpiece should look like.

Attachments:

Please Log in or Create an account to join the conversation.

Time to create page: 0.170 seconds