New Mill Build...Can I use LinuxCNC?

- Mayberry Customs

- Offline

- Senior Member

-

Less

More

- Posts: 62

- Thank you received: 8

03 May 2020 20:19 #166536

by Mayberry Customs

Replied by Mayberry Customs on topic New Mill Build...Can I use LinuxCNC?

Ok thanks...ya that’s what it looked like to me and as far as I can tell no built in spindle control, definitely want that...any walk through tutorials or video suggestions for the 7i76e? I found what appeared to be a good video on YouTube but it’s in German! I’m sure there’s plenty of info out there, just trying to find what I can ahead of time.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21345

- Thank you received: 7284

04 May 2020 00:54 #166557

by tommylight

Replied by tommylight on topic New Mill Build...Can I use LinuxCNC?

On the first post there is a PDF attached that has wiring diagrams and a lot of explanations, very nicely done:

forum.linuxcnc.org/27-driver-boards/3191...76e-connection-sheet

forum.linuxcnc.org/27-driver-boards/3191...76e-connection-sheet

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11729

- Thank you received: 3972

04 May 2020 03:57 #166567

by rodw

Replied by rodw on topic New Mill Build...Can I use LinuxCNC?

The 7i96 is for sure is a nice baord with built in relays but it does not support the spindle without extenral hardware and the PWM is at the expense of a stepgen or something similar. You can add 2 MPG's to it but that is at the expense of input pins so if you add another bord for more IO you are up to tthe 7i76e in cost.

Please Log in or Create an account to join the conversation.

- Mayberry Customs

- Offline

- Senior Member

-

Less

More

- Posts: 62

- Thank you received: 8

05 May 2020 17:09 #166779

by Mayberry Customs

Replied by Mayberry Customs on topic New Mill Build...Can I use LinuxCNC?

This is more of a general Linux question…I was thinking about the fact that I would be using a separate computer to do the CAD and CAM and would like to share the G code file across the network to the controller computer...When I got to thinking about this though I realize that the Mesa card would be using my ethernet connection… Is there a way to use this ethernet connection for that purpose, but also have a Wi-Fi connection that is functional so I can share and access files on the network? I know this is trivial and I can use a USB stick to transfer the file, but it would be nice for convenience just to be able to access it on a network. Thanks, Andy

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17728

- Thank you received: 5186

05 May 2020 17:16 #166780

by PCW

Replied by PCW on topic New Mill Build...Can I use LinuxCNC?

Yes you can have WIFI in addition to the Ethernet or you can also add a second

Ethernet connection for network access with a USB --> Ethernet Dongle

Ethernet connection for network access with a USB --> Ethernet Dongle

Please Log in or Create an account to join the conversation.

- Mayberry Customs

- Offline

- Senior Member

-

Less

More

- Posts: 62

- Thank you received: 8

05 May 2020 20:07 #166795

by Mayberry Customs

Replied by Mayberry Customs on topic New Mill Build...Can I use LinuxCNC?

Ok great, thanks!

Please Log in or Create an account to join the conversation.

- Mayberry Customs

- Offline

- Senior Member

-

Less

More

- Posts: 62

- Thank you received: 8

16 May 2020 01:08 #167916

by Mayberry Customs

Replied by Mayberry Customs on topic New Mill Build...Can I use LinuxCNC?

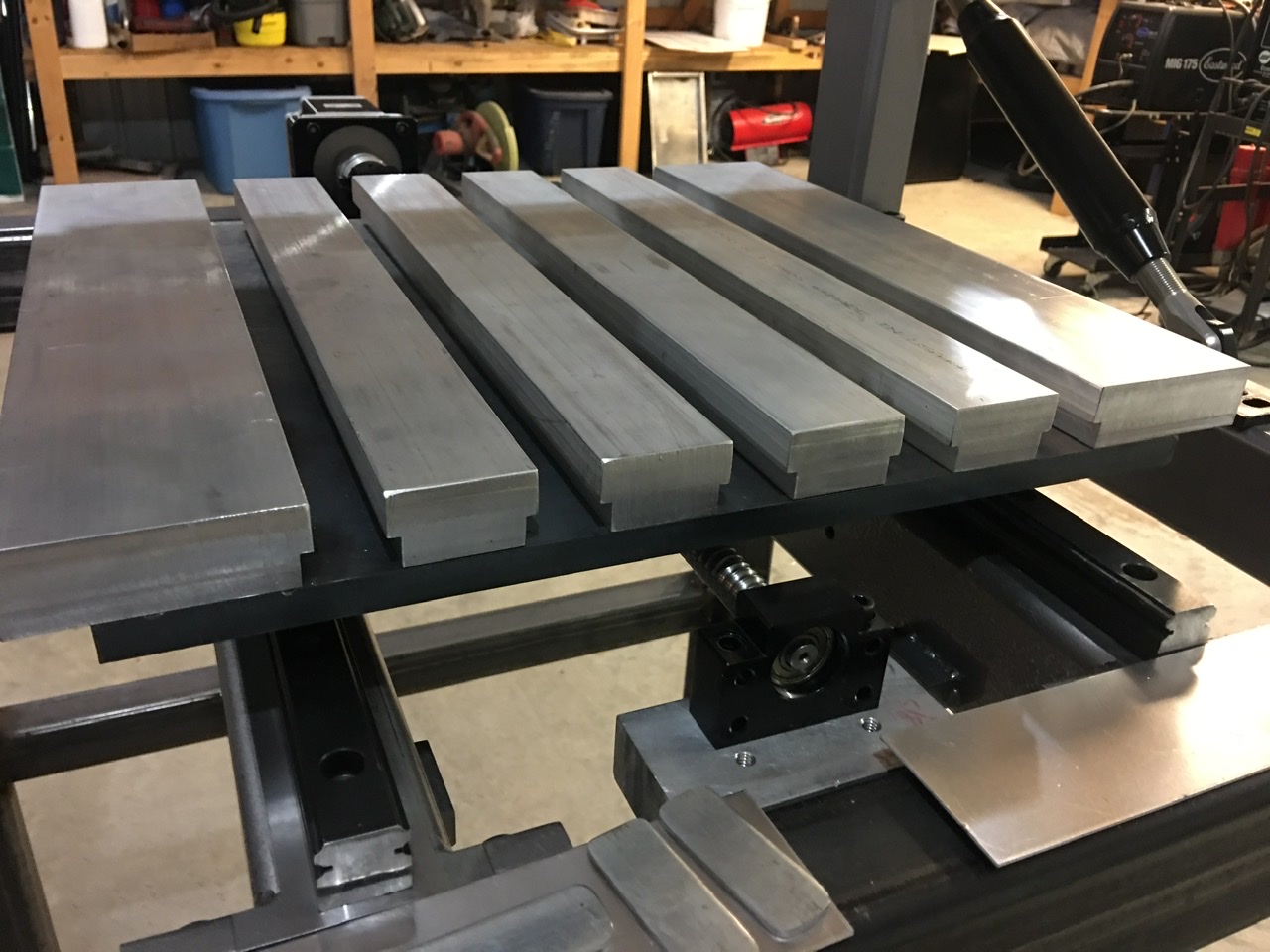

The 7i76E is on its way!!...Still going to grab a 24v PS, does the PS posted above look correct?...made a little progress on the multi piece aluminum t slot table, plan to mill the surface with the machine, it’s a semi permanent set up...they will bolt on from the bottom...they can be decked off several times, and swapped out for more aluminum or steel whenever necessary. Thanks, Andy

Please Log in or Create an account to join the conversation.

- Mayberry Customs

- Offline

- Senior Member

-

Less

More

- Posts: 62

- Thank you received: 8

19 May 2020 02:09 #168221

by Mayberry Customs

Replied by Mayberry Customs on topic New Mill Build...Can I use LinuxCNC?

Received the board today, excited to get it wired up...just a quick question on limit switches. On my previous small router I used both work offsets and just finding X and Y zeroing and working from there. I don’t see my self using work offsets with this mill. My original plan was to just wire the switches in series and connect them to one input. I would never use them except when I make a mistake and exceed the travel of the machine... Can any body tell me a good reason for wiring home switches or limit switches individually, besides using work offsets?

Also in the wiring diagram posted earlier it shows the limit switches under “digital inputs.” The switches I am using are just standard mechanical switches so this naming seemed a little strange...I just wanted to verify that this wiring is still correct for my switches? Also on the old Chinese board one wire was wired to the input and one wire to a common terminal...this wiring diagram shows that leg being wired to field power which also seemed strange, and I also wanted to verify that? Thanks in advance, Andy

Also in the wiring diagram posted earlier it shows the limit switches under “digital inputs.” The switches I am using are just standard mechanical switches so this naming seemed a little strange...I just wanted to verify that this wiring is still correct for my switches? Also on the old Chinese board one wire was wired to the input and one wire to a common terminal...this wiring diagram shows that leg being wired to field power which also seemed strange, and I also wanted to verify that? Thanks in advance, Andy

Please Log in or Create an account to join the conversation.

- JohnnyCNC

-

- Offline

- Platinum Member

-

Less

More

- Posts: 570

- Thank you received: 111

19 May 2020 02:29 #168223

by JohnnyCNC

Replied by JohnnyCNC on topic New Mill Build...Can I use LinuxCNC?

One reason to wire them individually is that if you do end up on a limit switch the software will tell you which limit switch you are on. Or, if one of the switches or wires fails and goes open LinuxCNC will tell you which axis. I also use mechanical micro switches. Just wire them as shown for the digital inputs.

John

John

Please Log in or Create an account to join the conversation.

- ttt

- Offline

- New Member

-

Less

More

- Posts: 11

- Thank you received: 23

19 May 2020 04:57 #168227

by ttt

I have used both the 7I96 and 7I76e. I would say for 95% of all cases a 7I96 will do just fine. The main difference is the lack of an analog spindle output and less overall I/O pins on the 7I96. But if you have a VFD driven spindle you should drive that using modbus anyway, unless your VFD driver is 40 years old... As for pins, how many do you need? There is enough for XYZ end stops and emergency buttons on the 7I96.

Replied by ttt on topic New Mill Build...Can I use LinuxCNC?

Since i never used a 7i96 i am not best suited to reply, but as far as i know 7i96 has less I/O and is better suited for plasma while 7i76E has everything needed for a mill and then some....can anyone elaborate on the difference between the 7i76e and the 7i96.

I have used both the 7I96 and 7I76e. I would say for 95% of all cases a 7I96 will do just fine. The main difference is the lack of an analog spindle output and less overall I/O pins on the 7I96. But if you have a VFD driven spindle you should drive that using modbus anyway, unless your VFD driver is 40 years old... As for pins, how many do you need? There is enough for XYZ end stops and emergency buttons on the 7I96.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

Time to create page: 0.133 seconds