2 seperate MPG handwheels for each axis - CNC Lathe build

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11737

- Thank you received: 3973

17 May 2020 12:38 #168054

by rodw

Replied by rodw on topic 2 seperate MPG handwheels for each axis - CNC Lathe build

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21379

- Thank you received: 7290

17 May 2020 12:38 #168055

by tommylight

Replied by tommylight on topic 2 seperate MPG handwheels for each axis - CNC Lathe build

To speed things up a bit, i am going to eat something and grab one of my 7i77 and a 5i25 or 6i25 if i can find them and do a mock up for testing, and some encoders. Back in 20 to 30 minutes.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11737

- Thank you received: 3973

17 May 2020 12:40 #168056

by rodw

Great stuff! I did say I did not use resistors!

Replied by rodw on topic 2 seperate MPG handwheels for each axis - CNC Lathe build

Works!

What i did. I took the second MPG handwheel i had lying around and connected all 4 wires to the terminals but without the resistors. Halmeter shows counts!

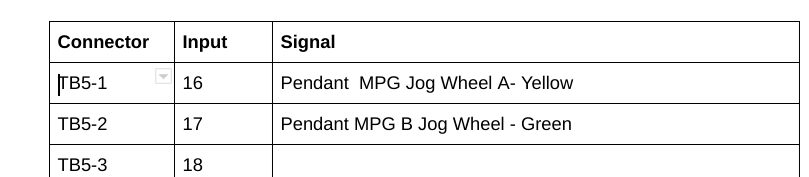

EDIT: and of course i changed the white and blue wire back to TB5

Great stuff! I did say I did not use resistors!

Please Log in or Create an account to join the conversation.

- denhen89

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 298

- Thank you received: 26

17 May 2020 12:53 - 17 May 2020 12:56 #168057

by denhen89

Replied by denhen89 on topic 2 seperate MPG handwheels for each axis - CNC Lathe build

Okay, one MPG works, but the one where the resistors were wired, does not work. I put all wires back to the first MPG, but of course without the resitors and hal does not show the counts.

Have wired up the second mpg again, halmeter shows counts. Back again to the first= no counts.

Is it possible that the MPG got damaged because of the resistors? (2k0 resistors)

Have wired up the second mpg again, halmeter shows counts. Back again to the first= no counts.

Is it possible that the MPG got damaged because of the resistors? (2k0 resistors)

Last edit: 17 May 2020 12:56 by denhen89.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11737

- Thank you received: 3973

17 May 2020 12:59 #168058

by rodw

Replied by rodw on topic 2 seperate MPG handwheels for each axis - CNC Lathe build

swap the known good MPG to the other input and see if it will count

Please Log in or Create an account to join the conversation.

- denhen89

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 298

- Thank you received: 26

17 May 2020 13:06 #168059

by denhen89

Replied by denhen89 on topic 2 seperate MPG handwheels for each axis - CNC Lathe build

Rodw, thanks but it seems i found the problem.

I measure Ohm on the terminals of both MPGs:

Red stick(dont know the correct word) on terminal 0V and black stick A, then B , then the A and B terminals on bottom of the mpg. All are giving 5.4 Ohm.

But, on the MPG which does not show any counts i get on all 5.4 Ohm, but not on the main "A" terminal. It shows: 0.001 Ohm

So it seems something with the terminal A on the first MPG i tested is not okay. Right now i am not sure if its because of the resistors or if i shorted something

I measure Ohm on the terminals of both MPGs:

Red stick(dont know the correct word) on terminal 0V and black stick A, then B , then the A and B terminals on bottom of the mpg. All are giving 5.4 Ohm.

But, on the MPG which does not show any counts i get on all 5.4 Ohm, but not on the main "A" terminal. It shows: 0.001 Ohm

So it seems something with the terminal A on the first MPG i tested is not okay. Right now i am not sure if its because of the resistors or if i shorted something

The following user(s) said Thank You: tommylight, rodw

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21379

- Thank you received: 7290

17 May 2020 14:18 #168062

by tommylight

Replied by tommylight on topic 2 seperate MPG handwheels for each axis - CNC Lathe build

To late?

Glad it works, not glad for the faulty MPG.

2KOhm resistors can not do any damage as they were connected, must have had a 5V connected to output A at some point in it's lifetime. Anyway, i have a Mesa 7i77 and some others here, just in case.

Glad it works, not glad for the faulty MPG.

2KOhm resistors can not do any damage as they were connected, must have had a 5V connected to output A at some point in it's lifetime. Anyway, i have a Mesa 7i77 and some others here, just in case.

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

Less

More

- Posts: 2203

- Thank you received: 482

17 May 2020 14:45 - 17 May 2020 14:45 #168068

by Clive S

Replied by Clive S on topic 2 seperate MPG handwheels for each axis - CNC Lathe build

To late now put I have done a mill with a 7i96 with this code no switches

# Include your customized HAL commands here

#7i96 mesa baz

# change number of encoders here

loadrt encoder num_chan=5

addf encoder.capture-position servo-thread

addf encoder.update-counters servo-thread

# MPG stuff here

#### load ilowpass for mpg smoothing ###

loadrt ilowpass names=ilowpass.mpgX,ilowpass.mpgY,ilowpass.mpgZ

addf ilowpass.mpgX servo-thread

addf ilowpass.mpgY servo-thread

addf ilowpass.mpgZ servo-thread

setp ilowpass.mpgX.scale 1

setp ilowpass.mpgX.gain 0.1

setp ilowpass.mpgY.scale 1

setp ilowpass.mpgY.gain 0.1

setp ilowpass.mpgZ.scale 1

setp ilowpass.mpgZ.gain 0.1

# for velocity mode (when you stop spinning the dial the axis stops)

# must be set for each axis

setp joint.0.jog-vel-mode 1

setp axis.x.jog-vel-mode 1

setp joint.1.jog-vel-mode 1

setp axis.y.jog-vel-mode 1

setp joint.2.jog-vel-mode 1

setp axis.z.jog-vel-mode 1

# "times 4 mode" one count per full quadrature cycle, instead of the usual one count per edge.

# mpg jog wheels often have a full quadrature cycle per "click". 0 for off and 1 for on.

setp encoder.0.x4-mode 0

setp encoder.1.x4-mode 0

setp encoder.2.x4-mode 0

#set axis to the required increment ( 0.01)

net jog-inc-x joint.0.jog-scale axis.x.jog-scale

sets jog-inc-x 0.05

net jog-inc-y joint.1.jog-scale axis.y.jog-scale

sets jog-inc-y 0.01

net jog-inc-z joint.2.jog-scale axis.z.jog-scale

sets jog-inc-z 0.01

#set inputs to 7i96

#encoder X

net mpg-xa encoder.0.phase-A <= hm2_7i96.0.gpio.000.in

net mpg-xb encoder.0.phase-B <= hm2_7i96.0.gpio.001.in

#encoder Y

net mpg-ya encoder.1.phase-A <= hm2_7i96.0.gpio.002.in

net mpg-yb encoder.1.phase-B <= hm2_7i96.0.gpio.003.in

#encoder Z

net mpg-za encoder.2.phase-A <= hm2_7i96.0.gpio.004.in

net mpg-zb encoder.2.phase-B <= hm2_7i96.0.gpio.005.in

# send mpg-encoder counts to required axis

# x encoder

net enc-counts-x encoder.0.counts

net enc-counts-x ilowpass.mpgX.in

net enc_out-x ilowpass.mpgX.out

net enc_out-x axis.x.jog-counts

net enc_out-x joint.0.jog-counts

setp axis.x.jog-enable true

setp joint.0.jog-enable true

## The above line is to be able to jog without homing ##

# Y encoder

net enc-counts-y encoder.1.counts

net enc-counts-y ilowpass.mpgY.in

net enc_out-y ilowpass.mpgY.out

net enc_out-y axis.y.jog-counts

net enc_out-y joint.1.jog-counts

setp axis.y.jog-enable true

setp joint.1.jog-enable true

# Z encoder

net enc-counts-z encoder.2.counts

net enc-counts-z ilowpass.mpgZ.in

net enc_out-z ilowpass.mpgZ.out

net enc_out-z axis.z.jog-counts

net enc_out-z joint.2.jog-counts

setp axis.z.jog-enable true

setp joint.2.jog-enable true

Last edit: 17 May 2020 14:45 by Clive S.

The following user(s) said Thank You: Masiwood123

Please Log in or Create an account to join the conversation.

- denhen89

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 298

- Thank you received: 26

17 May 2020 14:48 - 17 May 2020 14:50 #168069

by denhen89

Replied by denhen89 on topic 2 seperate MPG handwheels for each axis - CNC Lathe build

Some good news: I managed to move the X axis with the MPG (only DRO, without motor). The scale i choose in the GUI and it works perfectly. I just had to home both axis first and then it worked. I am happy

I am really very thankful to you guys that you spent your time to help me out with those problems. I appreciate that a lot. I will return the favor with some pictures and video when the Lathe is finished

I will order a new MPG and wait until i get it and also get the switch for the scale and some buttons. In meantime i will do the mechanical part of the lathe and as soon everything is done i will start with the wiring and configuration.

It was good to make a break as you suggested me and now i can focus on the mechanical part better

I am pretty sure i will need some help later with the switches and buttons, but i bought the same type of switch for the scale as Rodw used for his plasma, so i might be able to copy and paste some lines.

Again thanks and i wish you a nice rest of the Sunday!

I am really very thankful to you guys that you spent your time to help me out with those problems. I appreciate that a lot. I will return the favor with some pictures and video when the Lathe is finished

I will order a new MPG and wait until i get it and also get the switch for the scale and some buttons. In meantime i will do the mechanical part of the lathe and as soon everything is done i will start with the wiring and configuration.

It was good to make a break as you suggested me and now i can focus on the mechanical part better

I am pretty sure i will need some help later with the switches and buttons, but i bought the same type of switch for the scale as Rodw used for his plasma, so i might be able to copy and paste some lines.

Again thanks and i wish you a nice rest of the Sunday!

Last edit: 17 May 2020 14:50 by denhen89.

The following user(s) said Thank You: tommylight, Clive S

Please Log in or Create an account to join the conversation.

- denhen89

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 298

- Thank you received: 26

17 May 2020 14:57 #168071

by denhen89

Replied by denhen89 on topic 2 seperate MPG handwheels for each axis - CNC Lathe build

@PCW: Good to know, but then it seems i somehow put 5v on A as you wrote, or the MPG was already faulty. Who knows, but good that i had a second one and tested it without the resistors, otherwise i would be screwed

@Clive S: Thanks for that! I will need that later for sure, but i saw that you used a fixed value for the scale for each axis and you are not able to change it in the GUI, correct?

Really nice to have that HAL file, i will later test it.

I had to put a code into the custom_postgui.hal, to choose the scale from the drop down menu in the GUI. Later when the Lathe is finished, i think its good to have a physical switch on a panel where the MPG will be mounted, but also good to know that its possible to use the MPG without any switches.

@Clive S: Thanks for that! I will need that later for sure, but i saw that you used a fixed value for the scale for each axis and you are not able to change it in the GUI, correct?

Really nice to have that HAL file, i will later test it.

I had to put a code into the custom_postgui.hal, to choose the scale from the drop down menu in the GUI. Later when the Lathe is finished, i think its good to have a physical switch on a panel where the MPG will be mounted, but also good to know that its possible to use the MPG without any switches.

Please Log in or Create an account to join the conversation.

Time to create page: 0.128 seconds