A Widescreen Blender-Style Interface

- BrendaEM

- Offline

- Elite Member

-

Less

More

- Posts: 266

- Thank you received: 120

17 Jul 2018 04:30 - 17 Jul 2018 05:14 #114352

by BrendaEM

Replied by BrendaEM on topic A Widescreen Blender-Style Interface

What I wanted, but may not add: is a way to store named feed/speed pairs for semi-manual operations, such as repair work, re-manufacturing, one-offs, and a lot of little jobs which are often still done with a manual mill (or lathe.)

The convenience I thought could be had: the user wouldn't have to write them down and readjust them, just page though the settings until they get the one they want, and use them.

Flycut - .05 DOC - Aluminum = 500RPM .5IPS

[ > ]

Shellmill - 1. DOC - Aluminum = 2000RPM 10IPS

[ > ]

Shellmill - 1. DOC - Cast Iron = 1000RPM 10IPS

[USE]

For now, I guess that this is the kind of thing that can be programmed on a MDI command button.

The convenience I thought could be had: the user wouldn't have to write them down and readjust them, just page though the settings until they get the one they want, and use them.

Flycut - .05 DOC - Aluminum = 500RPM .5IPS

[ > ]

Shellmill - 1. DOC - Aluminum = 2000RPM 10IPS

[ > ]

Shellmill - 1. DOC - Cast Iron = 1000RPM 10IPS

[USE]

For now, I guess that this is the kind of thing that can be programmed on a MDI command button.

Last edit: 17 Jul 2018 05:14 by BrendaEM.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19782

- Thank you received: 4604

17 Jul 2018 14:11 #114390

by andypugh

I do a lot of semi-manual work, so can see the attraction in this idea.

Replied by andypugh on topic A Widescreen Blender-Style Interface

What I wanted, but may not add: is a way to store named feed/speed pairs for semi-manual operations,

I do a lot of semi-manual work, so can see the attraction in this idea.

The following user(s) said Thank You: BrendaEM

Please Log in or Create an account to join the conversation.

- BrendaEM

- Offline

- Elite Member

-

Less

More

- Posts: 266

- Thank you received: 120

17 Jul 2018 20:11 - 17 Jul 2018 20:33 #114412

by BrendaEM

Replied by BrendaEM on topic A Widescreen Blender-Style Interface

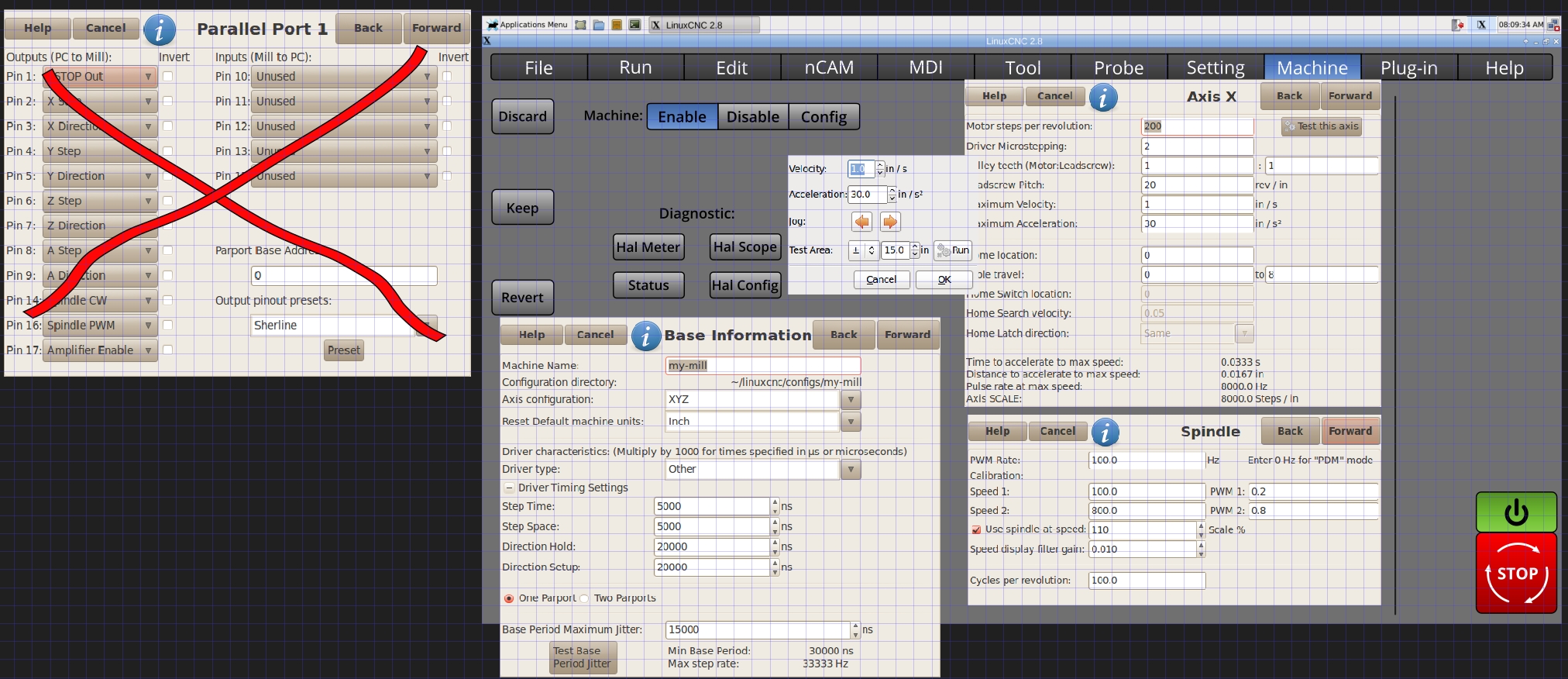

Machine ponderings:

I am conducting an experiment with the Machine menu, to see, if machine adjustments might be made from within the UI, things such as axis acceleration, steps--some but not all of the things that Stepconf handles.

Trying to look at LinuxCNC as a whole...other than giving the user a minor ability to toggle/relay sent warning sounds and events, I think that UI should also be hardware abstracted, and so hardware dependent things, perhaps things such as the parallel-port to HAL connection settings should not be on a "Machine" menu.

Though, I am trying to consider the other settings in the .ini. What if the user wants to fine tune the acceleration? Or change the steps per-unit for microstepping? Or have that one metric job? Or what if their spindle is not modbus, and they want to change perhaps not their PWM settings, but their spindle speed settings?

Stepconf has a good overall design. I think that it is a valuable feature, an asset for LinuxCNC. I feel that it's powerful, in that it affects both the HAL and the .INI. Settings. It has and likely is beneficial that it works with all LinuxCNC UI's.

Of course, I cannot look at Stepconf or the Machine settings without looking at the .INI. I like that the .INI is human readable and editable. I am unconvinced as it's structure. As someone with a quite custom setup, I feel that the preservation of comments and their proximity to their relate statements is important. Perhaps a 2D file such an XML-like file would better serve for a go-between for UI settings, though I am not in favor of anything not human editable with a text editor.

Looking at Stepconf--Are its changes generally surgical enough?

If a new UI is created, will it even be supported by Stepconf?

Could things like axis settings be represented generic enough (To fit in LinuxCNC's ideals) to be represented/changed from inside the GUI, like other programs?

Odddly, there appears to be almost enough room for the more generic controls. Perhaps more can be eliminated by virtual to their machine dependence.

I am conducting an experiment with the Machine menu, to see, if machine adjustments might be made from within the UI, things such as axis acceleration, steps--some but not all of the things that Stepconf handles.

Trying to look at LinuxCNC as a whole...other than giving the user a minor ability to toggle/relay sent warning sounds and events, I think that UI should also be hardware abstracted, and so hardware dependent things, perhaps things such as the parallel-port to HAL connection settings should not be on a "Machine" menu.

Though, I am trying to consider the other settings in the .ini. What if the user wants to fine tune the acceleration? Or change the steps per-unit for microstepping? Or have that one metric job? Or what if their spindle is not modbus, and they want to change perhaps not their PWM settings, but their spindle speed settings?

Stepconf has a good overall design. I think that it is a valuable feature, an asset for LinuxCNC. I feel that it's powerful, in that it affects both the HAL and the .INI. Settings. It has and likely is beneficial that it works with all LinuxCNC UI's.

Of course, I cannot look at Stepconf or the Machine settings without looking at the .INI. I like that the .INI is human readable and editable. I am unconvinced as it's structure. As someone with a quite custom setup, I feel that the preservation of comments and their proximity to their relate statements is important. Perhaps a 2D file such an XML-like file would better serve for a go-between for UI settings, though I am not in favor of anything not human editable with a text editor.

Looking at Stepconf--Are its changes generally surgical enough?

If a new UI is created, will it even be supported by Stepconf?

Could things like axis settings be represented generic enough (To fit in LinuxCNC's ideals) to be represented/changed from inside the GUI, like other programs?

Odddly, there appears to be almost enough room for the more generic controls. Perhaps more can be eliminated by virtual to their machine dependence.

Last edit: 17 Jul 2018 20:33 by BrendaEM.

The following user(s) said Thank You: KCJ

Please Log in or Create an account to join the conversation.

- KCJ

-

- Offline

- Platinum Member

-

Less

More

- Posts: 328

- Thank you received: 267

17 Jul 2018 20:24 - 17 Jul 2018 20:25 #114413

by KCJ

Replied by KCJ on topic A Widescreen Blender-Style Interface

stepconf and pncconf already use XML files ...

The reason changes in the INI and HAL files are not preserved is that stepconf and pncconf read from the XML file instead of the HAL and INI files. It would be impossible to recreate a machine config to load into the wizards by reading the HAL and INI files, as they don't contain enough info.

It is possible to change some of the INI settings "on the fly" using the calibration tool. It sets the HAL values and can rewrite the INI file (preserving comments). I agree it would be nice to expand that to support more settings, but I am not sure how many settings can be changed on the fly, since LCNC only reads the INI on start up.

Cheers,

Kurt

The reason changes in the INI and HAL files are not preserved is that stepconf and pncconf read from the XML file instead of the HAL and INI files. It would be impossible to recreate a machine config to load into the wizards by reading the HAL and INI files, as they don't contain enough info.

It is possible to change some of the INI settings "on the fly" using the calibration tool. It sets the HAL values and can rewrite the INI file (preserving comments). I agree it would be nice to expand that to support more settings, but I am not sure how many settings can be changed on the fly, since LCNC only reads the INI on start up.

Cheers,

Kurt

Last edit: 17 Jul 2018 20:25 by KCJ. Reason: Fix Typos

The following user(s) said Thank You: BrendaEM

Please Log in or Create an account to join the conversation.

- BrendaEM

- Offline

- Elite Member

-

Less

More

- Posts: 266

- Thank you received: 120

17 Jul 2018 20:51 - 17 Jul 2018 20:58 #114415

by BrendaEM

Replied by BrendaEM on topic A Widescreen Blender-Style Interface

Thank you, Kurt.

I have used many programs that have to Save/Exit/Restart, so that alone might not discourage me from investigating. There is a line between the generic and the specific. Many of the current .ini settings would seem like attractive things to incorporate. Almost every setting in the .HAL would seem like settings to avoid setting including on the Machine menu.

LinuxCNC is a deep feature-rich system. Looking at the UI--what would be convenient for the user that's still universal?

I have used many programs that have to Save/Exit/Restart, so that alone might not discourage me from investigating. There is a line between the generic and the specific. Many of the current .ini settings would seem like attractive things to incorporate. Almost every setting in the .HAL would seem like settings to avoid setting including on the Machine menu.

LinuxCNC is a deep feature-rich system. Looking at the UI--what would be convenient for the user that's still universal?

Last edit: 17 Jul 2018 20:58 by BrendaEM.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19782

- Thank you received: 4604

17 Jul 2018 21:53 #114421

by andypugh

Most of these seem like one-time setup things, and are not really something that needs to be done more than once. It seems a waste of effort to put them in the GUI.

The exception is the one-off metric job, and that is already handled by the G20 / G21 commands. The GUI certainly need the ability to switch _displayed_ units, though. And it would be nice for the jog increments to switch.

(For info, LinuxCNC is internally metric, except for the Axis GUI which is internally Imperial)

Replied by andypugh on topic A Widescreen Blender-Style Interface

Though, I am trying to consider the other settings in the .ini. What if the user wants to fine tune the acceleration? Or change the steps per-unit for microstepping? Or have that one metric job?

Most of these seem like one-time setup things, and are not really something that needs to be done more than once. It seems a waste of effort to put them in the GUI.

The exception is the one-off metric job, and that is already handled by the G20 / G21 commands. The GUI certainly need the ability to switch _displayed_ units, though. And it would be nice for the jog increments to switch.

(For info, LinuxCNC is internally metric, except for the Axis GUI which is internally Imperial)

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11648

- Thank you received: 3919

18 Jul 2018 00:23 #114439

by rodw

I agree with the configuration being one off and should not be in a GUI. I'm not sure that its included in all branches of Linuxcnc but in the external offsets branch, there is a SIM_PIN function that you can add into your INI file to expose key tuning parameters of your choosing in a separate window that allows you to play with any tuning parameter on the fly. Very useful.

Please avoid the temptation of scope creep just because something sounds cool.

Replied by rodw on topic A Widescreen Blender-Style Interface

Shame on you Andy! In my world, there is nothing but metric. It took many years of pain to be able to think that way ..... but I now struggle with imperial units. I even had to buy a new set of metric feeler gauges to avoid thinking in thou's.The exception is the one-off metric job

I agree with the configuration being one off and should not be in a GUI. I'm not sure that its included in all branches of Linuxcnc but in the external offsets branch, there is a SIM_PIN function that you can add into your INI file to expose key tuning parameters of your choosing in a separate window that allows you to play with any tuning parameter on the fly. Very useful.

Please avoid the temptation of scope creep just because something sounds cool.

Please Log in or Create an account to join the conversation.

- BrendaEM

- Offline

- Elite Member

-

Less

More

- Posts: 266

- Thank you received: 120

18 Jul 2018 03:02 - 18 Jul 2018 03:12 #114440

by BrendaEM

Replied by BrendaEM on topic A Widescreen Blender-Style Interface

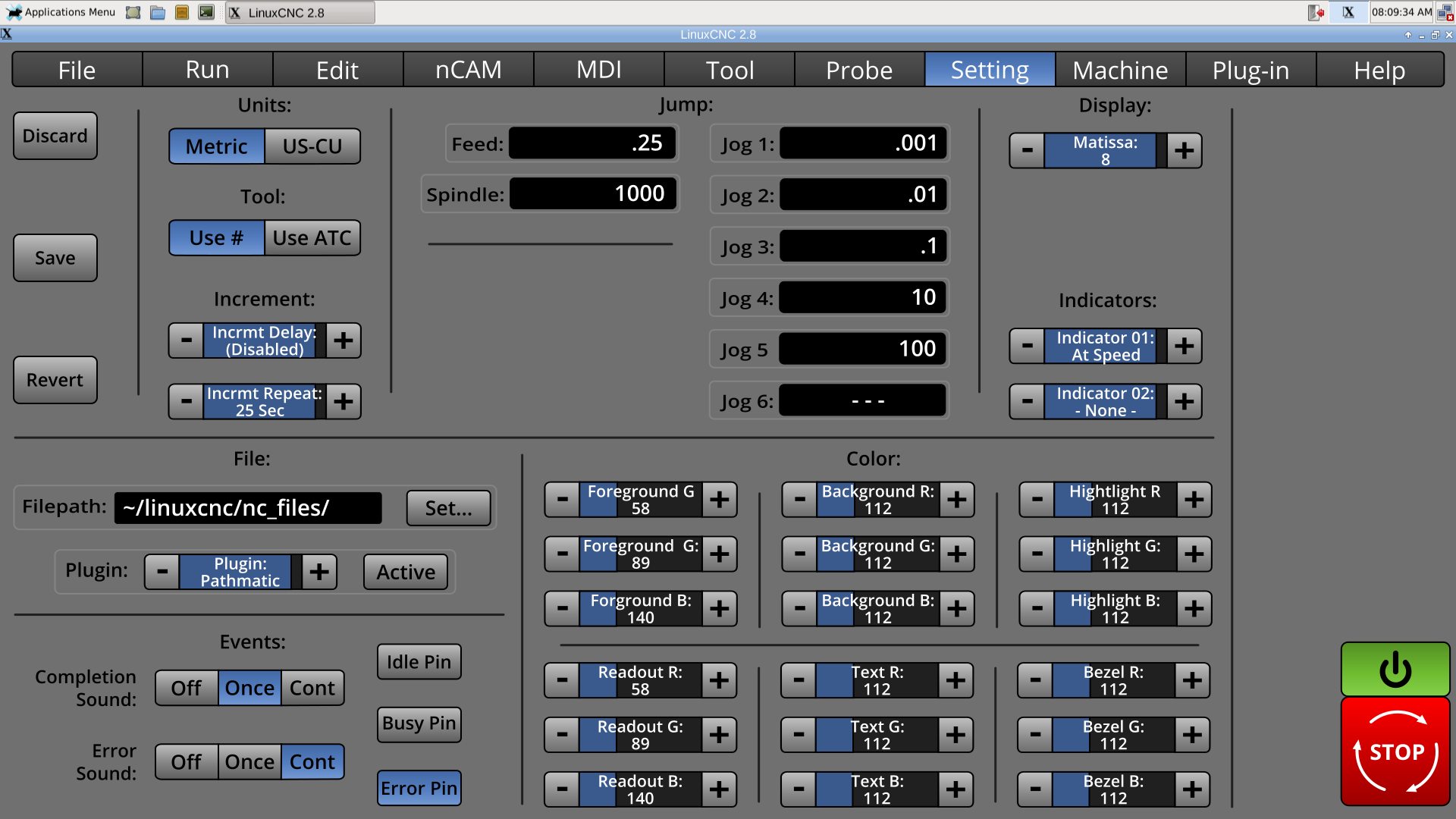

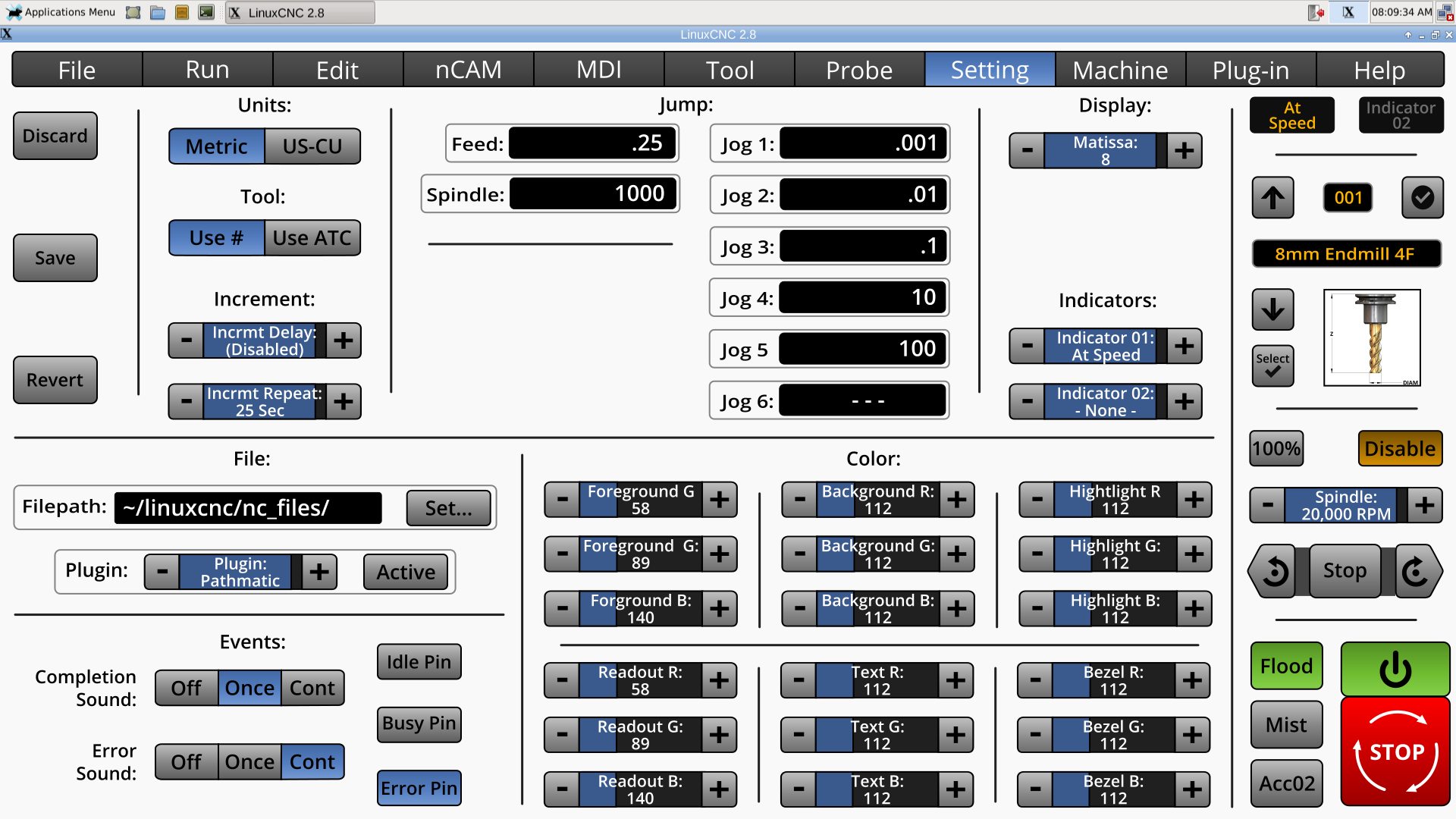

* Added Metric / US CU toggle to Setting menu.

Interesting that SAE, Imperial, English, are all wrong names for this crappy measuring system we too-often have here in the United States. en.wikipedia.org/wiki/United_States_customary_units

Oddly, I suspect that for most people the grid sizes and the Jump sizes could be the same. I had also included 9, perhaps 6 could do.

I reduced the color selector area, again.

For those who are curious, this is the interface with a white background. I think the standard colors, most of which were chosen by Blender3D are still a pretty good choice, but someone may have ones more to their liking. You just have to pretend that the color selectors for the background read 255, 255, 255 : )

Interesting that SAE, Imperial, English, are all wrong names for this crappy measuring system we too-often have here in the United States. en.wikipedia.org/wiki/United_States_customary_units

Oddly, I suspect that for most people the grid sizes and the Jump sizes could be the same. I had also included 9, perhaps 6 could do.

I reduced the color selector area, again.

For those who are curious, this is the interface with a white background. I think the standard colors, most of which were chosen by Blender3D are still a pretty good choice, but someone may have ones more to their liking. You just have to pretend that the color selectors for the background read 255, 255, 255 : )

Last edit: 18 Jul 2018 03:12 by BrendaEM.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19782

- Thank you received: 4604

18 Jul 2018 11:15 #114459

by andypugh

I was quoting BrendaEM. Personally I am almost entirely metric, it's what we learned at school and I did Physics at college.

But I was brought up by an Imperial engineer, so I _guess_ in Imperial. "Hmm, 1 thou interference sounds good, so for this 22mm shaft I will bore to 21.97mm..."

I also spend a lot of my time making parts for old vehicles ( 1921 Ner-a-Car , 1916 Fire Engine ) but for those I CAD in Imperial but produce drawings in metric. (I use Inventor, you can just type "1 5/8in" in the dimension box and get "41.275"

Replied by andypugh on topic A Widescreen Blender-Style Interface

Shame on you Andy! In my world, there is nothing but metric..The exception is the one-off metric job

I was quoting BrendaEM. Personally I am almost entirely metric, it's what we learned at school and I did Physics at college.

But I was brought up by an Imperial engineer, so I _guess_ in Imperial. "Hmm, 1 thou interference sounds good, so for this 22mm shaft I will bore to 21.97mm..."

I also spend a lot of my time making parts for old vehicles ( 1921 Ner-a-Car , 1916 Fire Engine ) but for those I CAD in Imperial but produce drawings in metric. (I use Inventor, you can just type "1 5/8in" in the dimension box and get "41.275"

Please Log in or Create an account to join the conversation.

- tommylight

-

- Online

- Moderator

-

Less

More

- Posts: 21184

- Thank you received: 7238

18 Jul 2018 12:19 #114463

by tommylight

Replied by tommylight on topic A Widescreen Blender-Style Interface

nonpartisaneducation.org/Review/Essays/v3n3.htm

And just to add some fun to it

I rest my case, thank you !

P.S.

There is also a report done by a Norwegian company some time ago estimating the cost to the US that had way to many zeros on it to remember as they went into detail, but i could not find it now.

And just to add some fun to it

I rest my case, thank you !

P.S.

There is also a report done by a Norwegian company some time ago estimating the cost to the US that had way to many zeros on it to remember as they went into detail, but i could not find it now.

Please Log in or Create an account to join the conversation.

Time to create page: 1.272 seconds