Mesa modbus and pktUart

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17718

- Thank you received: 5185

02 Sep 2023 00:33 #279633

by PCW

Replied by PCW on topic Mesa modbus and pktUart

Unless you cross compiled the mesa_modbus_AS_Driver.so on the X86 system,

it will not run on a ARM system

it will not run on a ARM system

Please Log in or Create an account to join the conversation.

- Donno

-

- Offline

- Premium Member

-

Less

More

- Posts: 137

- Thank you received: 17

02 Sep 2023 16:47 #279666

by Donno

Replied by Donno on topic Mesa modbus and pktUart

I downloaded Linuxcnc 2.9pre image for raspberry pi 4B and compiled linuxcnc-dev

I copied driver to another raspberry with linuxcnc2.9pre and copied driver to /usr/lib/linuxcnc/modules/mesa_modbus_A5_Driver.so

I now get the following error in linuxcnc

Any help PCW ?

git clone https://github.com/LinuxCNC/linuxcnc.git linuxcnc-dev

cd linuxcnc-dev/src

sudo apt install automake

./autogen.sh

sudo apt-get install libmodbus-dev

sudo apt-get install libusb-1.0-0-dev

sudo apt-get install yapps2

sudo apt-get install intltool

sudo apt-get install libboost

sudo apt install devscripts

sudo apt install dh-python libudev-dev tcl8.6-dev tk8.6-dev asciidoc dblatex

sudo apt install libreadline-gplv2-dev docbook-xsl dvipng ghostscript graphviz

sudo apt install groff imagemagick inkscape python-lxml source-highlight

sudo apt install texlive-extra-utils texlive-font-utils texlive-fonts-recommended

sudo apt install texlive-lang-cyrillic texlive-lang-french texlive-lang-german

sudo apt install texlive-lang-polish texlive-lang-spanish texlive-latex-recommended

sudo apt install w3c-linkchecker xsltproc python-dev python-tk libxmu-dev

sudo apt install libglu1-mesa-dev libgtk2.0-dev intltool libboost-python-dev

sudo apt install libmodbus-dev libusb-1.0-0-dev desktop-file-utils yapps2

sudo apt install python-yapps bwidget libtk-img mesa-utils tclx8.4

sudo apt install tcl-tclreadline python-configobj python-gtkglext1

sudo apt install python-xlib gstreamer0.10-plugins-base netcat

sudo apt install python-pil python-glade2 python-pil.imagetk

sudo apt install python-gst-1.0 w3c-linkchecker libxmu-dev libtirpc-dev

sudo apt install gdebi gdebi-core

sudo apt install libreadline-dev

sudo apt install libeditreadline-dev

sudo apt install libxmu-headers

sudo apt install libxmu-dev

./configure --with-realtime=uspace

make

sudo make setuid

source ../scripts/rip-environment

cd ~/linuxcnc-dev/bin

(edit modcompile to use ../src instead of src else it will not find makefile.modinc)

./modcompile mesa_modbus_A5_Driver.modI copied driver to another raspberry with linuxcnc2.9pre and copied driver to /usr/lib/linuxcnc/modules/mesa_modbus_A5_Driver.so

I now get the following error in linuxcnc

Debug file information:

Note: Using POSIX non-realtime

mesa_modbus_A5_Driver: dlopen: /usr/lib/linuxcnc/modules/mesa_modbus_A5_Driver.so: undefined symbol: hm2_pktuart_setup_rx

./Lathe_7i92T_0.hal:10: waitpid failed /usr/bin/rtapi_app mesa_modbus_A5_Driver

./Lathe_7i92T_0.hal:10: /usr/bin/rtapi_app exited without becoming ready

./Lathe_7i92T_0.hal:10: insmod for mesa_modbus_A5_Driver failed, returned -1

2759

Stopping realtime threads

Unloading hal components

Note: Using POSIX non-realtimeAny help PCW ?

Please Log in or Create an account to join the conversation.

- Donno

-

- Offline

- Premium Member

-

Less

More

- Posts: 137

- Thank you received: 17

02 Sep 2023 16:51 #279667

by Donno

Replied by Donno on topic Mesa modbus and pktUart

Driver :

// Lichuan A5 AC Servo Drive Driver

#define MAX_MSG_LEN 16 // may be increased if necessary to max 251

#define DEBUG 1

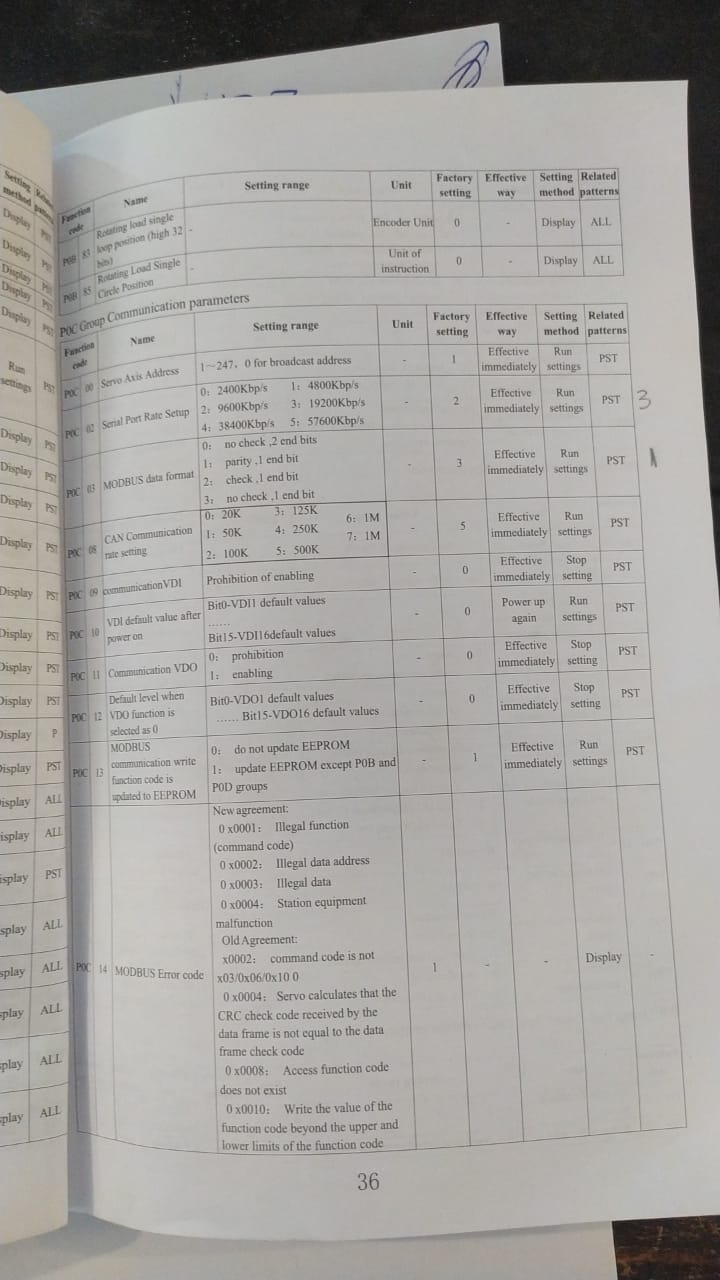

static const hm2_modbus_chan_descriptor_t channels[] = {

/* {TYPE, FUNC, ADDR, COUNT, pin_name} */

{HAL_U32, 3, 0x9C8, 1, "speed-actual"},

{HAL_U32, 3, 0x9C9, 1, "speed-instruction"},

{HAL_U32, 3, 0x9CA, 1, "torque-instruction"},

{HAL_U32, 3, 0x9D4, 1, "avg-load-rate"},

{HAL_U32, 3, 0x9E0, 1, "phase-current"},

{HAL_U32, 3, 0x9E2, 1, "bus-voltage"},

{HAL_U32, 3, 0x9E3, 1, "tempreture"},

{HAL_U32, 6, 0x4CB, 1, "set-speed"},

};Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17718

- Thank you received: 5185

02 Sep 2023 17:37 #279668

by PCW

Replied by PCW on topic Mesa modbus and pktUart

What is you loardrt line in your hal file?

Does your firmware have a pktuart?

Does your firmware have a pktuart?

Please Log in or Create an account to join the conversation.

- Donno

-

- Offline

- Premium Member

-

Less

More

- Posts: 137

- Thank you received: 17

02 Sep 2023 17:53 #279671

by Donno

Replied by Donno on topic Mesa modbus and pktUart

mesaflash --device 7i92T --addr 192.168.1.121 --readhmid

Hal File loadrt mesa_modbus_A5_Driver names=hm2_7i92.0.pktuart.0 and addf mesa_modbus_A5_Driver servo-thread

donno@linuxcnc:~/Desktop $ mesaflash --device 7i92T --addr 192.168.1.121 --readhmid

Configuration Name: HOSTMOT2

General configuration information:

BoardName : MESA7I92

FPGA Size: 20 KGates

FPGA Pins: 256

Number of IO Ports: 2

Width of one I/O port: 17

Clock Low frequency: 100.0000 MHz

Clock High frequency: 175.0000 MHz

IDROM Type: 3

Instance Stride 0: 4

Instance Stride 1: 64

Register Stride 0: 256

Register Stride 1: 256

Modules in configuration:

Module: DPLL

There are 1 of DPLL in configuration

Version: 0

Registers: 7

BaseAddress: 7000

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: WatchDog

There are 1 of WatchDog in configuration

Version: 0

Registers: 3

BaseAddress: 0C00

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: IOPort

There are 2 of IOPort in configuration

Version: 0

Registers: 5

BaseAddress: 1000

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: QCount

There are 2 of QCount in configuration

Version: 2

Registers: 5

BaseAddress: 3000

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: StepGen

There are 10 of StepGen in configuration

Version: 2

Registers: 10

BaseAddress: 2000

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: PWM

There are 2 of PWM in configuration

Version: 0

Registers: 5

BaseAddress: 4100

ClockFrequency: 175.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: LED

There are 1 of LED in configuration

Version: 0

Registers: 1

BaseAddress: 0200

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: PktUARTTX

There are 1 of PktUARTTX in configuration

Version: 0

Registers: 4

BaseAddress: 6100

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: PktUARTRX

There are 1 of PktUARTRX in configuration

Version: 0

Registers: 4

BaseAddress: 6500

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Configuration pin-out:

IO Connections for P2

DB25 pin# I/O Pri. func Sec. func Chan Sec. Pin func Sec. Pin Dir

1 0 IOPort PWM 0 PWM (Out)

14 1 IOPort StepGen 0 Step/Table1 (Out)

2 2 IOPort StepGen 0 Dir/Table2 (Out)

15 3 IOPort StepGen 1 Step/Table1 (Out)

3 4 IOPort StepGen 1 Dir/Table2 (Out)

16 5 IOPort None

4 6 IOPort None

17 7 IOPort None

5 8 IOPort None

6 9 IOPort QCount 0 Quad-A (In)

7 10 IOPort QCount 0 Quad-B (In)

8 11 IOPort QCount 0 Quad-IDX (In)

9 12 IOPort None

10 13 IOPort None

11 14 IOPort None

12 15 IOPort None

13 16 IOPort None

IO Connections for P1

DB25 pin# I/O Pri. func Sec. func Chan Sec. Pin func Sec. Pin Dir

1 17 IOPort PktUARTRX 0 RXData (In)

14 18 IOPort PktUARTTX 0 TXData (Out)

2 19 IOPort PktUARTTX 0 TXEna (Out)

15 20 IOPort None

3 21 IOPort None

16 22 IOPort None

4 23 IOPort None

17 24 IOPort None

5 25 IOPort None

6 26 IOPort None

7 27 IOPort None

8 28 IOPort None

9 29 IOPort None

10 30 IOPort None

11 31 IOPort None

12 32 IOPort None

13 33 IOPort None Hal File loadrt mesa_modbus_A5_Driver names=hm2_7i92.0.pktuart.0 and addf mesa_modbus_A5_Driver servo-thread

# Generated by PNCconf at Mon Aug 28 20:19:10 2023

# Using LinuxCNC version: Master (2.9)

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

loadrt [KINS]KINEMATICS

loadrt [EMCMOT]EMCMOT servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[KINS]JOINTS

loadrt hostmot2

loadrt hm2_eth board_ip="192.168.1.121" config="num_encoders=1 num_pwmgens=0 num_stepgens=2"

loadrt mesa_modbus_A5_Driver names=hm2_7i92.0.pktuart.0

setp hm2_7i92.0.watchdog.timeout_ns 5000000

loadrt pid names=pid.x,pid.z,pid.s

loadrt abs names=abs.spindle

loadrt lowpass names=lowpass.spindle

loadrt scale names=scale.spindle

loadrt near

addf hm2_7i92.0.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf pid.x.do-pid-calcs servo-thread

addf pid.z.do-pid-calcs servo-thread

addf pid.s.do-pid-calcs servo-thread

addf scale.spindle servo-thread

addf abs.spindle servo-thread

addf lowpass.spindle servo-thread

addf near.0 servo-thread

addf hm2_7i92.0.write servo-thread

addf mesa_modbus_A5_Driver servo-thread

setp hm2_7i92.0.dpll.01.timer-us -50

setp hm2_7i92.0.stepgen.timer-number 1

# external output signals

# --- DOUT-00 ---

setp hm2_7i92.0.gpio.000.is_output true

net dout-00 => hm2_7i92.0.gpio.000.out

# --- SPINDLE-ENABLE ---

setp hm2_7i92.0.gpio.005.is_output true

net spindle-enable => hm2_7i92.0.gpio.005.out

# --- SPINDLE-CW ---

setp hm2_7i92.0.gpio.006.is_output true

net spindle-cw => hm2_7i92.0.gpio.006.out

# --- SPINDLE-CCW ---

setp hm2_7i92.0.gpio.007.is_output true

net spindle-ccw => hm2_7i92.0.gpio.007.out

# --- COOLANT-MIST ---

setp hm2_7i92.0.gpio.008.is_output true

net coolant-mist => hm2_7i92.0.gpio.008.out

# --- DOUT-01 ---

setp hm2_7i92.0.gpio.013.is_output true

net dout-01 => hm2_7i92.0.gpio.013.out

# --- DOUT-02 ---

setp hm2_7i92.0.gpio.015.is_output true

net dout-02 => hm2_7i92.0.gpio.015.out

# --- DOUT-03 ---

setp hm2_7i92.0.gpio.016.is_output true

net dout-03 => hm2_7i92.0.gpio.016.out

# --- ESTOP-OUT ---

setp hm2_7i92.0.gpio.030.is_output true

net estop-out => hm2_7i92.0.gpio.030.out

# --- MACHINE-IS-ENABLED ---

setp hm2_7i92.0.gpio.032.is_output true

net machine-is-enabled => hm2_7i92.0.gpio.032.out

# --- SPINDLE-ENABLE ---

setp hm2_7i92.0.gpio.033.is_output true

net spindle-enable => hm2_7i92.0.gpio.033.out

# external input signals

# --- HOME-X ---

net home-x <= hm2_7i92.0.gpio.012.in

# --- HOME-Z ---

net home-z <= hm2_7i92.0.gpio.014.in

# --- DIN-00 ---

net din-00 <= hm2_7i92.0.gpio.019.in

# --- DIN-01 ---

net din-01 <= hm2_7i92.0.gpio.020.in

# --- DIN-02 ---

net din-02 <= hm2_7i92.0.gpio.021.in

# --- DIN-03 ---

net din-03 <= hm2_7i92.0.gpio.022.in

# --- ESTOP-EXT ---

net estop-ext <= hm2_7i92.0.gpio.023.in

# --- PROBE-IN ---

net probe-in <= hm2_7i92.0.gpio.024.in

#*******************

# AXIS X JOINT 0

#*******************

setp pid.x.Pgain [JOINT_0]P

setp pid.x.Igain [JOINT_0]I

setp pid.x.Dgain [JOINT_0]D

setp pid.x.bias [JOINT_0]BIAS

setp pid.x.FF0 [JOINT_0]FF0

setp pid.x.FF1 [JOINT_0]FF1

setp pid.x.FF2 [JOINT_0]FF2

setp pid.x.deadband [JOINT_0]DEADBAND

setp pid.x.maxoutput [JOINT_0]MAX_OUTPUT

setp pid.x.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.x.maxerror 0.012700

net x-index-enable => pid.x.index-enable

net x-enable => pid.x.enable

net x-pos-cmd => pid.x.command

net x-pos-fb => pid.x.feedback

net x-output <= pid.x.output

# Step Gen signals/setup

setp hm2_7i92.0.stepgen.00.dirsetup [JOINT_0]DIRSETUP

setp hm2_7i92.0.stepgen.00.dirhold [JOINT_0]DIRHOLD

setp hm2_7i92.0.stepgen.00.steplen [JOINT_0]STEPLEN

setp hm2_7i92.0.stepgen.00.stepspace [JOINT_0]STEPSPACE

setp hm2_7i92.0.stepgen.00.position-scale [JOINT_0]STEP_SCALE

setp hm2_7i92.0.stepgen.00.step_type 0

setp hm2_7i92.0.stepgen.00.control-type 1

setp hm2_7i92.0.stepgen.00.maxaccel [JOINT_0]STEPGEN_MAXACCEL

setp hm2_7i92.0.stepgen.00.maxvel [JOINT_0]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net x-pos-cmd <= joint.0.motor-pos-cmd

net x-vel-cmd <= joint.0.vel-cmd

net x-output => hm2_7i92.0.stepgen.00.velocity-cmd

net x-pos-fb <= hm2_7i92.0.stepgen.00.position-fb

net x-pos-fb => joint.0.motor-pos-fb

net x-enable <= joint.0.amp-enable-out

net x-enable => hm2_7i92.0.stepgen.00.enable

# ---setup home / limit switch signals---

net home-x => joint.0.home-sw-in

net x-neg-limit => joint.0.neg-lim-sw-in

net x-pos-limit => joint.0.pos-lim-sw-in

#*******************

# AXIS Z JOINT 1

#*******************

setp pid.z.Pgain [JOINT_1]P

setp pid.z.Igain [JOINT_1]I

setp pid.z.Dgain [JOINT_1]D

setp pid.z.bias [JOINT_1]BIAS

setp pid.z.FF0 [JOINT_1]FF0

setp pid.z.FF1 [JOINT_1]FF1

setp pid.z.FF2 [JOINT_1]FF2

setp pid.z.deadband [JOINT_1]DEADBAND

setp pid.z.maxoutput [JOINT_1]MAX_OUTPUT

setp pid.z.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.z.maxerror 0.012700

net z-index-enable => pid.z.index-enable

net z-enable => pid.z.enable

net z-pos-cmd => pid.z.command

net z-pos-fb => pid.z.feedback

net z-output <= pid.z.output

# Step Gen signals/setup

setp hm2_7i92.0.stepgen.01.dirsetup [JOINT_1]DIRSETUP

setp hm2_7i92.0.stepgen.01.dirhold [JOINT_1]DIRHOLD

setp hm2_7i92.0.stepgen.01.steplen [JOINT_1]STEPLEN

setp hm2_7i92.0.stepgen.01.stepspace [JOINT_1]STEPSPACE

setp hm2_7i92.0.stepgen.01.position-scale [JOINT_1]STEP_SCALE

setp hm2_7i92.0.stepgen.01.step_type 0

setp hm2_7i92.0.stepgen.01.control-type 1

setp hm2_7i92.0.stepgen.01.maxaccel [JOINT_1]STEPGEN_MAXACCEL

setp hm2_7i92.0.stepgen.01.maxvel [JOINT_1]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net z-pos-cmd <= joint.1.motor-pos-cmd

net z-vel-cmd <= joint.1.vel-cmd

net z-output => hm2_7i92.0.stepgen.01.velocity-cmd

net z-pos-fb <= hm2_7i92.0.stepgen.01.position-fb

net z-pos-fb => joint.1.motor-pos-fb

net z-enable <= joint.1.amp-enable-out

net z-enable => hm2_7i92.0.stepgen.01.enable

# ---setup home / limit switch signals---

net home-z => joint.1.home-sw-in

net z-neg-limit => joint.1.neg-lim-sw-in

net z-pos-limit => joint.1.pos-lim-sw-in

#*******************

# SPINDLE

#*******************

setp pid.s.Pgain [SPINDLE_0]P

setp pid.s.Igain [SPINDLE_0]I

setp pid.s.Dgain [SPINDLE_0]D

setp pid.s.bias [SPINDLE_0]BIAS

setp pid.s.FF0 [SPINDLE_0]FF0

setp pid.s.FF1 [SPINDLE_0]FF1

setp pid.s.FF2 [SPINDLE_0]FF2

setp pid.s.deadband [SPINDLE_0]DEADBAND

setp pid.s.maxoutput [SPINDLE_0]MAX_OUTPUT

setp pid.s.error-previous-target true

net spindle-index-enable => pid.s.index-enable

net spindle-enable => pid.s.enable

net spindle-vel-cmd-rpm-abs => pid.s.command

net spindle-vel-fb-rpm-abs => pid.s.feedback

net spindle-output <= pid.s.output

# ---Encoder feedback signals/setup---

setp hm2_7i92.0.encoder.00.counter-mode 0

setp hm2_7i92.0.encoder.00.filter 1

setp hm2_7i92.0.encoder.00.index-invert 0

setp hm2_7i92.0.encoder.00.index-mask 0

setp hm2_7i92.0.encoder.00.index-mask-invert 0

setp hm2_7i92.0.encoder.00.scale [SPINDLE_0]ENCODER_SCALE

net spindle-revs <= hm2_7i92.0.encoder.00.position

net spindle-vel-fb-rps <= hm2_7i92.0.encoder.00.velocity

net spindle-vel-fb-rpm <= hm2_7i92.0.encoder.00.velocity-rpm

net spindle-index-enable <=> hm2_7i92.0.encoder.00.index-enable

# ---setup spindle control signals---

net spindle-vel-cmd-rps <= spindle.0.speed-out-rps

net spindle-vel-cmd-rps-abs <= spindle.0.speed-out-rps-abs

net spindle-vel-cmd-rpm <= spindle.0.speed-out

net spindle-vel-cmd-rpm-abs <= spindle.0.speed-out-abs

net spindle-enable <= spindle.0.on

net spindle-cw <= spindle.0.forward

net spindle-ccw <= spindle.0.reverse

net spindle-brake <= spindle.0.brake

net spindle-revs => spindle.0.revs

net spindle-at-speed => spindle.0.at-speed

net spindle-vel-fb-rps => spindle.0.speed-in

net spindle-index-enable <=> spindle.0.index-enable

# ---Setup spindle at speed signals---

net spindle-vel-cmd-rps => near.0.in1

net spindle-vel-fb-rps => near.0.in2

net spindle-at-speed <= near.0.out

setp near.0.scale 1.000000

setp near.0.difference 0.166667

# Use ACTUAL spindle velocity from spindle encoder

# spindle-velocity bounces around so we filter it with lowpass

# spindle-velocity is signed so we use absolute component to remove sign

# ACTUAL velocity is in RPS not RPM so we scale it.

setp scale.spindle.gain 60

setp lowpass.spindle.gain 1.000000

net spindle-vel-fb-rps => scale.spindle.in

net spindle-fb-rpm scale.spindle.out => abs.spindle.in

net spindle-fb-rpm-abs abs.spindle.out => lowpass.spindle.in

net spindle-fb-rpm-abs-filtered lowpass.spindle.out

#******************************

# connect miscellaneous signals

#******************************

# ---HALUI signals---

net axis-select-x halui.axis.x.select

net jog-x-pos halui.axis.x.plus

net jog-x-neg halui.axis.x.minus

net jog-x-analog halui.axis.x.analog

net x-is-homed halui.joint.0.is-homed

net axis-select-z halui.axis.z.select

net jog-z-pos halui.axis.z.plus

net jog-z-neg halui.axis.z.minus

net jog-z-analog halui.axis.z.analog

net z-is-homed halui.joint.1.is-homed

net jog-selected-pos halui.axis.selected.plus

net jog-selected-neg halui.axis.selected.minus

net spindle-manual-cw halui.spindle.0.forward

net spindle-manual-ccw halui.spindle.0.reverse

net spindle-manual-stop halui.spindle.0.stop

net machine-is-on halui.machine.is-on

net jog-speed halui.axis.jog-speed

net MDI-mode halui.mode.is-mdi

# ---coolant signals---

net coolant-mist <= iocontrol.0.coolant-mist

net coolant-flood <= iocontrol.0.coolant-flood

# ---probe signal---

net probe-in => motion.probe-input

# ---motion control signals---

net in-position <= motion.in-position

net machine-is-enabled <= motion.motion-enabled

# ---digital in / out signals---

net dout-00 <= motion.digital-out-00

net dout-01 <= motion.digital-out-01

net dout-02 <= motion.digital-out-02

net dout-03 <= motion.digital-out-03

net din-00 => motion.digital-in-00

net din-01 => motion.digital-in-01

net din-02 => motion.digital-in-02

net din-03 => motion.digital-in-03

# ---estop signals---

net estop-out <= iocontrol.0.user-enable-out

net estop-ext => iocontrol.0.emc-enable-in

# ---manual tool change signals---

net tool-change-request <= iocontrol.0.tool-change

net tool-change-confirmed => iocontrol.0.tool-changed

net tool-number <= iocontrol.0.tool-prep-number

# ---Use external manual tool change dialog---

loadusr -W hal_manualtoolchange

net tool-change-request => hal_manualtoolchange.change

net tool-change-confirmed <= hal_manualtoolchange.changed

net tool-number => hal_manualtoolchange.number

# ---ignore tool prepare requests---

net tool-prepare-loopback iocontrol.0.tool-prepare => iocontrol.0.tool-preparedPlease Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17718

- Thank you received: 5185

02 Sep 2023 18:20 - 02 Sep 2023 18:33 #279673

by PCW

Replied by PCW on topic Mesa modbus and pktUart

Don't know, maybe some difference in the build and run systems.

Also the loadrt line should have "ports" instead of "names"

I was able to launch your configuration here without error

(I shortened the name to lichuan)

halcmd: loadrt lichuan ports=hm2_7i96s.0.pktuart.0

halcmd: addf lichuan.00 servo-thread

halcmd:

Also the loadrt line should have "ports" instead of "names"

I was able to launch your configuration here without error

(I shortened the name to lichuan)

halcmd: loadrt lichuan ports=hm2_7i96s.0.pktuart.0

halcmd: addf lichuan.00 servo-thread

halcmd:

Last edit: 02 Sep 2023 18:33 by PCW.

Please Log in or Create an account to join the conversation.

- Donno

-

- Offline

- Premium Member

-

Less

More

- Posts: 137

- Thank you received: 17

03 Sep 2023 08:25 #279701

by Donno

Replied by Donno on topic Mesa modbus and pktUart

Thanks for showing me the mistake:

halcmd: loadrt lichuan ports=hm2_7i96s.0.pktuart.0

halcmd: addf lichuan.00 servo-thread

I manage to find the hm2_pktuart_setup_rx -> hostmot2-serial.h i then copied hostmot2.so from linuxcnc-dev/rtlib to /usr/lib/linuxcnc/modules it then through error about hm2_eth so i did the same with hm2_eth.so

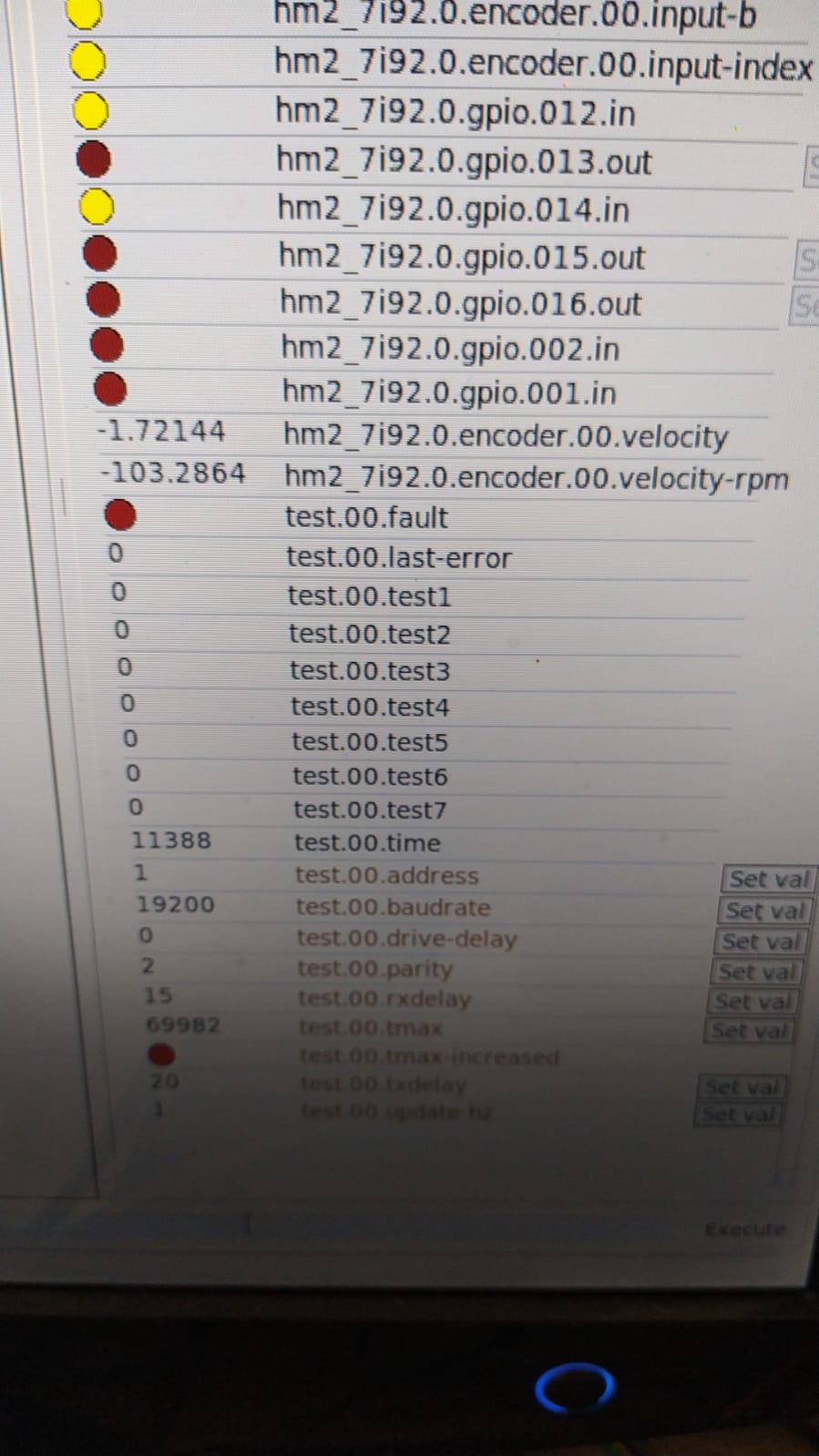

I manage to load linuxcnc and found my driver under Pins in HALSHOW will try to get communication going

halcmd: loadrt lichuan ports=hm2_7i96s.0.pktuart.0

halcmd: addf lichuan.00 servo-thread

I manage to find the hm2_pktuart_setup_rx -> hostmot2-serial.h i then copied hostmot2.so from linuxcnc-dev/rtlib to /usr/lib/linuxcnc/modules it then through error about hm2_eth so i did the same with hm2_eth.so

I manage to load linuxcnc and found my driver under Pins in HALSHOW will try to get communication going

Please Log in or Create an account to join the conversation.

- Donno

-

- Offline

- Premium Member

-

Less

More

- Posts: 137

- Thank you received: 17

03 Sep 2023 10:40 #279709

by Donno

Replied by Donno on topic Mesa modbus and pktUart

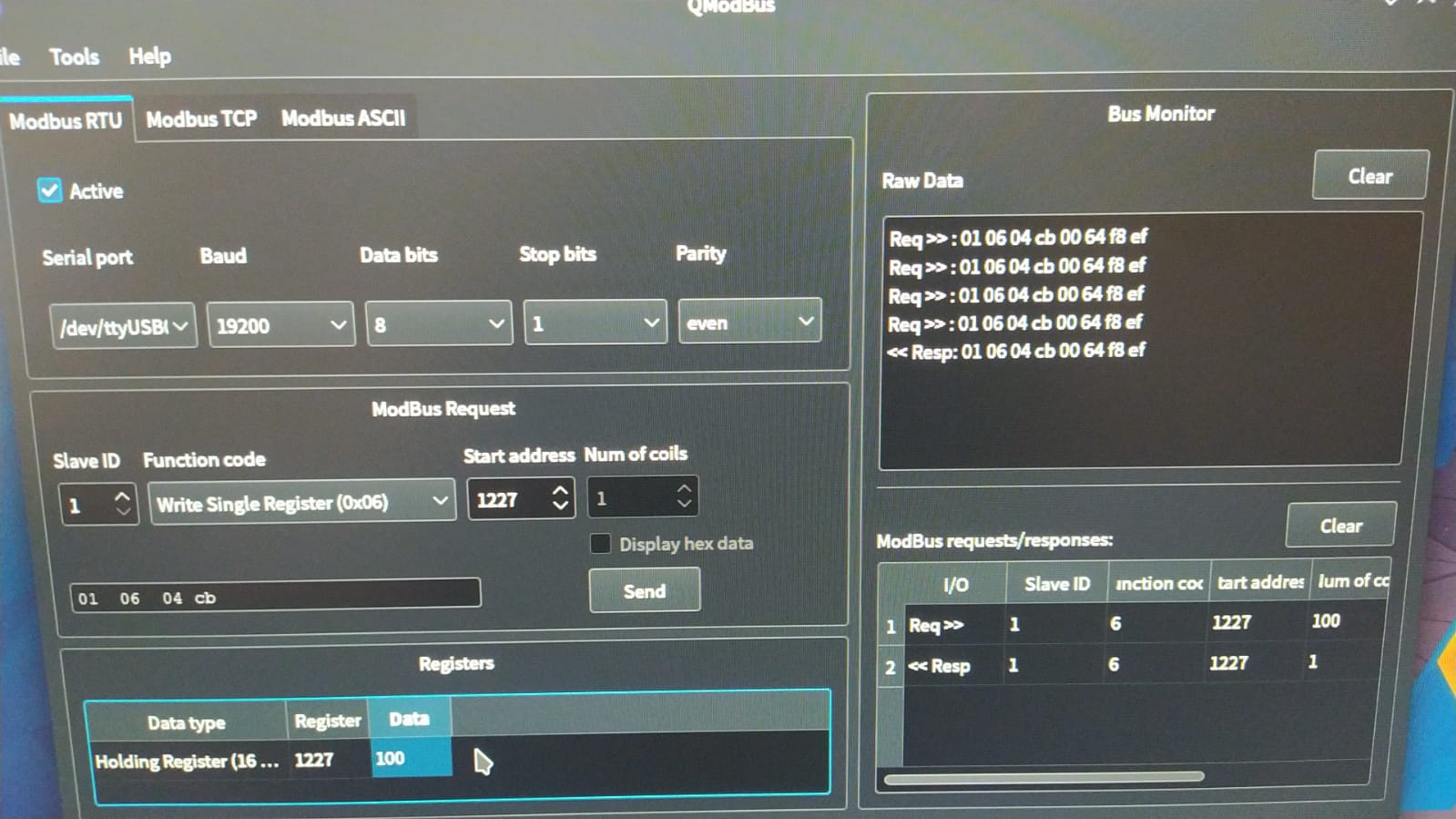

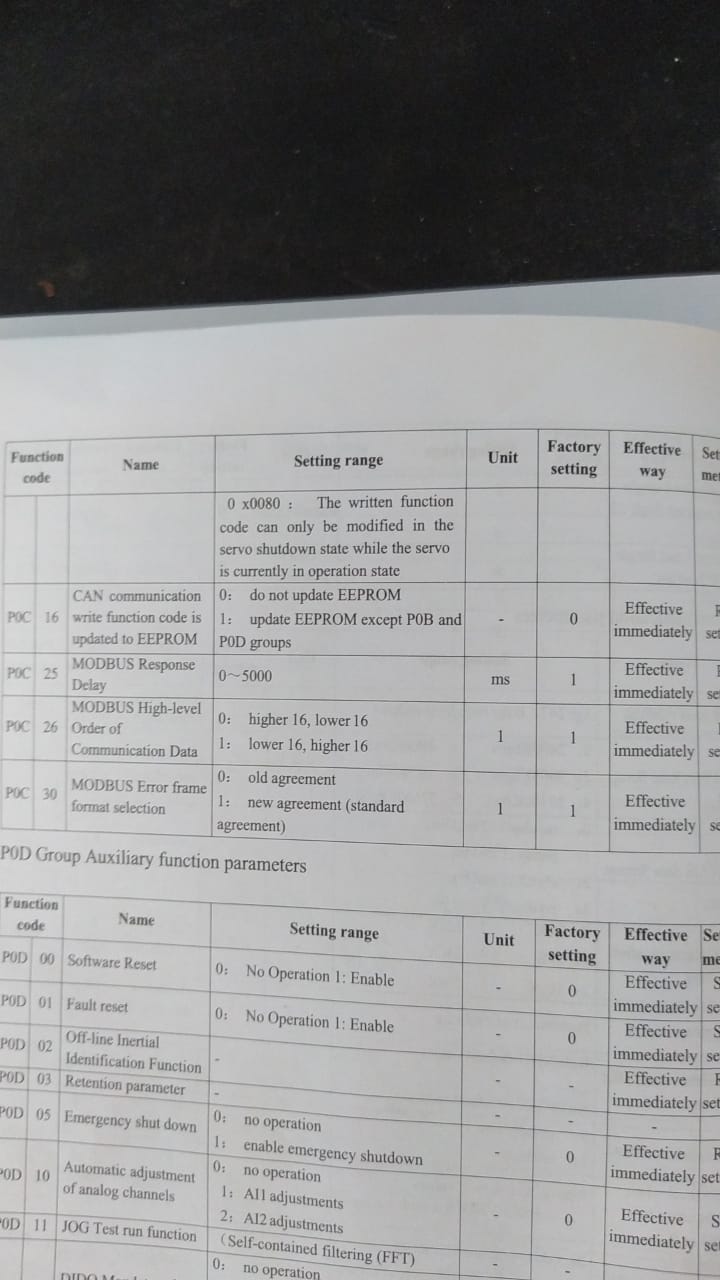

Attachments:

Please Log in or Create an account to join the conversation.

- Donno

-

- Offline

- Premium Member

-

Less

More

- Posts: 137

- Thank you received: 17

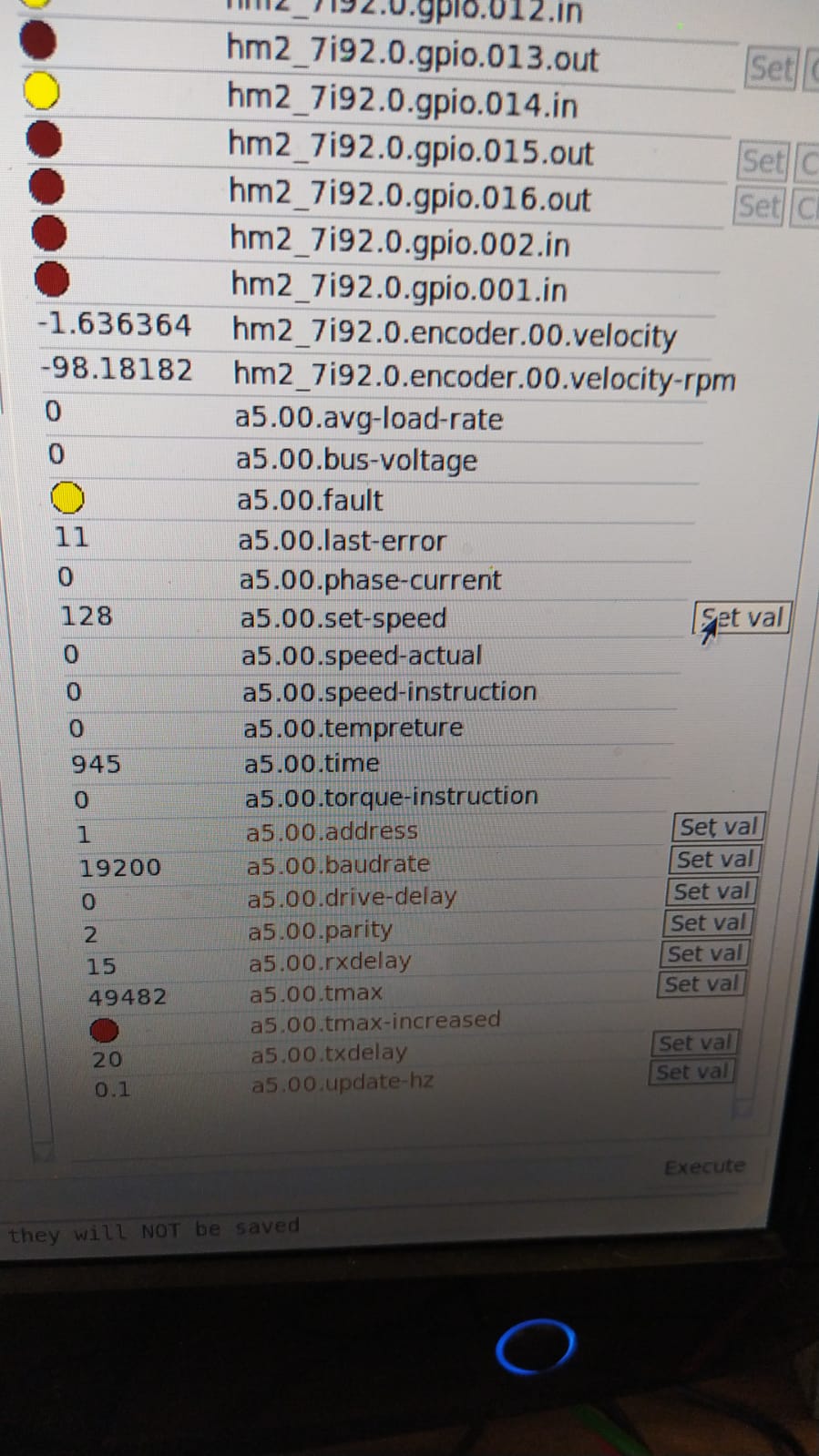

04 Sep 2023 10:33 #279811

by Donno

Replied by Donno on topic Mesa modbus and pktUart

Attachments:

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17718

- Thank you received: 5185

04 Sep 2023 14:45 #279834

by PCW

Replied by PCW on topic Mesa modbus and pktUart

1. Do you have the RS-485 bias resistors added as shown earlier in this thread?

2. You might try enabling debug (=3) to see whats going on (and post the results here)

2. You might try enabling debug (=3) to see whats going on (and post the results here)

Please Log in or Create an account to join the conversation.

Time to create page: 0.240 seconds