THC config that works.

- kpj10

- Offline

- Junior Member

-

Less

More

- Posts: 30

- Thank you received: 1

28 Oct 2017 18:15 #100948

by kpj10

Replied by kpj10 on topic THC config that works.

Dear Tom,

How can i reduce the default speed of Z axis it's running quite fast, when I start the F9 procedure. Changes to default and max velocity of ini didn't help.

How can i reduce the default speed of Z axis it's running quite fast, when I start the F9 procedure. Changes to default and max velocity of ini didn't help.

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2345

02 Jan 2018 20:16 - 02 Jan 2018 20:19 #103964

by Grotius

Replied by Grotius on topic THC config that works.

I was looking at the source code for this THC software. The Hal section looks very difficult. Does anyone know

the basic signal (kind of signal (problably a float, and how to use this) to let the z-axis move up and down?

So that i can try a simple thing from beginning to let the z-axis go up for example. My goal is to integrate a simple THC into stand alone application. I have a complete working setup to test this.

Therefor i use glade and pyton. What i can do to start with is use the complete code and integrate it with the glade user interface and pyton into my application. But that is not what i really like to do.

Here some item's from the hal section :

loadrt updown

setp oneshot.3.falling 1

setp oneshot.3.rising 0

net PosZ-cmd mux2.4.out => stepgen.2.position-cmd comp.1.in1

net PosZ-fb stepgen.2.position-fb => joint.2.motor-pos-fb mux2.2.in1 comp.1.in0

net MoveDown parport.0.pin-12-in-not => or2.0.in0

net MoveUp parport.0.pin-11-in-not => or2.0.in1 mux2.1.sel

If this is working, i want to make a Hypertherm 45xp with modbuss configuration. I have this machine already in my shop to test.

Thank you, Michel

the basic signal (kind of signal (problably a float, and how to use this) to let the z-axis move up and down?

So that i can try a simple thing from beginning to let the z-axis go up for example. My goal is to integrate a simple THC into stand alone application. I have a complete working setup to test this.

Therefor i use glade and pyton. What i can do to start with is use the complete code and integrate it with the glade user interface and pyton into my application. But that is not what i really like to do.

Here some item's from the hal section :

loadrt updown

setp oneshot.3.falling 1

setp oneshot.3.rising 0

net PosZ-cmd mux2.4.out => stepgen.2.position-cmd comp.1.in1

net PosZ-fb stepgen.2.position-fb => joint.2.motor-pos-fb mux2.2.in1 comp.1.in0

net MoveDown parport.0.pin-12-in-not => or2.0.in0

net MoveUp parport.0.pin-11-in-not => or2.0.in1 mux2.1.sel

If this is working, i want to make a Hypertherm 45xp with modbuss configuration. I have this machine already in my shop to test.

Thank you, Michel

Last edit: 02 Jan 2018 20:19 by Grotius.

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2345

03 Jan 2018 00:07 - 03 Jan 2018 00:07 #103970

by Grotius

Replied by Grotius on topic THC config that works.

Hi,

I have integrated the full code and i have a little error code :

joint 2 following error emc/task/taskintf.cc 617: Error on axis 2, command number 243

I have tried to lower speeds, etc. Also i had a z-limit error, so deactived this limit switch.

Its strange. In the plasma program the z-axis is moving about 0.5mm and then error.

Also my jog buttons don't work even my e-stop led's don't work. Only mdi homing buttons are working good.

So it looks like the code is manupulating more then the z-axis. because it is separated from the python code.

I have integrated the full code and i have a little error code :

joint 2 following error emc/task/taskintf.cc 617: Error on axis 2, command number 243

I have tried to lower speeds, etc. Also i had a z-limit error, so deactived this limit switch.

Its strange. In the plasma program the z-axis is moving about 0.5mm and then error.

Also my jog buttons don't work even my e-stop led's don't work. Only mdi homing buttons are working good.

So it looks like the code is manupulating more then the z-axis. because it is separated from the python code.

Last edit: 03 Jan 2018 00:07 by Grotius.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11615

- Thank you received: 3908

03 Jan 2018 08:02 #103983

by rodw

Replied by rodw on topic THC config that works.

Can you post your hal and ini files?

Following errors can be due to incorrectly configured settings in your ini file. (Joint 2 is your Z axis right?)

Its amazing what a determined mind can achieve when at first thought it is very difficult

Following errors can be due to incorrectly configured settings in your ini file. (Joint 2 is your Z axis right?)

Its amazing what a determined mind can achieve when at first thought it is very difficult

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2345

03 Jan 2018 15:38 - 03 Jan 2018 16:00 #103992

by Grotius

Replied by Grotius on topic THC config that works.

Hi Rodw,

You are right again. The motor adjustment in the ini file was the problem of getting out of joint position.

I did a 24 hour non stop LinuxCNC study to get the THC working.

And finally it works very good. I solved the issue with off course with the information of John Thornton.

I tried this configuration thcud − Torch Height Control Up/Down Input

After a time i solved most of the signal's. The last signal problem was solved here at the forum.

I will write it down, this works for the z-axis, and i add some comment :

Okey good news so far. I can now start the serial connection with the Hypertherm Powermax 45xp ...

I don't know how this works, but maybe with a little help things are working soon. !!!

You are right again. The motor adjustment in the ini file was the problem of getting out of joint position.

I did a 24 hour non stop LinuxCNC study to get the THC working.

And finally it works very good. I solved the issue with off course with the information of John Thornton.

I tried this configuration thcud − Torch Height Control Up/Down Input

After a time i solved most of the signal's. The last signal problem was solved here at the forum.

I will write it down, this works for the z-axis, and i add some comment :

#copy sample code from here:

setp stepgen.2.position-scale [AXIS_2]SCALE

setp stepgen.2.steplen 1

setp stepgen.2.stepspace 0

setp stepgen.2.dirhold 35000

setp stepgen.2.dirsetup 35000

setp stepgen.2.maxaccel [AXIS_2]STEPGEN_MAXACCEL

### orginal with Linuxcnc stepconfigure you see the 2 lines below activated, deactivate them.

#net zpos-cmd axis.2.motor-pos-cmd => stepgen.2.position-cmd

#net zpos-fb stepgen.2.position-fb => axis.2.motor-pos-fb

### you must un-link-p (p=pin) all connection's of axis 2 position (pos) command and the feedback (fb )command.

unlinkp axis.2.motor-pos-cmd

unlinkp axis.2.motor-pos-fb

### make a connection between z pos value and the motor position command value

### expression can also be without the " <= " mark : net Zpos thcud.z-pos-in axis.2.motor-pos-cmd

net Zpos thcud.z-pos-in <= axis.2.motor-pos-cmd

### make more connections

net thc-pos-out thcud.z-pos-out => stepgen.2.position-cmd

net thc-pos-fb axis.2.motor-pos-fb <= thcud.z-fb-out

### this is interesting, the value must be very low i have tested. now for example is 0.001 % and 0.01 speed

### if you do it like this, you can link the value to your user interface : setp thcud.velocity-tol gui3_test.hal_scalebutton1

### don't forget do it only in the postgui.hal section if you want things to work, like led's etc.

setp thcud.velocity-tol 0.001

setp thcud.correction-vel 0.01

### orginal from linuxcnc step config wizard ...

net zstep <= stepgen.2.step

net zdir <= stepgen.2.dir

net zenable axis.2.amp-enable-out => stepgen.2.enable

### also important to place this in the file.

net requested-vel thcud.requested-vel <= motion.requested-vel

net current-vel thcud.current-vel <= motion.current-vel

#end ample codeOkey good news so far. I can now start the serial connection with the Hypertherm Powermax 45xp ...

I don't know how this works, but maybe with a little help things are working soon. !!!

Last edit: 03 Jan 2018 16:00 by Grotius.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11615

- Thank you received: 3908

03 Jan 2018 21:42 #103997

by rodw

Glad you got it going. I sent you an email with a couple of ideas on the serial link yesterday.

Replied by rodw on topic THC config that works.

Hi Rodw,

Okey good news so far. I can now start the serial connection with the Hypertherm Powermax 45xp ...

I don't know how this works, but maybe with a little help things are working soon. !!!

Glad you got it going. I sent you an email with a couple of ideas on the serial link yesterday.

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21158

- Thank you received: 7224

04 Jan 2018 12:12 #104017

by tommylight

On this thread there is a mention of how to limit the Z axis velocity, just look for it.

Am on the phone, so i will look for it later.

Replied by tommylight on topic THC config that works.

Dear Tom,

How can i reduce the default speed of Z axis it's running quite fast, when I start the F9 procedure. Changes to default and max velocity of ini didn't help.

On this thread there is a mention of how to limit the Z axis velocity, just look for it.

Am on the phone, so i will look for it later.

Please Log in or Create an account to join the conversation.

- Plasmaguy

-

- Offline

- Senior Member

-

Less

More

- Posts: 76

- Thank you received: 9

30 Mar 2018 16:39 #108113

by Plasmaguy

Replied by Plasmaguy on topic THC config that works.

I have an issue or two regarding setting up the 150.

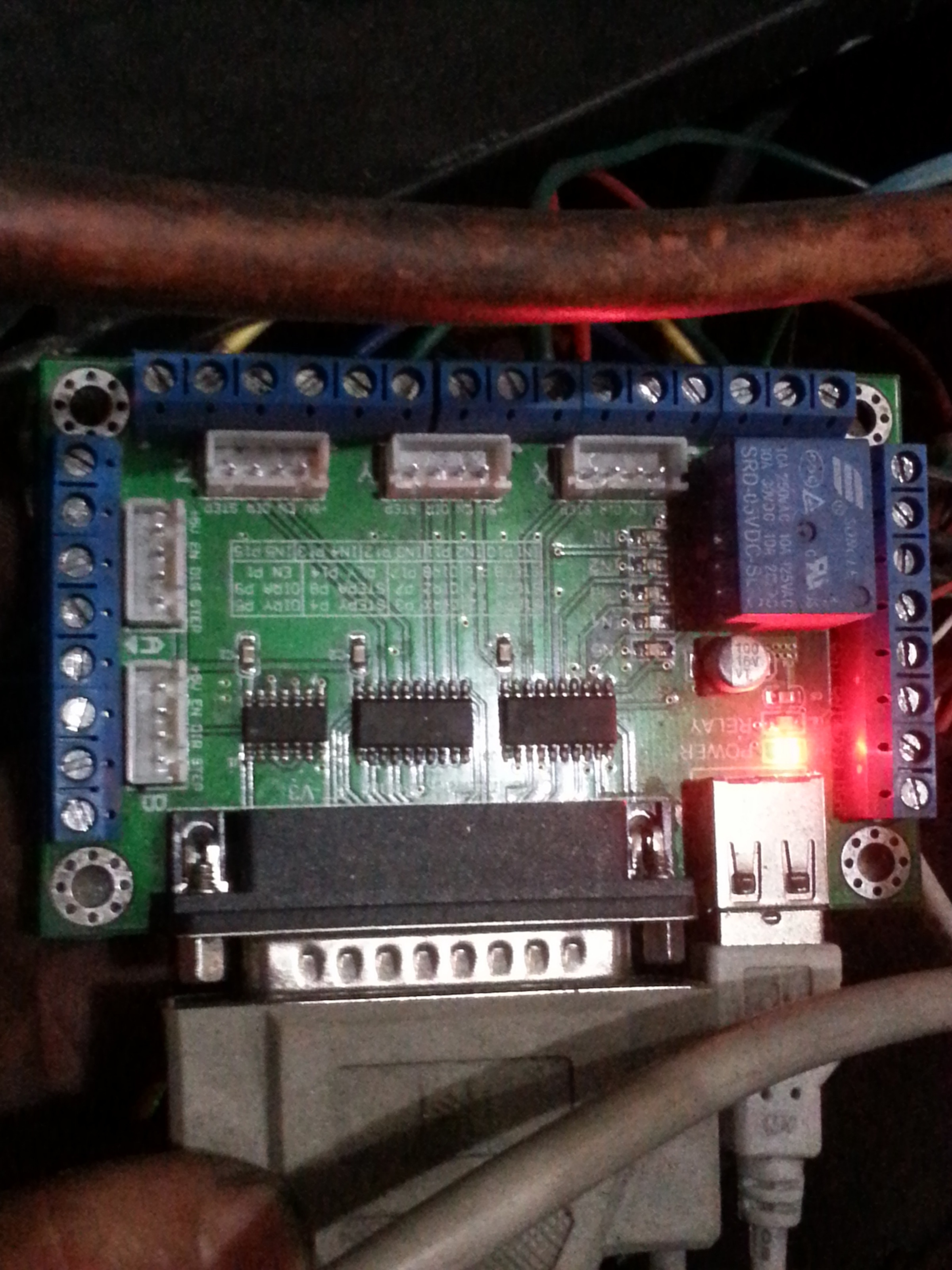

The THC unit is wired into the BOB, in test mode the indicator lights are flashing as they should; Arc OK, Up & Down and Limit Switch.

I've inverted my pins as needed so the screen indicator lights are unlit and I can toggle the E-Stop.

When I turn on machine power I immediately get the message "joint 2 error on limit switch". The only way around this is to check "override limits" but I still get the message whenever I go to move an axis.

I retrieved my acceleration, scale, etc settings from my working .ini file and plugged them into the thc-toma.ini file so am fairly certain everything should be ok there.

I also noticed that my onscreen limit switch indicator is not lighting when machine power is turned on and I trigger the limit switch by hand.. although it does register on my BOB.

Another thing I noticed is that when turning on my spindle that my Z axis goes down to -25mm which is where my Z minimum limit is set to. When I turn the spindle off the Z is going back to 0. Apparently I have done something incorrectly but from what I can tell everything is set up as it should be.

Any help is greatly appreciated!

My config files are below for reference.

The THC unit is wired into the BOB, in test mode the indicator lights are flashing as they should; Arc OK, Up & Down and Limit Switch.

I've inverted my pins as needed so the screen indicator lights are unlit and I can toggle the E-Stop.

When I turn on machine power I immediately get the message "joint 2 error on limit switch". The only way around this is to check "override limits" but I still get the message whenever I go to move an axis.

I retrieved my acceleration, scale, etc settings from my working .ini file and plugged them into the thc-toma.ini file so am fairly certain everything should be ok there.

I also noticed that my onscreen limit switch indicator is not lighting when machine power is turned on and I trigger the limit switch by hand.. although it does register on my BOB.

Another thing I noticed is that when turning on my spindle that my Z axis goes down to -25mm which is where my Z minimum limit is set to. When I turn the spindle off the Z is going back to 0. Apparently I have done something incorrectly but from what I can tell everything is set up as it should be.

Any help is greatly appreciated!

My config files are below for reference.

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21158

- Thank you received: 7224

30 Mar 2018 22:32 #108150

by tommylight

Replied by tommylight on topic THC config that works.

Your hal file has a minor error, one of the inputs is not set as "in-not" but all the others are, so do check that.

The other thing to check is the BOB, you need to be sure that it is set as "pull up" or "pull down", on some you can change that with jumpers, on cheap ones you can not, so adding pull up resistors is the only way to make it work.

The behaviour of the Z axis you describe is normal, when you press F9 or use M3 in gcode it will start to go down to search for the material.

The other thing to check is the BOB, you need to be sure that it is set as "pull up" or "pull down", on some you can change that with jumpers, on cheap ones you can not, so adding pull up resistors is the only way to make it work.

The behaviour of the Z axis you describe is normal, when you press F9 or use M3 in gcode it will start to go down to search for the material.

The following user(s) said Thank You: Plasmaguy

Please Log in or Create an account to join the conversation.

- Plasmaguy

-

- Offline

- Senior Member

-

Less

More

- Posts: 76

- Thank you received: 9

07 Apr 2018 19:45 - 07 Apr 2018 21:48 #108565

by Plasmaguy

Replied by Plasmaguy on topic THC config that works.

I have tried inverting the pin as suggested, and went back and deleted all the files and started with fresh files. Still no luck, I can't get any of the axes to move and am still getting the joint 2 on limit switch error...I've tried changing many things back and forth without any luck yet..I'm lost as to what else to try.

My table is working alright for now without a Z correction, but I have to keep an eye on it in case the sheet starts to warp and manually adjust the arc gap...time I desperately need to be spending working on other stuff while the table runs on its own.

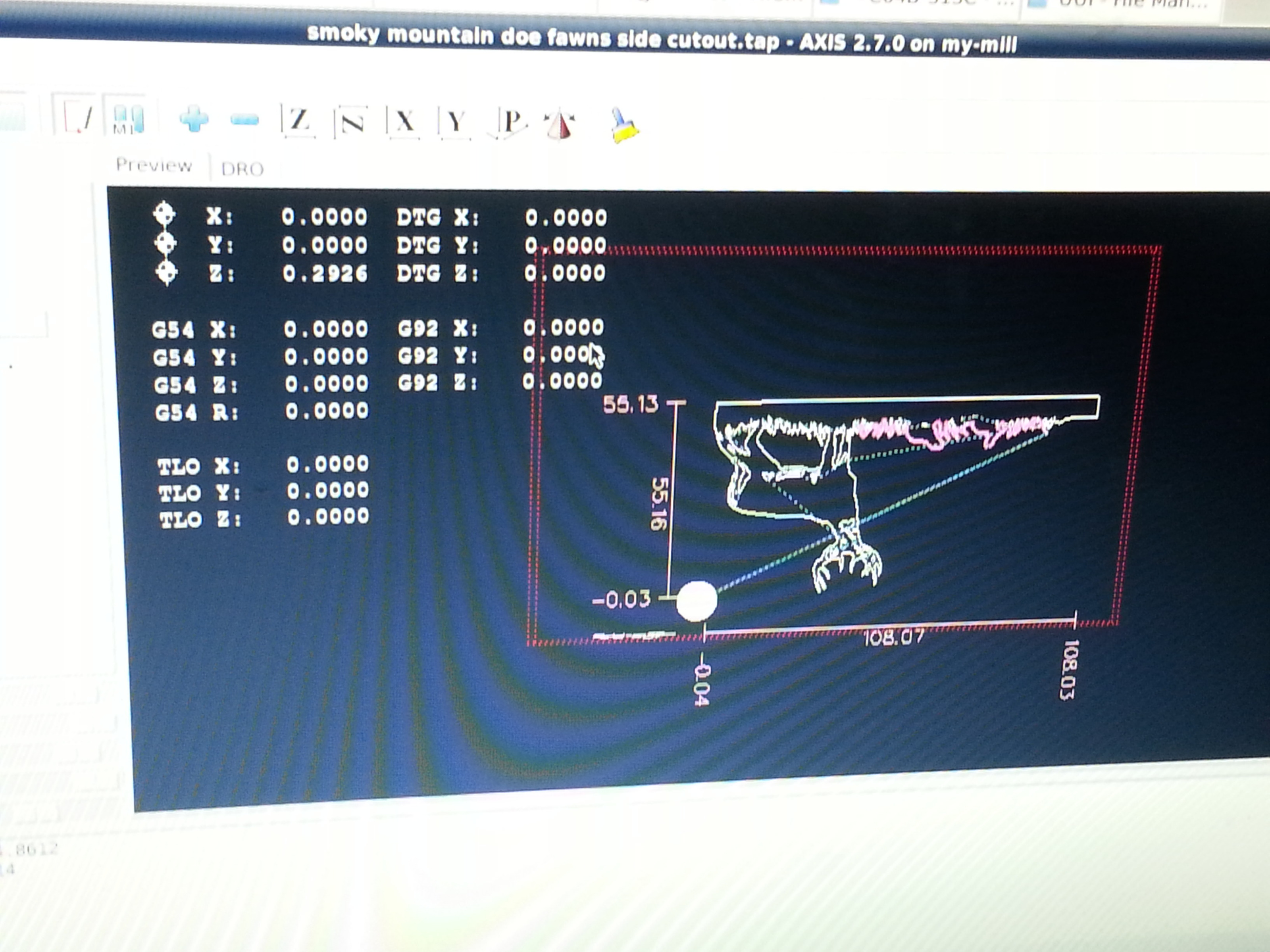

Table running w "my-mill" config

My table is working alright for now without a Z correction, but I have to keep an eye on it in case the sheet starts to warp and manually adjust the arc gap...time I desperately need to be spending working on other stuff while the table runs on its own.

Table running w "my-mill" config

Last edit: 07 Apr 2018 21:48 by Plasmaguy.

Please Log in or Create an account to join the conversation.

Time to create page: 0.480 seconds